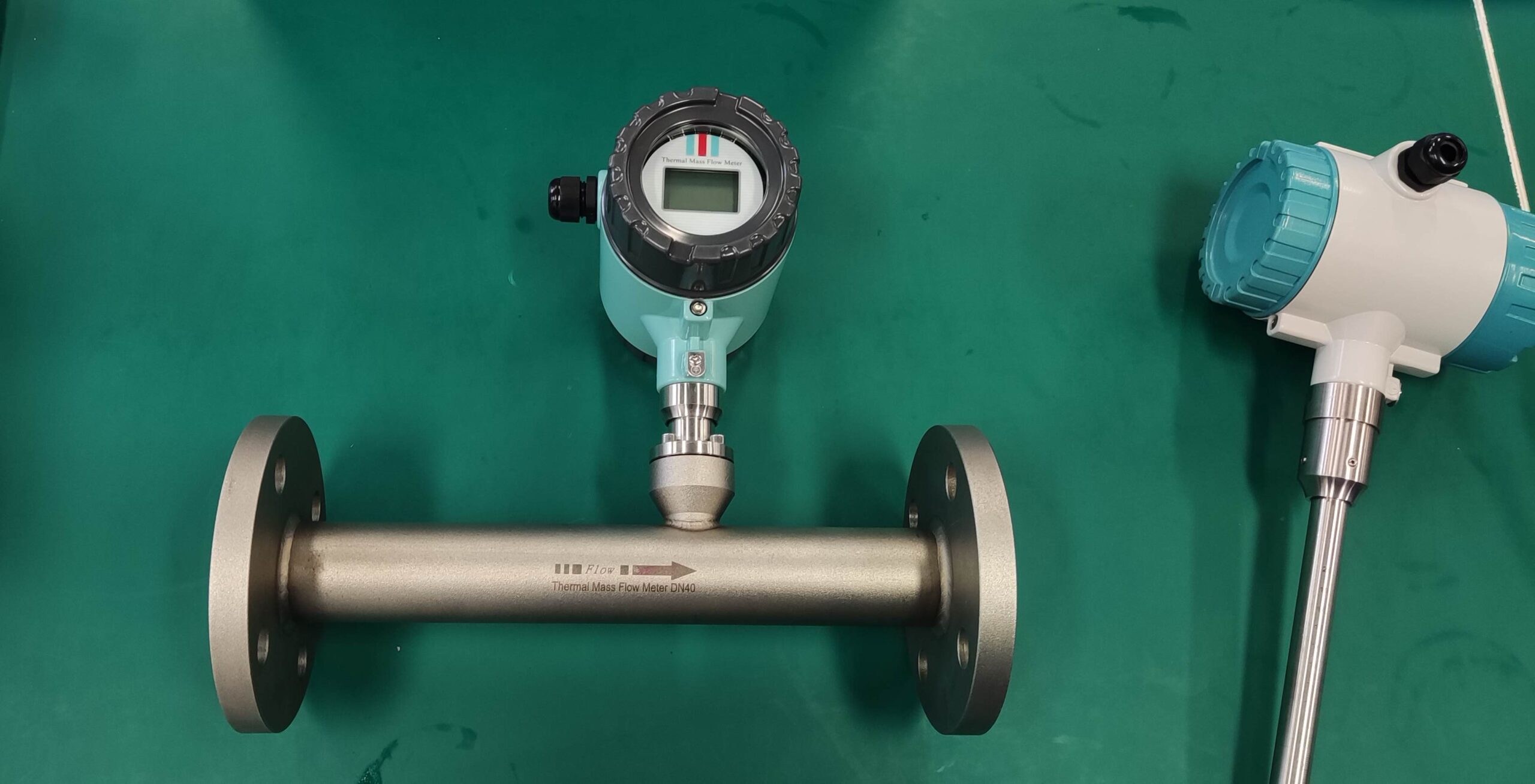

Working principle and application of thermal gas mass flow meter

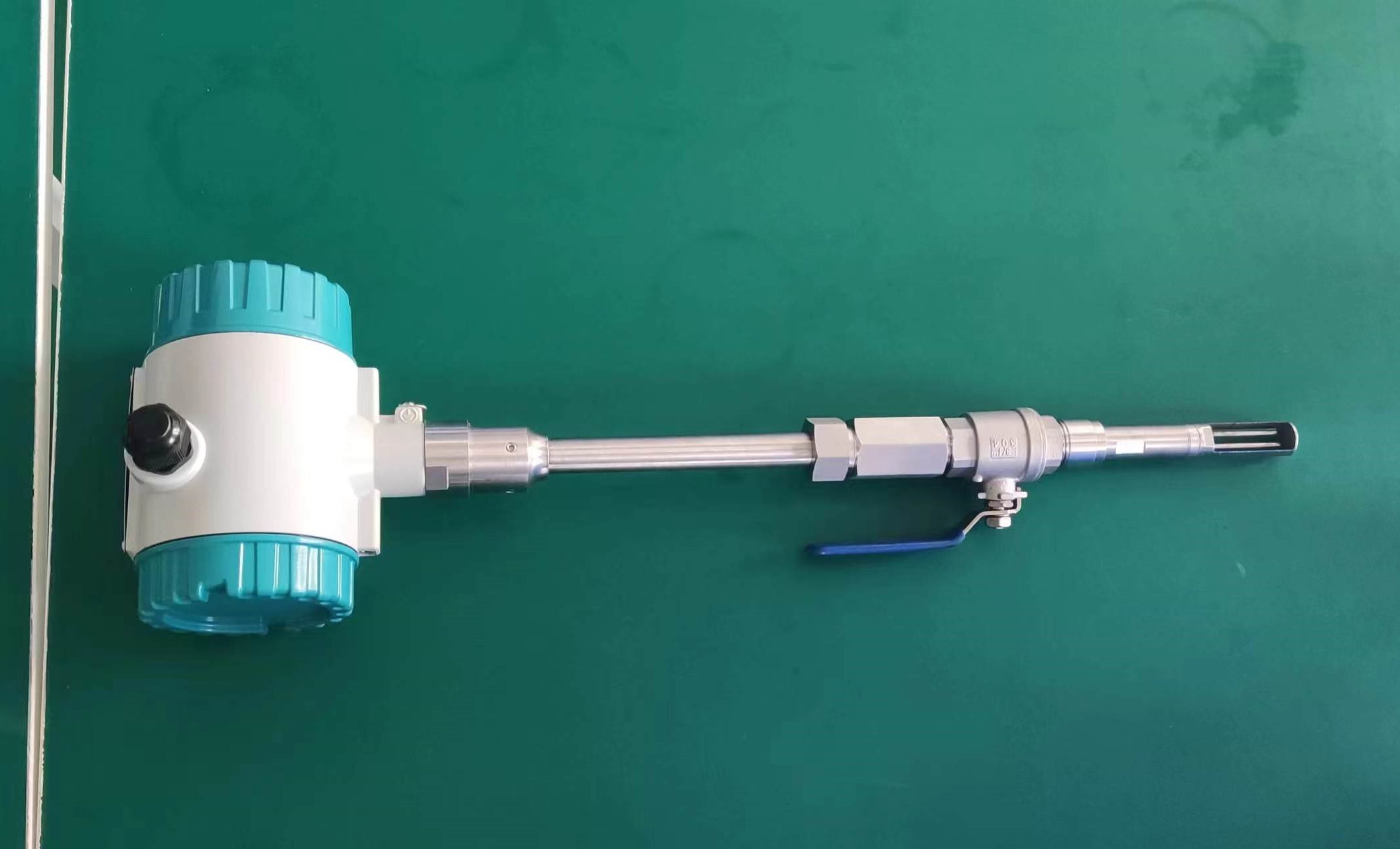

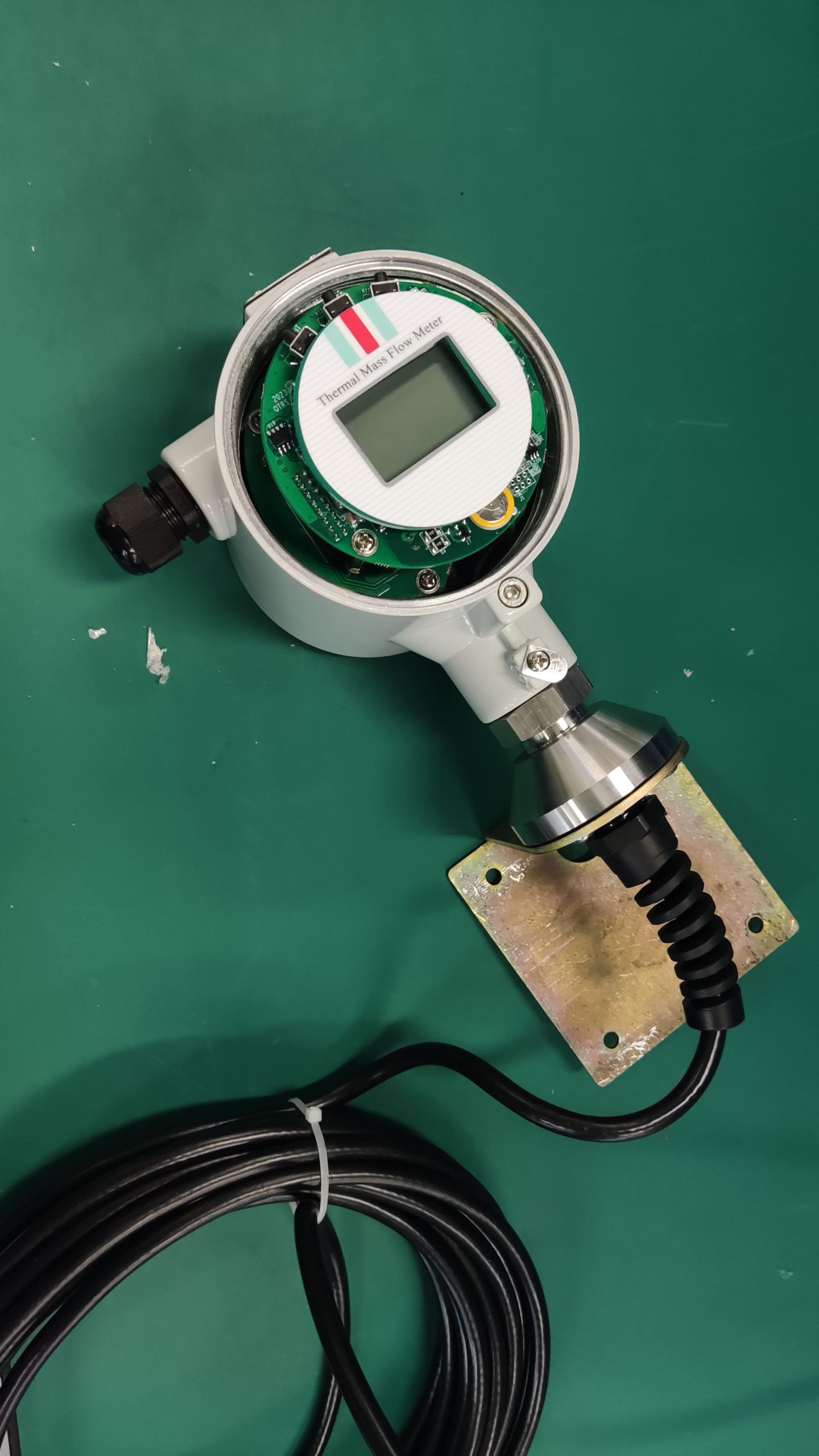

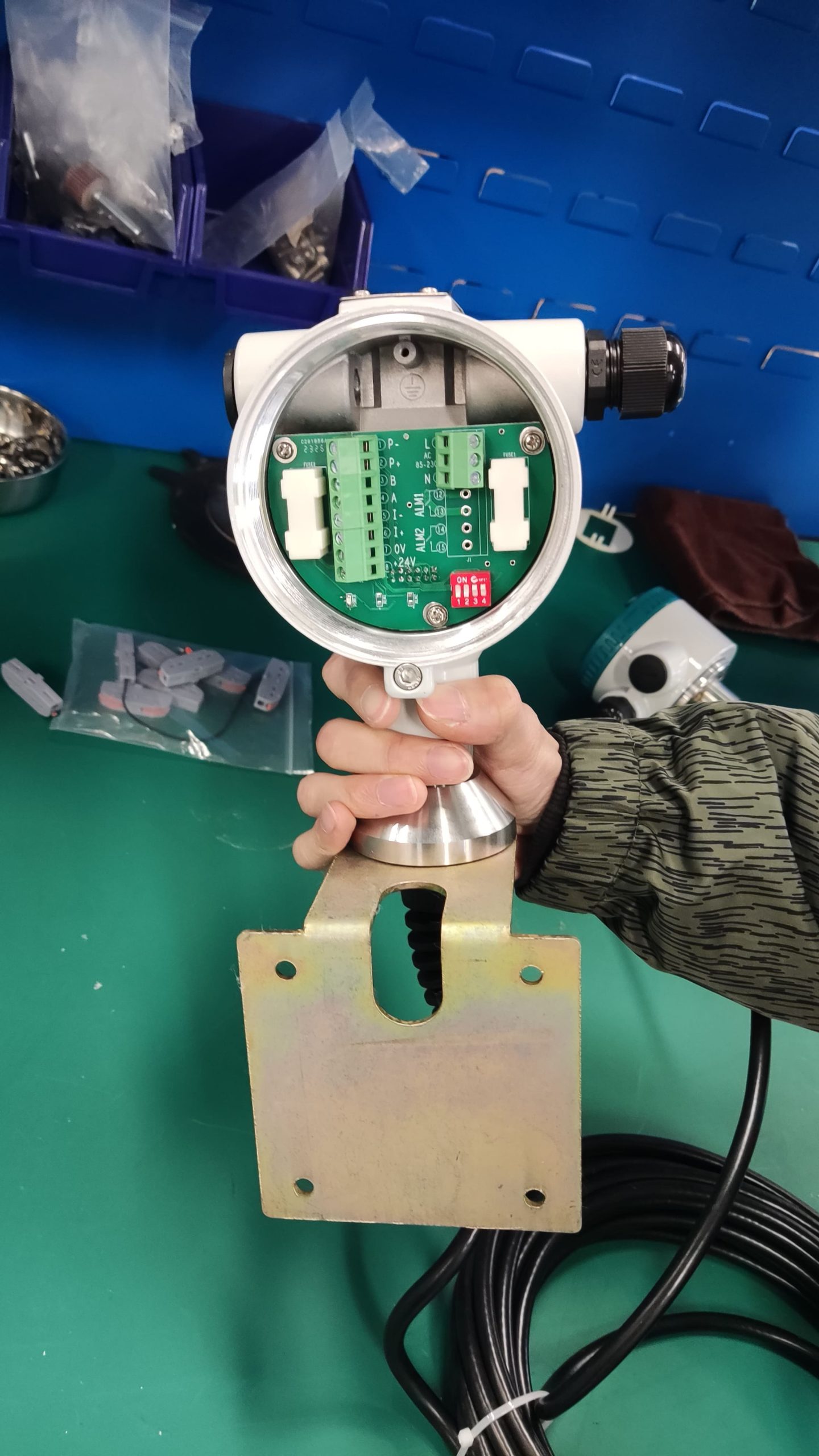

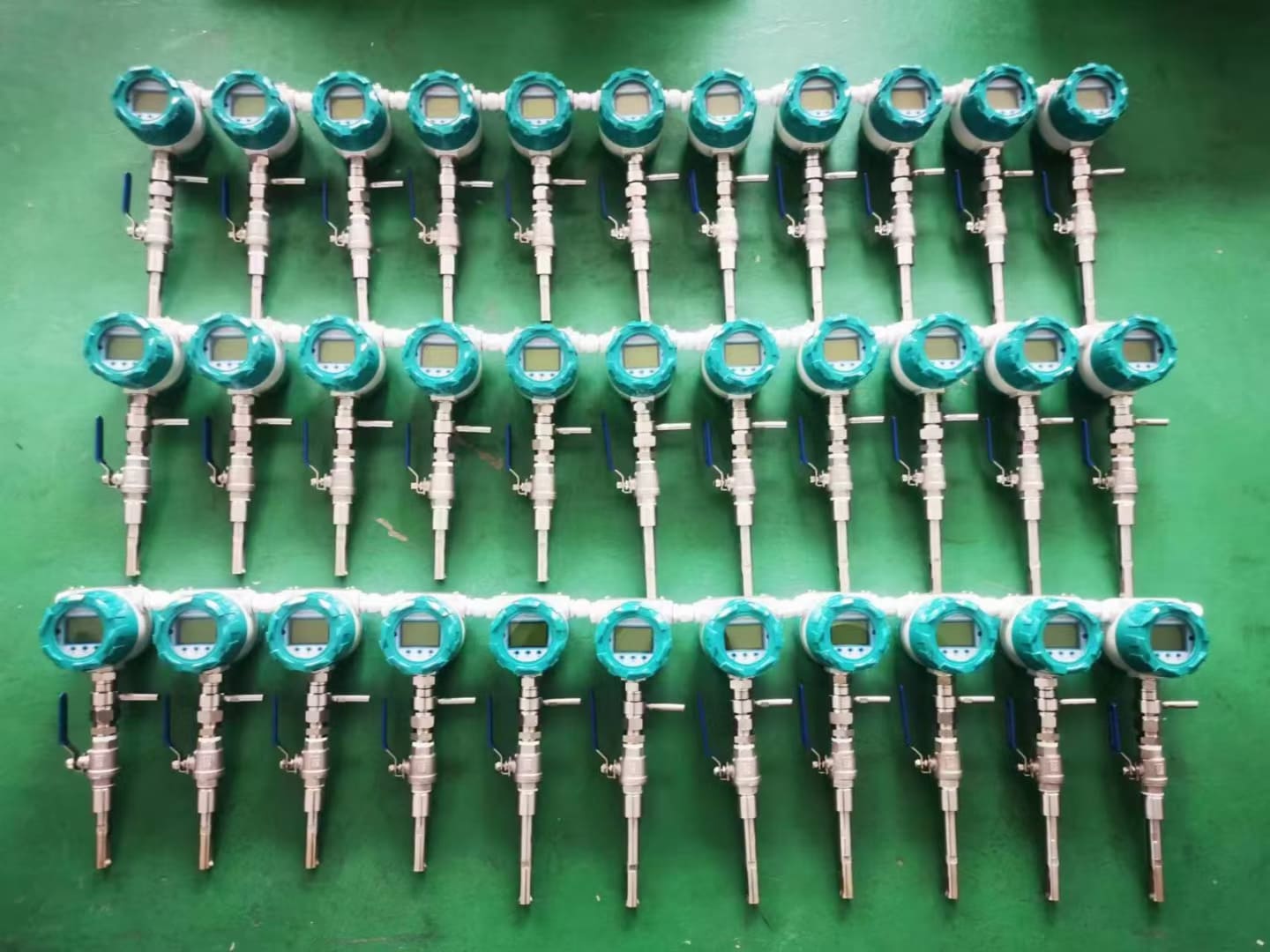

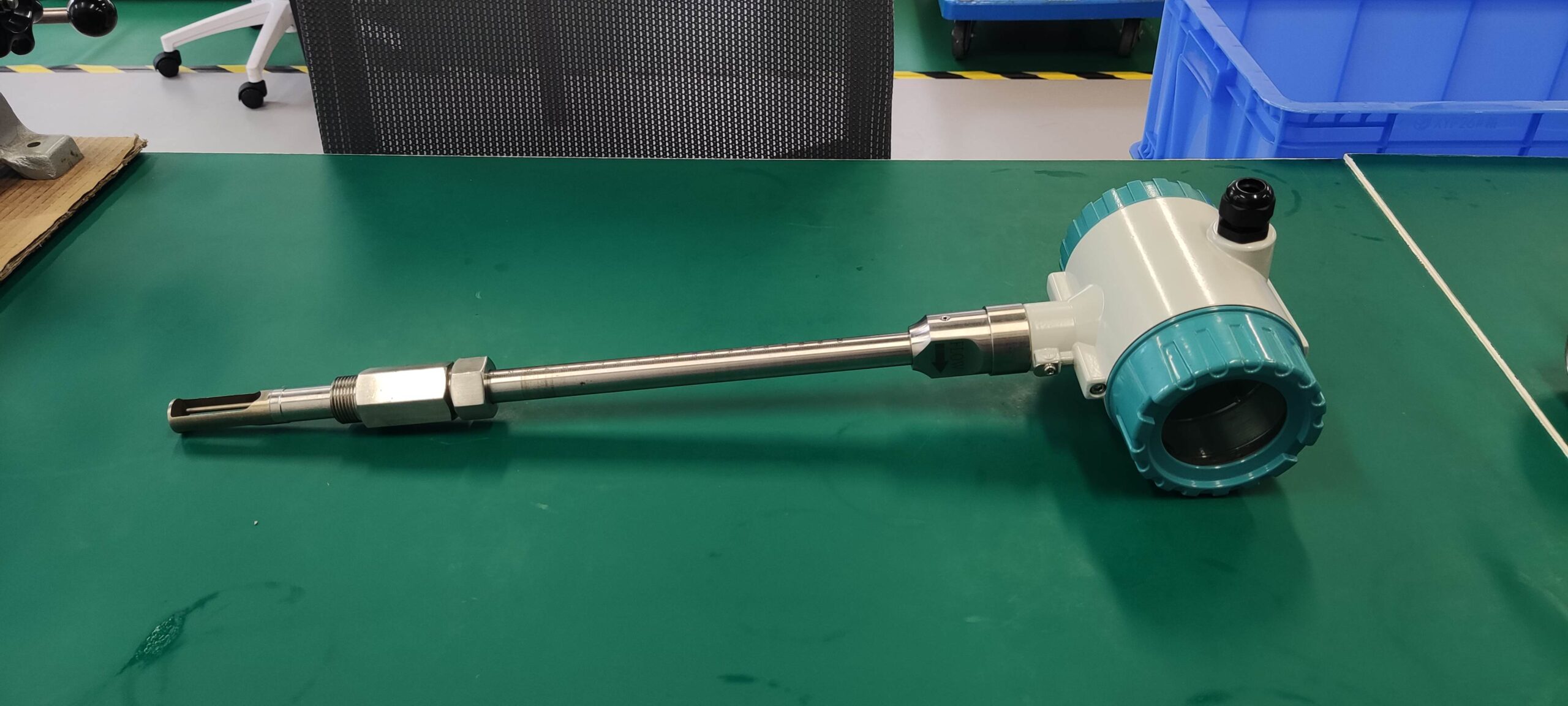

The thermal gas flowmeter adopts the principle of thermal diffusion, and the thermal diffusion technology is a technology with excellent performance and high reliability under harsh conditions. Typical sensing elements of thermal gas mass flowmeters include two thermal resistors (PT100), one is a speed sensor and one is a temperature sensor that automatically compensates for changes in gas temperature.

When two thermal resistors are placed in the medium, the velocity sensor is heated to a constant temperature above the ambient temperature, and the other temperature sensor is used to sense the medium temperature. The mass flow of gas through the velocity sensor is calculated by the heat transfer of the sensing element. As the gas flow rate increases, the heat carried away by the medium increases. The temperature of the sensor decreases accordingly. In order to maintain a constant temperature, the working current through the sensor must be increased, and the increased part of the current is proportional to the flow rate of the medium.

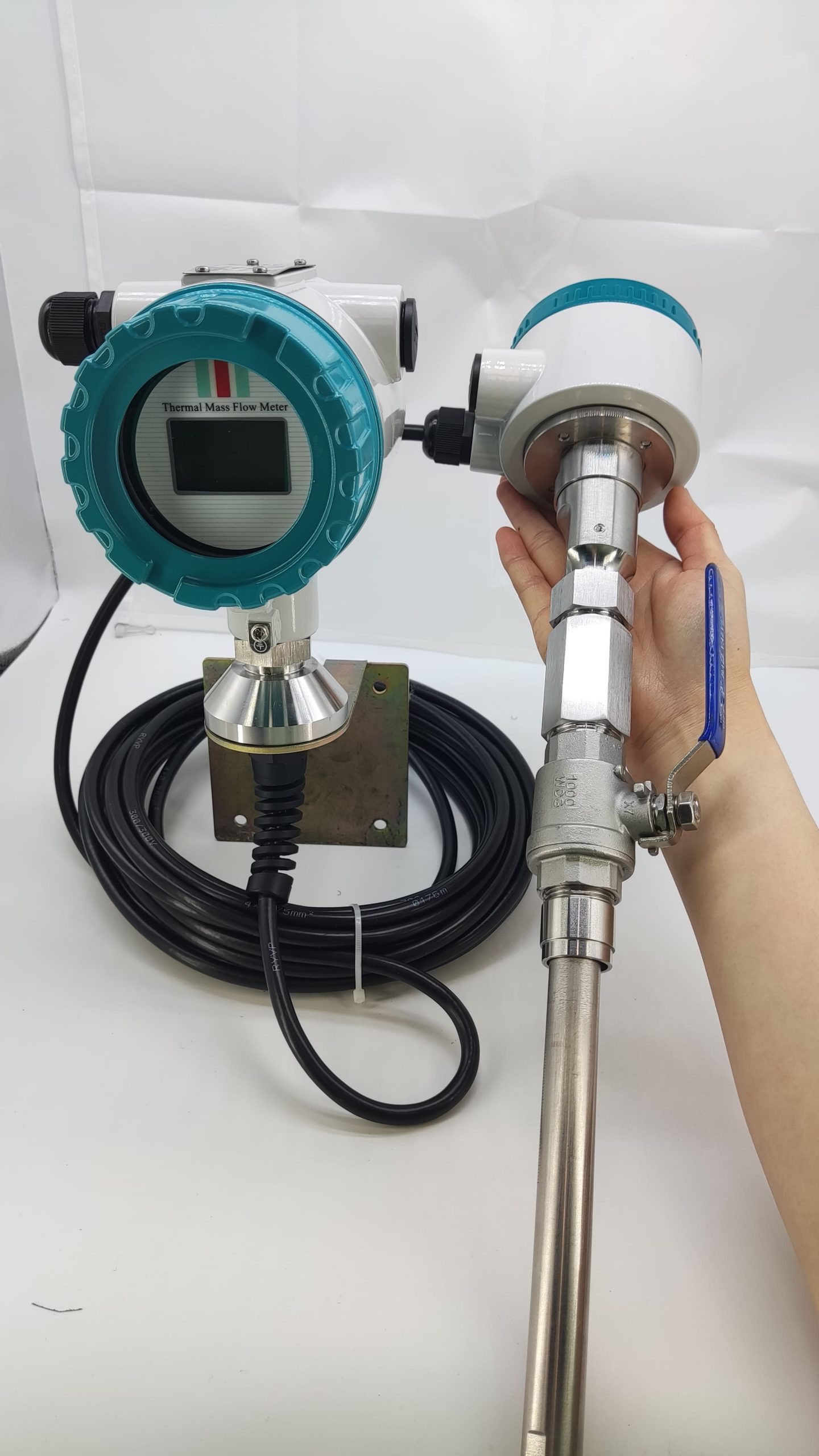

Thermal gas mass flowmeter suitable for:

1. Petrochemical industry

Application: Flare gas emission monitoring

Product advantages: wide range ratio, sensor is not easy to plug, can be plugged and cleaned online, suitable for a wide range of gases

2. Power industry

Application: Boiler primary air, secondary air, grinding coal air volume measurement

Product advantages: easy installation, no straight pipe section requirements, low pressure loss, no temperature and pressure compensation, can be used under harsh conditions (such as: air containing dust, particles, serious wear, low pressure, etc.).

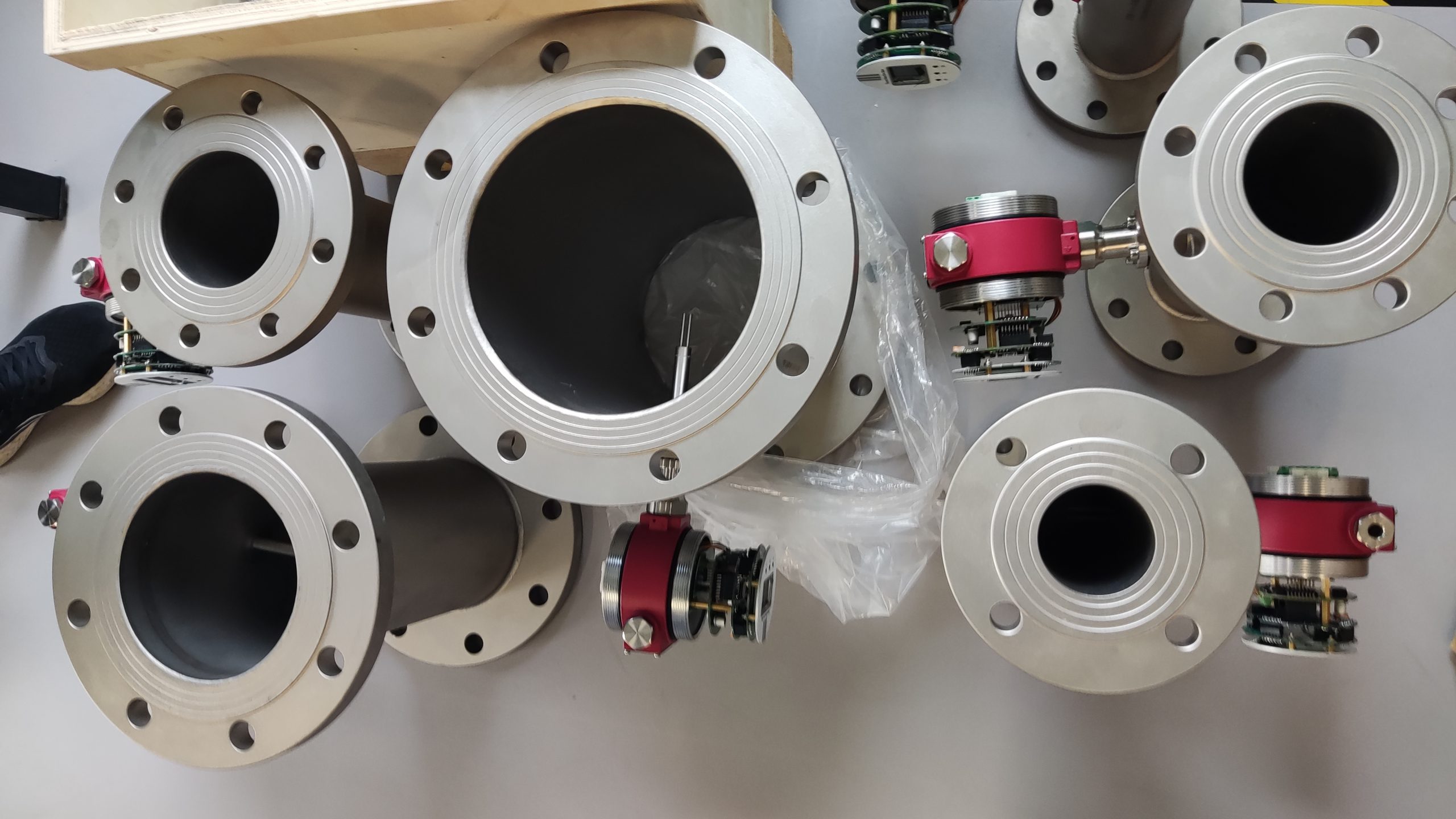

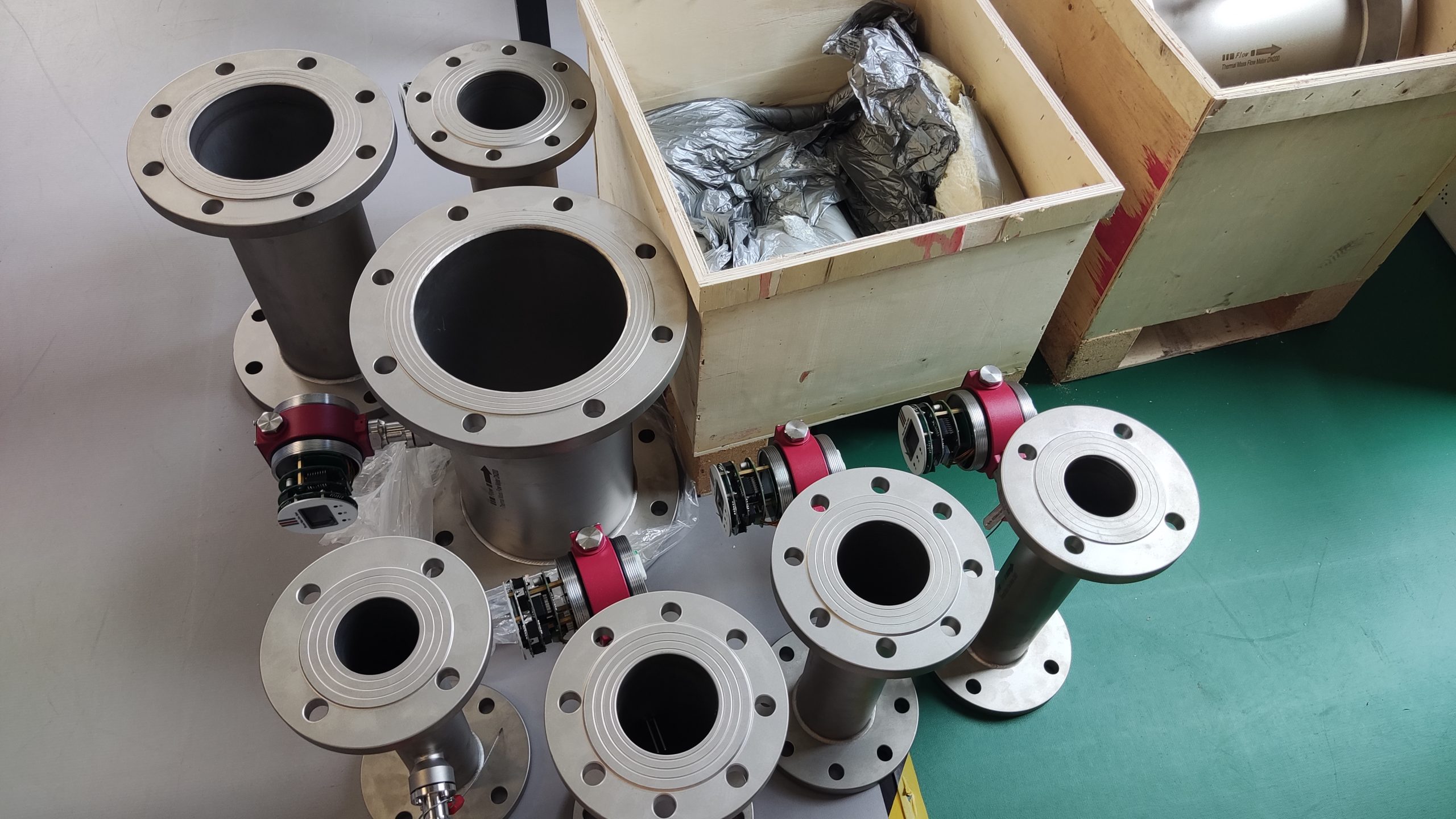

3. Metallurgical industry

Application: blast furnace gas, coke oven gas measurement

Product advantages: calibrated according to the actual media components, the component changes can be corrected, the sensor can be cleaned online, and the insertion length can be adjusted at will

4. Electronics industry

Application: High purity gas mass flow measurement

Product advantages: Mass flow is measured directly without temperature and pressure compensation, and the sensor head is highly polished for trade settlement

5. Heating, Ventilation and Air Conditioning Systems (HVAC)

Product advantages: The product is responsive, reliable operation, no strict requirements for the installation of straight pipe section

6. Water treatment industry

Application: Measuring air flow in aeration tank

Product advantages: dirt resistance, dust resistance, real no pressure drop, easy to install on site

7. Food industry

Application: Proper amount of gas is injected into the reactor to control the process and quality

Product advantages: sanitary grade 3A, high purity, all liquid surface made of stainless steel, wide range ratio.