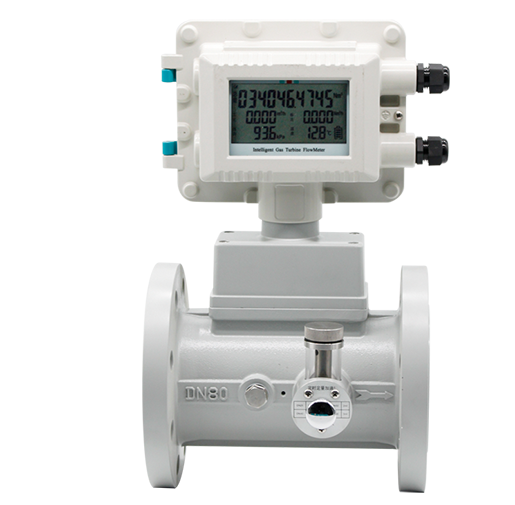

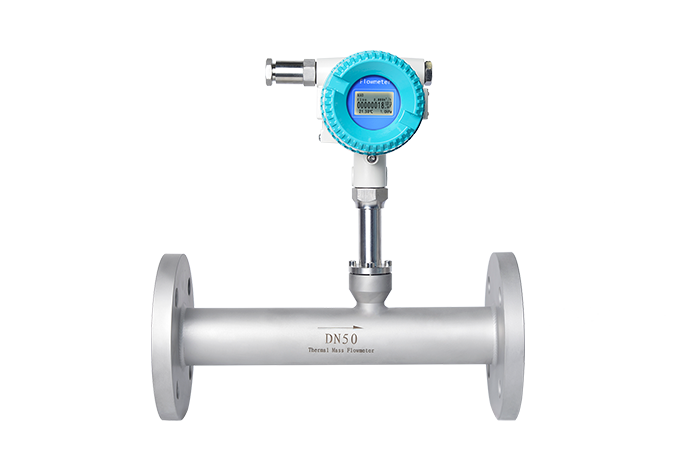

ATWG Gas Turbine Flowmeter

Nominal diameter:

DN50-DN400

Functional application:

Mainly used for trade settlement, mobile prepaid system, remote meter reading

Advantages and characteristics:

Low starting flow, good repeatability, small pressure loss

Applicable medium:

Natural gas, compressed air, nitrogen, etc

ATWG gas turbine flowmeter is mainly used for the flow measurement of natural gas, air, nitrogen and other medium fluids in industrial pipelines, and is almost unaffected by fluid density, pressure, temperature, viscosity and other parameters when measuring the volume flow under working conditions.