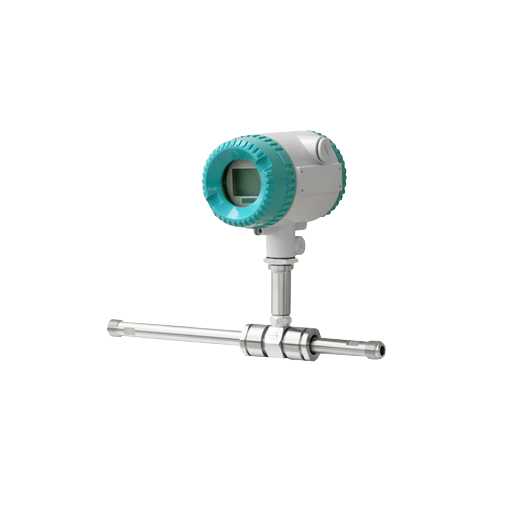

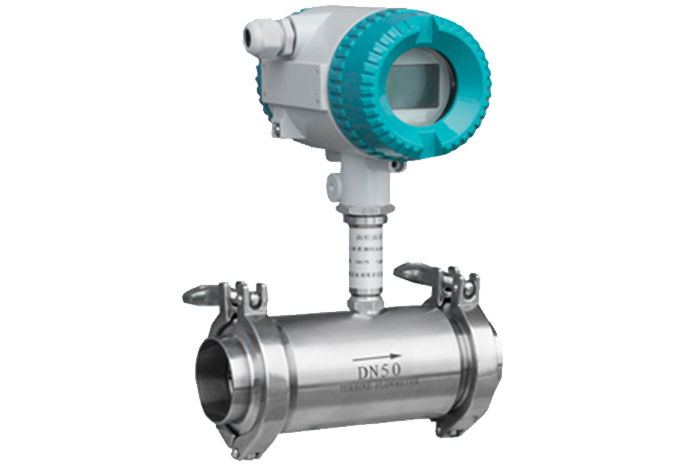

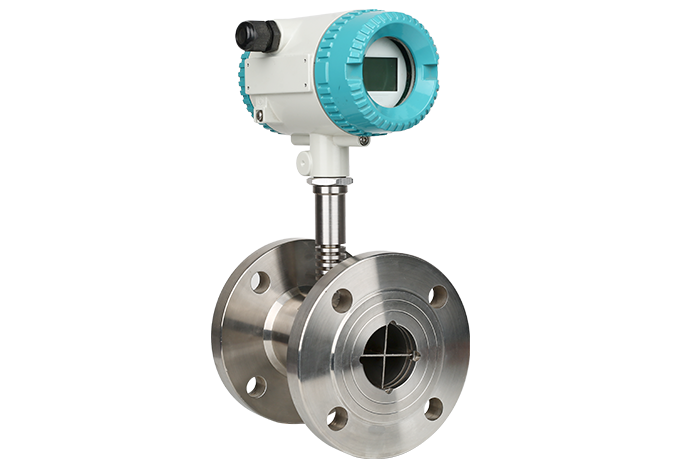

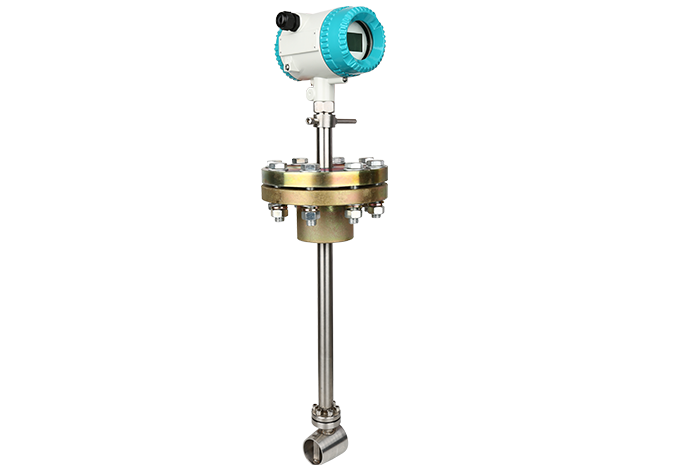

ATWY Threaded Liquid Turbine Flowmeter

Nominal diameter:

DN4-DN200mm

Accuracy:

±1%R、±0.5%R、±0.2%R (to be customized)

Instrument type:

Field display type, pulse output type, 4-20mA output type, split remote display type

Applicable medium:

No impurities, low viscosity, no strong corrosive liquid

The threaded liquid turbine flowmeter is a kind of precision flow measuring instrument, which can be used to measure the flow and total amount of liquid with the corresponding flow integrating instrument. Widely used in petroleum, chemical industry, metallurgy, scientific research and other fields of measurement, control system. Threaded liquid turbine flowmeter sensors with sanitary fittings can be used in the pharmaceutical industry.