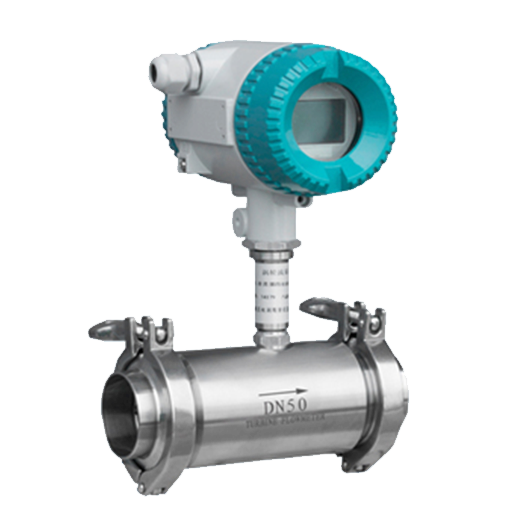

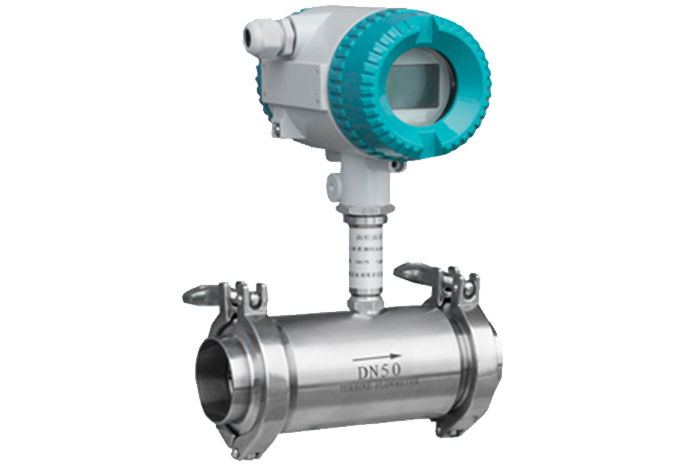

ATWY Clamp liquid turbine flowmeter

Nominal diameter:

DN15-DN200mm

Accuracy level:

±1%R、±0.5%R、±0.2%R (to be customized)

Instrument type:

Field display type, pulse output type, 4-20mA output type, split remote display type

Applicable medium:

No impurities, low viscosity, no strong corrosive liquid

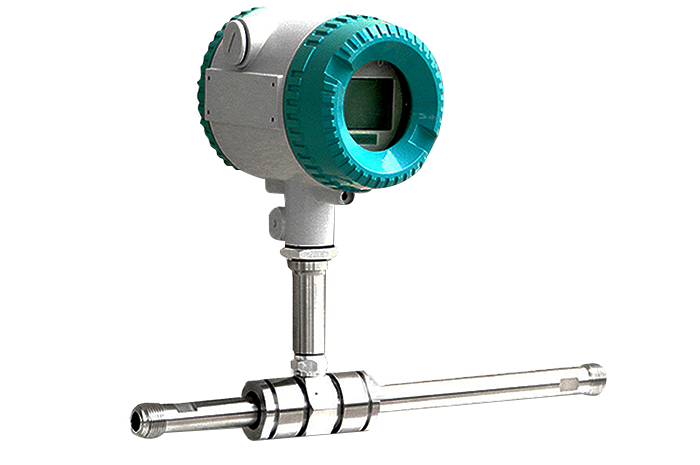

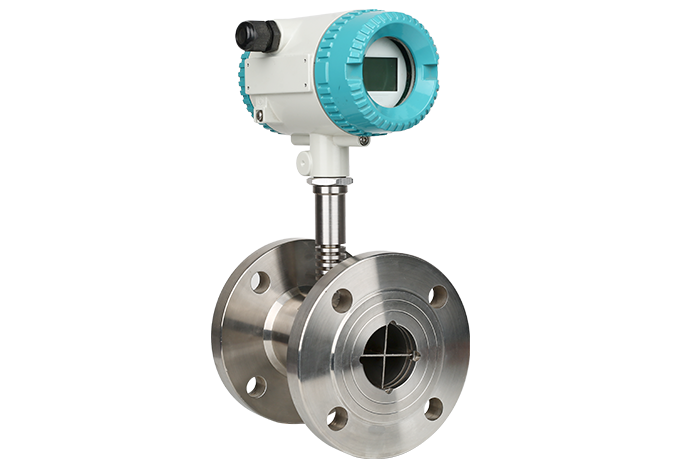

Clamp turbine flowmeter is a turbine flowmeter with simple structure, light weight, high precision, good repeatability, sensitive response, easy installation and maintenance, etc. It is widely used to measure the closed pipeline and stainless steel 1Cr18Ni9Ti, 2Cr13 and corundum Al2O3, carbide corrosion effect, and no fibers, particles and other impurities.