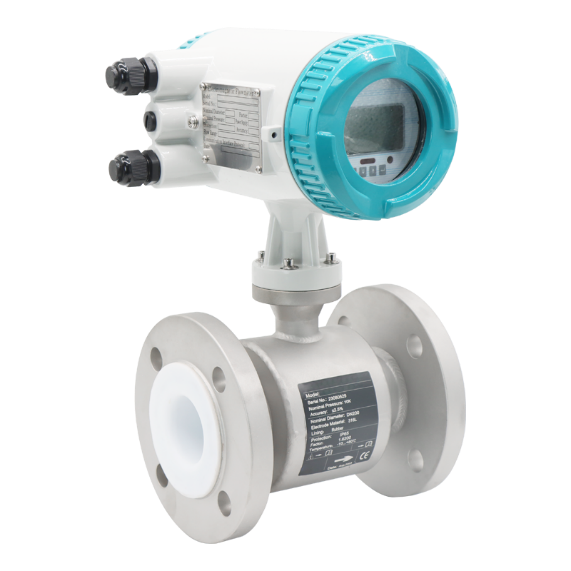

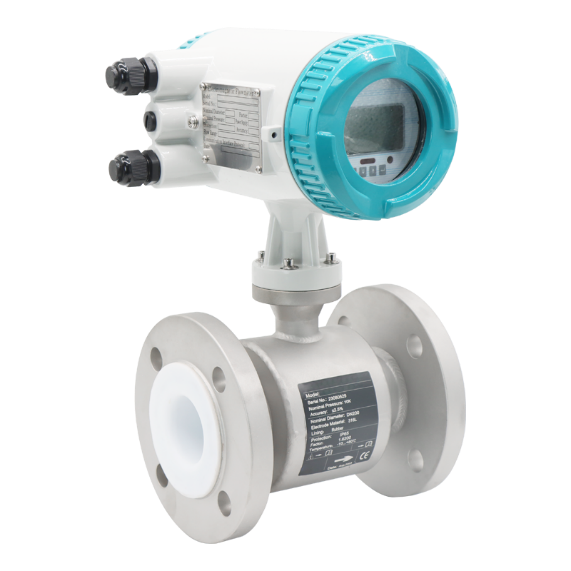

Characteristics of electromagnetic flowmeter

2024-05-09

Characteristics of electromagnetic flow meter

1. The measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity;

2. There are no obstructing parts in the measuring tube, no pressure loss, and the straight pipe section has low requirements. Unique adaptability to slurry measurement;

3. Reasonable selection of sensor lining and electrode material, that is, it has good corrosion resistance and wear resistance;

4. The converter adopts novel excitation mode, low power consumption, zero stability and high accuracy. Flow range up to 150:1;

5. The transducer can be composed of one type or separate type with the sensor;

6. The converter adopts 16-bit high-performance microprocessor, 2x16LCD display, easy parameter setting, reliable programming;

7. The flowmeter is a bidirectional measuring system with three integrators: forward total, reverse total and difference total; Can display positive and reverse flow, and has a variety of outputs: current, pulse, digital communication, HART;

8. The converter adopts surface mounting technology (SMT), with self-test and self-diagnosis function;

9. The measurement accuracy is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity, and the sensor induced voltage signal has a linear relationship with the average flow rate, so the measurement accuracy is high;

10. Measure the free flow parts in the pipeline, so there is no additional pressure loss; There are no moving parts in the measuring pipe, so the sensor life is extremely long;

11. Because the induced voltage signal is formed in the entire space filled with magnetic field and is the average value on the surface of the pipeline, the straight pipe section required by the sensor is shorter, the length is 5 times the diameter of the pipeline;

12. The converter adopts the latest and most advanced single-chip microcomputer (MCU) and surface mount technology (SMT), with reliable performance, high precision, low power consumption, zero stability and convenient parameter setting. Click the Chinese display LCD to display the cumulative flow, instantaneous flow, flow rate, flow percentage, etc.

13. Two-way measuring system, can measure forward flow, reverse flow. Special production processes and high-quality materials are used to ensure that the performance of the product remains stable over a long period of time.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

1. The measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity;

2. There are no obstructing parts in the measuring tube, no pressure loss, and the straight pipe section has low requirements. Unique adaptability to slurry measurement;

3. Reasonable selection of sensor lining and electrode material, that is, it has good corrosion resistance and wear resistance;

4. The converter adopts novel excitation mode, low power consumption, zero stability and high accuracy. Flow range up to 150:1;

5. The transducer can be composed of one type or separate type with the sensor;

6. The converter adopts 16-bit high-performance microprocessor, 2x16LCD display, easy parameter setting, reliable programming;

7. The flowmeter is a bidirectional measuring system with three integrators: forward total, reverse total and difference total; Can display positive and reverse flow, and has a variety of outputs: current, pulse, digital communication, HART;

8. The converter adopts surface mounting technology (SMT), with self-test and self-diagnosis function;

9. The measurement accuracy is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity, and the sensor induced voltage signal has a linear relationship with the average flow rate, so the measurement accuracy is high;

10. Measure the free flow parts in the pipeline, so there is no additional pressure loss; There are no moving parts in the measuring pipe, so the sensor life is extremely long;

11. Because the induced voltage signal is formed in the entire space filled with magnetic field and is the average value on the surface of the pipeline, the straight pipe section required by the sensor is shorter, the length is 5 times the diameter of the pipeline;

12. The converter adopts the latest and most advanced single-chip microcomputer (MCU) and surface mount technology (SMT), with reliable performance, high precision, low power consumption, zero stability and convenient parameter setting. Click the Chinese display LCD to display the cumulative flow, instantaneous flow, flow rate, flow percentage, etc.

13. Two-way measuring system, can measure forward flow, reverse flow. Special production processes and high-quality materials are used to ensure that the performance of the product remains stable over a long period of time.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference