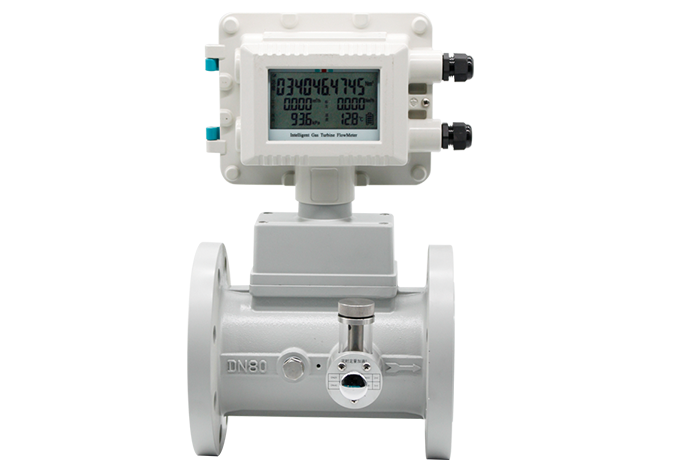

ATLU Swirl Vortex Flowmeter

Nominal diameter:

DN15-DN200mm

Accuracy:

1.0/1.5

Body material:

Aluminum alloy, 304 stainless steel

Applicable media:

Compressed air, oxygen, nitrogen, carbon dioxide, natural gas, argon, liquefied gas, etc., corrosion, moisture can not be measured, such as chlorine, hydrogen, steam, ammonia.

Intelligent precession vortex flowmeter is a new type of gas flow meter developed by our company. The flowmeter integrates the function of flow, temperature and pressure detection, and can automatically compensate the temperature, pressure and compression factor. It is an ideal instrument for gas measurement in petroleum, chemical industry, electric power, metallurgy and other industries.