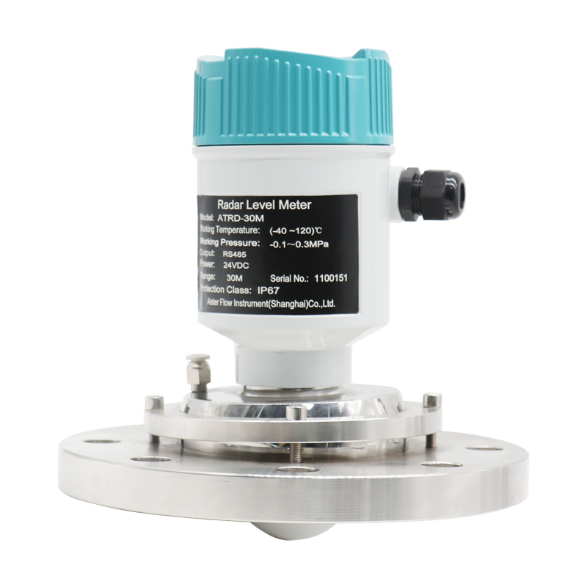

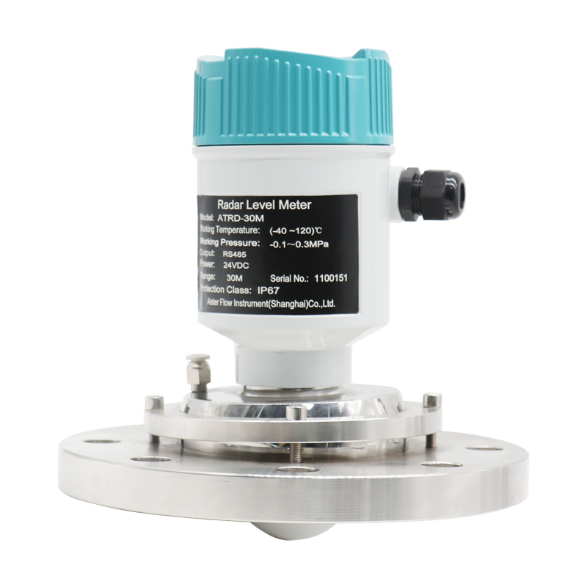

Radar level meter failure and treatment

2024-04-24

Radar level meter often fails in daily use, and its failure is roughly divided into four types: data unchanged, data suddenly maximum, data suddenly zero, data deviation from the actual value is too large or too small and remains unchanged. There is no way to eradicate these failures, and it is only possible to solve the problems targeted.

1. Power off and restart

The radar level meter itself has many protective functions. If the radar level meter itself has fault protection during normal operation, it can be powered off and restarted. At this time, the fault inside the radar level meter may be eliminated, and the radar level meter will return to normal after being powered on again. This treatment method is suitable for the maintenance of high level tank radar level gauge. After all, more than ten meters high storage tank, climbing to the top of the tank to deal with the radar level gauge is not a simple matter, can be solved on the ground first.

2. Eliminate faults through the panel

If the power off and restart still can not eliminate the fault, to the actual site to check the fault, through the radar level meter panel first observe whether there is an error code, there is no fault protection measures, if there is cleared through the panel, restart to observe whether the radar level meter is normal.

3. Learning false signals

The measurement principle of the radar level meter is to detect the received electromagnetic wave. If there is strong electromagnetic wave reflection or interference in the clearance between the measured liquid and the radar antenna, the radar level meter is very likely to treat the reflected radar wave as the radar reflection wave of the real liquid surface, so as to obtain the wrong liquid level display. Then we need to learn the false signal and block it.

The operation of radar level meter learning false signal is relatively simple, and can be set at the field panel. The field operation is as follows: Enter the learning menu → Detect false operation → Set the test distance height → detected false signal. To deal with this kind of fault, we can use the software function inside the radar level meter to learn the false signal. The false signals received are shielded in the circuit, and the signal reflected by the real liquid level can be detected, so as to obtain the real liquid level.

4. Remove the radar level gauge and wipe the antenna

This is the last processing step of the radar level meter. If the previous three processing methods still cannot eliminate the fault of the radar level meter, it is necessary to remove the radar level meter, check the dirt condition of the antenna, and clean the dirt. The reason why this is the last resort is because the medium measured by the radar level meter used in the field usually contains substances harmful to the human body, and do not disassemble as a last resort. When removing the radar level gauge, safety protection measures should be taken, and a cover plate should be found in advance to block the installation port of the radar level gauge to reduce the vapor volatilization of the measured substance. If necessary, wear a gas mask or respirator.

Although the radar level meter is a high-precision liquid level detection instrument that can reach the millimeter level, there are no advantages such as long service life of moving parts, but the actual use will encounter a variety of problems, these problems are different from other liquid level measurement instruments, and the deviation from the true value is only a small range. Radar level meter problems are catastrophic, not the largest is the smallest, not the number of dead is unchanged, so radar level meter in the actual use of maintenance skills must be skilled.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

1. Power off and restart

The radar level meter itself has many protective functions. If the radar level meter itself has fault protection during normal operation, it can be powered off and restarted. At this time, the fault inside the radar level meter may be eliminated, and the radar level meter will return to normal after being powered on again. This treatment method is suitable for the maintenance of high level tank radar level gauge. After all, more than ten meters high storage tank, climbing to the top of the tank to deal with the radar level gauge is not a simple matter, can be solved on the ground first.

2. Eliminate faults through the panel

If the power off and restart still can not eliminate the fault, to the actual site to check the fault, through the radar level meter panel first observe whether there is an error code, there is no fault protection measures, if there is cleared through the panel, restart to observe whether the radar level meter is normal.

3. Learning false signals

The measurement principle of the radar level meter is to detect the received electromagnetic wave. If there is strong electromagnetic wave reflection or interference in the clearance between the measured liquid and the radar antenna, the radar level meter is very likely to treat the reflected radar wave as the radar reflection wave of the real liquid surface, so as to obtain the wrong liquid level display. Then we need to learn the false signal and block it.

The operation of radar level meter learning false signal is relatively simple, and can be set at the field panel. The field operation is as follows: Enter the learning menu → Detect false operation → Set the test distance height → detected false signal. To deal with this kind of fault, we can use the software function inside the radar level meter to learn the false signal. The false signals received are shielded in the circuit, and the signal reflected by the real liquid level can be detected, so as to obtain the real liquid level.

4. Remove the radar level gauge and wipe the antenna

This is the last processing step of the radar level meter. If the previous three processing methods still cannot eliminate the fault of the radar level meter, it is necessary to remove the radar level meter, check the dirt condition of the antenna, and clean the dirt. The reason why this is the last resort is because the medium measured by the radar level meter used in the field usually contains substances harmful to the human body, and do not disassemble as a last resort. When removing the radar level gauge, safety protection measures should be taken, and a cover plate should be found in advance to block the installation port of the radar level gauge to reduce the vapor volatilization of the measured substance. If necessary, wear a gas mask or respirator.

Although the radar level meter is a high-precision liquid level detection instrument that can reach the millimeter level, there are no advantages such as long service life of moving parts, but the actual use will encounter a variety of problems, these problems are different from other liquid level measurement instruments, and the deviation from the true value is only a small range. Radar level meter problems are catastrophic, not the largest is the smallest, not the number of dead is unchanged, so radar level meter in the actual use of maintenance skills must be skilled.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference