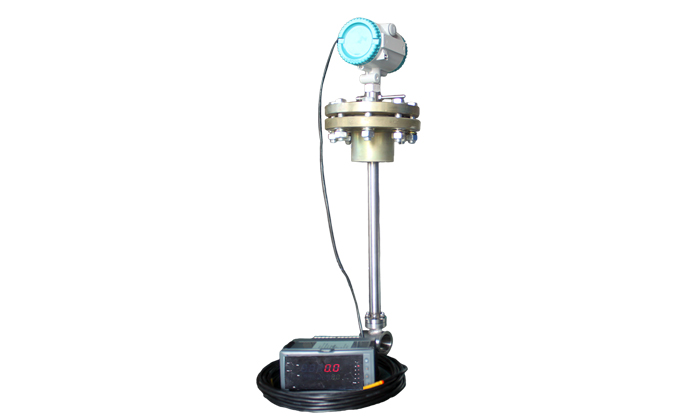

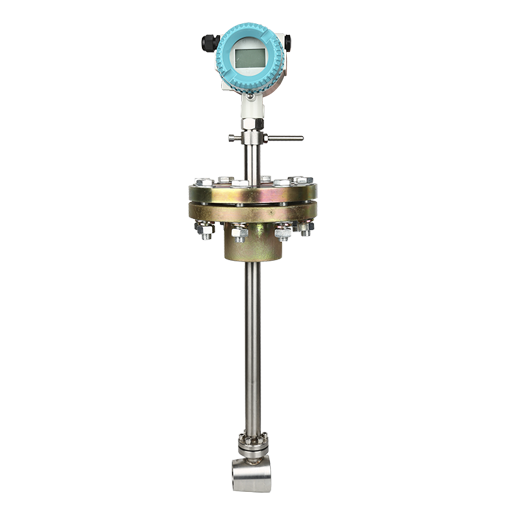

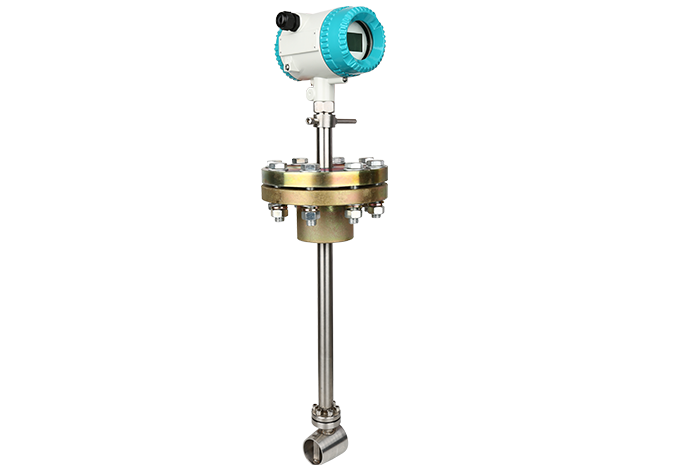

LUGB Insertion Vortex Flowmeter

Nominal diameter:

DN100-3000mm

Accuracy:

±2.5%

Shell material:

Carbon steel, stainless steel

Measuring medium:

liquid, gas, saturated steam, superheated steam

The Insertion vortex flowmeter is mainly used for the flow measurement of large-diameter gas, liquid and steam medium fluids in industrial pipelines in various industries. It is characterized by small pressure loss, large range and high accuracy. It is almost unaffected by fluid density, pressure, temperature, viscosity and other parameters when measuring volume flow under working conditions. There are no moving mechanical parts, so the reliability is high and the maintenance is small.