What should we pay attention to the connection of electromagnetic flow meters and converters?

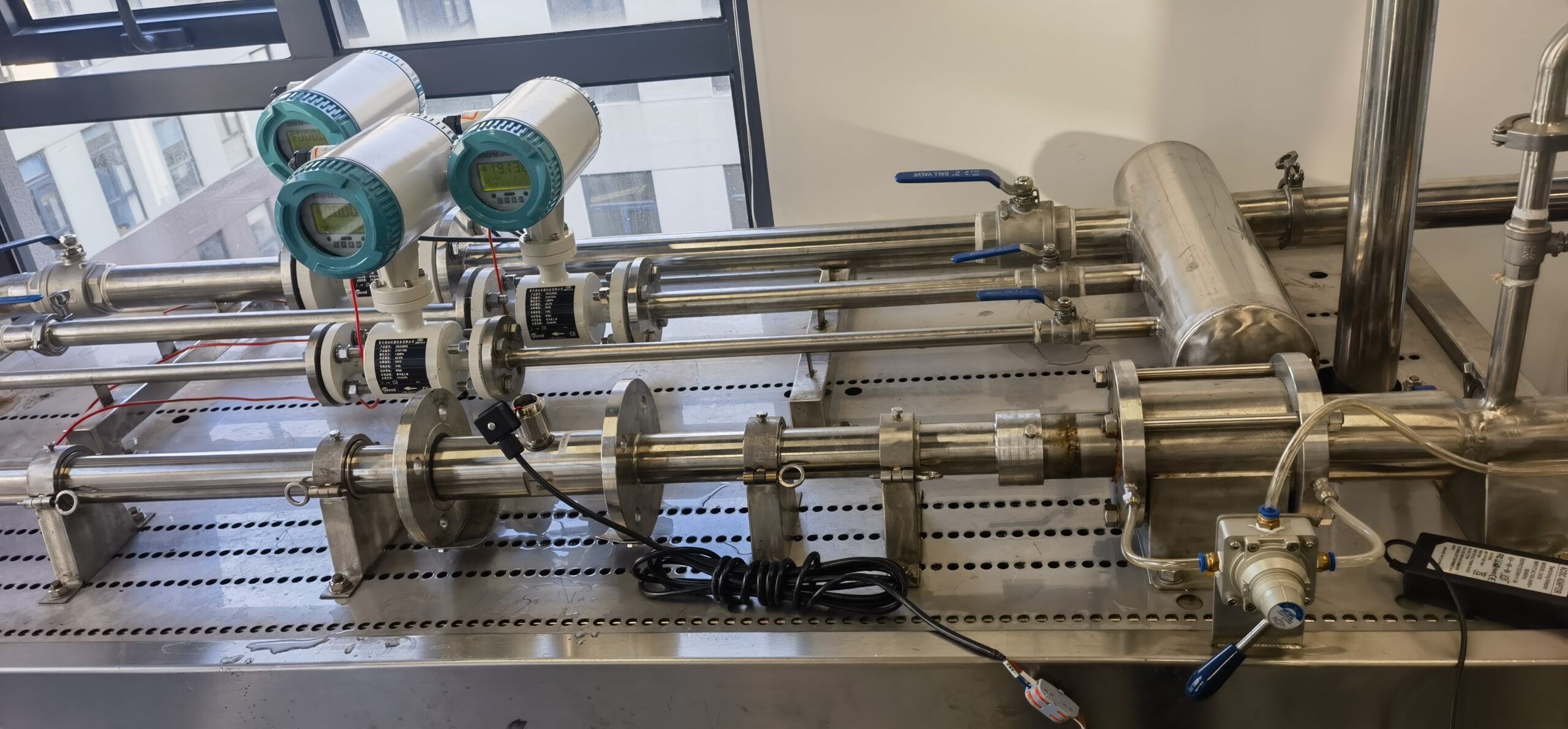

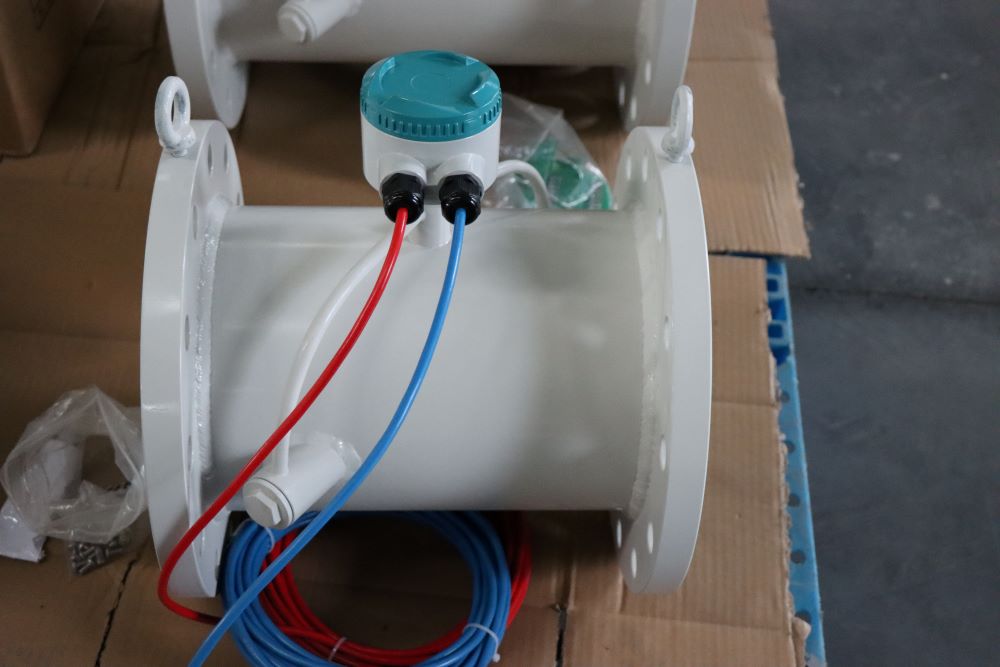

A type electromagnetic flowmeter does not require a separate converter; The separation electromagnetic flowmeter type converter is installed near the sensor or the instrument room, the place to choose is larger, the environmental conditions are better than the sensor, and the protection level is IP65 or IP64 (dust and splash level).

1. When measuring mixed phase liquid, select something that will not cause phase separation; When measuring two-component liquids, avoid loading downstream where the mixture has not been uniform; When measuring the chemical reaction pipe, it should be installed downstream of the reaction fully completed section;

2. Avoid negative pressure in the measuring tube as much as possible;

3. Choose a place with small vibration, especially for a type instrument;

4. Avoid large motors and transformers nearby to avoid electromagnetic field interference;

5. A place where the sensor is easily grounded separately;

6. Avoid high-concentration corrosive gases in the surrounding environment as much as possible;

7. The ambient temperature is in the range of 25/10 to 50/60 ° C, and the temperature of a shape structure is also subject to electronic components, and the range is narrower;

8. The relative humidity of the environment is in the range of 10% to 90%;

9. Avoid direct sunlight if possible;

10. Avoid rain soaking, will not be submerged by water.

The distance between the electromagnetic meter converter and the sensor is subject to the conductivity of the measured medium and the signal cable type; That is, the distributed capacitance of the cable, the cross section of the wire and the number of shielding layers. Use the signal cable that the manufacturer included with the meter (or specified model). When the conductivity of the liquid is low and the transmission distance is long, there are also provisions for the use of three-layer shielded cables. The general instrument “instruction manual” gives the corresponding transmission distance range for liquids with different electrical conductivity. Single-layer shielded cables for industrial water or acid lye can usually be transmitted over a distance of 100 m. In order to avoid interfering with the signal, the signal cable must be worn separately in the grounding protection steel pipe, and the signal cable and the power cable cannot be installed in the same steel pipe.

-.jpg)

-.jpg)

-.jpg)