A few steps before Intelligent electromagnetic flowmeter installation

2023-12-27

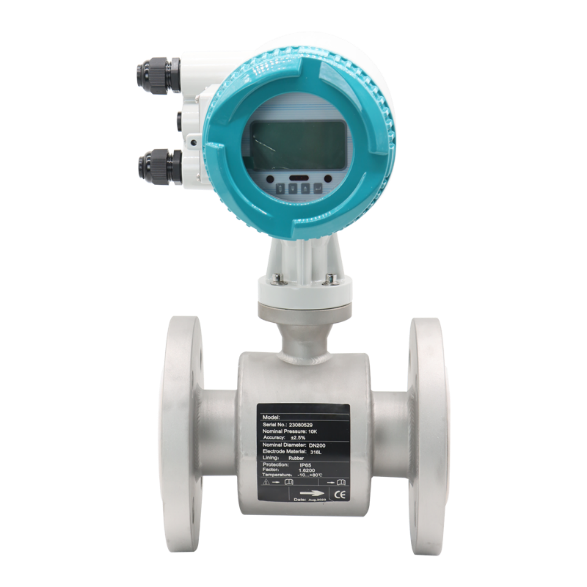

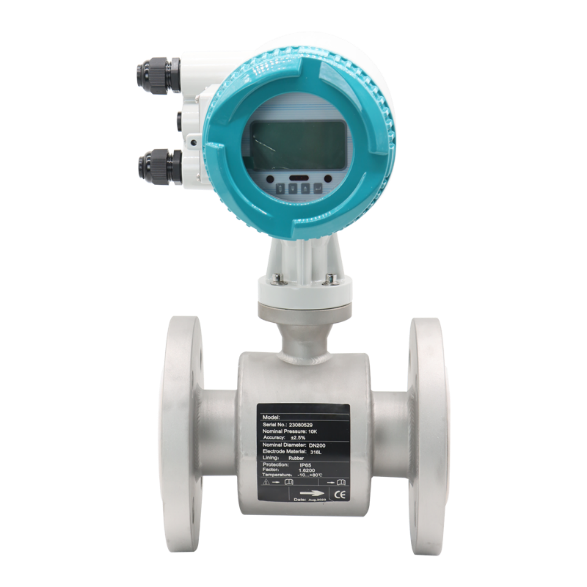

Intelligent electromagnetic flowmeter is an instrument used to measure the flow of conductive liquid, which determines the flow rate of a fluid by measuring the change of induced electromotive force in the liquid. This type of flow meter is mainly used in water, wastewater, chemical, food and beverage, pharmaceutical and other fields of flow monitoring and control. The following are several steps to be done before the installation of the intelligent electromagnetic flowmeter:

1. Measurement point preparation: Select the appropriate measurement point to ensure fluid stability and uniform flow rate. Avoid installation in elbow, pump, in front of the valve and other positions that have an impact on fluid flow.

2. Understanding of fluid media: understanding the properties of fluids, including temperature, pressure, density, conductivity and other information. This helps to choose the right electromagnetic flowmeter model and material.

3. Power and environmental conditions: Ensure that there is a stable power supply near the installation location, while considering the environmental temperature, humidity and protection conditions, in order to meet the working environment requirements of the electromagnetic flowmeter.

4. Pipeline preparation: Check the integrity and cleanliness of the pipeline. Make sure there are no foreign objects, dirt or impurities in the pipe to avoid affecting the accuracy of the fluid measurement.

5. Installation position selection: Choose the appropriate installation position, usually the electromagnetic flowmeter needs to be installed horizontally, and in the horizontal pipeline, the installation should be far away from pipe bending, valves, pumps and other equipment to ensure a stable flow rate.

6. Avoid electromagnetic interference: Avoid installation near electromagnetic interference sources, such as strong current equipment, motors, etc., to ensure the measurement accuracy of electromagnetic flowmeters.

7. Ground connection: Before installation, ensure that the electromagnetic flowmeter has a reliable ground connection to ensure the safety and normal operation of the equipment.

8. Sealing and anti-corrosion: Select the appropriate sealing material according to the nature of the fluid, and consider anti-corrosion measures to extend the service life of the electromagnetic flowmeter.

9. Regular calibration: Before installation, it is planned to regularly calibrate the electromagnetic flowmeter to ensure the accuracy of the measurement results.

When performing the above steps, you should refer to the installation manual of the specific type of electromagnetic flowmeter, and consult the manufacturer of Aister meter for details. Adequate preparation before installation is essential for the long-term stable operation and accurate measurement of the electromagnetic flowmeter.

1. Measurement point preparation: Select the appropriate measurement point to ensure fluid stability and uniform flow rate. Avoid installation in elbow, pump, in front of the valve and other positions that have an impact on fluid flow.

2. Understanding of fluid media: understanding the properties of fluids, including temperature, pressure, density, conductivity and other information. This helps to choose the right electromagnetic flowmeter model and material.

3. Power and environmental conditions: Ensure that there is a stable power supply near the installation location, while considering the environmental temperature, humidity and protection conditions, in order to meet the working environment requirements of the electromagnetic flowmeter.

4. Pipeline preparation: Check the integrity and cleanliness of the pipeline. Make sure there are no foreign objects, dirt or impurities in the pipe to avoid affecting the accuracy of the fluid measurement.

5. Installation position selection: Choose the appropriate installation position, usually the electromagnetic flowmeter needs to be installed horizontally, and in the horizontal pipeline, the installation should be far away from pipe bending, valves, pumps and other equipment to ensure a stable flow rate.

6. Avoid electromagnetic interference: Avoid installation near electromagnetic interference sources, such as strong current equipment, motors, etc., to ensure the measurement accuracy of electromagnetic flowmeters.

7. Ground connection: Before installation, ensure that the electromagnetic flowmeter has a reliable ground connection to ensure the safety and normal operation of the equipment.

8. Sealing and anti-corrosion: Select the appropriate sealing material according to the nature of the fluid, and consider anti-corrosion measures to extend the service life of the electromagnetic flowmeter.

9. Regular calibration: Before installation, it is planned to regularly calibrate the electromagnetic flowmeter to ensure the accuracy of the measurement results.

When performing the above steps, you should refer to the installation manual of the specific type of electromagnetic flowmeter, and consult the manufacturer of Aister meter for details. Adequate preparation before installation is essential for the long-term stable operation and accurate measurement of the electromagnetic flowmeter.

Share To:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference