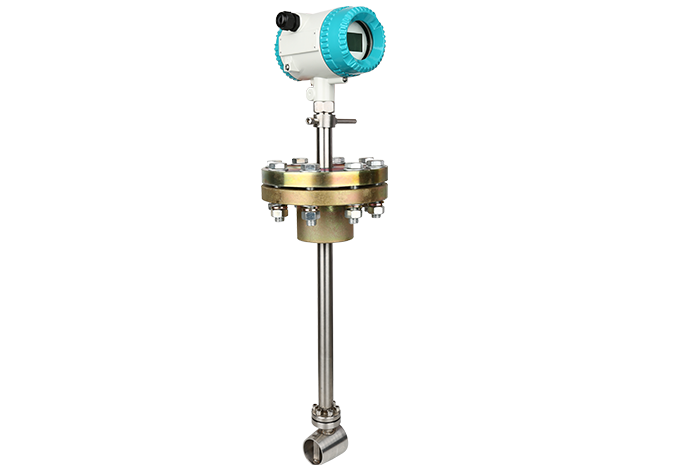

LUGB Clamp Connected Vortex Flowmeter

Nominal diameter:

DN15~DN65mm

Accuracy:

liquid ±1.0%, gas (steam) ±1.5%, plug-in ±2.5%

Material:

304, 316L various materials

Measuring medium:

Sanitary measureable steam, compressed air, liquid (single-phase medium)

LUGB clamp vortex flowmeter is a new design concept, the temperature, pressure, flow signals in one, through the intelligent digital processor will be mixed processing three signals output a compensated standard flow, so as to achieve the gas, steam temperature and pressure compensation function.