How to install a thermal gas mass flow meter?

2022-07-25

As we all know, thermal gas mass flow meters are divided into two types: insertion type and inline type. Does anyone know the specific installation process? Let Aister come and tell you how to install a thermal gas mass flow meter.

Installation of Insertion Type Thermal Gas Mass Flow Meter:

1)Before installing the insertion type thermal gas mass flow meter, please confirm the actual inner diameter and wall thickness of the pipeline.

2)Install the remaining parts of the thermal gas mass flow meter into a dedicated ball valve. Calculate the depth to be inserted based on the actual inner diameter and wall thickness of the pipeline. At this step, you can insert an approximate size and tighten the nut by hand.

3)Rotate the sensor linkage to align the marked arrow with the direction of the media flow.

4)Convert the corresponding scale on the sensor linkage based on the field-measured data and tighten the nut.

5)If you are installing the display screen of this instrument horizontally, it can be flexibly installed at 90°, 180°, or 270° to meet your actual on-site requirements.

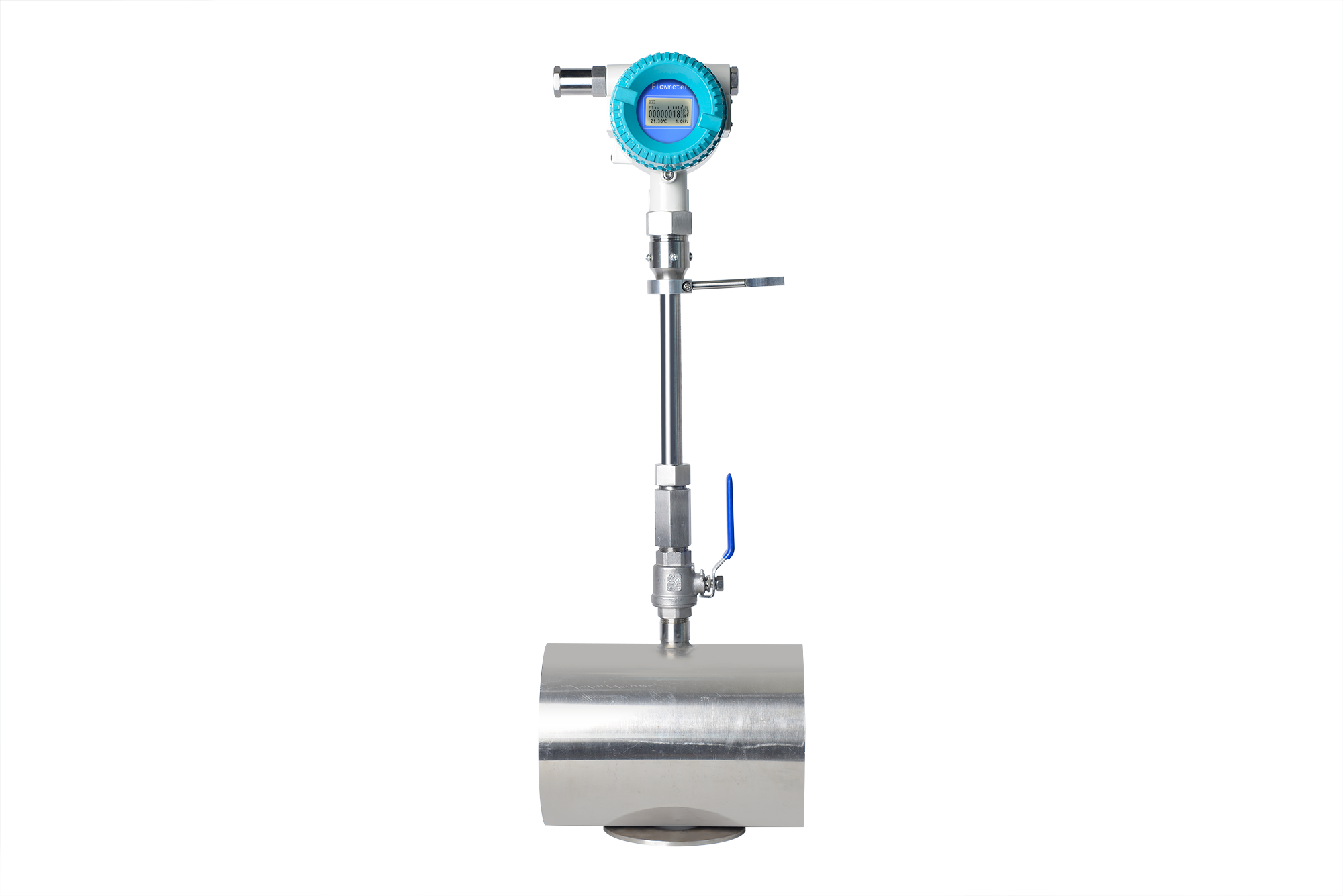

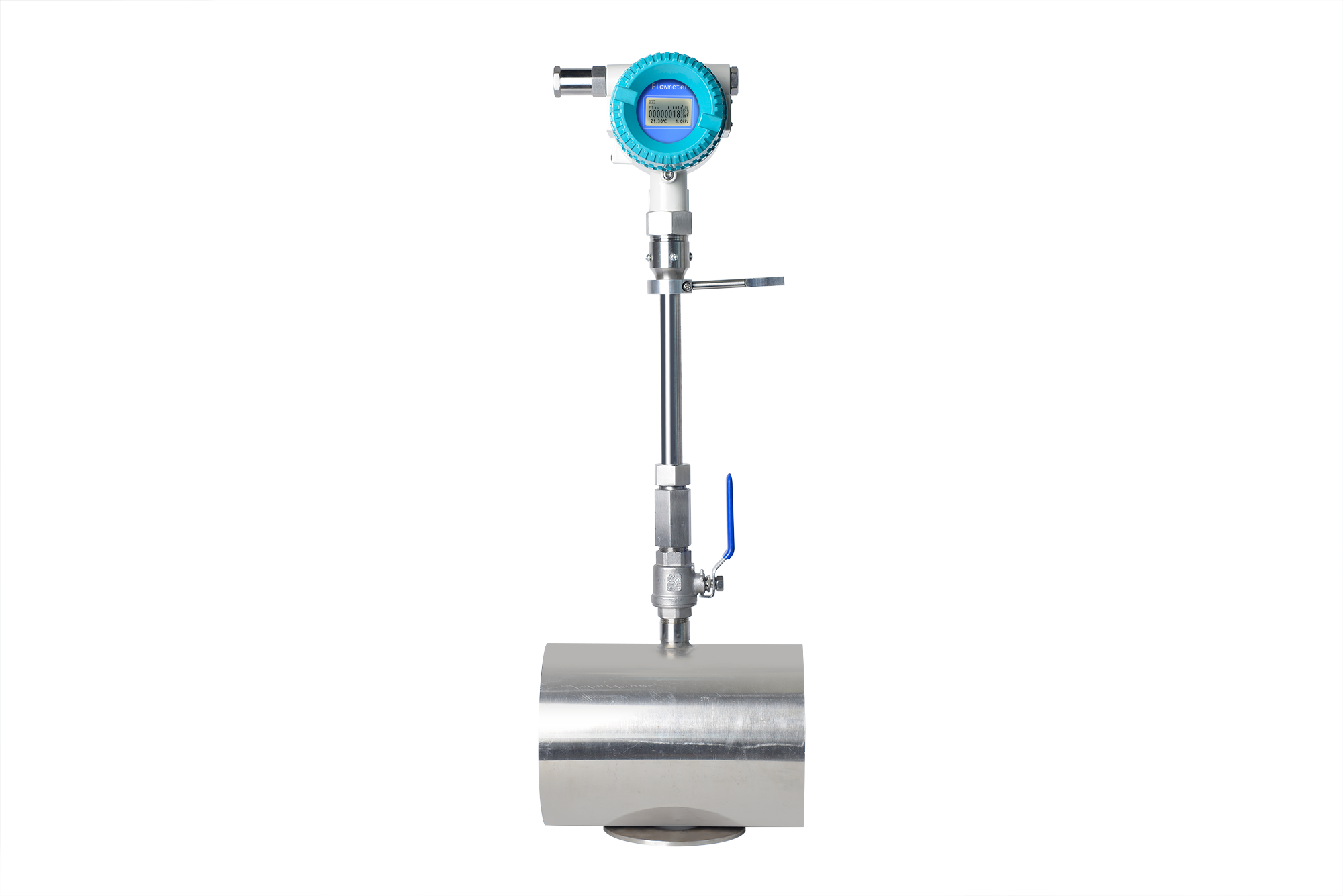

Installation of In-line Type Thermal Gas Mass Flow Meter:

Before pre-installation, please confirm the connection method of the inline type flow meter, and prepare related items such as gaskets and bolts for flange connection.

Production must be stopped before installation, and strict adherence to the factory's relevant regulations is required.

The in-line type flow meter is already assembled with the sensor correctly mounted on a dedicated pipe section when it leaves the factory. Users only need to assemble the pipeline on-site, making the installation relatively simpler compared to the insertion type. First, select a suitable installation point on the pipeline, then cut the pipeline to the necessary length and install the corresponding flange and bolts. Ensure that the fluid flow rate matches the flow rate indicated on the full pipe type thermal gas mass flow meter. The display screen should be vertical to the horizontal plane, and the pipeline axis should be parallel to the horizontal plane with an error not exceeding ±2.5°. Finally, tighten the flow meter with bolts.

Installation of Insertion Type Thermal Gas Mass Flow Meter:

1)Before installing the insertion type thermal gas mass flow meter, please confirm the actual inner diameter and wall thickness of the pipeline.

2)Install the remaining parts of the thermal gas mass flow meter into a dedicated ball valve. Calculate the depth to be inserted based on the actual inner diameter and wall thickness of the pipeline. At this step, you can insert an approximate size and tighten the nut by hand.

3)Rotate the sensor linkage to align the marked arrow with the direction of the media flow.

4)Convert the corresponding scale on the sensor linkage based on the field-measured data and tighten the nut.

5)If you are installing the display screen of this instrument horizontally, it can be flexibly installed at 90°, 180°, or 270° to meet your actual on-site requirements.

Installation of In-line Type Thermal Gas Mass Flow Meter:

Before pre-installation, please confirm the connection method of the inline type flow meter, and prepare related items such as gaskets and bolts for flange connection.

Production must be stopped before installation, and strict adherence to the factory's relevant regulations is required.

The in-line type flow meter is already assembled with the sensor correctly mounted on a dedicated pipe section when it leaves the factory. Users only need to assemble the pipeline on-site, making the installation relatively simpler compared to the insertion type. First, select a suitable installation point on the pipeline, then cut the pipeline to the necessary length and install the corresponding flange and bolts. Ensure that the fluid flow rate matches the flow rate indicated on the full pipe type thermal gas mass flow meter. The display screen should be vertical to the horizontal plane, and the pipeline axis should be parallel to the horizontal plane with an error not exceeding ±2.5°. Finally, tighten the flow meter with bolts.

Share To:

Previous Post:

News

- Why is the thermal gas mass flowmeter not affected by pressure strength and temperature?

- What to do when a thermal gas mass flow meter fails?

- How are thermal gas mass flow meters used? What are the applications?

- Under what circumstances is the gas measurement need to be regulated compensated vortex flowmeter

- Why Is The Aister Thermal Gas Mass Flowmeter So Popular ?

- Gas turbine flowmeter manufacturers explain their main advantages in measurement

- Gas turbine flowmeter manufacturer Aister instrument field experience summary

- Aister Instrument Empowerment Conference