Different categories of electromagnetic flow meter in various fields of application

2024-01-04

Electromagnetic flow meter can be classified based on various criteria, including design, construction, and application. Here's a classification based on design and construction:

Insertion Electromagnetic Flow Meter:

These flowmeters are inserted into the pipe, and they do not require the pipe to be cut for installation. They are suitable for larger pipe sizes where the cost of a full-bore electromagnetic flowmeter is prohibitive.

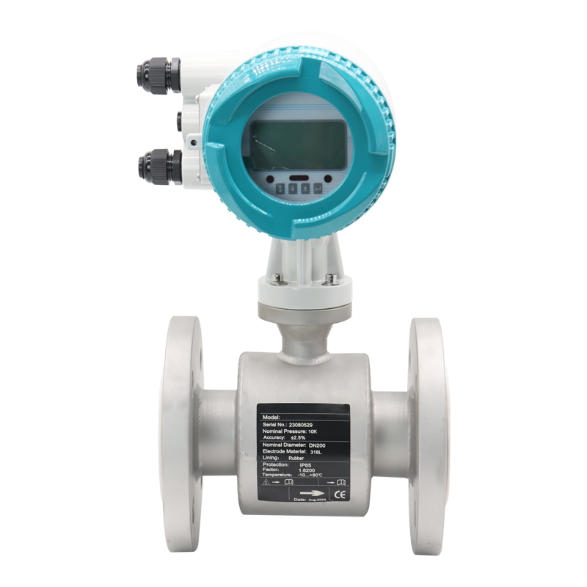

Full-Bore Electromagnetic Flow Meter:

Also known as inline or pipe-type flowmeters, these are installed directly in the pipeline and provide a full cross-section for fluid flow. They are common in various industries and applications.

Low-Flow Electromagnetic Flow Meter:

Designed specifically for accurate measurement of low flow rates, these flowmeters are often used in applications where precise measurement of small volumes is crucial.

High-Temperature Electromagnetic Flow Meter:

These flowmeters are capable of measuring the flow of fluids at elevated temperatures, making them suitable for applications where the fluid temperature exceeds the capabilities of standard flowmeters.

Sanitary Electromagnetic Flow Meter:

Constructed with materials and design features that meet sanitary standards, these flowmeters are suitable for applications in pharmaceuticals, biotechnology, food and beverage processing, and other industries with strict hygiene requirements.

Chemical-Resistant Electromagnetic Flow Meter:

Designed to withstand the corrosive effects of certain chemicals, these flowmeters are used in chemical processing plants where resistance to chemical corrosion is essential.

Abrasive Fluid Electromagnetic Flow Meter:

Constructed to handle fluids containing abrasive particles, such as slurries in mining, wastewater treatment, and other industries where abrasion resistance is necessary.

Battery-Powered Electromagnetic Flow Meter:

Equipped with battery power sources, these flowmeters are suitable for remote or temporary installations where a continuous power supply may not be readily available.

Integral Electromagnetic Flow Meter:

These flowmeters have the transmitter integrated into the flow sensor, offering a compact design suitable for applications with space constraints.

Remote Electromagnetic Flow Meter:

Designed for installations where the flowmeter needs to be located remotely from the measurement point, often used in challenging or hazardous environments.

Standard Electromagnetic Flow Meter:

General-purpose flowmeters suitable for a wide range of industries and applications.

Insertion Electromagnetic Flow Meter:

These flowmeters are inserted into the pipe, and they do not require the pipe to be cut for installation. They are suitable for larger pipe sizes where the cost of a full-bore electromagnetic flowmeter is prohibitive.

Full-Bore Electromagnetic Flow Meter:

Also known as inline or pipe-type flowmeters, these are installed directly in the pipeline and provide a full cross-section for fluid flow. They are common in various industries and applications.

Low-Flow Electromagnetic Flow Meter:

Designed specifically for accurate measurement of low flow rates, these flowmeters are often used in applications where precise measurement of small volumes is crucial.

High-Temperature Electromagnetic Flow Meter:

These flowmeters are capable of measuring the flow of fluids at elevated temperatures, making them suitable for applications where the fluid temperature exceeds the capabilities of standard flowmeters.

Sanitary Electromagnetic Flow Meter:

Constructed with materials and design features that meet sanitary standards, these flowmeters are suitable for applications in pharmaceuticals, biotechnology, food and beverage processing, and other industries with strict hygiene requirements.

Chemical-Resistant Electromagnetic Flow Meter:

Designed to withstand the corrosive effects of certain chemicals, these flowmeters are used in chemical processing plants where resistance to chemical corrosion is essential.

Abrasive Fluid Electromagnetic Flow Meter:

Constructed to handle fluids containing abrasive particles, such as slurries in mining, wastewater treatment, and other industries where abrasion resistance is necessary.

Battery-Powered Electromagnetic Flow Meter:

Equipped with battery power sources, these flowmeters are suitable for remote or temporary installations where a continuous power supply may not be readily available.

Integral Electromagnetic Flow Meter:

These flowmeters have the transmitter integrated into the flow sensor, offering a compact design suitable for applications with space constraints.

Remote Electromagnetic Flow Meter:

Designed for installations where the flowmeter needs to be located remotely from the measurement point, often used in challenging or hazardous environments.

Standard Electromagnetic Flow Meter:

General-purpose flowmeters suitable for a wide range of industries and applications.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference