Compressed Air Flowmeter

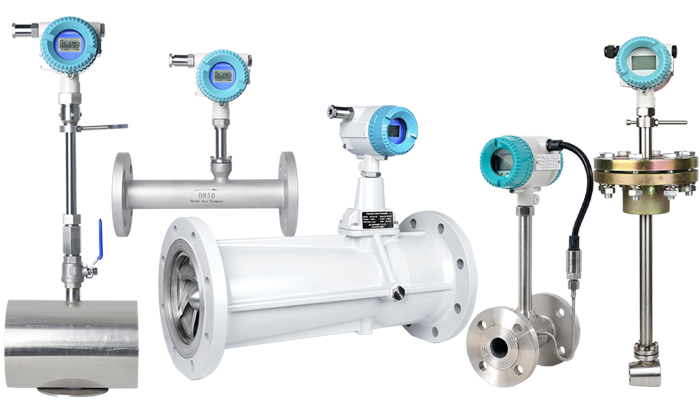

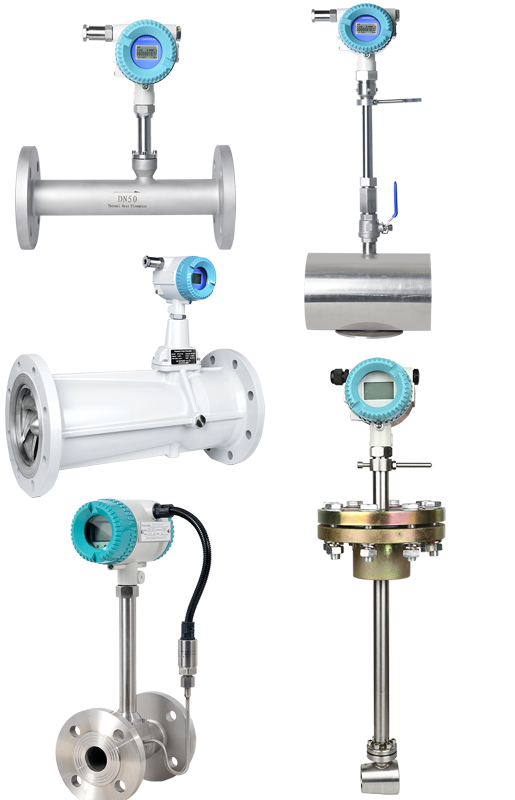

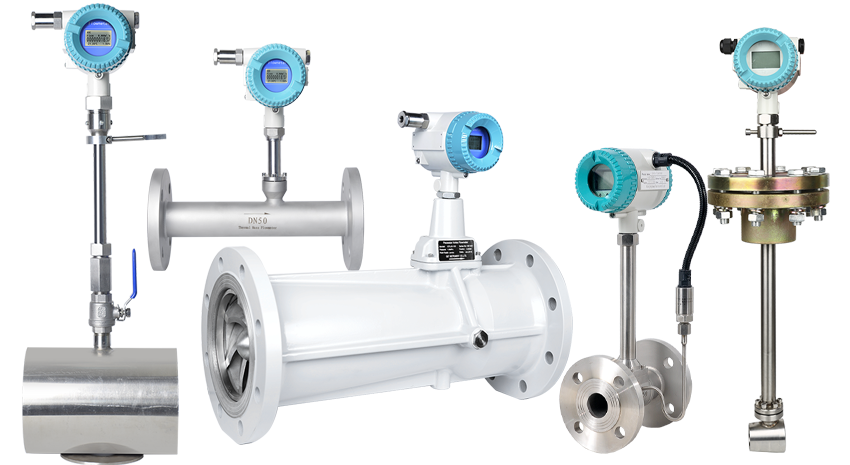

Vortex flowmeter:

Built-in temperature, pressure sensor, simple structure, easy to install

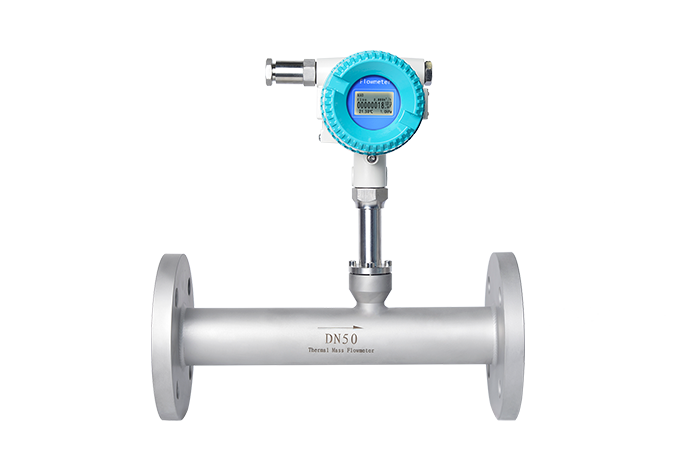

Thermal gas mass flowmeter:

The air measured cannot contain water, and water and gas separation equipment must be installed

Precession vortex flowmeter:

Built-in temperature and pressure compensation, low flow limit

Compressed air measurement conditions and customer requirements are different, the choice of a suitable compressed air flow meter has become a difficult problem. Shanghai Aister Instrument focus on gas flow meter production, sales, research and development as one of the technical enterprises, can provide customers with compressed air flow measurement solutions and professional selection.