Why should medium viscosity be considered in turbine flow meter selection?

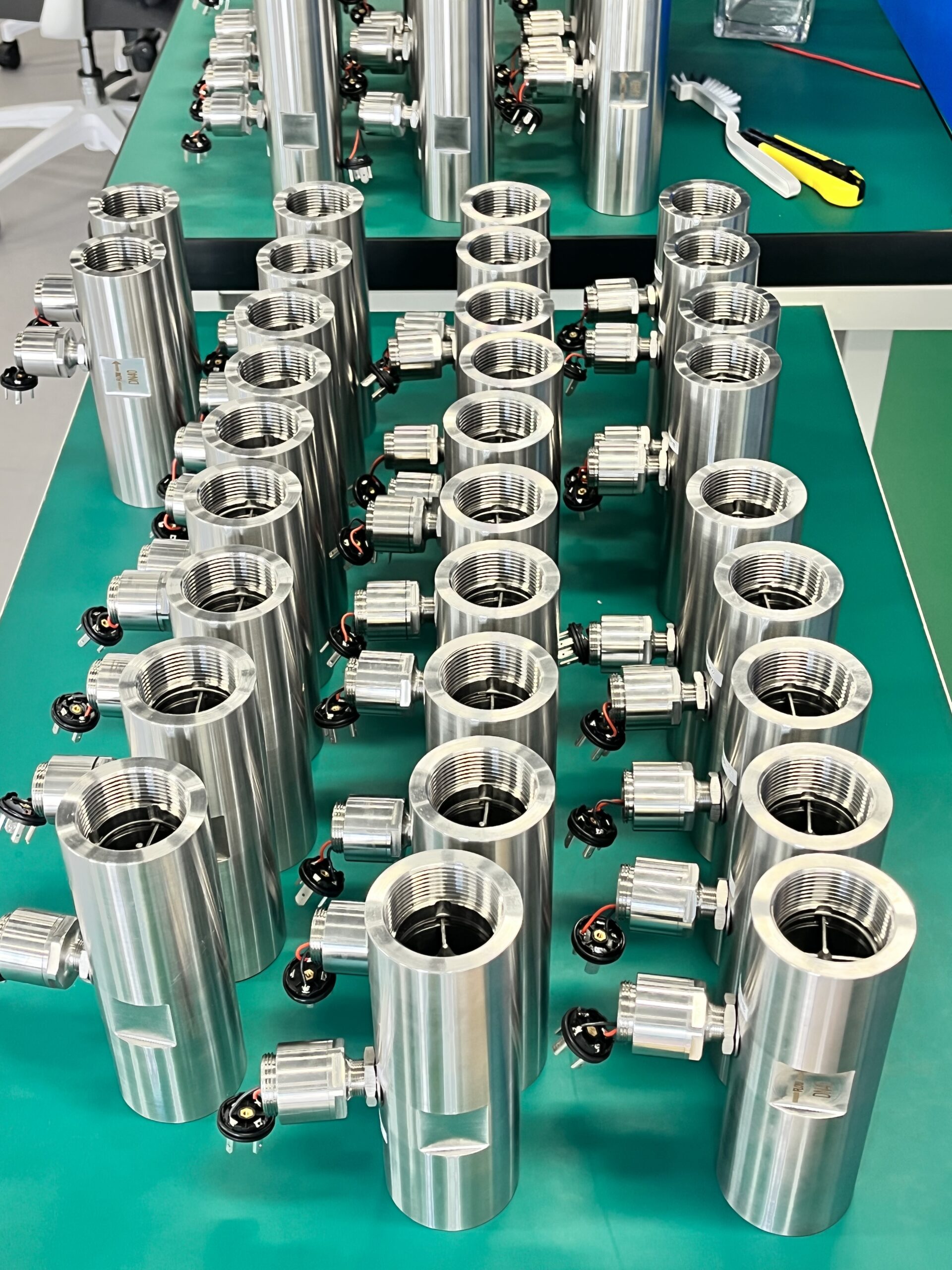

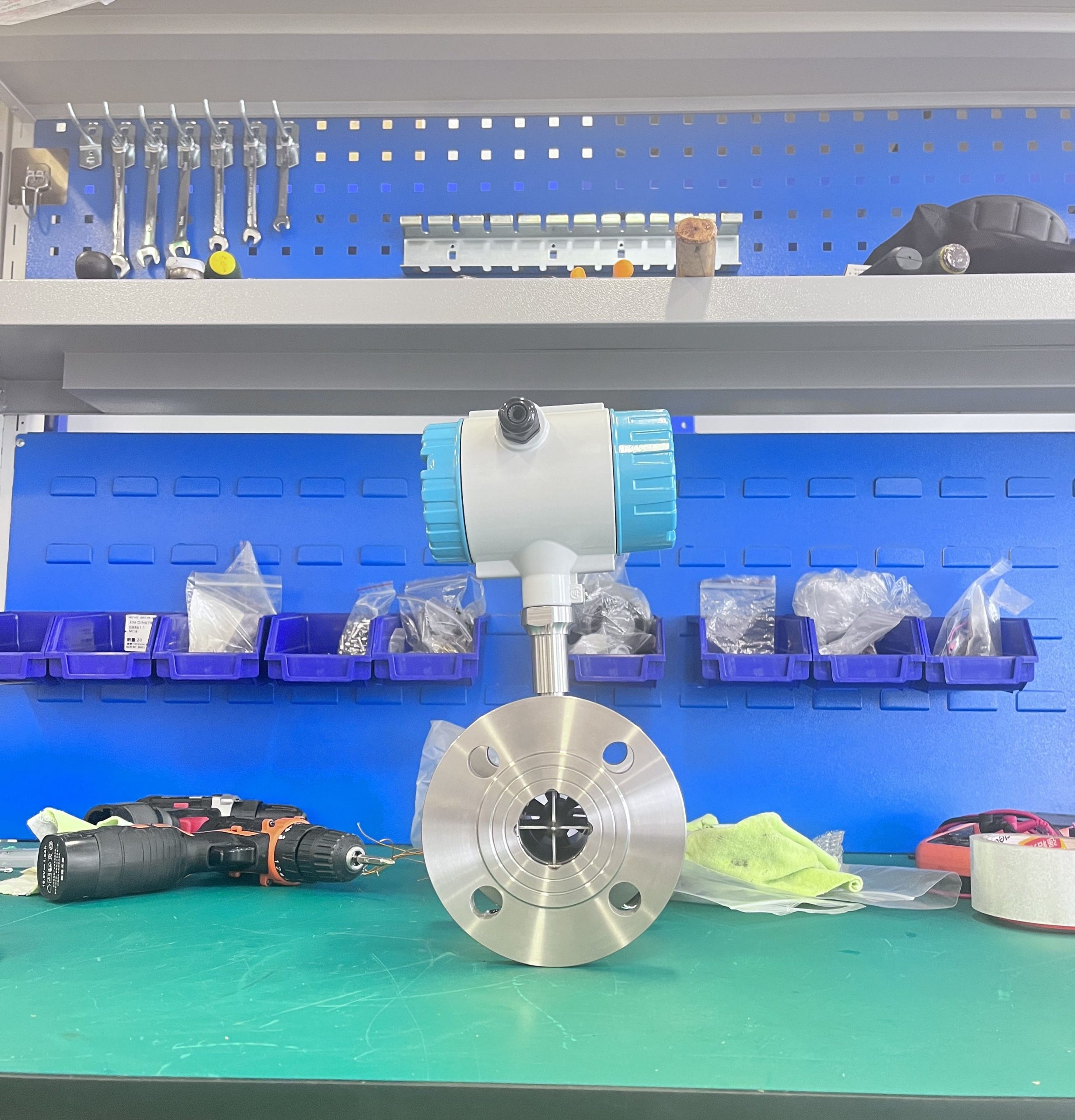

Turbine flowmeter has the characteristics of simple structure, light weight, high precision, good repeatability, sensitive response, easy installation and maintenance, etc., widely used in petroleum, chemical industry, metallurgy, water supply, paper and other industries.

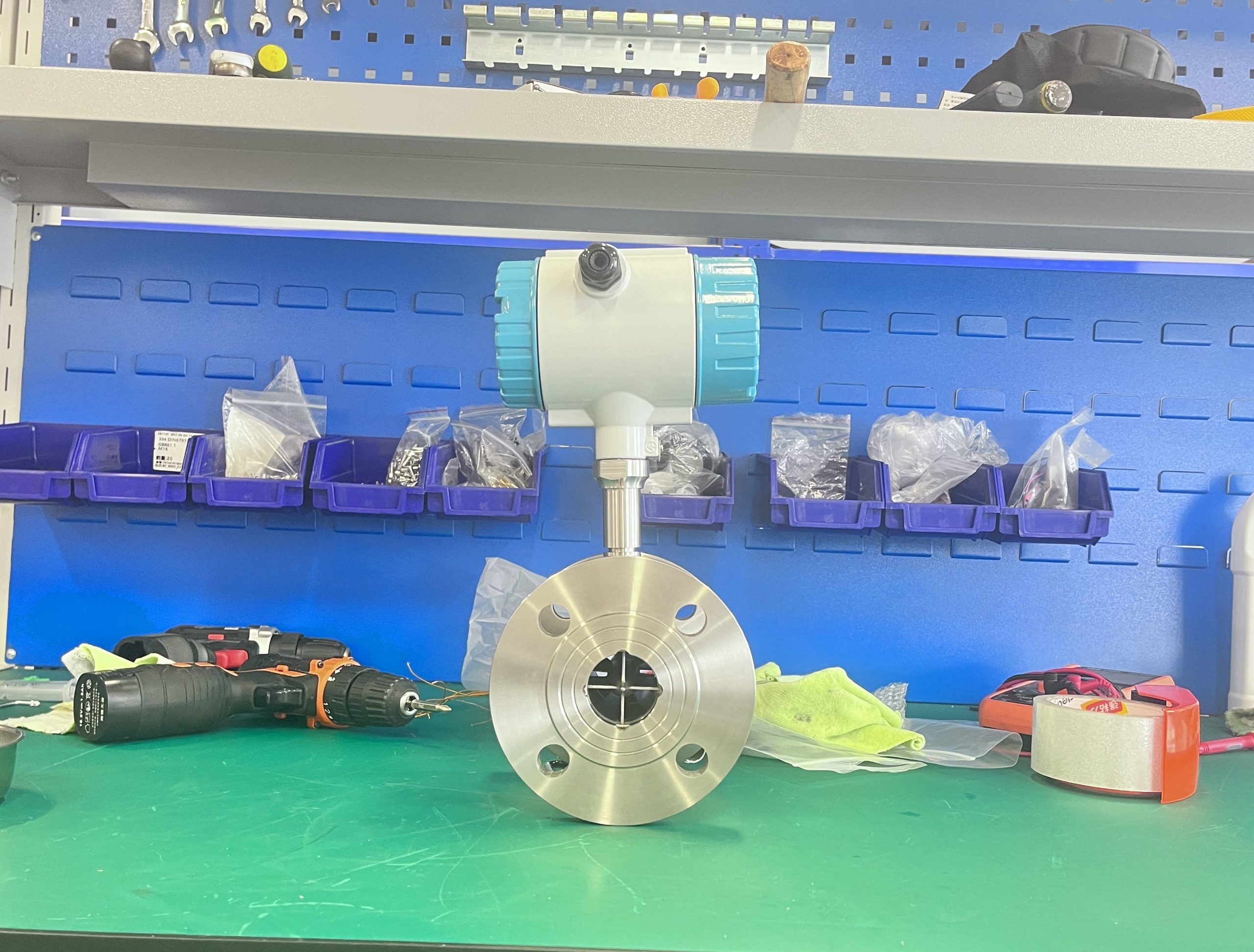

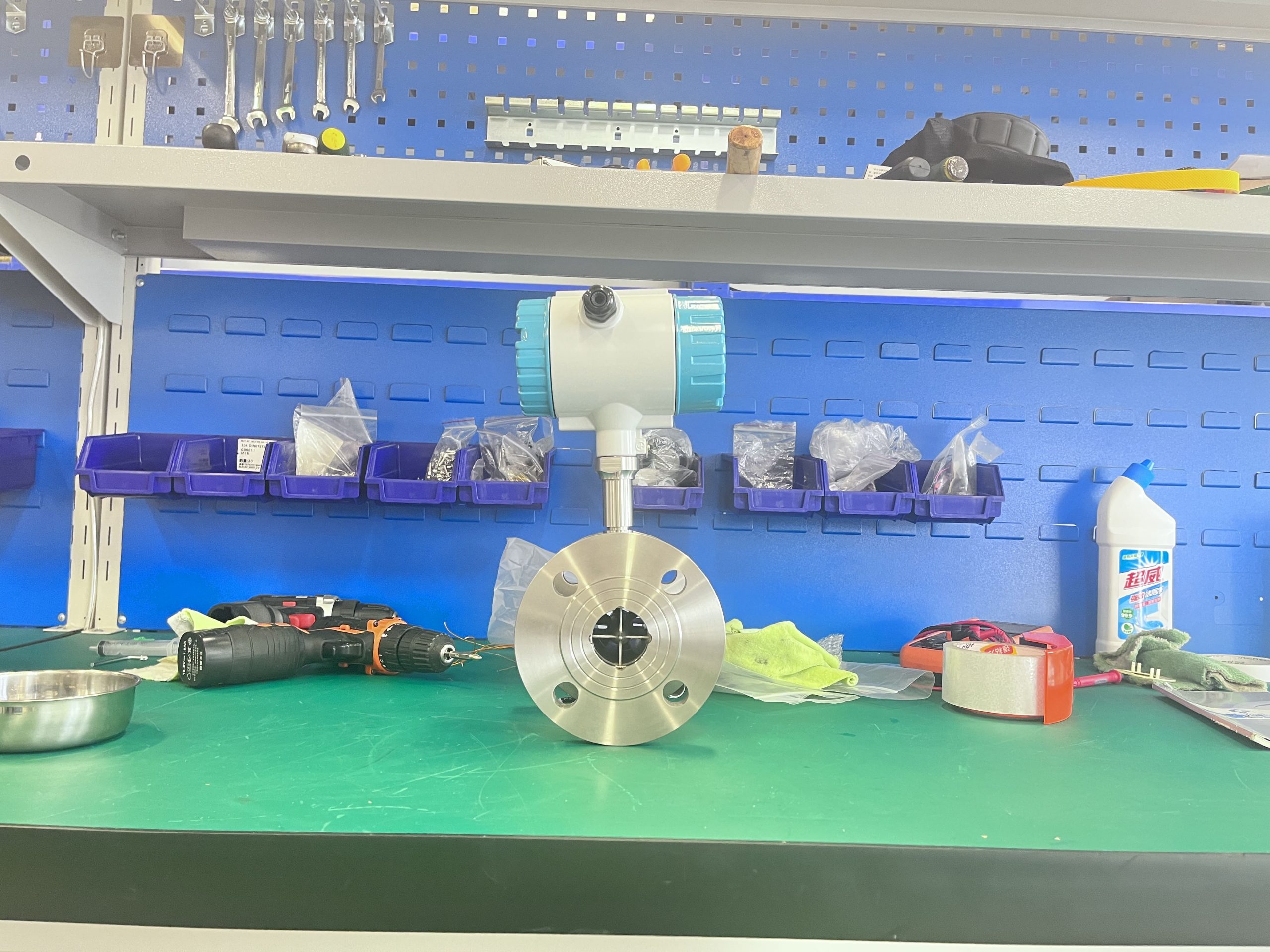

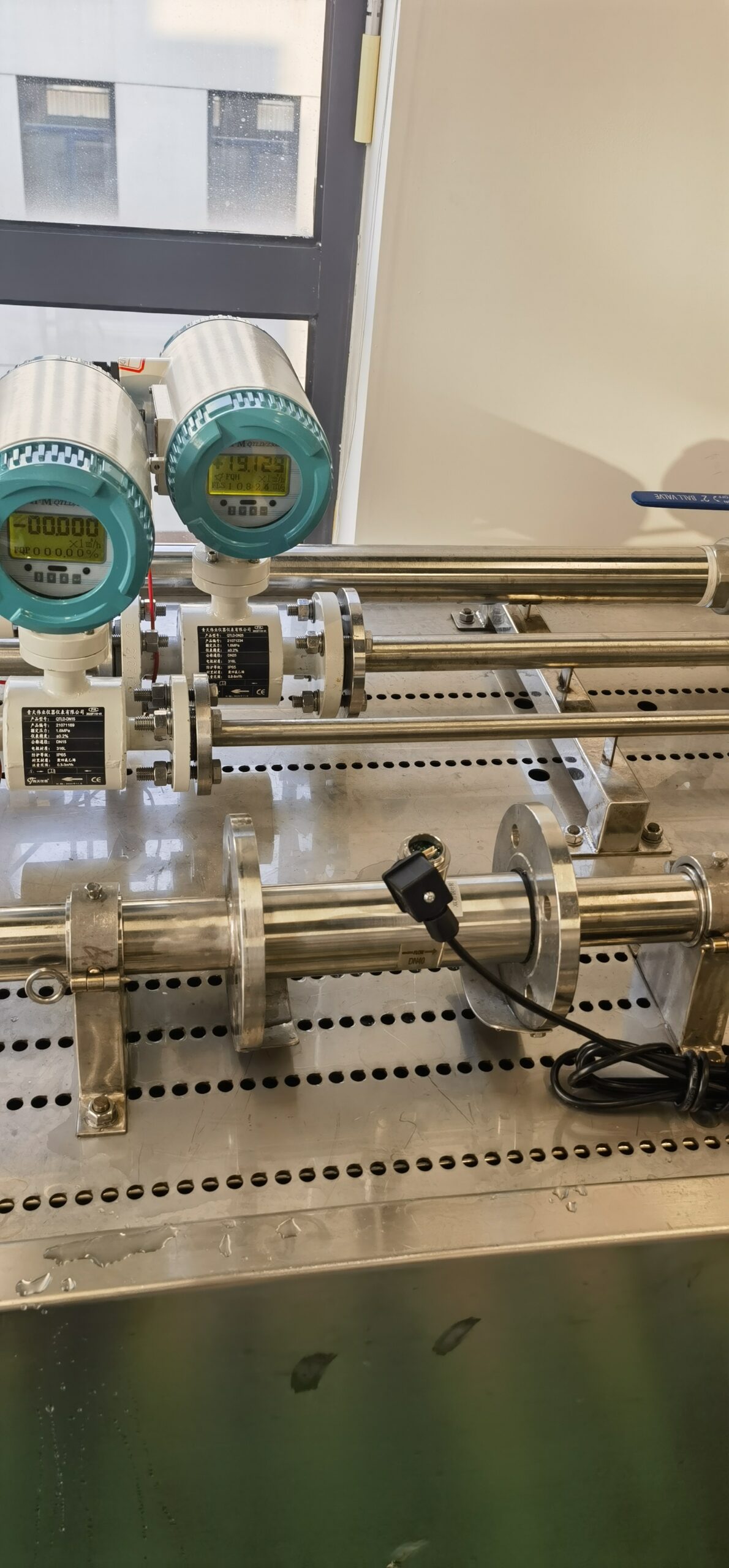

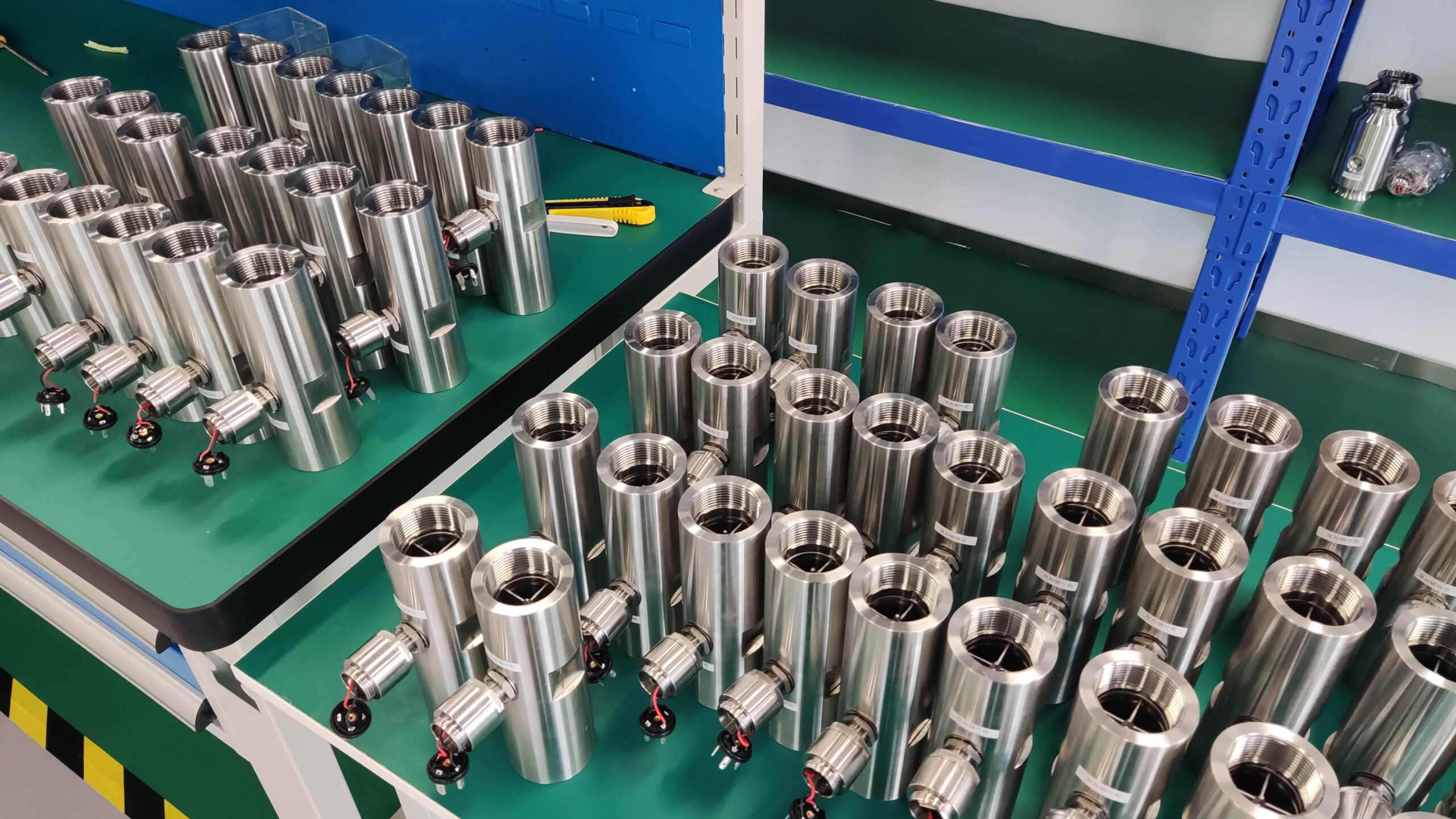

Turbine flowmeter has the characteristics of simple structure, light weight, high precision, good repeatability, sensitive response, easy installation and maintenance, etc., widely used in petroleum, chemical industry, metallurgy, water supply, paper and other industries. It is an ideal instrument for flow measurement and energy saving, widely used to measure the closed pipeline with stainless steel 1Cr18Ni9Ti, 2Cr13 and cemented carbide do not corrode, and there are no impurities such as fibers, particles, and the liquid with kinetic viscosity less than 5×10^-6m2/s at working temperature, for the liquid with kinetic viscosity greater than 5×10^-6m2/s, can be convection The meter is used after solid liquid calibration. If it is matched with a display instrument with special functions, it can also carry out quantitative control, excessive alarm, etc., which is an ideal instrument for flow measurement and energy saving.

Due to the influence of the eccentricity of the impeller and the slight change of the mechanical friction resistance moment, the turbine flowmeter will have a periodic speed change in the same rotation cycle, which also makes it difficult for the turbine to have a very low speed, because at this time it is very easy to be disturbed and stop rotating.

The influence of viscosity on turbine flowmeter has the following points:

1. With the increase of viscosity, the starting displacement of the turbine flowmeter will decrease, and the minimum speed of response will also decrease.

2. With the increase of viscosity, the K value of the turbine flowmeter will decrease, and the linearity will also become worse.

3. Before entering the linear section of turbine response, the K value continues to rise and increases exponentially with the inlet Reynolds number of the flow meter.

4. For low-producing Wells with high production fluid viscosity, it is advisable to use the more sensitive turbine of the acquisition system so that it can accurately collect signals at low speed (less than 0.01r/s).

5. For turbine flowmeter used to measure different viscous fluids, only one calibration of different flow Reynolds number under high viscosity conditions can approximate the relationship between K value of the turbine flowmeter and Reynolds number, and invert the response curve of the turbine to different viscous fluids.