What are the installation requirements for Coriolis mass flowmeters

2024-01-03

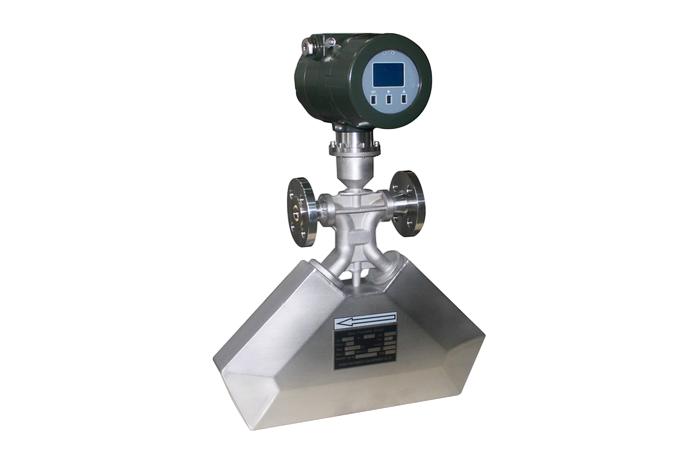

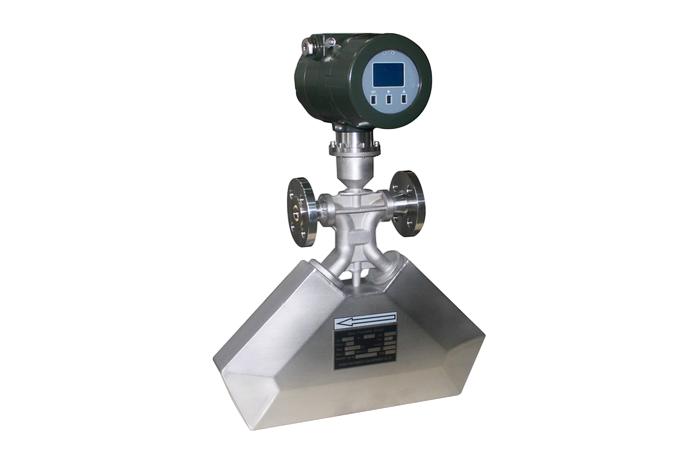

Coriolis mass flowmeters are instruments used to measure the mass flow rate of fluids based on the Coriolis effect. Proper installation is crucial to ensure accurate and reliable measurements. Here are some general installation requirements for Coriolis mass flowmeters:

Straight Run:

Ensure sufficient straight pipe lengths before and after the Coriolis mass flowmeter to allow for stable fluid flow. Typically, a minimum of 10 pipe diameters upstream and 5 pipe diameters downstream is recommended.

Horizontal Orientation:

Coriolis mass flowmeters are typically designed for horizontal installation to ensure accurate measurement. If vertical installation is necessary, follow the manufacturer's recommendations and use appropriate measures to compensate for any potential errors.

Vibration and Shock:

Avoid exposing the mass flowmeter to excessive vibration or shock, as this can affect its performance and accuracy. Consider implementing damping solutions when needed.

Temperature and Pressure:

Ensure that the fluid temperature and pressure are within the specified operating range of the mass flowmeter. High-temperature or high-pressure conditions may require special considerations to maintain safety and performance.

Pipe Diameter Match:

Select a Coriolis mass flowmeter that matches the size of the pipe diameter to ensure accurate measurement. Improper sizing can lead to measurement errors.

Maintenance Access:

Provide adequate space around the flowmeter for installation, maintenance, and inspection. Accessibility is essential for routine checks and maintenance activities.

Grounding:

Properly ground the mass flowmeter to prevent electrical interference and ensure the safety of the equipment and personnel.

Corrosion Protection:

Consider the environment where the mass flowmeter is installed and take measures to protect it from corrosion, ensuring long-term reliability.

Electrical Connections:

Follow the manufacturer's guidelines for electrical connections. Ensure proper electrical grounding and shielding to minimize the impact of electromagnetic interference.

Flow Direction:

Install the Coriolis mass flowmeter with the correct flow direction as indicated by the manufacturer. Incorrect installation can lead to inaccurate measurements.

Calibration:

Perform calibration according to the manufacturer's recommendations after installation to ensure accurate and reliable measurements.

Always refer to the specific guidelines provided by the manufacturer in the product documentation. Proper installation should be carried out by qualified personnel to guarantee optimal performance and accurate readings from the Coriolis mass flowmeter.

Straight Run:

Ensure sufficient straight pipe lengths before and after the Coriolis mass flowmeter to allow for stable fluid flow. Typically, a minimum of 10 pipe diameters upstream and 5 pipe diameters downstream is recommended.

Horizontal Orientation:

Coriolis mass flowmeters are typically designed for horizontal installation to ensure accurate measurement. If vertical installation is necessary, follow the manufacturer's recommendations and use appropriate measures to compensate for any potential errors.

Vibration and Shock:

Avoid exposing the mass flowmeter to excessive vibration or shock, as this can affect its performance and accuracy. Consider implementing damping solutions when needed.

Temperature and Pressure:

Ensure that the fluid temperature and pressure are within the specified operating range of the mass flowmeter. High-temperature or high-pressure conditions may require special considerations to maintain safety and performance.

Pipe Diameter Match:

Select a Coriolis mass flowmeter that matches the size of the pipe diameter to ensure accurate measurement. Improper sizing can lead to measurement errors.

Maintenance Access:

Provide adequate space around the flowmeter for installation, maintenance, and inspection. Accessibility is essential for routine checks and maintenance activities.

Grounding:

Properly ground the mass flowmeter to prevent electrical interference and ensure the safety of the equipment and personnel.

Corrosion Protection:

Consider the environment where the mass flowmeter is installed and take measures to protect it from corrosion, ensuring long-term reliability.

Electrical Connections:

Follow the manufacturer's guidelines for electrical connections. Ensure proper electrical grounding and shielding to minimize the impact of electromagnetic interference.

Flow Direction:

Install the Coriolis mass flowmeter with the correct flow direction as indicated by the manufacturer. Incorrect installation can lead to inaccurate measurements.

Calibration:

Perform calibration according to the manufacturer's recommendations after installation to ensure accurate and reliable measurements.

Always refer to the specific guidelines provided by the manufacturer in the product documentation. Proper installation should be carried out by qualified personnel to guarantee optimal performance and accurate readings from the Coriolis mass flowmeter.

Share To:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference