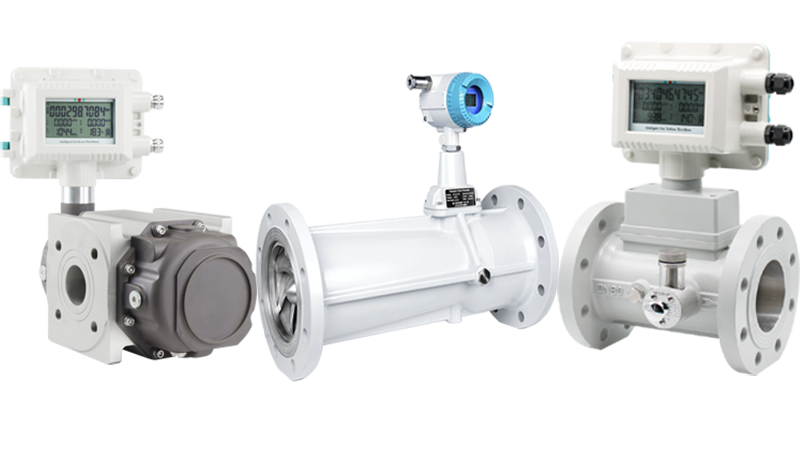

Introduction to correct maintenance and troubleshooting of gas turbine flowmeter

2021-06-17

The correct maintenance and troubleshooting of gas turbine flowmeter is introduced by Shanghai Aister Instrument for you. Welcome to read and understand.

In order to ensure the long-term normal operation of the gas turbine flowmeter, it is necessary to regularly check the operating status of the turbine flowmeter, do a good job of maintenance, and eliminate problems in time.

ATWG gas turbine flow meter maintenance method:

1. Before the gas turbine flowmeter is put into operation, the instrument coefficient should be set and carefully checked to ensure that the flowmeter is correctly connected and well grounded before it can be powered.

2. Regularly clean, check and re-check the flowmeter. Flow meters equipped with lubricating oil or cleaning fluid injection ports should be regularly injected with lubricating oil or cleaning fluid according to the requirements of the instructions to maintain the good operation of the impeller.

3. Monitor and display the status of the instrument, evaluate and display the reading of the instrument, and check whether there is an anomaly in time.

4. Keep the filter unblocked. If the filter is blocked by impurities, it can be judged from the increase in the difference between the readings of the inlet and outlet pressure gauges, and the blockage should be eliminated in time, otherwise it will seriously reduce the flow rate.

5. For large flow trade settlement measurement, in order to ensure the accuracy of the flow meter, it is necessary to check the flow meter frequently. On-site calibration equipment should be equipped with online or mobile calibration equipment. Although the one-time investment is relatively large, it is worth it considering the long-term economic benefits.

Gas turbine flowmeter troubleshooting method:

1.ATWG gas turbine flow meter sensor or supporting display instrument has no output signal; Fault cause: wiring error, impeller stuck, no rotation, detection coil open or short circuit, poor preamplifier, preamplifier no power supply or power supply voltage is too low, indicating that the instrument itself is faulty; Elimination method: Check whether the wiring is correct, whether there is debris in the pipeline, check the amplifier, check the amplifier or increase the power supply voltage to the specified requirements, check the display.

2. When the flow rate is zero, there is still a signal output; Fault cause: Strong external electromagnetic field interferes with pipeline vibration, causing the impeller to swing back and forth. Pipe vibration causes relative motion between the magnetic steel and the coil. Elimination method: Check whether the shielded wire is well grounded or eliminate interference, eliminate pipeline vibration, and eliminate pipeline vibration.

3. The indicated traffic is different from the actual traffic. Cause of failure: The second cause of failure is poor air or steam mixed into the preamplifier, low pipe outlet pressure, bearing wear, impurities attached to the impeller, stolen goods and defective pipes, indicating instrument failure. Elimination methods: Eliminate pipe vibration, repair amplifier, install air separator, pressurize, replace bearing, clean pipe, reinstall pipe, repair display instrument.

Aister Instrument is a quality gas flow meter manufacturer, looking forward to serving you. The above is the correct maintenance and troubleshooting of the gas turbine flowmeter.

Share To:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference