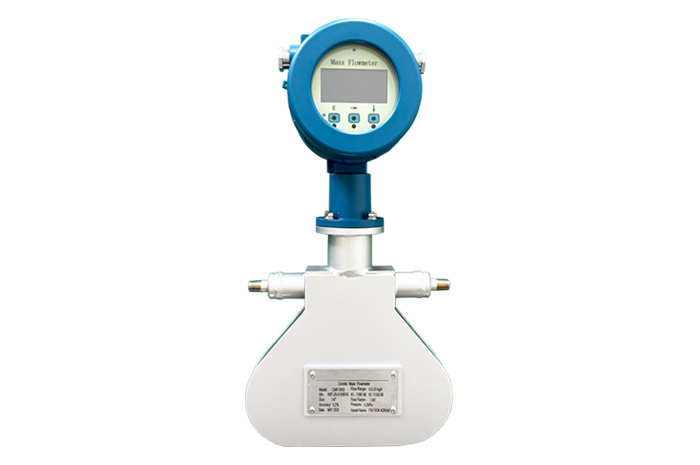

ATCMF Integrated Coriolis mass flowmeter

Diameter:

DN3~DN200mm

Density measuring:

0.3~3.000g/cm3

Temperature range:

-200~300ºC (Standard Model -50~200ºC)

Environment humidity:

≤90%RH

A Coriolis mass flow meter is a type of flow meter designed to measure the mass flow rate of fluids, such as liquids or gases. It operates based on the principles of the Coriolis effect, which is the apparent deflection of an object moving in a rotating system. In the context of a Coriolis mass flow meter, this effect is utilized to measure the mass flow of the fluid passing through a vibrating tube.