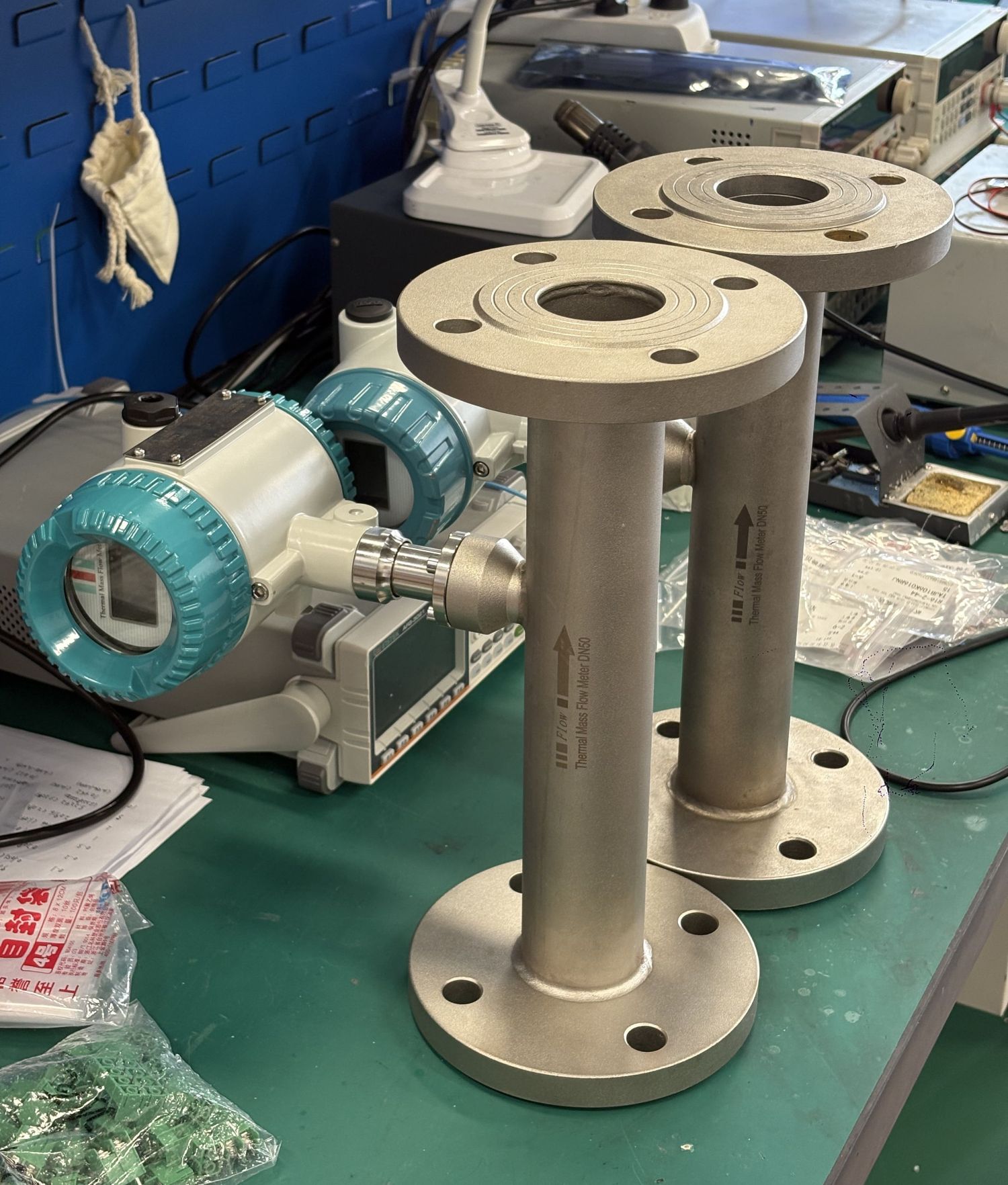

Working principle and manufacturing process of thermal gas mass flow meter

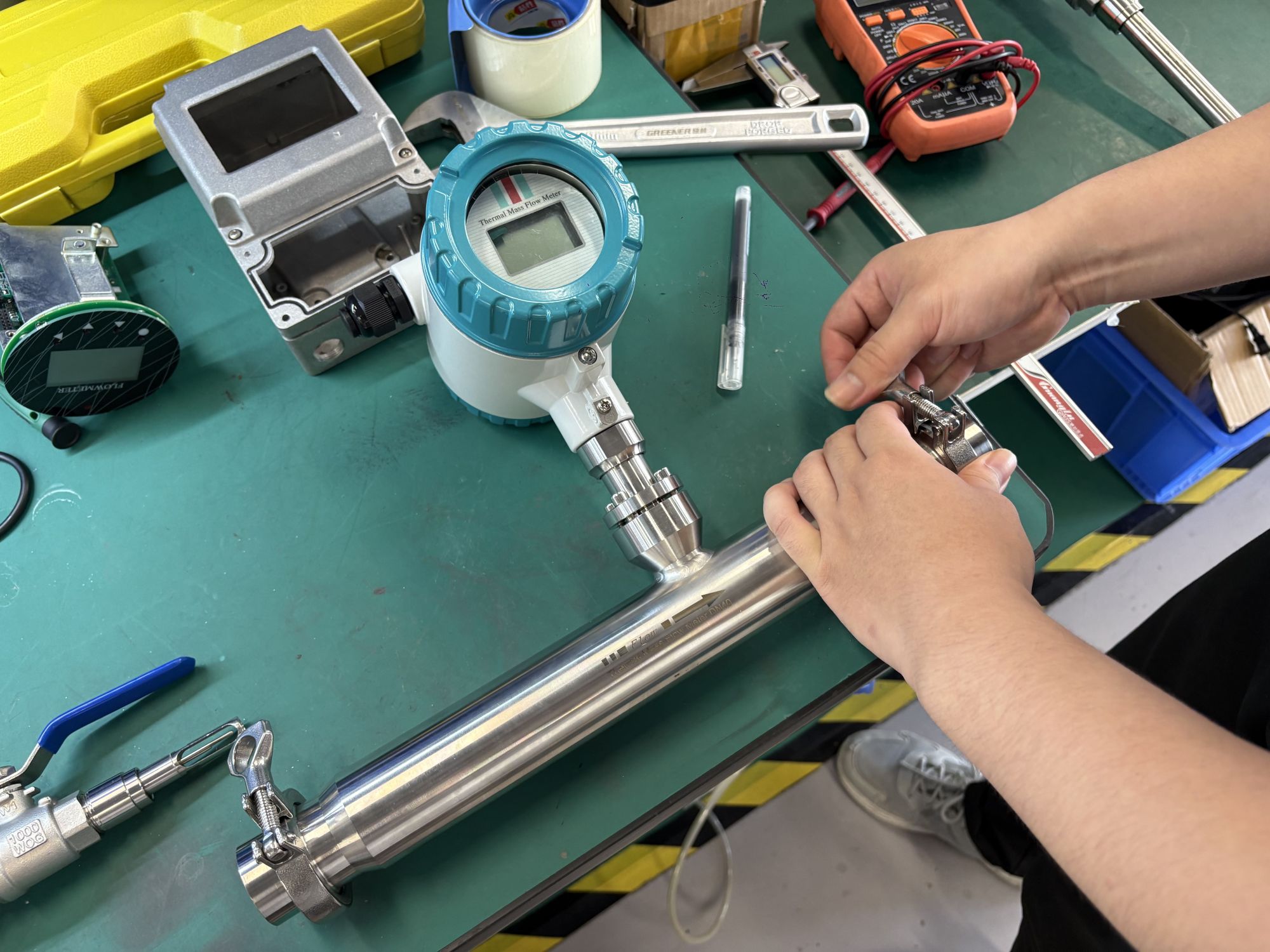

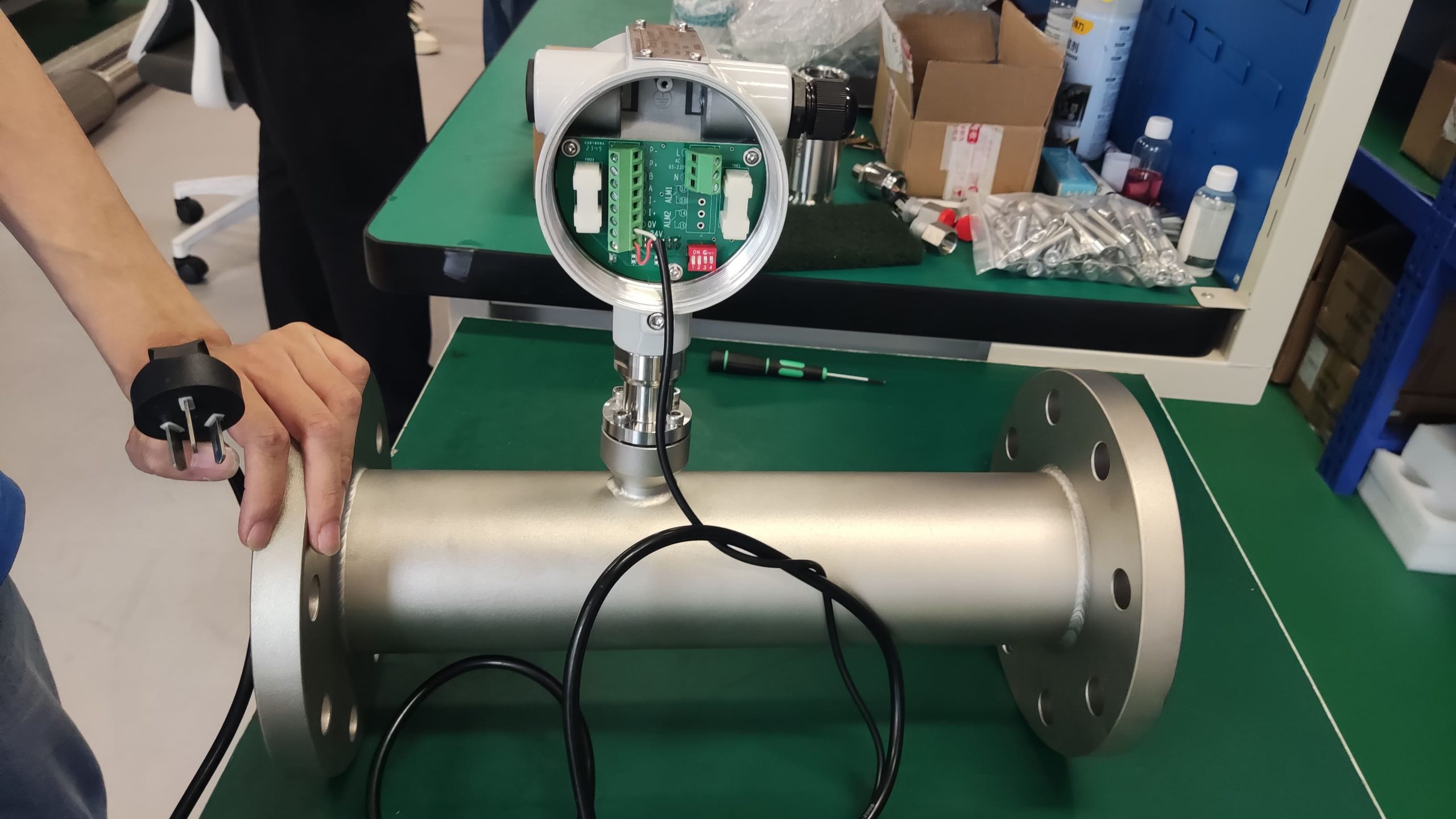

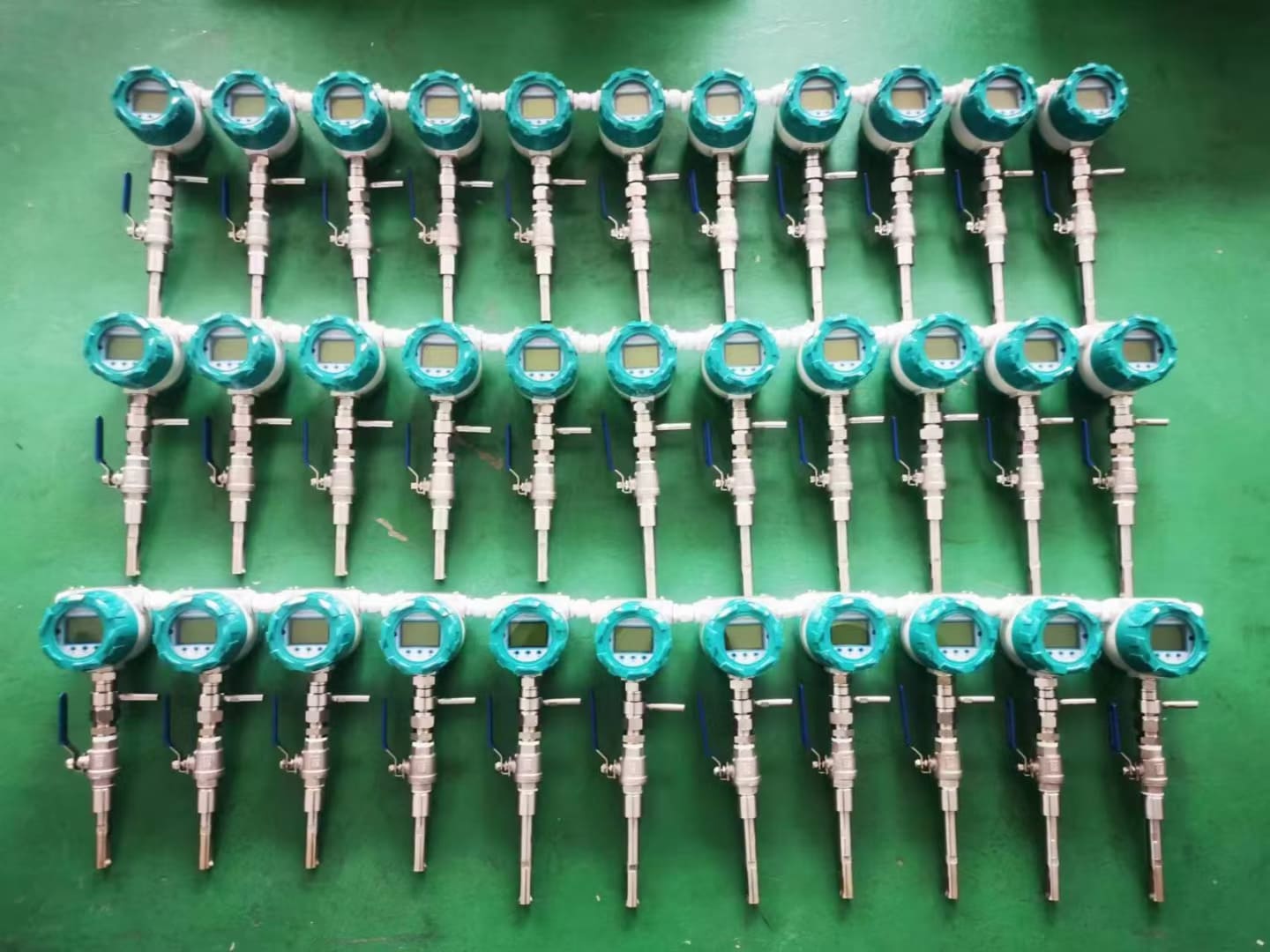

The thermal gas mass flowmeter is designed based on the principle of thermal diffusion. The meter uses constant temperature difference method to measure the gas accurately. The thermal gas mass flowmeter has the advantages of small volume, high digitization, easy installation and accurate measurement.

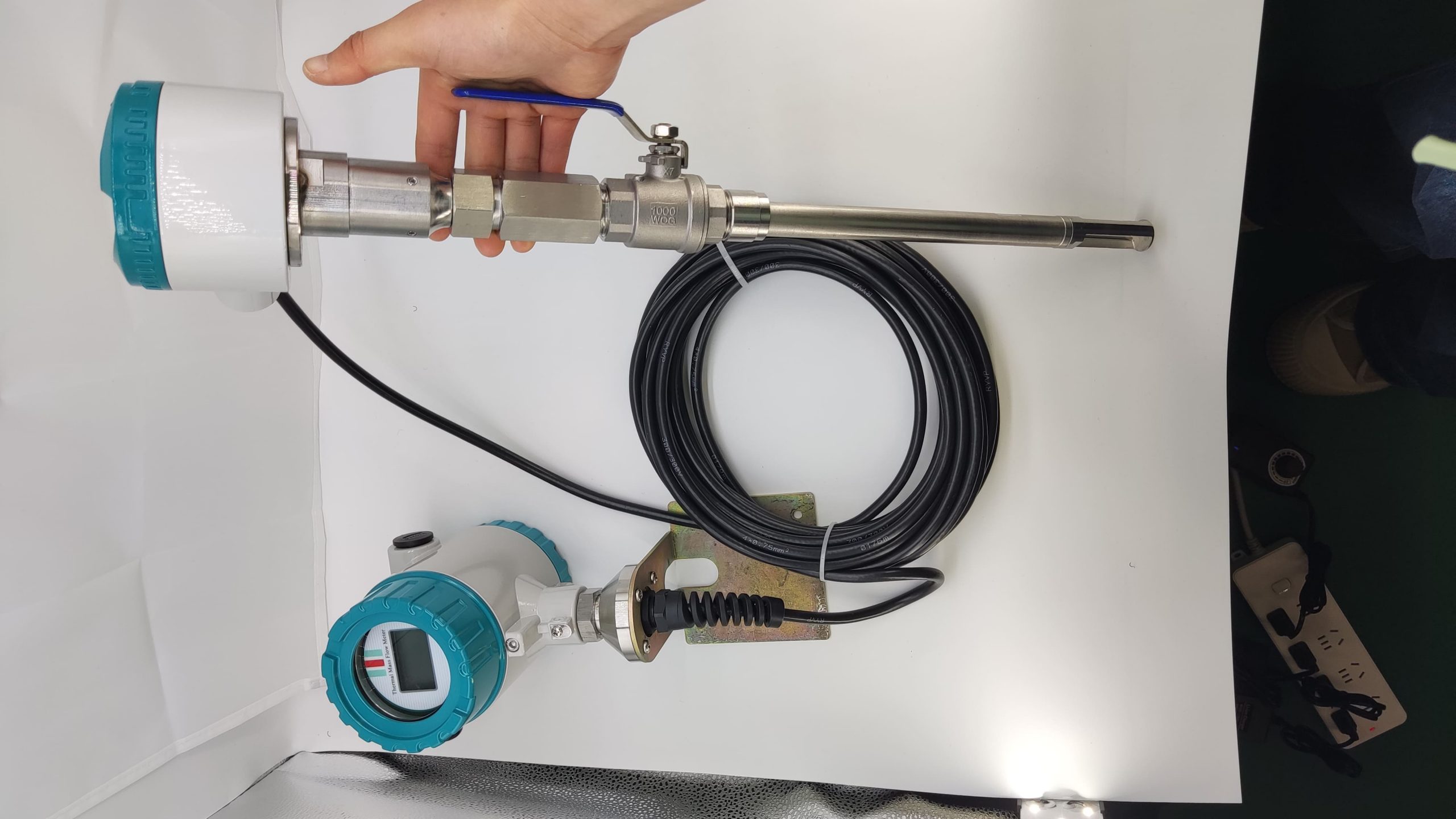

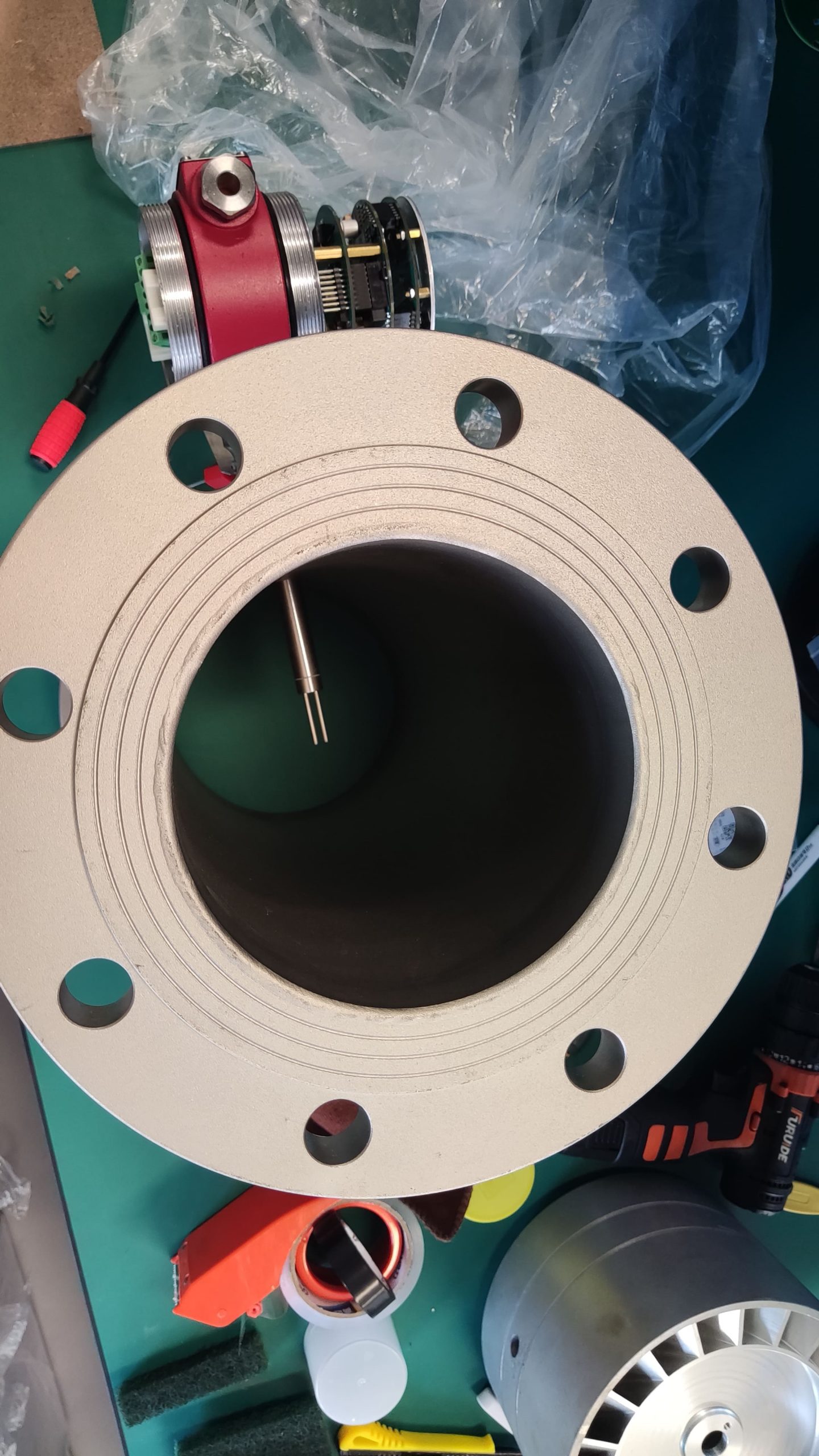

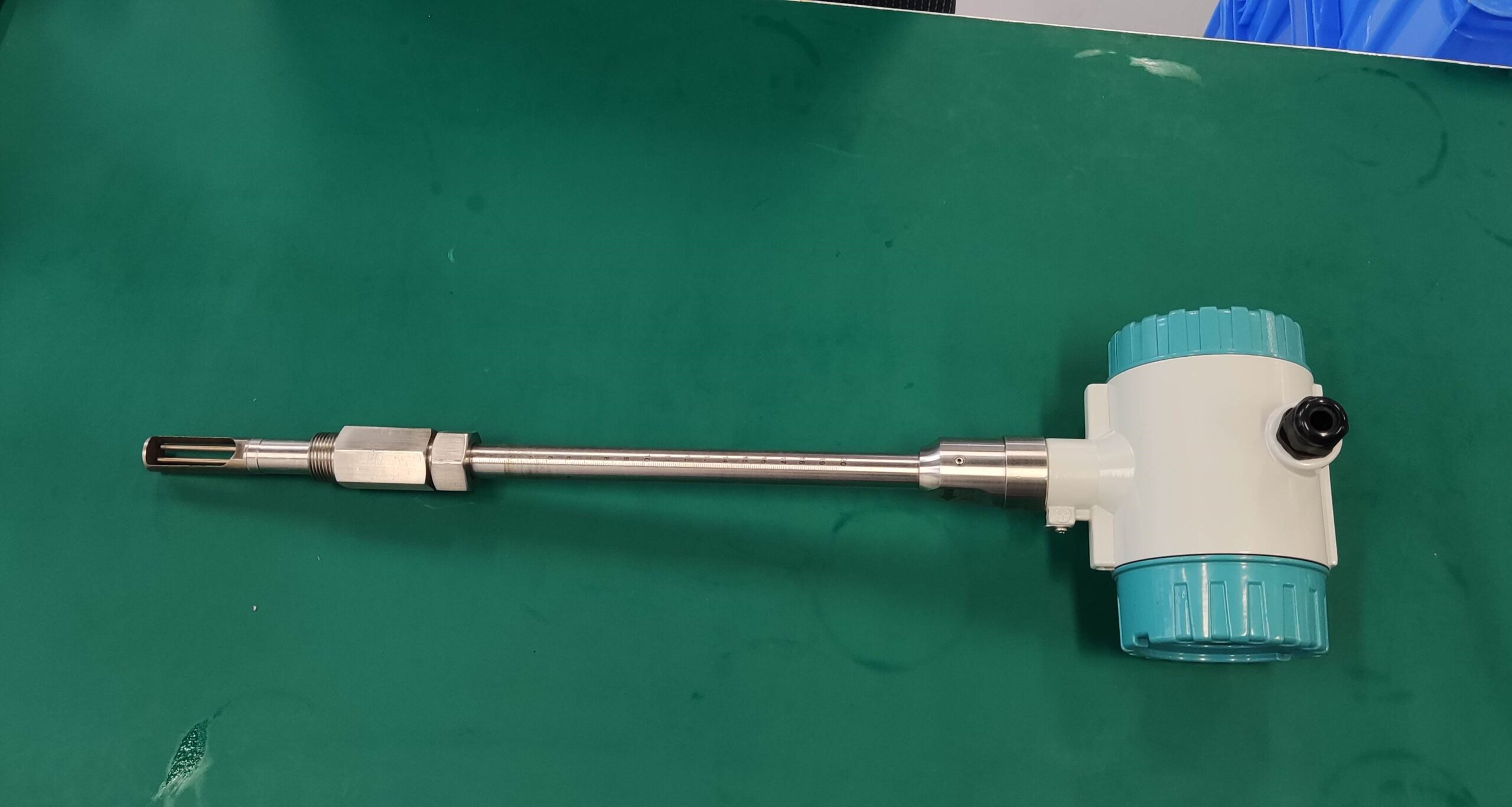

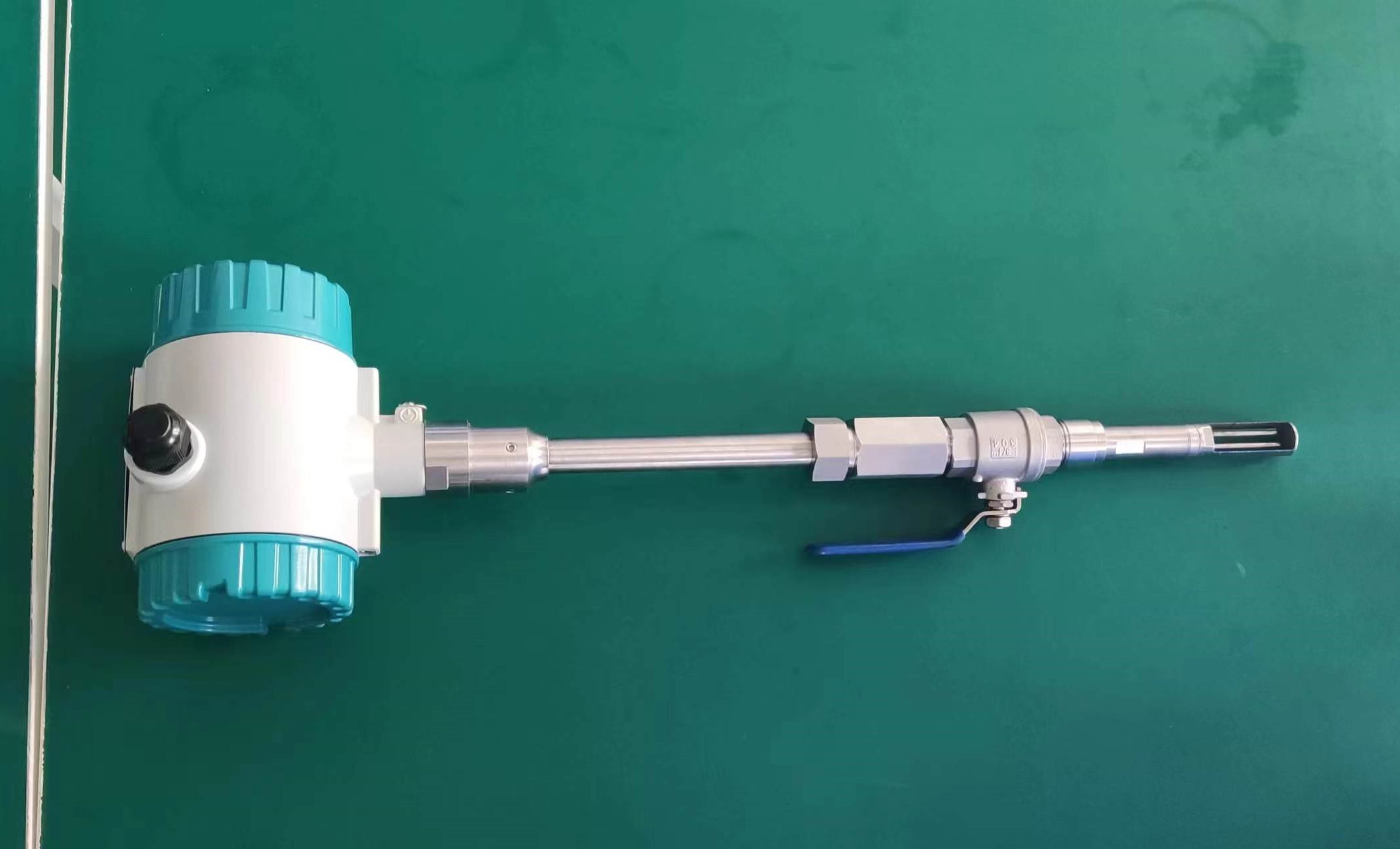

The sensor of Aister thermal gas mass flowmeter is composed of two reference platinum resistance temperature sensors. When the instrument is working, one sensor continuously measures the medium temperature T1; The other sensor is self-heated to a temperature higher than the medium temperature T2, which is used to sense the flow rate of the flow body, called the velocity sensor.

The temperature ΔT=T2-T1, T2>T1, when there is a fluid flowing, because the gas molecules collide with the sensor and take away the heat of T2, so that the temperature of T2 drops, if the ΔT remains unchanged, it is necessary to increase the power supply current of T2, the gas flow speed is hot, the more heat is taken away, the gas flow rate and the increased heat there is a fixed functional relationship. This is the principle of constant temperature difference.

The thermal gas mass flowmeter has the following technical advantages:

1. The real mass flowmeter, the gas flow measurement without temperature and pressure compensation, measurement is convenient and accurate. The mass flow rate or standard volume flow rate of the gas can be obtained.

2. Wide range ratio, can measure the flow rate up to 100Nm/s to 0.1Nm/s gas, can be used for gas leak detection.

3. Good seismic performance and long service life. The sensor has no moving parts and pressure sensing parts, and is not affected by vibration on the measurement accuracy.

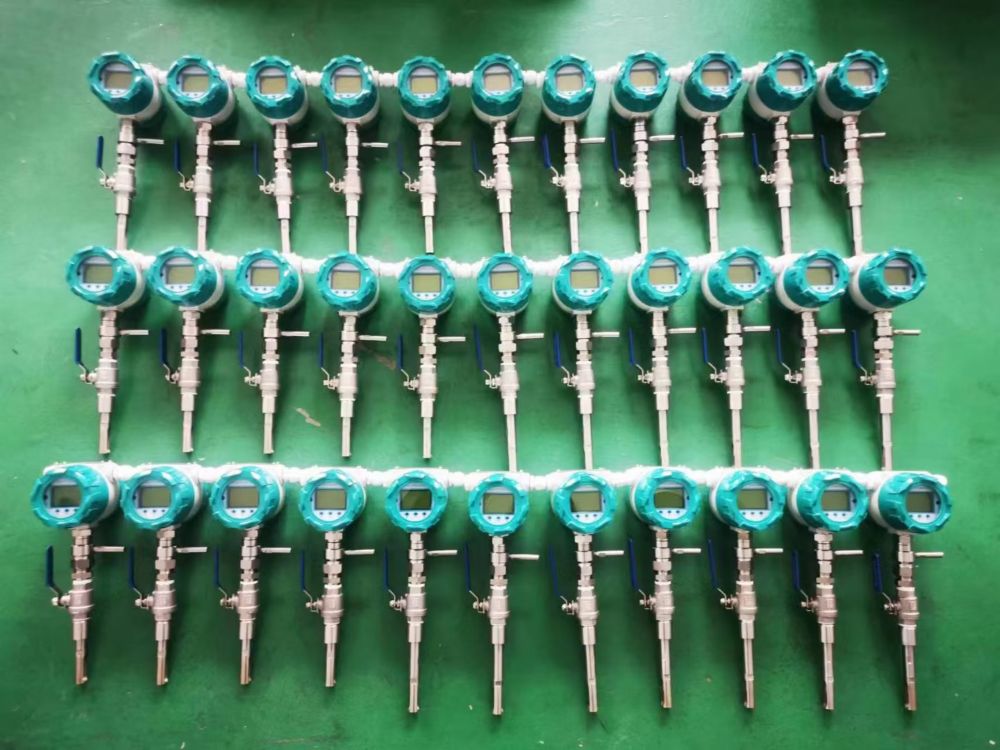

4. Easy installation and maintenance. If site conditions permit, it can be installed and maintained without stopping production.

5. Digital design. Overall digital circuit measurement, accurate measurement, easy maintenance.

6. RS-485 communication, or HART communication, can achieve factory automation and integration.