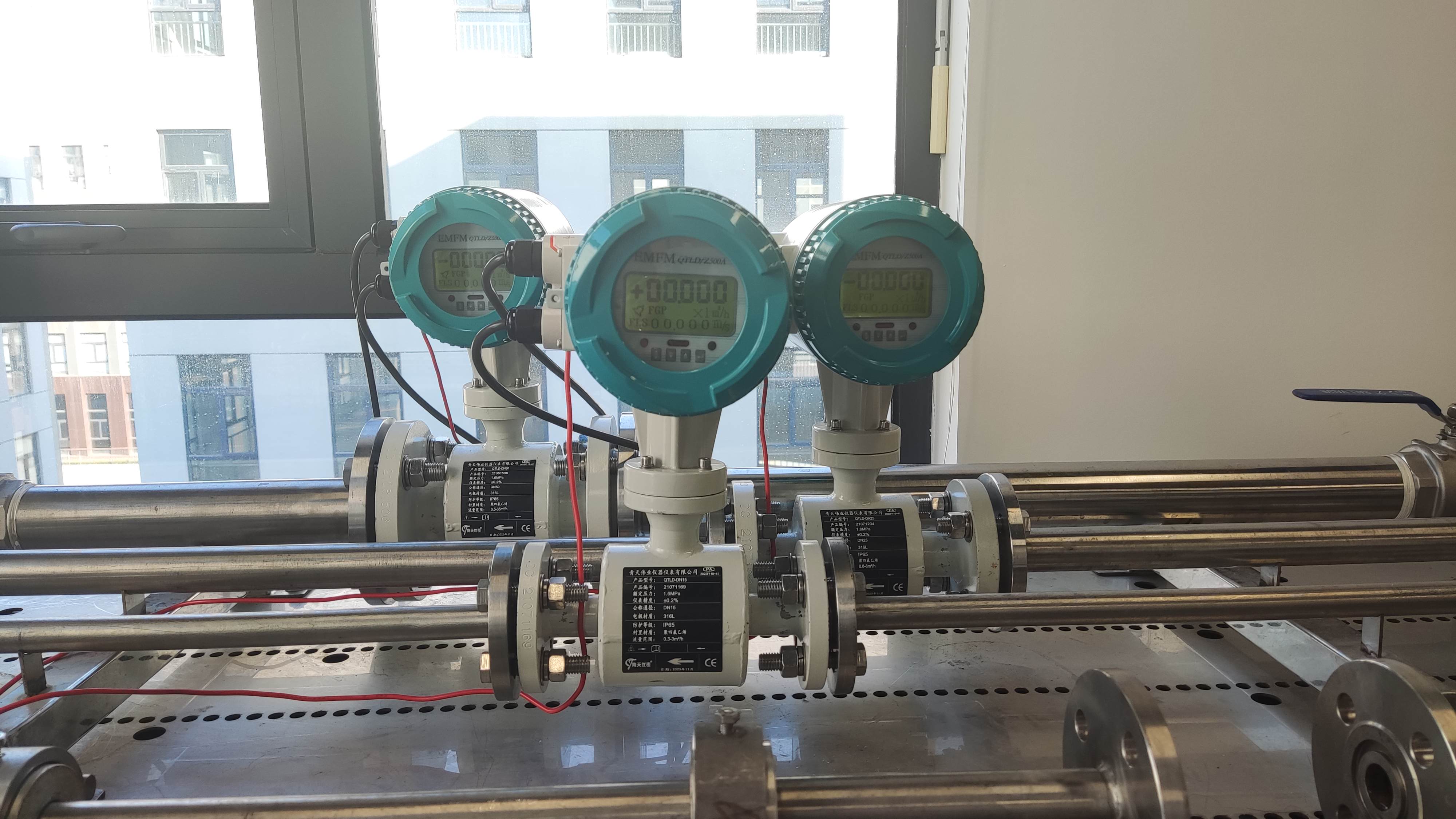

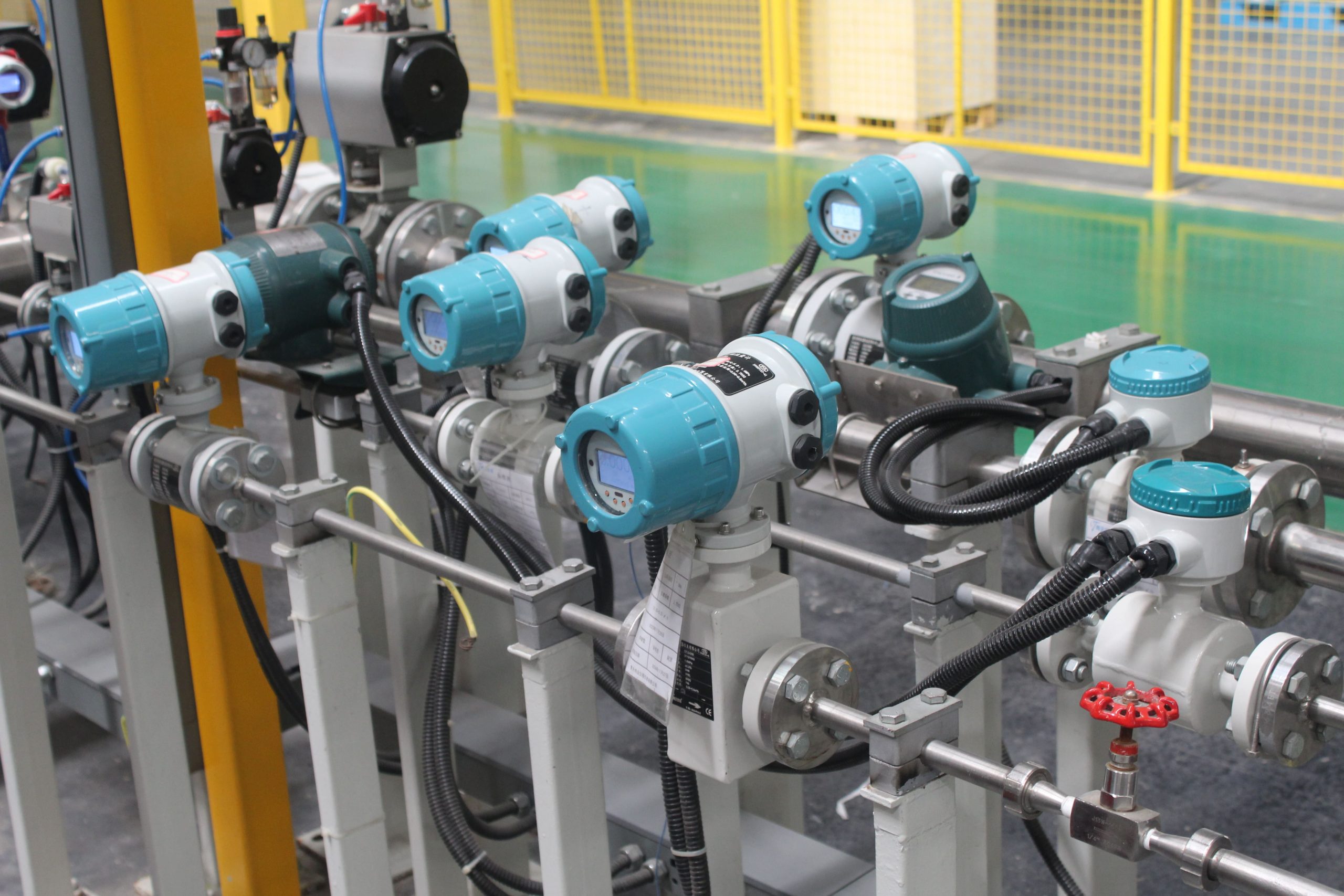

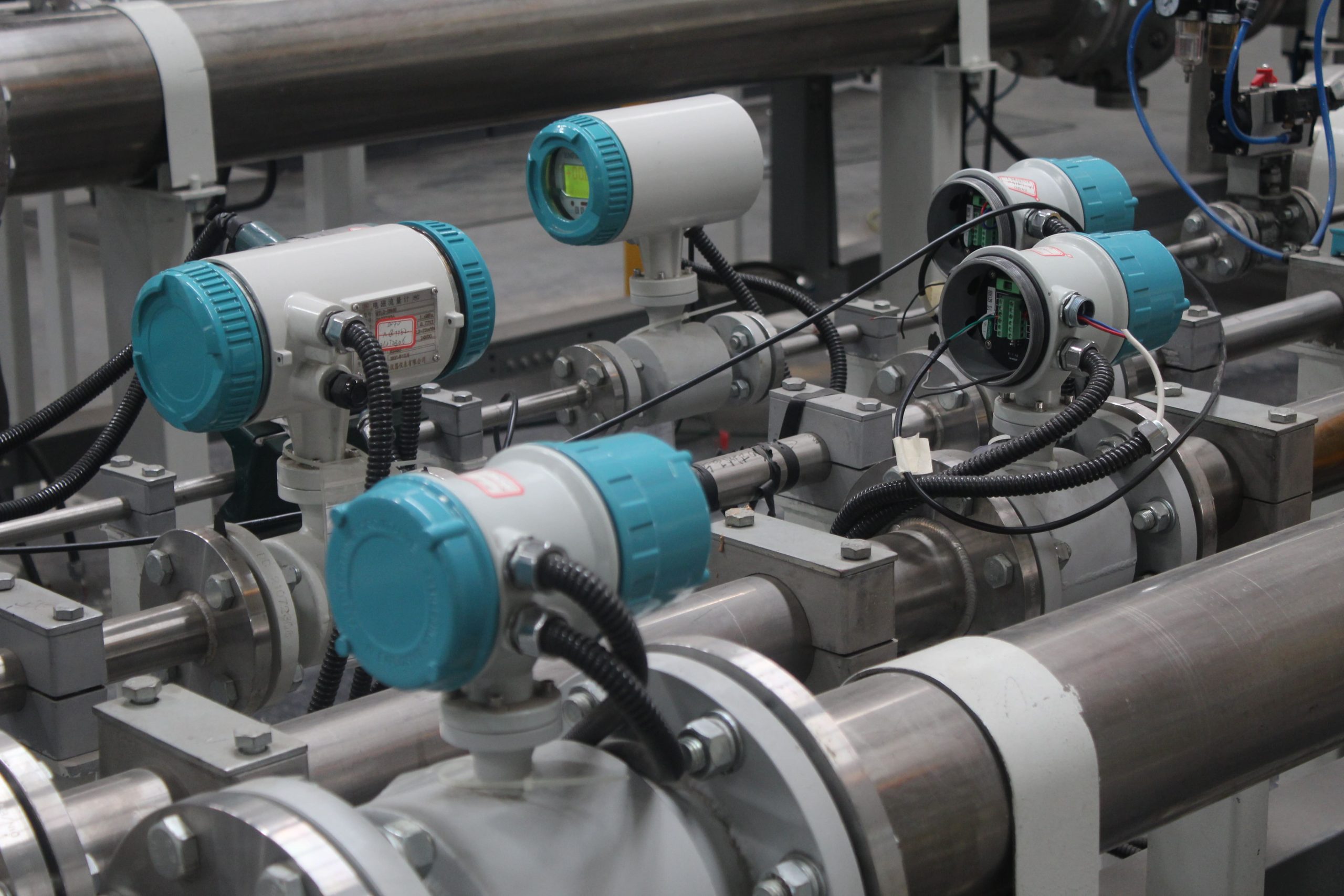

Wireless Data Logger Electromagnetic Flowmeter Water Pump Liquid Magnetic Flow Meter

The converter direction of an electromagnetic flowmeter refers to the orientation or alignment of the flowmeter’s electronic converter unit concerning the flow direction within the pipe. Electromagnetic flowmeters typically have a preferred or specified direction for the converter to achieve optimal performance. The converter contains the electronics and signal processing components essential for accurate flow measurement.

In most cases, the converter direction is marked or specified by the manufacturer. Here are two common scenarios regarding the converter direction:

Bi-Directional Flowmeters:

Some electromagnetic flowmeters are designed to measure flow in both directions (bidirectional flow). In such cases, the converter may not have a specific orientation requirement, as it can accommodate flow in either direction. Manufacturers often indicate this capability in the product documentation, and the converter may be installed without strict adherence to a specific direction.

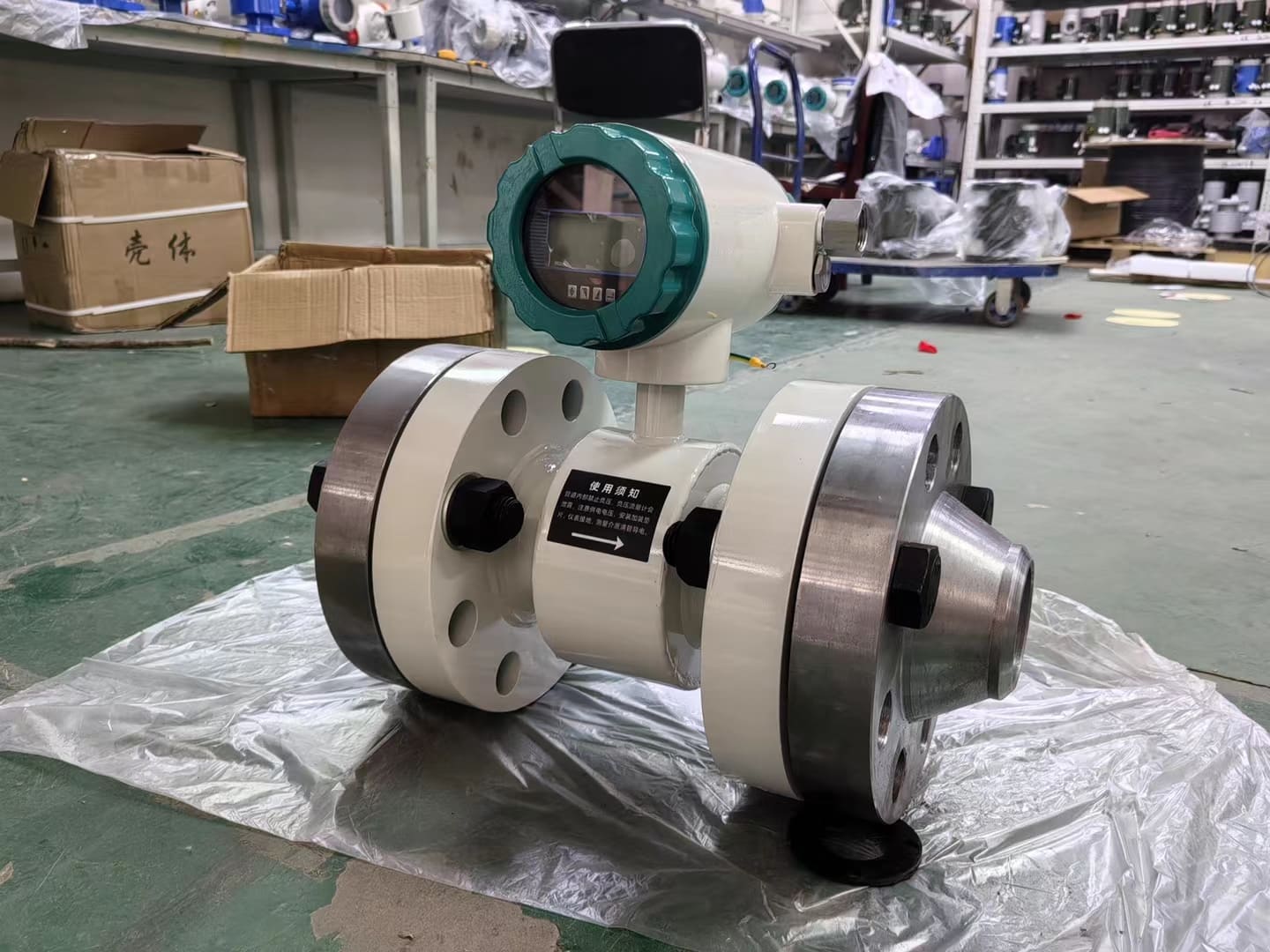

Uni-Directional Flowmeters:

Uni-directional flowmeters are designed to measure flow in one specific direction. The converter will have a designated inlet and outlet, and it must be installed with the correct orientation for accurate measurements. The manufacturer’s guidelines and product documentation will provide information on the proper converter direction. Incorrect installation may lead to inaccurate readings and affect the flowmeter’s performance.

Steps to Determine and Change Converter Direction:

Check Manufacturer Documentation:

Refer to the electromagnetic flowmeter’s product documentation, technical specifications, or installation manual provided by the manufacturer. Look for information on the converter direction and any specific requirements for uni-directional or bidirectional flow measurement.

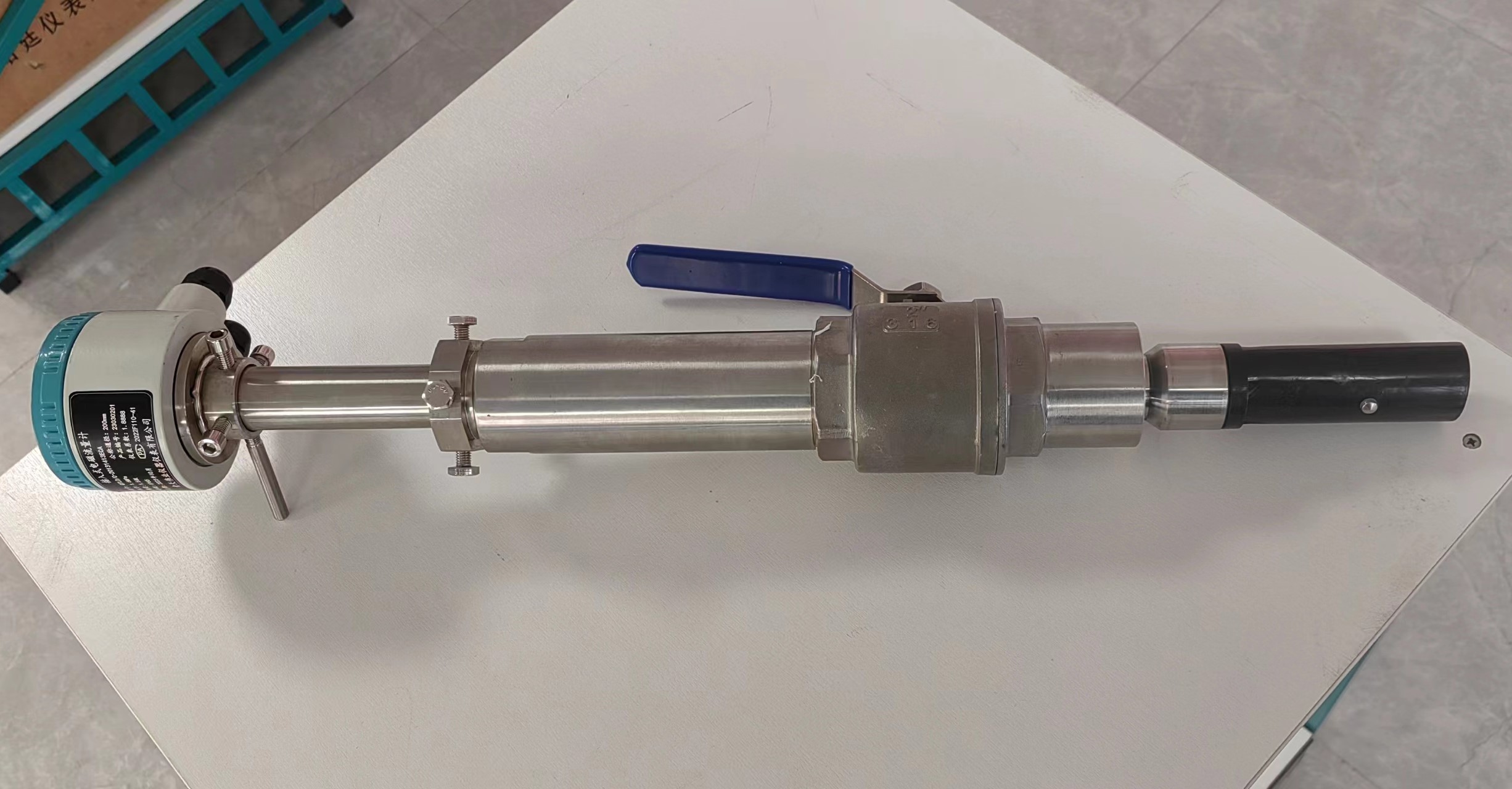

Inspect Converter Markings:

Examine the converter unit for any markings indicating the direction of flow. Manufacturers often label the converter with arrows or other indicators to show the preferred flow direction.

Contact Manufacturer or Supplier:

If you are unsure about the converter direction or need clarification, reach out to the manufacturer’s technical support or your equipment supplier. They can provide guidance on the correct installation procedure and any considerations related to the converter direction.

Adjust Converter Orientation:

If the electromagnetic flowmeter allows for bidirectional flow, and there is no specific orientation requirement, the converter can be installed without strict adherence to flow direction. If it is a uni-directional flowmeter and the converter direction needs to be changed, follow the manufacturer’s instructions for adjusting the orientation. This may involve physically rotating the converter to align with the desired flow direction.

Always adhere to the manufacturer’s guidelines and recommendations during the installation, orientation, and operation of electromagnetic flowmeters to ensure accurate and reliable flow measurements. Incorrect installation may lead to measurement errors, decreased accuracy, and potential damage to the flowmeter components.

-.jpg)