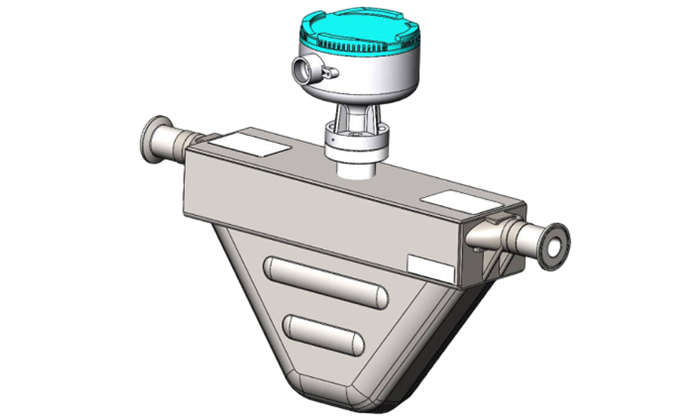

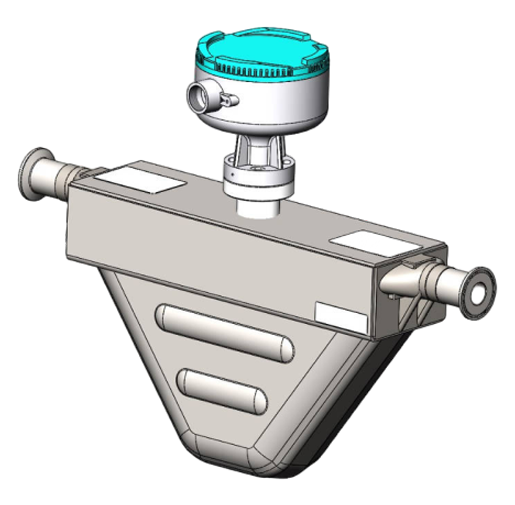

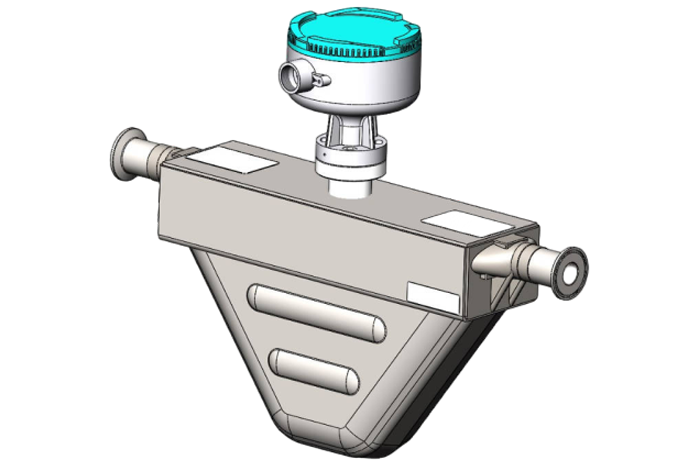

ATCF Coriolis mass flowmeter

Medium:

Liquid, gas, slurry

Accuracy:

0.1%, 0.15%, 0.2%, 0.5%

Power Supply:

DC24V、AC220V

Pressure (MPa):

1.6、2.5、4.0、6.3; Customized for high pressure: 10.0, 16.0, 26.0

Mass Flowmeter is designed according to the Coriolis Principle. It can be widely used for the process detecting and custody transfer/fiscal unit in many industries such as petroleum, petroleum and chemical, chemical industry, pharmacy, paper making, food and energy, and so on. As a fairly advanced kind of flow measurement instrument, it has been paid attention by the circle of measurement and accepted by many customers home and abroad.