Precautions of natural gas flowmeter in the process of measuring coke oven gas

2021-04-23

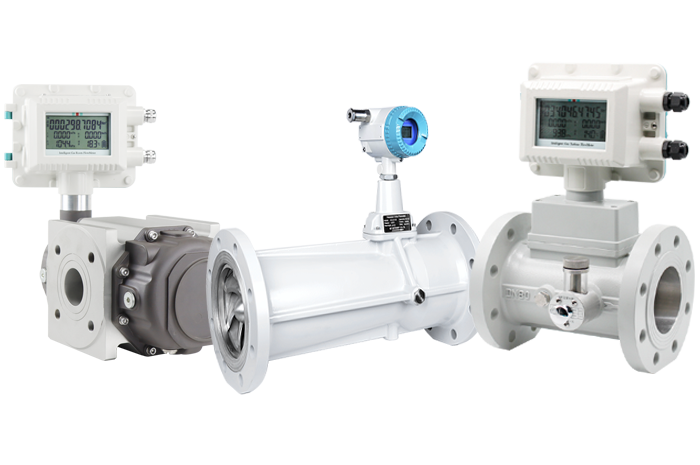

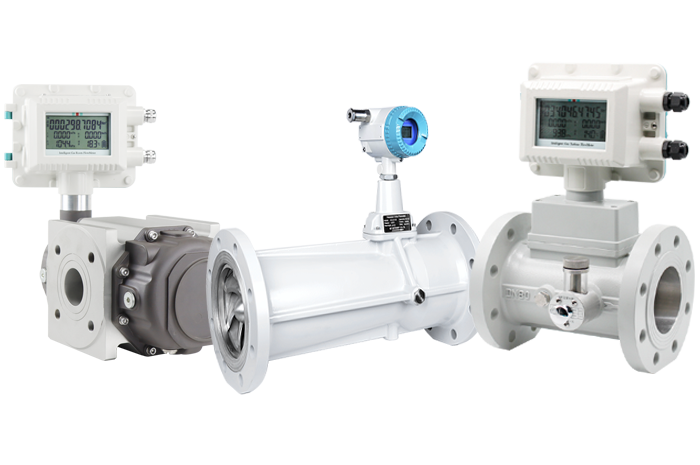

Natural gas flow meter breaks through the limitations of traditional analog processing of natural gas signals, through modern digital signal processing methods to identify and screen natural gas probe signals, so as to obtain normal flow signals, greatly improve the seismic performance of natural gas, and fundamentally solve the problem of non-seismic natural gas for decades.

Natural gas flow meter is a kind of widely used flow meter, almost can be used in all gas, liquid and steam flow meter measurement and control, intelligent natural gas flow meter, it breaks through the traditional analog way to deal with the limitations of natural gas signal, through modern digital signal processing method to identify and screen the natural gas probe signal, so as to get the normal flow signal. Greatly improve the seismic performance of natural gas, fundamentally solve the problem around natural gas for decades of non-seismic, it is widely used in petrochemical, light industry, thermal power, paper and other industries of water supply, salt, wind flow.

The application of natural gas flowmeter in the measurement of coke oven gas is still more, but there will be some problems, to say the cause and solution of these problems: the cause of the failure of the on-site measurement system can be summarized as two main reasons, one is caused by flow meters or their associated equipment. The second reason is non-flow meter, that is, the flow meter is normal, and the environmental or system reasons cause failure, which is difficult to find. In addition to requiring technical personnel to be familiar with the performance of the instrument, it is also necessary to have a wide range of knowledge and rich field experience for analysis, reasoning, and multi-party testing to confirm.

Some failures are the result of unexpected events. The failure of the non-flow meter is often manifested as an unstable output signal. According to practical experience, when natural gas flowmeter measures coke oven gas, the output signal is unstable for the following reasons:

1)Natural gas flowmeter is not suitable for installation in the case of strong vibration is widely known by users, but in the case of frequent changes in the magnetic field, the natural gas flow sensor will measure higher than normal signal output. Practice has proved that in the field without gas flow, when the natural gas flow sensor is in the changing magnetic field at the moment of the magnetic field change, the natural gas flow meter sensor will sense an error signal and output, when the change is over and the instrument is in a stable magnetic field, the instrument will output a normal signal.

2)Coke oven gas has high temperature and high humidity when leaving the factory, so there will be moisture in the gas transportation process. The gas flow drives the water to fluctuate back and forth, thus forming a pulsating flow. When the natural gas flow sensor is in this fluid state, the output data is large and small, which cannot reflect the production status.

3)Because coke oven gas has many impurities and is easy to crystallize, impurities condense in the sensing head, resulting in mismeasurement. When the temperature rises, the impurities volatilize, the sensitivity increases, and the signal is enhanced. On the contrary, it decreases. Thus, the data is unstable.

4)The pressure line in the process of instrument wiring is not solid, resulting in intermittent signals in the transmission process.

5)The grounding wire of the instrument does not meet the requirements of the specification, so that the 50Hz interference in the strong current enters, and the normal signal is output when the normal signal is higher than 50Hz, and the wrong signal will be output.

Solutions to the problems caused by the use of natural gas flowmeters:

1)In the process of instrument installation and connection, we should ensure the accuracy of each link, including the inspection of the site before installation, the installation process of instrument wiring, system grounding wire and other aspects of control engineering network, so as to ensure that the real data is detected and can be accurately output.

2)For the measurement system in operation, the method of“Measurement control engineering network copyright, comparison and confirmation”and the“alternative method”can be used to confirm and eliminate the fault of the measurement instrument in operation.

3)Regularly clean the instrument as a whole, and if necessary purge the sensing head part of the instrument to avoid condensation of impurities at the sensing head. In the cold season, the addition of heat tracing device in the metering pipe section and the meter part is also beneficial to alleviate the condensation of impurities in the meter.

4)Drain the pipe regularly, especially the water in front of the straight pipe section, and set a special person to discharge it regularly according to the specific situation, so as to reduce the water in the metering pipe section as much as possible and eliminate the pulsation in the fluid to the maximum extent.

5)Strengthen the management of the data of the natural gas flowmeter metering system, set up the timing printing function, and analyze the operation of the instrument according to the printing data combined with the production status.

Natural gas flow meter is a kind of widely used flow meter, almost can be used in all gas, liquid and steam flow meter measurement and control, intelligent natural gas flow meter, it breaks through the traditional analog way to deal with the limitations of natural gas signal, through modern digital signal processing method to identify and screen the natural gas probe signal, so as to get the normal flow signal. Greatly improve the seismic performance of natural gas, fundamentally solve the problem around natural gas for decades of non-seismic, it is widely used in petrochemical, light industry, thermal power, paper and other industries of water supply, salt, wind flow.

The application of natural gas flowmeter in the measurement of coke oven gas is still more, but there will be some problems, to say the cause and solution of these problems: the cause of the failure of the on-site measurement system can be summarized as two main reasons, one is caused by flow meters or their associated equipment. The second reason is non-flow meter, that is, the flow meter is normal, and the environmental or system reasons cause failure, which is difficult to find. In addition to requiring technical personnel to be familiar with the performance of the instrument, it is also necessary to have a wide range of knowledge and rich field experience for analysis, reasoning, and multi-party testing to confirm.

Some failures are the result of unexpected events. The failure of the non-flow meter is often manifested as an unstable output signal. According to practical experience, when natural gas flowmeter measures coke oven gas, the output signal is unstable for the following reasons:

1)Natural gas flowmeter is not suitable for installation in the case of strong vibration is widely known by users, but in the case of frequent changes in the magnetic field, the natural gas flow sensor will measure higher than normal signal output. Practice has proved that in the field without gas flow, when the natural gas flow sensor is in the changing magnetic field at the moment of the magnetic field change, the natural gas flow meter sensor will sense an error signal and output, when the change is over and the instrument is in a stable magnetic field, the instrument will output a normal signal.

2)Coke oven gas has high temperature and high humidity when leaving the factory, so there will be moisture in the gas transportation process. The gas flow drives the water to fluctuate back and forth, thus forming a pulsating flow. When the natural gas flow sensor is in this fluid state, the output data is large and small, which cannot reflect the production status.

3)Because coke oven gas has many impurities and is easy to crystallize, impurities condense in the sensing head, resulting in mismeasurement. When the temperature rises, the impurities volatilize, the sensitivity increases, and the signal is enhanced. On the contrary, it decreases. Thus, the data is unstable.

4)The pressure line in the process of instrument wiring is not solid, resulting in intermittent signals in the transmission process.

5)The grounding wire of the instrument does not meet the requirements of the specification, so that the 50Hz interference in the strong current enters, and the normal signal is output when the normal signal is higher than 50Hz, and the wrong signal will be output.

Solutions to the problems caused by the use of natural gas flowmeters:

1)In the process of instrument installation and connection, we should ensure the accuracy of each link, including the inspection of the site before installation, the installation process of instrument wiring, system grounding wire and other aspects of control engineering network, so as to ensure that the real data is detected and can be accurately output.

2)For the measurement system in operation, the method of“Measurement control engineering network copyright, comparison and confirmation”and the“alternative method”can be used to confirm and eliminate the fault of the measurement instrument in operation.

3)Regularly clean the instrument as a whole, and if necessary purge the sensing head part of the instrument to avoid condensation of impurities at the sensing head. In the cold season, the addition of heat tracing device in the metering pipe section and the meter part is also beneficial to alleviate the condensation of impurities in the meter.

4)Drain the pipe regularly, especially the water in front of the straight pipe section, and set a special person to discharge it regularly according to the specific situation, so as to reduce the water in the metering pipe section as much as possible and eliminate the pulsation in the fluid to the maximum extent.

5)Strengthen the management of the data of the natural gas flowmeter metering system, set up the timing printing function, and analyze the operation of the instrument according to the printing data combined with the production status.

Share To:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference