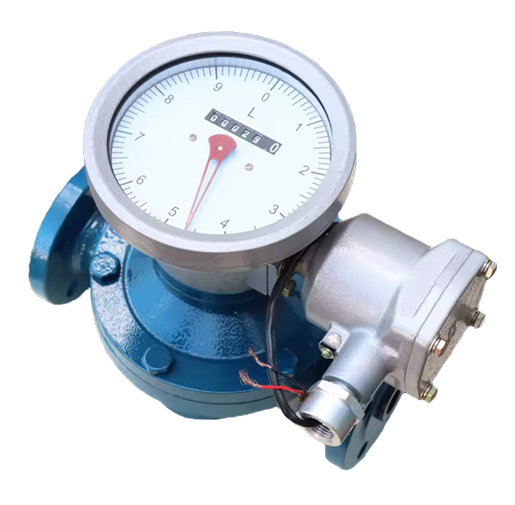

ATLC Oval Gear Flow Meter

Measuring medium:

Various high viscosity liquids (no solid particles, no air bubbles)

Pipe diameter range:

DN10-200mm

Accuracy Degree:

±0.2%,0.5%

Pipe material:

Cast iron type, stainless steel type, cast steel type

Oval gear flowmeter is a volumetric flowmeter, used for precise continuous or intermittent measurement of liquid flow in the pipeline or instantaneous flow. It is particularly suitable for heavy oil, polyvinyl alcohol, resin and other high viscosity media flow measurement. Elliptic gear flowmeter using mechanical measuring elements to continuously divide the fluid into a single known volume part, according to the measurement chamber one by one, the number of times the volume part of the repeated filling and discharging of the fluid to measure the total volume of fluid.