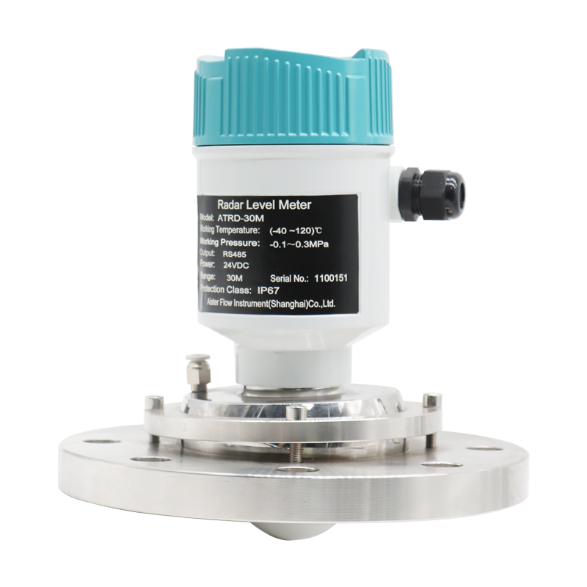

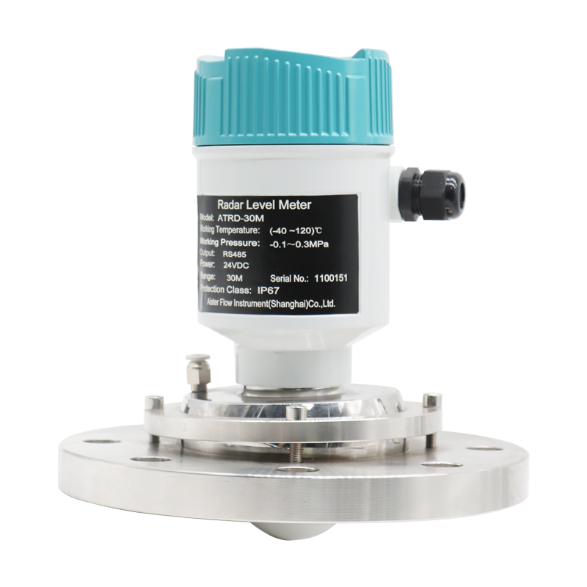

Radar level meter common problems and treatment methods

2024-04-26

Radar level meter has been widely promoted and applied in chemical industry because of its advantages such as small blind area, high continuous measurement accuracy, small influence by medium characteristics, large measuring range, high temperature and high pressure resistance and non-contact measurement method. Due to the complexity of the measured object, high temperature and high pressure corrosion, as well as foam, stirring, steam and other serious damage, radar level meter frequent failure, instrument maintenance is large, seriously affecting the production equipment. Therefore, it is necessary to understand the daily fault problems of radar level gauge and its treatment methods.

1. Check whether the power supply is normal

If the production site finds that the radar level meter changes very slowly after the liquid level rises to a certain value, it should immediately check whether the power supply of the radar level meter is normal, and the relevant staff should also check the power supply of the radar level meter in detail in the daily maintenance, and whether there is normal output after the power supply. The liquid level changes slowly or does not change at all, it is necessary to check whether the fuse of the equipment is burned out at the first time, if there is no current output, it can be basically judged that there is a problem with the instrument, which should be replaced or repaired according to the situation. In addition, management should be strengthened in the process of instrument installation and debugging to prevent inaccurate instrument parameter Settings from affecting production. Relevant staff also need to strengthen daily maintenance work, regular outage maintenance, so as to ensure the normal operation of radar level meter.

2. Check whether the communication device is normal

Once the communication equipment is found to be abnormal, the radar debugging software can be installed to read the radar configuration data and monitor the status of the radar sensor. The main check radar sensor can accurately judge the difference between the reflected echo and the false echo, whether the intensity of the reflected wave meets the predetermined standard, if there is no problem in the above test, you need to check other electronic components, if the communication unit of the radar level meter is damaged, you need to replace the components according to the situation, so as to ensure the normal communication of the radar level meter. In the daily maintenance work, the relevant staff should also strengthen the check of the communication of the radar level meter, and the radar debugging software can be used to access the signal line and the regulator can be used to maintain the communication equipment of the radar level meter.

3. Use temperature

In order to make the normal measurement of the radar level meter, the internal temperature of the radar level meter should be ensured to be below 50 ° C. Generally speaking, radar level gauges are used to measure high temperature media. Therefore, the shell of the radar level meter is made of materials with strong heat resistance, so in general, the interior of the radar level meter will not exceed 50 ° C, if the internal electronic components exceed this value, it must not be cooled with ice water, ice water will not only play a cooling and cooling role, and even paralyze the radar level meter. A copper tube can be used to blow a small amount of wind into the radar head to scientifically reduce the internal temperature of the radar level gauge.

4. The display value is incorrect

Inaccurate display value is a common problem of radar level meter, leading to the cause of inaccurate display value, which may be the contrast of the initial setting is not appropriate, or because the plug-in connection of the display module is not correct, relevant staff should try to avoid this problem, once the display value is not visible, the initial setting of the radar level meter should be checked. And check whether the connection of the display module plug-in is normal. If the two items are normal, it is necessary to deeply check whether the output current of the radar level meter is normal. If the output current is greater than 22mA, it can be judged that the display module of the radar level meter is faulty and needs to be replaced in time. If the output current is less than 3.5mA, it can be judged that the electronic module of the radar level meter is faulty, and the electronic module of the radar level meter needs to be replaced in time

5. An error message is displayed

The system of radar level gauge often displays error information, which is usually caused by the power cut off before the end of data storage, which needs to be calibrated and reset and re-calibrated. If the alarm is still sounded after the calibration reset and recalibration, the electronic module of the radar level meter needs to be replaced.

6. Antenna contamination and crystallization

When dealing with the failure of light contaminated oil tank, the possibility of antenna contamination and crystallization should be considered first. The treatment method is to wear appropriate protective equipment after power failure, remove the radar and put it down at a tilt, wipe the dirt or crystallization with a rag, do not let the antenna bend and damage, pay attention to handling gently, avoid scraping with iron, so as not to damage the antenna skin.

7. Diffuse reflection

If the liquid level is low or no liquid level, the biggest reason may be that there is a bracket or pipe at the bottom of the test container, or steam is generated during the process, which forms a diffuse reflection of the radar wave and leads to the liquid level failure. At this time, it can be automatically restored after the process level is normal and restarted. The diffuse reflection caused by steam will automatically recover after the temperature is normal.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

1. Check whether the power supply is normal

If the production site finds that the radar level meter changes very slowly after the liquid level rises to a certain value, it should immediately check whether the power supply of the radar level meter is normal, and the relevant staff should also check the power supply of the radar level meter in detail in the daily maintenance, and whether there is normal output after the power supply. The liquid level changes slowly or does not change at all, it is necessary to check whether the fuse of the equipment is burned out at the first time, if there is no current output, it can be basically judged that there is a problem with the instrument, which should be replaced or repaired according to the situation. In addition, management should be strengthened in the process of instrument installation and debugging to prevent inaccurate instrument parameter Settings from affecting production. Relevant staff also need to strengthen daily maintenance work, regular outage maintenance, so as to ensure the normal operation of radar level meter.

2. Check whether the communication device is normal

Once the communication equipment is found to be abnormal, the radar debugging software can be installed to read the radar configuration data and monitor the status of the radar sensor. The main check radar sensor can accurately judge the difference between the reflected echo and the false echo, whether the intensity of the reflected wave meets the predetermined standard, if there is no problem in the above test, you need to check other electronic components, if the communication unit of the radar level meter is damaged, you need to replace the components according to the situation, so as to ensure the normal communication of the radar level meter. In the daily maintenance work, the relevant staff should also strengthen the check of the communication of the radar level meter, and the radar debugging software can be used to access the signal line and the regulator can be used to maintain the communication equipment of the radar level meter.

3. Use temperature

In order to make the normal measurement of the radar level meter, the internal temperature of the radar level meter should be ensured to be below 50 ° C. Generally speaking, radar level gauges are used to measure high temperature media. Therefore, the shell of the radar level meter is made of materials with strong heat resistance, so in general, the interior of the radar level meter will not exceed 50 ° C, if the internal electronic components exceed this value, it must not be cooled with ice water, ice water will not only play a cooling and cooling role, and even paralyze the radar level meter. A copper tube can be used to blow a small amount of wind into the radar head to scientifically reduce the internal temperature of the radar level gauge.

4. The display value is incorrect

Inaccurate display value is a common problem of radar level meter, leading to the cause of inaccurate display value, which may be the contrast of the initial setting is not appropriate, or because the plug-in connection of the display module is not correct, relevant staff should try to avoid this problem, once the display value is not visible, the initial setting of the radar level meter should be checked. And check whether the connection of the display module plug-in is normal. If the two items are normal, it is necessary to deeply check whether the output current of the radar level meter is normal. If the output current is greater than 22mA, it can be judged that the display module of the radar level meter is faulty and needs to be replaced in time. If the output current is less than 3.5mA, it can be judged that the electronic module of the radar level meter is faulty, and the electronic module of the radar level meter needs to be replaced in time

5. An error message is displayed

The system of radar level gauge often displays error information, which is usually caused by the power cut off before the end of data storage, which needs to be calibrated and reset and re-calibrated. If the alarm is still sounded after the calibration reset and recalibration, the electronic module of the radar level meter needs to be replaced.

6. Antenna contamination and crystallization

When dealing with the failure of light contaminated oil tank, the possibility of antenna contamination and crystallization should be considered first. The treatment method is to wear appropriate protective equipment after power failure, remove the radar and put it down at a tilt, wipe the dirt or crystallization with a rag, do not let the antenna bend and damage, pay attention to handling gently, avoid scraping with iron, so as not to damage the antenna skin.

7. Diffuse reflection

If the liquid level is low or no liquid level, the biggest reason may be that there is a bracket or pipe at the bottom of the test container, or steam is generated during the process, which forms a diffuse reflection of the radar wave and leads to the liquid level failure. At this time, it can be automatically restored after the process level is normal and restarted. The diffuse reflection caused by steam will automatically recover after the temperature is normal.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference