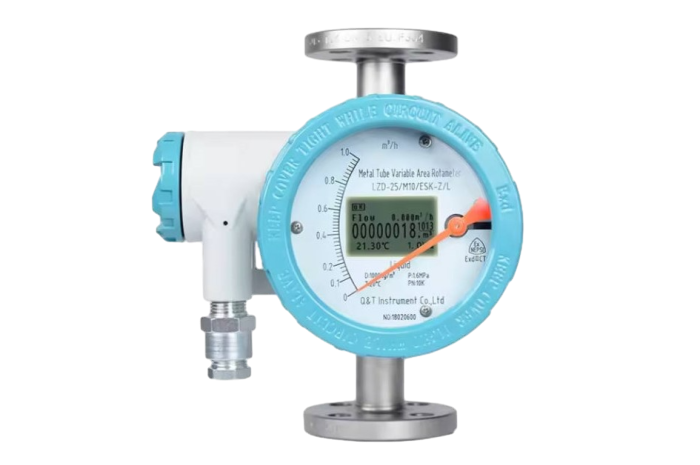

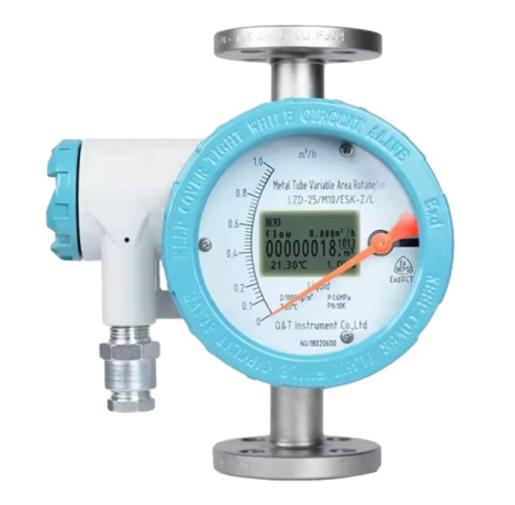

Metallic Tube Rotameter

Range ratio:

10:1(Special type 20:1)

Accuracy class:

2.5(Special type 1.5% or 1.0%)

Working pressure:

DN15~DN50 PN16 (Special type 2.5MPa)

Medium temperature:

Normalized type -80℃~+220℃

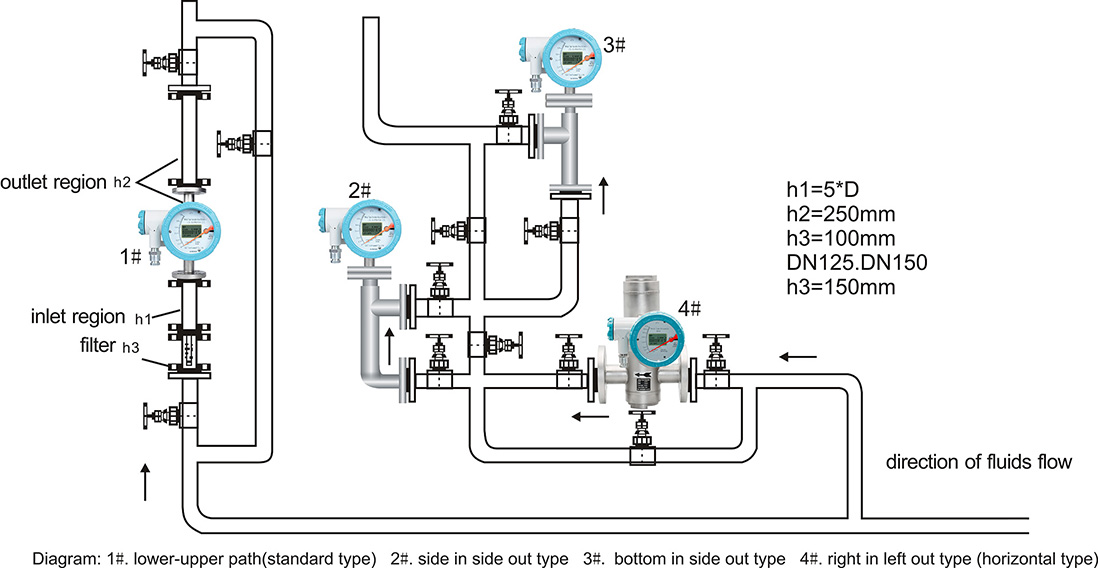

Vertical Display Variable Area Flowmeter is mainly suitable for small and medium flow measurement of single-phase liquid or gas with small and medium pipe diameter, low noise and Reynolds number of acetic acid, like Air, Water, lubricating oil,Steam,Hydrogen,O2,etc,and many other Liquid or gas in the Chemical, Pharmaceutical, Petrochemical, Food, Metallurgical Industry ,etc.