The development trend of natural gas flowmeter technology

2023-12-19

Natural gas flow meter measurement standards are constantly enriched, developed and improved, combined with foreign standards, China's measurement standards are developing in the direction of multi-standards.

In the natural gas metering model, it has been constantly evolving and changing, usually based on volume metering and equipped with heating metering devices. It is very fair to adopt this method of energy measurement to solve the problem. With the continuous improvement of China's market economy, energy measurement has become a general trend in China's natural gas industry.

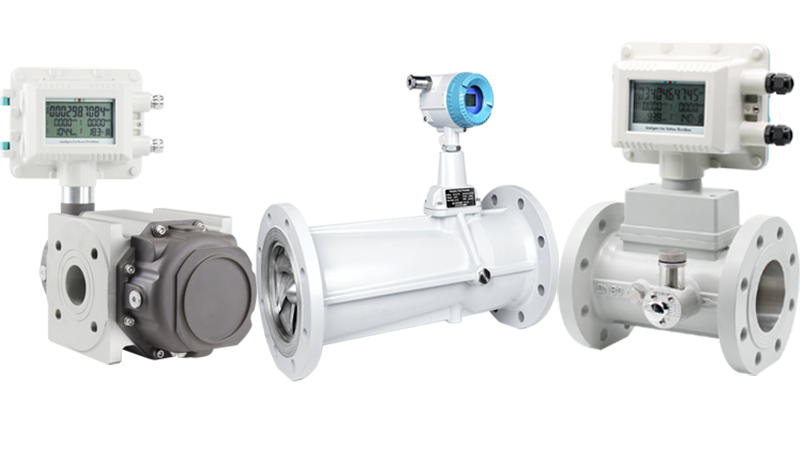

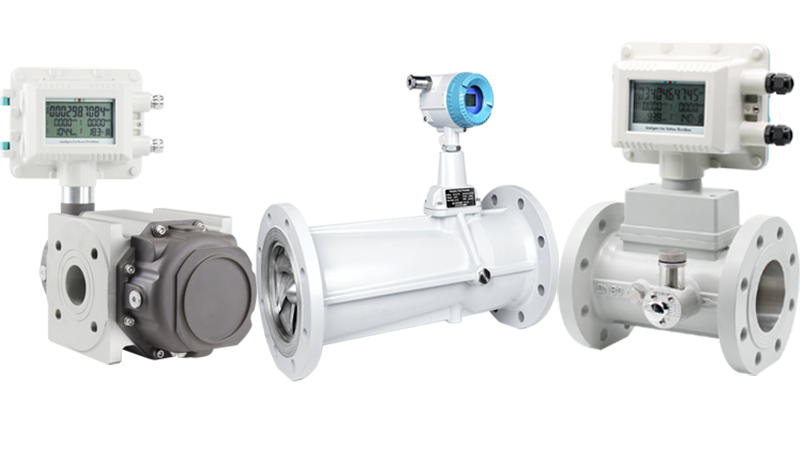

Natural gas flowmeters are developing rapidly in the direction of real-time, online and intelligent, relying on network technology to effectively achieve long-distance communication, management and control, such as the application of SCADA systems and the use of intelligent gas turbine flowmeters.

It can also be equipped with auxiliary instrument systems such as temperature sensors, pressure sensors, gas chromatographs and gas densitometers to record, store and transmit data in accordance with standard procedures, and publish data through transmission systems and computer networks. It is expected that the development of related technologies will accelerate the transmission speed of measurement information and continuously improve the measurement accuracy.

With the development of science and technology, the technology of natural gas flow meters is also constantly improving and improving. The following is a brief overview of the development trend of natural gas flowmeter technology.

Ultrasonic flowmeter:

Ultrasonic flowmeter is a method of measuring gas flow by using ultrasonic transmission time. Its measuring accuracy and stability are continuously improved, and the cost is gradually reduced, which makes the ultrasonic flowmeter widely used in the field of natural gas measurement.

Gas sensor:

With the continuous development of technology, the sensitivity and selectivity of gas sensors continue to improve, and the cost is gradually reduced. The application of gas sensor in natural gas flowmeter can realize real-time monitoring of natural gas composition and concentration, and achieve accurate measurement of natural gas flow.

Intelligent technology:

Intelligent technology is one of the important development directions of natural gas flowmeters in the future. Through the introduction of intelligent technology, the automation and remote control of natural gas flowmeters can be achieved, improving measurement accuracy and stability, reducing maintenance costs, and improving production efficiency.

Multiple flow meter integration:

Different flowmeters are integrated to achieve simultaneous measurement of multiple parameters, improving measurement accuracy and efficiency. For example, the integration of ultrasonic flowmeters and gas sensors can achieve accurate measurement of natural gas flow and real-time monitoring of gas composition.

High precision measurement:

With the development of natural gas industry, the measurement accuracy requirements of natural gas flowmeters are getting higher and higher. By using advanced measurement technology and algorithm, the measuring accuracy and stability of natural gas flowmeter can be improved to better meet the production needs.

In summary, with the continuous development of science and technology, the technology of natural gas flow meters is also constantly improving and improving. In the future, more advanced technologies and equipment will be applied to natural gas flowmeters to achieve more accurate, more stable and more efficient measurements.

In the natural gas metering model, it has been constantly evolving and changing, usually based on volume metering and equipped with heating metering devices. It is very fair to adopt this method of energy measurement to solve the problem. With the continuous improvement of China's market economy, energy measurement has become a general trend in China's natural gas industry.

Natural gas flowmeters are developing rapidly in the direction of real-time, online and intelligent, relying on network technology to effectively achieve long-distance communication, management and control, such as the application of SCADA systems and the use of intelligent gas turbine flowmeters.

It can also be equipped with auxiliary instrument systems such as temperature sensors, pressure sensors, gas chromatographs and gas densitometers to record, store and transmit data in accordance with standard procedures, and publish data through transmission systems and computer networks. It is expected that the development of related technologies will accelerate the transmission speed of measurement information and continuously improve the measurement accuracy.

With the development of science and technology, the technology of natural gas flow meters is also constantly improving and improving. The following is a brief overview of the development trend of natural gas flowmeter technology.

Ultrasonic flowmeter:

Ultrasonic flowmeter is a method of measuring gas flow by using ultrasonic transmission time. Its measuring accuracy and stability are continuously improved, and the cost is gradually reduced, which makes the ultrasonic flowmeter widely used in the field of natural gas measurement.

Gas sensor:

With the continuous development of technology, the sensitivity and selectivity of gas sensors continue to improve, and the cost is gradually reduced. The application of gas sensor in natural gas flowmeter can realize real-time monitoring of natural gas composition and concentration, and achieve accurate measurement of natural gas flow.

Intelligent technology:

Intelligent technology is one of the important development directions of natural gas flowmeters in the future. Through the introduction of intelligent technology, the automation and remote control of natural gas flowmeters can be achieved, improving measurement accuracy and stability, reducing maintenance costs, and improving production efficiency.

Multiple flow meter integration:

Different flowmeters are integrated to achieve simultaneous measurement of multiple parameters, improving measurement accuracy and efficiency. For example, the integration of ultrasonic flowmeters and gas sensors can achieve accurate measurement of natural gas flow and real-time monitoring of gas composition.

High precision measurement:

With the development of natural gas industry, the measurement accuracy requirements of natural gas flowmeters are getting higher and higher. By using advanced measurement technology and algorithm, the measuring accuracy and stability of natural gas flowmeter can be improved to better meet the production needs.

In summary, with the continuous development of science and technology, the technology of natural gas flow meters is also constantly improving and improving. In the future, more advanced technologies and equipment will be applied to natural gas flowmeters to achieve more accurate, more stable and more efficient measurements.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference