Type and selection of compressed air flow meter

2024-06-11

I. Compressed air flowmeter type

Industrial compressed air flowmeters are mainly divided into the following types according to the measurement principle and application requirements:

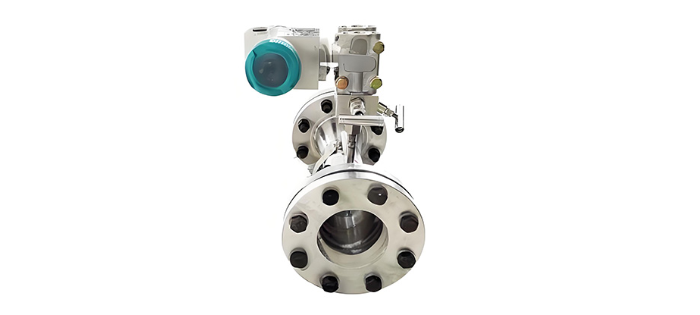

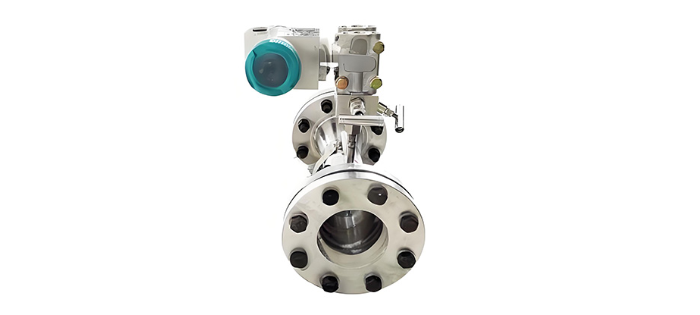

1, Differential pressure flowmeter: Based on the principle of Bernoulli equation, by measuring the flow generated by the pressure difference to calculate the flow, the following example differential pressure orifice flowmeter: Advantages:

Advantages:

Low cost: The orifice flowmeter is relatively simple to design and manufacture, so the cost is low.

Small pressure loss: Compared with vortex flowmeters, orifice flowmeters produce less pressure loss.

Cons:

Low accuracy: The measuring accuracy of orifice flowmeters is usually low and may not meet the needs of high-precision measurement.

Easy to wear: The erosion caused by fluid passing through the orifice may cause the orifice to wear, affecting the measurement accuracy.

2, Vortex flowmeter: use the frequency signal generated by the vortex to measure the flow rate, suitable for low flow rate and high compression ratio occasions. Advantages:

Simple structure: The structure of the vortex flowmeter is relatively simple, easy to understand and maintain.

Fast response speed: Vortex flowmeters can respond quickly to rapid changes in flow.

Easy installation: The installation environment is not high, easy to install and debug.

Cons:

Limited accuracy: Vortex flowmeters may have lower measurement accuracy than other flowmeters.

Large pressure loss: Due to the presence of fluid steering and flow resistance, vortex flowmeters may cause large pressure losses.

3. Precession vortex flowmeter Advantages:

High precision: Precession vortex flowmeters are designed with high measurement accuracy to meet the needs of most accurate measurements.

Good stability: its structure and working principle make it have good stability and is not easy to be disturbed by the external environment.

Wide traffic range: suitable for a wide range of traffic measurement, to meet a variety of application scenarios.

Cons:

High cost: Due to the high precision requirements in the design and manufacturing process, the cost is relatively high.

High installation requirements: professional installation and commissioning is required to ensure its accuracy and stability.

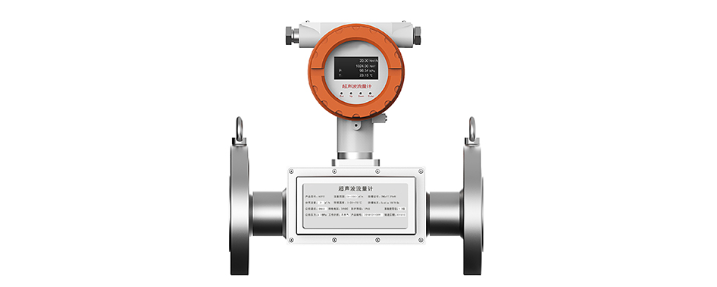

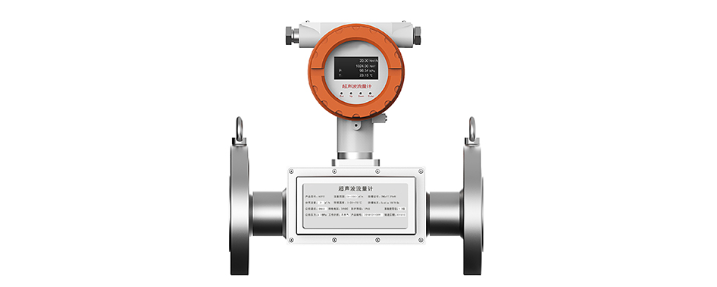

4, Thermal gas mass flowmeter: direct measurement of fluid mass flow, with high precision and fast response characteristics. The advantage is high precision, the disadvantage is expensive. 5, Ultrasonic gas flow meter: by measuring the speed of ultrasonic propagation in the fluid to calculate the flow rate, suitable for large diameter and low flow rate occasions. Ⅱ. Measurement principles

Ⅱ. Measurement principles

The measurement principle of industrial compressed air flowmeter mainly depends on the principle of fluid dynamics, such as Bernoulli equation, continuity equation and so on. Different types of flowmeters use different measuring principles to achieve accurate flow measurement.

Ⅲ. Application field

Industrial compressed air flowmeters are widely used in the following fields:

1, manufacturing: used to monitor the compressed air consumption on the production line, optimize the production process.

2. Energy industry: Monitor the compressed air flow in gas turbines, wind power generation and other equipment to ensure the normal operation of equipment.

3, pharmaceutical industry: in the drug production process, used to control the quality and flow of compressed air to ensure the quality of drugs.

4, the field of environmental protection: monitoring the compressed air flow in industrial waste gas, assess pollution emissions.

Ⅳ. Technical parameters

The main technical parameters of industrial compressed air flowmeter include:

1, measuring range: the minimum and maximum flow value that can be measured by the flowmeter.

2. Accuracy level: error range of flowmeter measurement results.

3, working pressure: flowmeter can withstand the maximum working pressure.

4. Ambient temperature: the ambient temperature range for the normal operation of the flowmeter.

5, response time: flowmeter response time to flow changes.

V. Installation and maintenance

In order to ensure the accuracy and stability of industrial compressed air flowmeters, the following points should be noted:

1, installation position: select stable air flow, no vibration interference position for installation.

2, pipeline connection: Ensure that the pipeline connection is firm, good sealing, to avoid leakage.

3, regular calibration: regularly calibrate the flow meter to ensure measurement accuracy.

4, maintenance: regularly clean the flow meter and sensor, keep the equipment dry and dust-free.

Ⅵ. Safety specifications

When using the industrial compressed air flow meter, the following safety specifications should be followed:

1, explosion-proof safety: When used in flammable and explosive places, explosion-proof flowmeters should be selected, and corresponding explosion-proof measures should be taken.

2, anti-electric shock: when used in wet or metal pipes, anti-electric shock measures should be taken to ensure the safety of personnel and equipment.

3, protection level: according to the use of the environment to choose the appropriate level of protection, to avoid damage to the flow meter.

Ⅶ. Selection guide

When choosing an industrial compressed air flow meter, the following factors should be considered:

1, measurement requirements: clear measurement range, accuracy level and other requirements, choose the right type of flow meter.

2, working environment: consider the impact of environmental factors such as working pressure and ambient temperature on the flow meter.

3, installation mode: according to the site conditions to choose the appropriate installation mode, such as horizontal installation, vertical installation, etc.

4, cost budget: according to the actual demand and cost budget, choose the right flowmeter brand and model.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Industrial compressed air flowmeters are mainly divided into the following types according to the measurement principle and application requirements:

1, Differential pressure flowmeter: Based on the principle of Bernoulli equation, by measuring the flow generated by the pressure difference to calculate the flow, the following example differential pressure orifice flowmeter:

Low cost: The orifice flowmeter is relatively simple to design and manufacture, so the cost is low.

Small pressure loss: Compared with vortex flowmeters, orifice flowmeters produce less pressure loss.

Cons:

Low accuracy: The measuring accuracy of orifice flowmeters is usually low and may not meet the needs of high-precision measurement.

Easy to wear: The erosion caused by fluid passing through the orifice may cause the orifice to wear, affecting the measurement accuracy.

2, Vortex flowmeter: use the frequency signal generated by the vortex to measure the flow rate, suitable for low flow rate and high compression ratio occasions. Advantages:

Simple structure: The structure of the vortex flowmeter is relatively simple, easy to understand and maintain.

Fast response speed: Vortex flowmeters can respond quickly to rapid changes in flow.

Easy installation: The installation environment is not high, easy to install and debug.

Cons:

Limited accuracy: Vortex flowmeters may have lower measurement accuracy than other flowmeters.

Large pressure loss: Due to the presence of fluid steering and flow resistance, vortex flowmeters may cause large pressure losses.

3. Precession vortex flowmeter Advantages:

High precision: Precession vortex flowmeters are designed with high measurement accuracy to meet the needs of most accurate measurements.

Good stability: its structure and working principle make it have good stability and is not easy to be disturbed by the external environment.

Wide traffic range: suitable for a wide range of traffic measurement, to meet a variety of application scenarios.

Cons:

High cost: Due to the high precision requirements in the design and manufacturing process, the cost is relatively high.

High installation requirements: professional installation and commissioning is required to ensure its accuracy and stability.

4, Thermal gas mass flowmeter: direct measurement of fluid mass flow, with high precision and fast response characteristics. The advantage is high precision, the disadvantage is expensive. 5, Ultrasonic gas flow meter: by measuring the speed of ultrasonic propagation in the fluid to calculate the flow rate, suitable for large diameter and low flow rate occasions.

The measurement principle of industrial compressed air flowmeter mainly depends on the principle of fluid dynamics, such as Bernoulli equation, continuity equation and so on. Different types of flowmeters use different measuring principles to achieve accurate flow measurement.

Ⅲ. Application field

Industrial compressed air flowmeters are widely used in the following fields:

1, manufacturing: used to monitor the compressed air consumption on the production line, optimize the production process.

2. Energy industry: Monitor the compressed air flow in gas turbines, wind power generation and other equipment to ensure the normal operation of equipment.

3, pharmaceutical industry: in the drug production process, used to control the quality and flow of compressed air to ensure the quality of drugs.

4, the field of environmental protection: monitoring the compressed air flow in industrial waste gas, assess pollution emissions.

Ⅳ. Technical parameters

The main technical parameters of industrial compressed air flowmeter include:

1, measuring range: the minimum and maximum flow value that can be measured by the flowmeter.

2. Accuracy level: error range of flowmeter measurement results.

3, working pressure: flowmeter can withstand the maximum working pressure.

4. Ambient temperature: the ambient temperature range for the normal operation of the flowmeter.

5, response time: flowmeter response time to flow changes.

V. Installation and maintenance

In order to ensure the accuracy and stability of industrial compressed air flowmeters, the following points should be noted:

1, installation position: select stable air flow, no vibration interference position for installation.

2, pipeline connection: Ensure that the pipeline connection is firm, good sealing, to avoid leakage.

3, regular calibration: regularly calibrate the flow meter to ensure measurement accuracy.

4, maintenance: regularly clean the flow meter and sensor, keep the equipment dry and dust-free.

Ⅵ. Safety specifications

When using the industrial compressed air flow meter, the following safety specifications should be followed:

1, explosion-proof safety: When used in flammable and explosive places, explosion-proof flowmeters should be selected, and corresponding explosion-proof measures should be taken.

2, anti-electric shock: when used in wet or metal pipes, anti-electric shock measures should be taken to ensure the safety of personnel and equipment.

3, protection level: according to the use of the environment to choose the appropriate level of protection, to avoid damage to the flow meter.

Ⅶ. Selection guide

When choosing an industrial compressed air flow meter, the following factors should be considered:

1, measurement requirements: clear measurement range, accuracy level and other requirements, choose the right type of flow meter.

2, working environment: consider the impact of environmental factors such as working pressure and ambient temperature on the flow meter.

3, installation mode: according to the site conditions to choose the appropriate installation mode, such as horizontal installation, vertical installation, etc.

4, cost budget: according to the actual demand and cost budget, choose the right flowmeter brand and model.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

Previous Post:

Next Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference