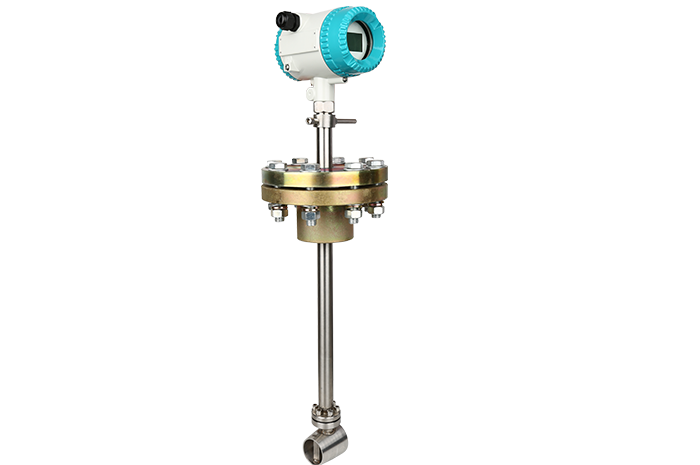

Insertion vortex flowmeter detail

2023-12-12

Insertion vortex flowmeter detail

1. Overview

The insertion vortex flowmeter is a new flowmeter, which has the characteristics of simple structure, light weight, high precision, good repeatability, sensitive response, easy installation, maintenance and use. It is improved on the basis of vortex flowmeter, not only retains the basic advantages of vortex flowmeter, but also realizes higher measurement accuracy and wider measurement range by using special structural design and signal processing technology. The insertion vortex flowmeter is widely used in petroleum, chemical, electric power, metallurgy and other fields, providing reliable flow measurement solutions for enterprises

2. The working principle

The insertion vortex flowmeter is based on the working principle of the vortex flowmeter. A fixed vortex generator is set up in the pipeline. When the fluid flows through the vortex generator, a series of vortices are formed downstream. The frequency of these vortices is proportional to the flow rate of the fluid. By measuring the frequency of the vortex, the flow rate of the fluid can be calculated, and the flow rate can be obtained. The insertion vortex flowmeter adopts special structure design, so that the sensor can be disassembled without interruption, which is convenient for installation and maintenance.

3. Structure composition

It mainly consists of two parts: sensor and amplifier. The sensor measures the frequency of the vortex and transmits the signal to the amplifier. The amplifier processes the signal and converts the result into a standard signal output. In addition, the insertion vortex flowmeter is equipped with an anti-disturbance circuit and anti-vibration sensing head to enhance its resistance to ambient vibration.

4. Scope of application

The insertion vortex flowmeter is widely used in electric power, sewage plant, textile, printing and dyeing, energy saving and environmental protection, chemical industry and other fields of measurement. In addition, it is also widely used in industrial process control, such as petrochemical, pharmaceutical manufacturing, food and beverage, metallurgy, steel and other industries in the production process, can achieve accurate measurement and control of fluids; At the same time, it can be used for real-time monitoring and control of water flow in water treatment, environmental protection and other fields.

Summary: It can measure various fluid media such as liquid, gas and steam. At the same time, because of its simple structure, high precision, easy maintenance and other characteristics, the insertion vortex flowmeter has a wide range of applications in many other fields

5. Working temperature

The insertion vortex flowmeter can be adapted to a wide temperature range, generally between -200°C and +400°C. However, the specific applicable temperature needs to be determined according to the actual working conditions and product models. When used in high or low temperature environments, it is necessary to choose the right model and accessories to ensure the normal operation of the flow meter and extend the service life. At the same time, it is also necessary to pay attention to the proper maintenance and maintenance of the flow meter, regularly check the status of the sensor and amplifier, and carry out regular cleaning and calibration.

6. Installation method

The installation method of the insertion vortex flowmeter is relatively simple. First, choose the right flowmeter according to the size of the pipe and the type of fluid. Then, make a hole in the pipe suitable for the size of the flow meter, insert the flow meter into the hole, and secure the flow meter to the pipe with a fixing screw or other means. Finally, the signal line between the amplifier and the sensor is connected, and the parameters of the amplifier are adjusted to make the flow meter work normally.

7. Debugging and calibration

The insertion vortex flowmeter needs to be debugged and calibrated before use. First, check that all connections are strong and that the signal transmission between the sensor and the amplifier is normal. Then, set the parameters of the flowmeter according to the actual situation, such as the fluid type and working pressure. Finally, the actual measurement and calibration are carried out to ensure that the measurement accuracy of the flowmeter meets the requirements.

8. Common faults and elimination

The insertion vortex flowmeter may have some faults during use, such as excessive measurement error and abnormal output signal. For these faults, the following methods can be used to eliminate them

(1) the measurement error is too large: it may be due to the instability of the flow rate in the pipeline or the fault of the sensor. At this point, you can check whether the flow rate in the pipeline is stable, or replace components such as sensors.

(2) Abnormal output signal: it may be caused by poor signal line connection or amplifier failure. At this time, you can check whether the signal line is firmly connected, or replace the amplifier and other components.

(3) other failures: may be due to power failure, environmental interference and other reasons. At this time, you can check whether the power supply is working normally, or take measures to reduce environmental interference.

9.Maintenance and maintenance

The insertion vortex flowmeter needs regular maintenance and maintenance during use to ensure its normal operation and improve its service life. Specific maintenance and maintenance measures include: regularly check whether the appearance of the flow meter is intact, whether the screws are loose; Regularly clean the debris and dirt inside the sensor: regularly check whether the parameters of the amplifier are normal, etc.

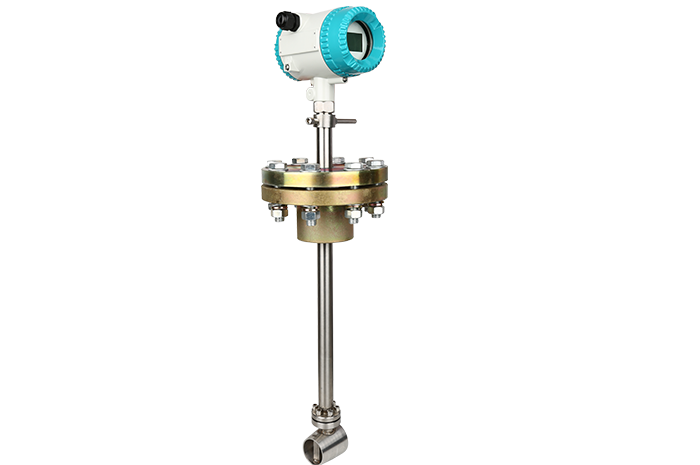

1. Overview

The insertion vortex flowmeter is a new flowmeter, which has the characteristics of simple structure, light weight, high precision, good repeatability, sensitive response, easy installation, maintenance and use. It is improved on the basis of vortex flowmeter, not only retains the basic advantages of vortex flowmeter, but also realizes higher measurement accuracy and wider measurement range by using special structural design and signal processing technology. The insertion vortex flowmeter is widely used in petroleum, chemical, electric power, metallurgy and other fields, providing reliable flow measurement solutions for enterprises

2. The working principle

The insertion vortex flowmeter is based on the working principle of the vortex flowmeter. A fixed vortex generator is set up in the pipeline. When the fluid flows through the vortex generator, a series of vortices are formed downstream. The frequency of these vortices is proportional to the flow rate of the fluid. By measuring the frequency of the vortex, the flow rate of the fluid can be calculated, and the flow rate can be obtained. The insertion vortex flowmeter adopts special structure design, so that the sensor can be disassembled without interruption, which is convenient for installation and maintenance.

3. Structure composition

It mainly consists of two parts: sensor and amplifier. The sensor measures the frequency of the vortex and transmits the signal to the amplifier. The amplifier processes the signal and converts the result into a standard signal output. In addition, the insertion vortex flowmeter is equipped with an anti-disturbance circuit and anti-vibration sensing head to enhance its resistance to ambient vibration.

4. Scope of application

The insertion vortex flowmeter is widely used in electric power, sewage plant, textile, printing and dyeing, energy saving and environmental protection, chemical industry and other fields of measurement. In addition, it is also widely used in industrial process control, such as petrochemical, pharmaceutical manufacturing, food and beverage, metallurgy, steel and other industries in the production process, can achieve accurate measurement and control of fluids; At the same time, it can be used for real-time monitoring and control of water flow in water treatment, environmental protection and other fields.

Summary: It can measure various fluid media such as liquid, gas and steam. At the same time, because of its simple structure, high precision, easy maintenance and other characteristics, the insertion vortex flowmeter has a wide range of applications in many other fields

5. Working temperature

The insertion vortex flowmeter can be adapted to a wide temperature range, generally between -200°C and +400°C. However, the specific applicable temperature needs to be determined according to the actual working conditions and product models. When used in high or low temperature environments, it is necessary to choose the right model and accessories to ensure the normal operation of the flow meter and extend the service life. At the same time, it is also necessary to pay attention to the proper maintenance and maintenance of the flow meter, regularly check the status of the sensor and amplifier, and carry out regular cleaning and calibration.

6. Installation method

The installation method of the insertion vortex flowmeter is relatively simple. First, choose the right flowmeter according to the size of the pipe and the type of fluid. Then, make a hole in the pipe suitable for the size of the flow meter, insert the flow meter into the hole, and secure the flow meter to the pipe with a fixing screw or other means. Finally, the signal line between the amplifier and the sensor is connected, and the parameters of the amplifier are adjusted to make the flow meter work normally.

7. Debugging and calibration

The insertion vortex flowmeter needs to be debugged and calibrated before use. First, check that all connections are strong and that the signal transmission between the sensor and the amplifier is normal. Then, set the parameters of the flowmeter according to the actual situation, such as the fluid type and working pressure. Finally, the actual measurement and calibration are carried out to ensure that the measurement accuracy of the flowmeter meets the requirements.

8. Common faults and elimination

The insertion vortex flowmeter may have some faults during use, such as excessive measurement error and abnormal output signal. For these faults, the following methods can be used to eliminate them

(1) the measurement error is too large: it may be due to the instability of the flow rate in the pipeline or the fault of the sensor. At this point, you can check whether the flow rate in the pipeline is stable, or replace components such as sensors.

(2) Abnormal output signal: it may be caused by poor signal line connection or amplifier failure. At this time, you can check whether the signal line is firmly connected, or replace the amplifier and other components.

(3) other failures: may be due to power failure, environmental interference and other reasons. At this time, you can check whether the power supply is working normally, or take measures to reduce environmental interference.

9.Maintenance and maintenance

The insertion vortex flowmeter needs regular maintenance and maintenance during use to ensure its normal operation and improve its service life. Specific maintenance and maintenance measures include: regularly check whether the appearance of the flow meter is intact, whether the screws are loose; Regularly clean the debris and dirt inside the sensor: regularly check whether the parameters of the amplifier are normal, etc.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference