How to select electromagnetic flowmeter?

2024-04-03

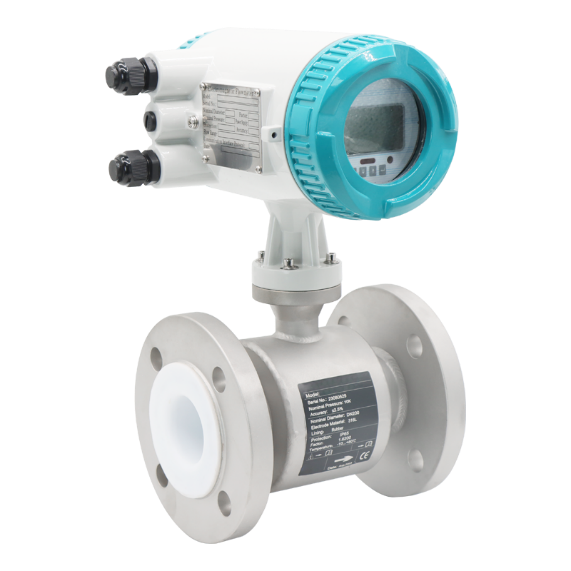

Electromagnetic Flow Meter is an instrument used to accurately measure the flow of corrosive liquids. It is widely used in industrial process control, environmental monitoring, scientific research and other fields. So how to choose the right flowmeter? Next, Aister will take you to understand the selection of electromagnetic flow meters.

(1) The first is to select the diameter according to the pipeline, in general, the diameter is one of the most important parameters of the flow meter. The most commonly used caliber is the nominal diameter dn, such as: dn15, dn 100,

(2) Select the lining and electrode according to the medium. The lining and electrode need to be in contact with the medium, so selecting them can greatly increase the service life of the electromagnetic flowmeter. Conventional lining is shown below:

316L:

For the measurement of water, sewage or inorganic, organic acid slightly corrosive media.

Hastelloy B(HB) :

It has good corrosion resistance to all concentrations of hydrochloric acid below the boiling point, as well as corrosion resistance to non-oxidizing acids, alkalis and non-oxidizing salts such as sulfuric acid, phosphoric acid, acid and organic acid.

Hastelloy C(HC) :

Resistant to oxidizing acids, such as nitric acid, mixed acid, or chromic acid and sulfuric acid mixed medium corrosion; It is also resistant to oxidation salts such as Fe+++, Cu++ or corrosion containing other oxidants, such as hypoxate solution at higher than normal temperature and seawater corrosion.

Titanium (Ti) :

Resistant to seawater, various oxides and hypoxates, oxidizing acids (including fuming nitric acid), organic acids, etc. It is not resistant to the corrosion of purer reducing acids (such as sulfuric acid, hydrochloric acid), but if the acid contains oxidants (such as nitric acid, Fe+++, Cu++), the corrosion resistance is greatly reduced.

Tantalum (Ta) :

It has excellent corrosion resistance and is very similar to glass. In addition to hydrofluoric acid, fuming sulfuric acid, fuming nitric acid, alkali, almost all chemical media (including boiling point hydrochloric acid, nitric acid, and sulfuric acid) corrosion. Not resistant to corrosion in alkali.

Platinum-iridium alloy: suitable for almost all chemicals, but not for aqua regia and ammonium salts.

Lining material selection:

The performance of common lining materials should be selected according to the corrosion, wear and temperature of the measured medium

Neoprene rubber (CR) :

1. Oil resistance, solvent resistance, oxidation resistance, general acid, alkali and salt and other medium corrosion.

2. Excellent elasticity, wear resistance, but poor cold resistance.

Silicone fluorine rubber (FVMQ) :

1. Good low temperature resistance, can still work normally under -55°C;

2. Outstanding heat resistance, can work for a long time at 180°C

Polyurethane rubber (PU) :

1. Excellent wear resistance and elasticity.

2. Acid and alkaline resistance is poor.

Teflon (PFA) :

1. Good hydrophobicity and non-viscosity, strong high temperature resistance.

2. Excellent corrosion resistance, strong acid, strong alkali, organic solvents and various salt solutions. 3. Good negative pressure resistance, metal mesh can be added to further improve negative pressure resistance. 4. Poor wear resistance.

Polyperfluorinated ethylene propylene (F46) :

1. Hydrophobic and non-viscous.

2. Corrosion resistance is second only to PFA.

3. Metal mesh can be added to improve negative pressure resistance.

4. Poor wear resistance.

Polytetrafluoroethylene (PTFE) :

1. Plastic chemical properties of the most stable a material, capable of boiling hydrochloric acid, sulfuric acid, nitric acid and aqua Regis, also capable of concentrated alkali and various organic solvents, not resistant to chlorine trifluoride, high temperature oxygen trifluoride, high flow rate liquid gas, liquid oxygen, ozone corrosion.

2. Poor wear resistance.

3. The negative pressure resistance is poor, and the lining is prone to deformation or fracture, resulting in electrode leakage.

(3) According to the situation of the site optional content, some sites will have certain requirements for waterproof level, we can make the battery flow meter into a split type, such as IP65,IP68 currently IP68 is the highest level of protection, when we want to measure some low conductivity of organic matter to choose this level, but also need to note that, If the pipeline is non-metallic, the site interference is relatively large, you can choose to install a ground ring. If the media wear is strong, should be used to protect the lining with a diameter grounding ring.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

(2) Select the lining and electrode according to the medium. The lining and electrode need to be in contact with the medium, so selecting them can greatly increase the service life of the electromagnetic flowmeter. Conventional lining is shown below:

316L:

For the measurement of water, sewage or inorganic, organic acid slightly corrosive media.

Hastelloy B(HB) :

It has good corrosion resistance to all concentrations of hydrochloric acid below the boiling point, as well as corrosion resistance to non-oxidizing acids, alkalis and non-oxidizing salts such as sulfuric acid, phosphoric acid, acid and organic acid.

Hastelloy C(HC) :

Resistant to oxidizing acids, such as nitric acid, mixed acid, or chromic acid and sulfuric acid mixed medium corrosion; It is also resistant to oxidation salts such as Fe+++, Cu++ or corrosion containing other oxidants, such as hypoxate solution at higher than normal temperature and seawater corrosion.

Titanium (Ti) :

Resistant to seawater, various oxides and hypoxates, oxidizing acids (including fuming nitric acid), organic acids, etc. It is not resistant to the corrosion of purer reducing acids (such as sulfuric acid, hydrochloric acid), but if the acid contains oxidants (such as nitric acid, Fe+++, Cu++), the corrosion resistance is greatly reduced.

Tantalum (Ta) :

It has excellent corrosion resistance and is very similar to glass. In addition to hydrofluoric acid, fuming sulfuric acid, fuming nitric acid, alkali, almost all chemical media (including boiling point hydrochloric acid, nitric acid, and sulfuric acid) corrosion. Not resistant to corrosion in alkali.

Platinum-iridium alloy: suitable for almost all chemicals, but not for aqua regia and ammonium salts.

Lining material selection:

The performance of common lining materials should be selected according to the corrosion, wear and temperature of the measured medium

Neoprene rubber (CR) :

1. Oil resistance, solvent resistance, oxidation resistance, general acid, alkali and salt and other medium corrosion.

2. Excellent elasticity, wear resistance, but poor cold resistance.

Silicone fluorine rubber (FVMQ) :

1. Good low temperature resistance, can still work normally under -55°C;

2. Outstanding heat resistance, can work for a long time at 180°C

Polyurethane rubber (PU) :

1. Excellent wear resistance and elasticity.

2. Acid and alkaline resistance is poor.

Teflon (PFA) :

1. Good hydrophobicity and non-viscosity, strong high temperature resistance.

2. Excellent corrosion resistance, strong acid, strong alkali, organic solvents and various salt solutions. 3. Good negative pressure resistance, metal mesh can be added to further improve negative pressure resistance. 4. Poor wear resistance.

Polyperfluorinated ethylene propylene (F46) :

1. Hydrophobic and non-viscous.

2. Corrosion resistance is second only to PFA.

3. Metal mesh can be added to improve negative pressure resistance.

4. Poor wear resistance.

Polytetrafluoroethylene (PTFE) :

1. Plastic chemical properties of the most stable a material, capable of boiling hydrochloric acid, sulfuric acid, nitric acid and aqua Regis, also capable of concentrated alkali and various organic solvents, not resistant to chlorine trifluoride, high temperature oxygen trifluoride, high flow rate liquid gas, liquid oxygen, ozone corrosion.

2. Poor wear resistance.

3. The negative pressure resistance is poor, and the lining is prone to deformation or fracture, resulting in electrode leakage.

(3) According to the situation of the site optional content, some sites will have certain requirements for waterproof level, we can make the battery flow meter into a split type, such as IP65,IP68 currently IP68 is the highest level of protection, when we want to measure some low conductivity of organic matter to choose this level, but also need to note that, If the pipeline is non-metallic, the site interference is relatively large, you can choose to install a ground ring. If the media wear is strong, should be used to protect the lining with a diameter grounding ring.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference