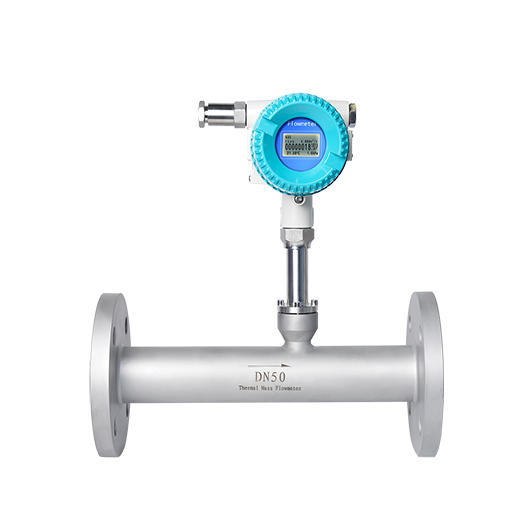

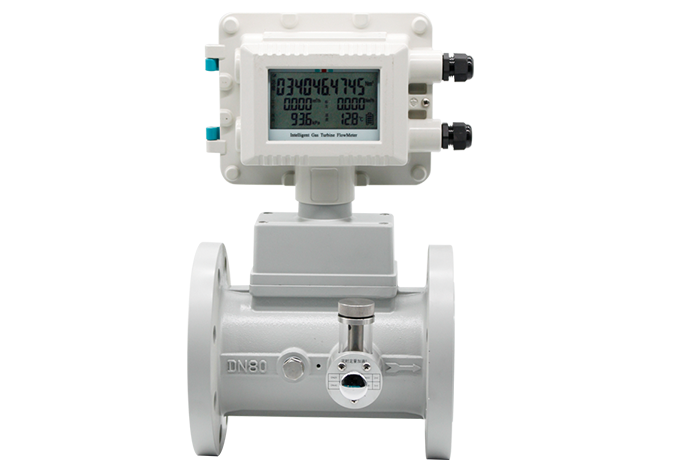

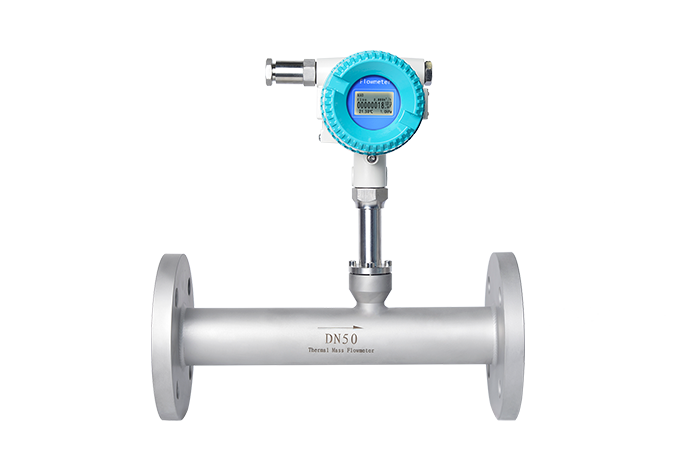

ATMF In-line Thermal Mass Flowmeter

Measuring medium:

Various gases (except acetylene gas)

Pipe diameter range:

DN10-2000mm

Accuracy Degree:

±1~2.5%

Pipe material:

Carbon steel, stainless steel, plastic, etc

The thermal mass flowmeter is a flow meter based on the principle of thermal diffusion. The device uses the constant temperature difference method to measure the gas accurately. It has the advantages of small size, high digitization, easy installation, accurate measurement and so on.