Why is electromagnetic flow meter measurement inaccurate?

2024-08-14

Electromagnetic flow meters are commonly used to measure the flow of conductive fluids, but during use, there are some factors that may cause the measurement results to be inaccurate:

1. Installation and environmental factors

If the installation position of the flow meter is too close to the power supply, it may be subjected to electromagnetic interference; Interference from external electromagnetic fields may also affect the measuring accuracy of the flowmeter, so be sure to ensure the installation position of the electromagnetic flowmeter.

2. Media conditions change

Changes in the physical properties of the medium: The electromagnetic flowmeter measures the flow of conductive fluid, and if the physical properties of the measuring medium such as temperature, density, viscosity change, it will also affect the measurement results.

Dielectric conductivity problem: If the dielectric conductivity is too low, it may lead to large fluctuations in measurement or inaccurate measurement.

3. Internal problems of flow meter

If the electrode material inside the electromagnetic flowmeter is not suitable for measuring the chemical composition of the fluid, the electrode may be corroded or passivated, and the connection of the internal electrode is short circuit or open circuit, which will also cause the flowmeter to fail to obtain accurate flow signals.

4. Wiring and calibration problems

Ensure that the connection points are correctly connected. Improper connections or corrosion of terminal blocks may result in inaccurate measurements. If the flow meter is not calibrated regularly, or the calibration is not accurate, it will also lead to a deviation between the measured value and the actual value.

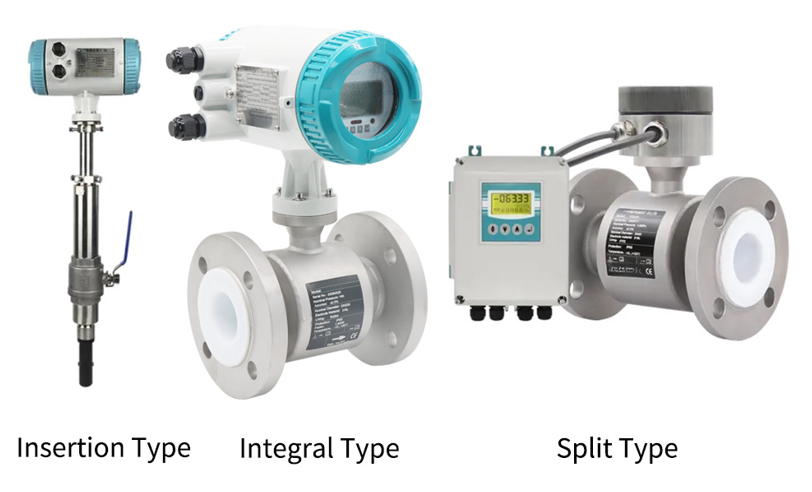

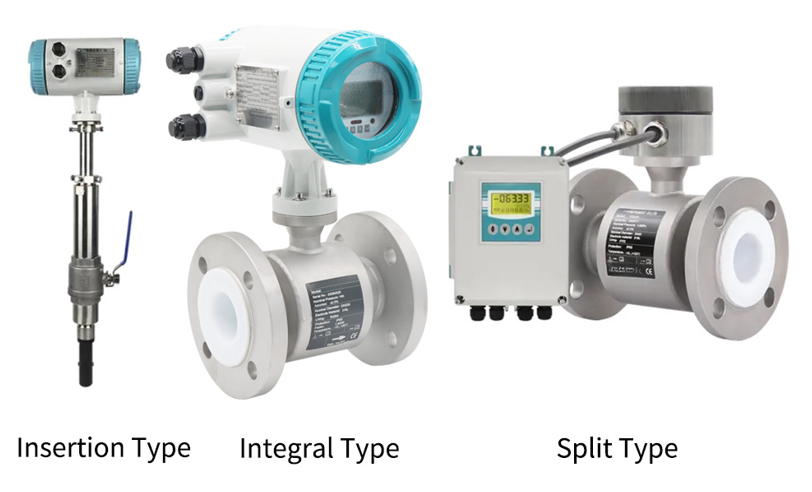

5. Selection and configuration problems

Improper flowmeter selection: If the selection of the flowmeter is not consistent with the actual application scenario, such as the diameter of the pipe, the flow range, etc., it will also lead to inaccurate measurement.

Configuration problems: The sensor and the converter instrument number is not consistent, or not the same set, need to check the pipe diameter, GK, GKL, excitation frequency configuration is appropriate.

solution

To solve the above problems, the following solutions can be adopted:

Check the installation position and environment: Ensure that the flow meter is installed in a position free of electromagnetic interference, and adjust the appropriate installation Angle.

Monitoring medium conditions: Regularly monitor the physical properties of the medium to ensure that the medium conditions are within the measurement range.

Maintain internal components: check and clean electrodes regularly to avoid contamination and wear; Inspect and replace aging sensors and insulation components.

Check wiring and calibration: Make sure the wiring is correct and calibrate the flow meter regularly to ensure accurate measurement.

Reasonable selection and configuration: Select the right flowmeter model and configuration according to the actual application scenario to ensure accurate and reliable measurement.

In addition, if the problem still exists, it is recommended to contact a professional flow meter maintenance personnel for inspection and maintenance. They have the experience and expertise to quickly locate problems and implement effective solutions.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

1. Installation and environmental factors

If the installation position of the flow meter is too close to the power supply, it may be subjected to electromagnetic interference; Interference from external electromagnetic fields may also affect the measuring accuracy of the flowmeter, so be sure to ensure the installation position of the electromagnetic flowmeter.

2. Media conditions change

Changes in the physical properties of the medium: The electromagnetic flowmeter measures the flow of conductive fluid, and if the physical properties of the measuring medium such as temperature, density, viscosity change, it will also affect the measurement results.

Dielectric conductivity problem: If the dielectric conductivity is too low, it may lead to large fluctuations in measurement or inaccurate measurement.

3. Internal problems of flow meter

If the electrode material inside the electromagnetic flowmeter is not suitable for measuring the chemical composition of the fluid, the electrode may be corroded or passivated, and the connection of the internal electrode is short circuit or open circuit, which will also cause the flowmeter to fail to obtain accurate flow signals.

4. Wiring and calibration problems

Ensure that the connection points are correctly connected. Improper connections or corrosion of terminal blocks may result in inaccurate measurements. If the flow meter is not calibrated regularly, or the calibration is not accurate, it will also lead to a deviation between the measured value and the actual value.

5. Selection and configuration problems

Improper flowmeter selection: If the selection of the flowmeter is not consistent with the actual application scenario, such as the diameter of the pipe, the flow range, etc., it will also lead to inaccurate measurement.

Configuration problems: The sensor and the converter instrument number is not consistent, or not the same set, need to check the pipe diameter, GK, GKL, excitation frequency configuration is appropriate.

solution

To solve the above problems, the following solutions can be adopted:

Check the installation position and environment: Ensure that the flow meter is installed in a position free of electromagnetic interference, and adjust the appropriate installation Angle.

Monitoring medium conditions: Regularly monitor the physical properties of the medium to ensure that the medium conditions are within the measurement range.

Maintain internal components: check and clean electrodes regularly to avoid contamination and wear; Inspect and replace aging sensors and insulation components.

Check wiring and calibration: Make sure the wiring is correct and calibrate the flow meter regularly to ensure accurate measurement.

Reasonable selection and configuration: Select the right flowmeter model and configuration according to the actual application scenario to ensure accurate and reliable measurement.

In addition, if the problem still exists, it is recommended to contact a professional flow meter maintenance personnel for inspection and maintenance. They have the experience and expertise to quickly locate problems and implement effective solutions.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference