Air mass flow meter --Aister Instrument

2024-06-03

Air mass flow meter is a kind of instrument specially used to measure the mass flow in the air, the following is a detailed introduction to it:

Definition and principle:

Air mass flowmeters, also known as thermal mass flowmeters (TME), operate on the principle of heat transfer. The thermal gas mass flowmeter is an instrument for measuring gas flow by using the principle of thermal diffusion. The sensor consists of two reference thermal resistors (RTDS). One is the speed sensor RH, and the other is the temperature sensor RMG, which measures the temperature change of the gas. When the two RTDS are placed in the measured gas, one sensor RH is heated and the other sensor RMG is used to sense the measured gas temperature. As the gas flow rate increases, the airflow carries away more heat, and the temperature of the sensor RH drops.

Features and advantages:

High accuracy: Due to the direct measurement of the mass of the gas, its accuracy is usually high.

Good stability: The measurement results are less affected by temperature and pressure changes, and the stability is good.

Wide range of application: can measure a variety of gases, such as natural gas, air, hydrogen, oxygen, etc.

Range width: (greater than 100:1);

High temperature measurement: proprietary high humidity, high temperature algorithm, medium temperature up to 500℃.

Application scenario:

Air treatment and environmental monitoring: such as air quality monitoring stations, industrial emission control, etc.

Research and teaching: For the study of aerodynamics and fluid mechanics.

Key points of selection:

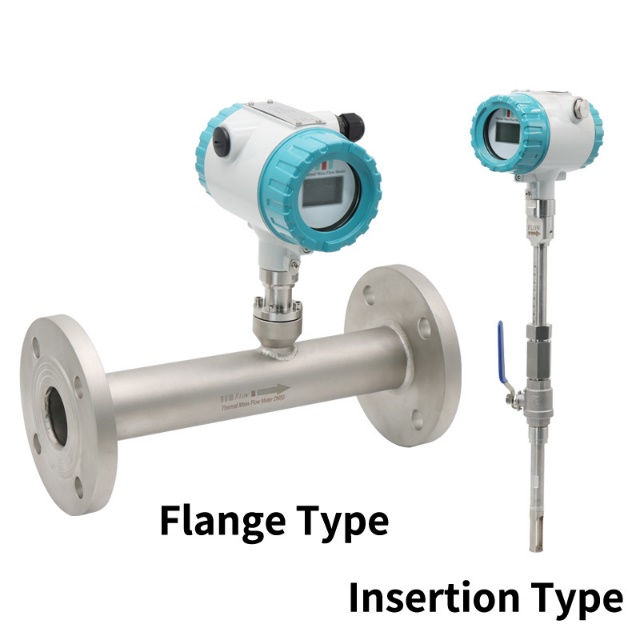

Measurement requirements: Select the appropriate air quality flowmeter model according to the specific application scenario and measurement requirements. Suitable pipe diameter: DN15 ~ 2000mm; Insert suitable pipe diameter: above DN32 caliber.

Environmental conditions: Consider the temperature, humidity, pressure and other factors of the environment, sensor: -40℃ ~ +220℃, converter: -20℃ ~ +45℃; Medium pressure ≤4.0Mpa;

Medium characteristics: Pay attention to the composition, water content, pressure and other characteristics of the gas to ensure that the selected flowmeter can accurately measure the target gas. If the air contains moisture, additional drying equipment may be required.

Installation position: Select the appropriate installation position to ensure that the flow meter can accurately measure the gas flow and avoid interference.

Straight pipe section requirements: there needs to be a certain length of straight pipe section before and after the flow meter to ensure the accuracy of the measurement results.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Air mass flowmeters, also known as thermal mass flowmeters (TME), operate on the principle of heat transfer. The thermal gas mass flowmeter is an instrument for measuring gas flow by using the principle of thermal diffusion. The sensor consists of two reference thermal resistors (RTDS). One is the speed sensor RH, and the other is the temperature sensor RMG, which measures the temperature change of the gas. When the two RTDS are placed in the measured gas, one sensor RH is heated and the other sensor RMG is used to sense the measured gas temperature. As the gas flow rate increases, the airflow carries away more heat, and the temperature of the sensor RH drops.

Features and advantages:

High accuracy: Due to the direct measurement of the mass of the gas, its accuracy is usually high.

Good stability: The measurement results are less affected by temperature and pressure changes, and the stability is good.

Wide range of application: can measure a variety of gases, such as natural gas, air, hydrogen, oxygen, etc.

Range width: (greater than 100:1);

High temperature measurement: proprietary high humidity, high temperature algorithm, medium temperature up to 500℃.

Application scenario:

Air treatment and environmental monitoring: such as air quality monitoring stations, industrial emission control, etc.

Research and teaching: For the study of aerodynamics and fluid mechanics.

Key points of selection:

Measurement requirements: Select the appropriate air quality flowmeter model according to the specific application scenario and measurement requirements. Suitable pipe diameter: DN15 ~ 2000mm; Insert suitable pipe diameter: above DN32 caliber.

Environmental conditions: Consider the temperature, humidity, pressure and other factors of the environment, sensor: -40℃ ~ +220℃, converter: -20℃ ~ +45℃; Medium pressure ≤4.0Mpa;

Medium characteristics: Pay attention to the composition, water content, pressure and other characteristics of the gas to ensure that the selected flowmeter can accurately measure the target gas. If the air contains moisture, additional drying equipment may be required.

Installation position: Select the appropriate installation position to ensure that the flow meter can accurately measure the gas flow and avoid interference.

Straight pipe section requirements: there needs to be a certain length of straight pipe section before and after the flow meter to ensure the accuracy of the measurement results.

If you want to know more about the flow meter or flow meter selection, please consult the Aister flow meter manufacturer email: sales@aistermeter.com for help.

Share To:

Previous Post:

Next Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference