What should I do when the gas turbine flowmeter fails?

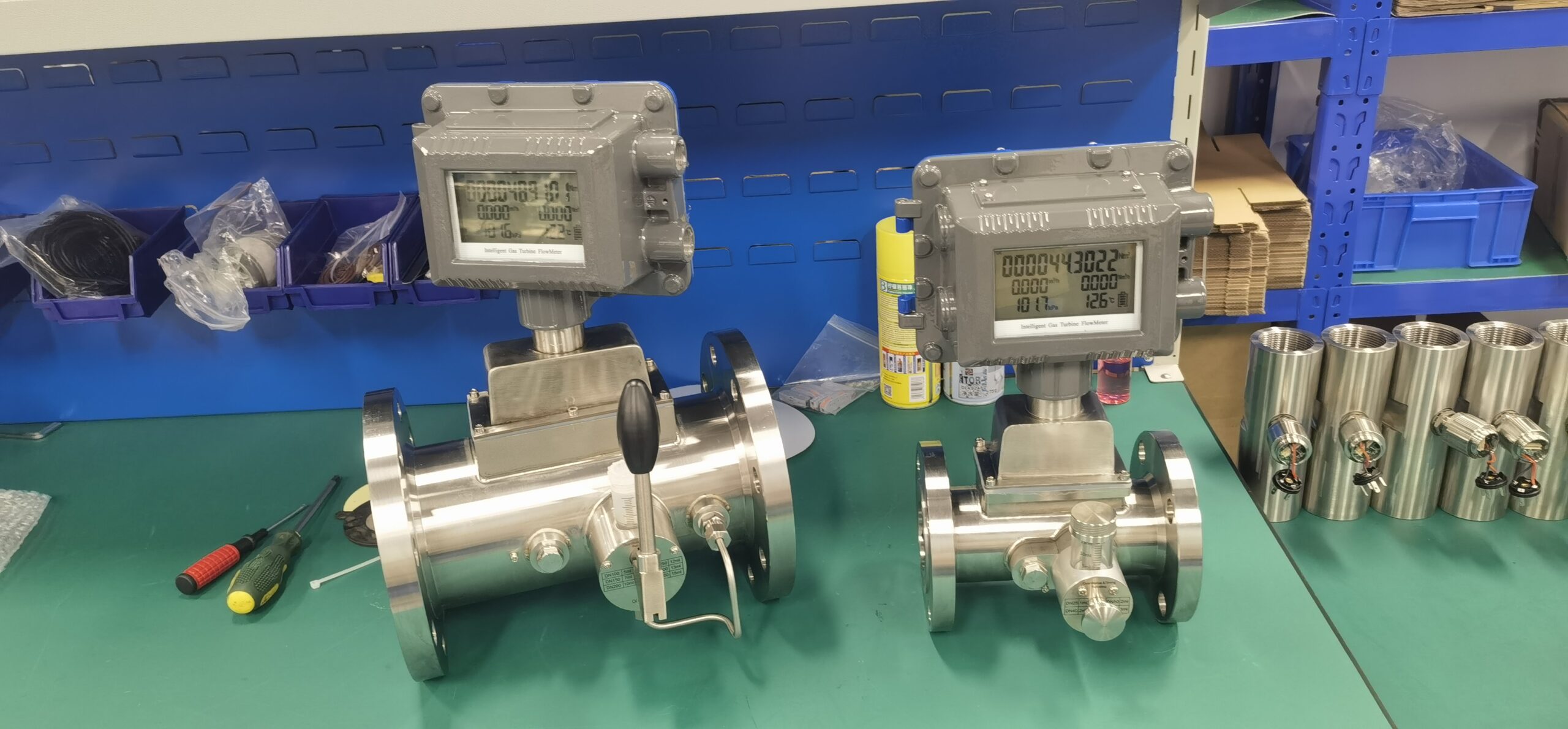

Gas turbine flowmeter has high measurement accuracy and stable performance, so it can be seen in many applications with high configuration requirements. Today, the flowmeter manufacturer Qingtian Instrument Xiaobian mainly to talk with you about some problems encountered in the application process of gas turbine flowmeter and the corresponding treatment methods.

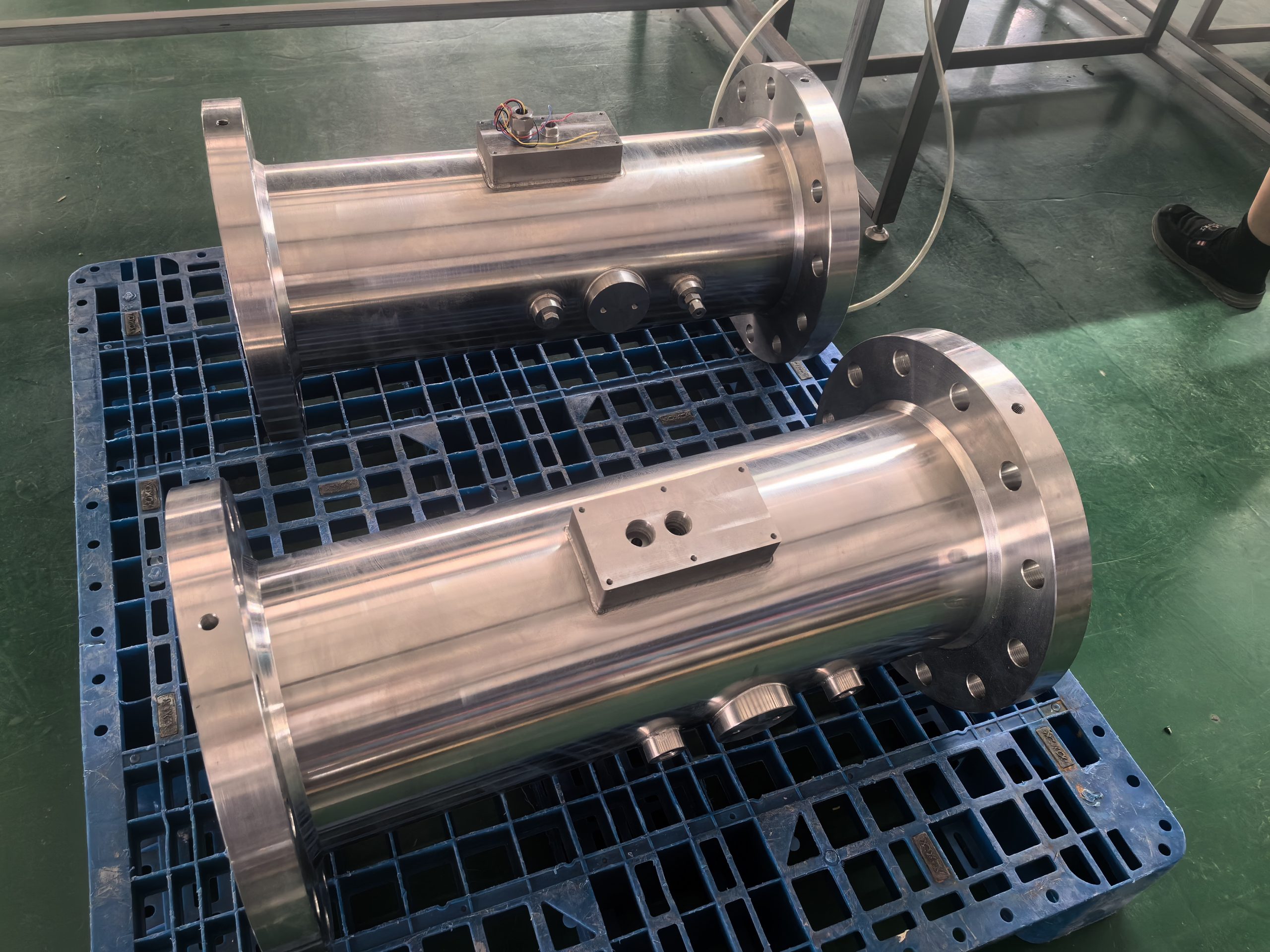

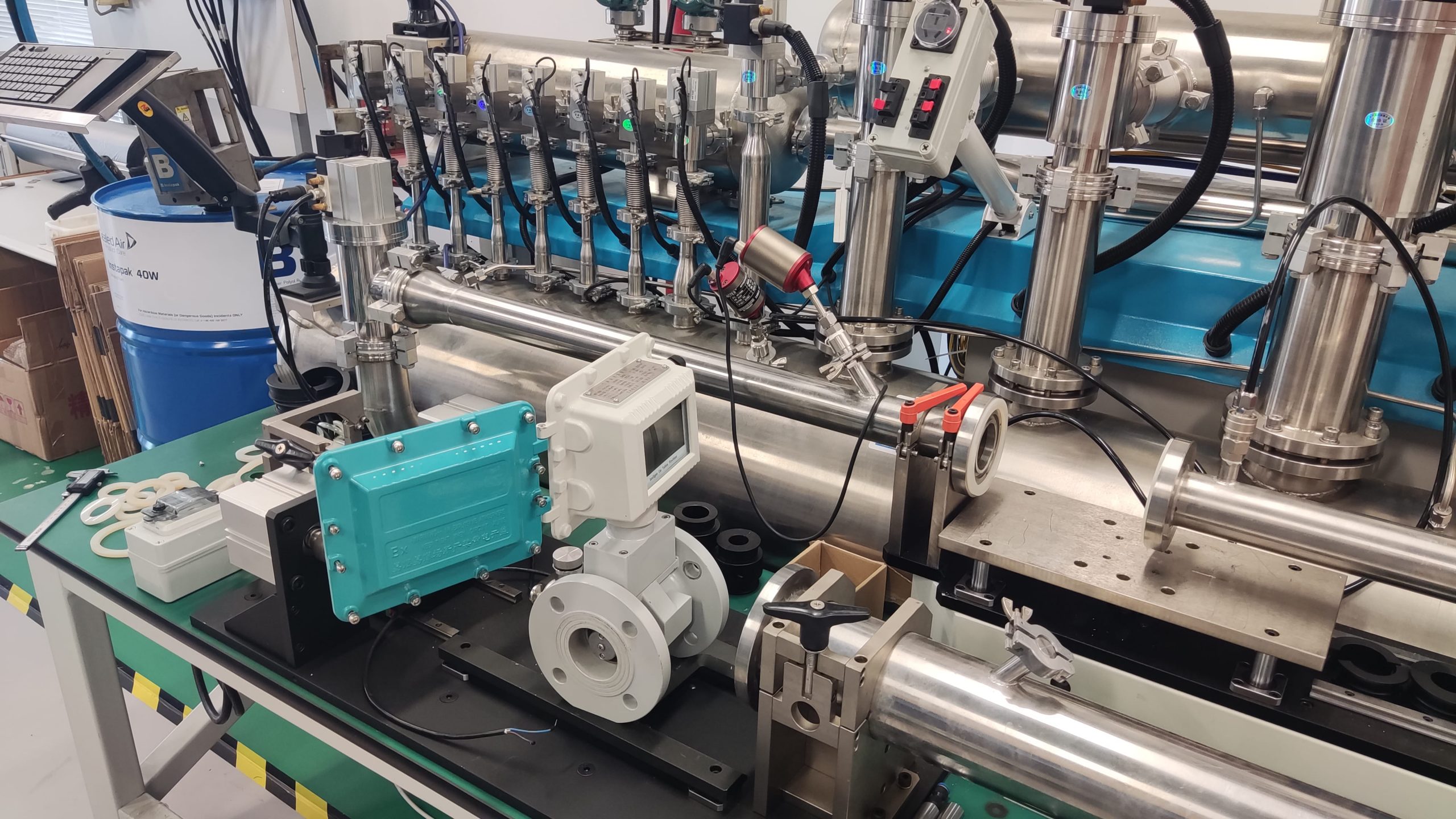

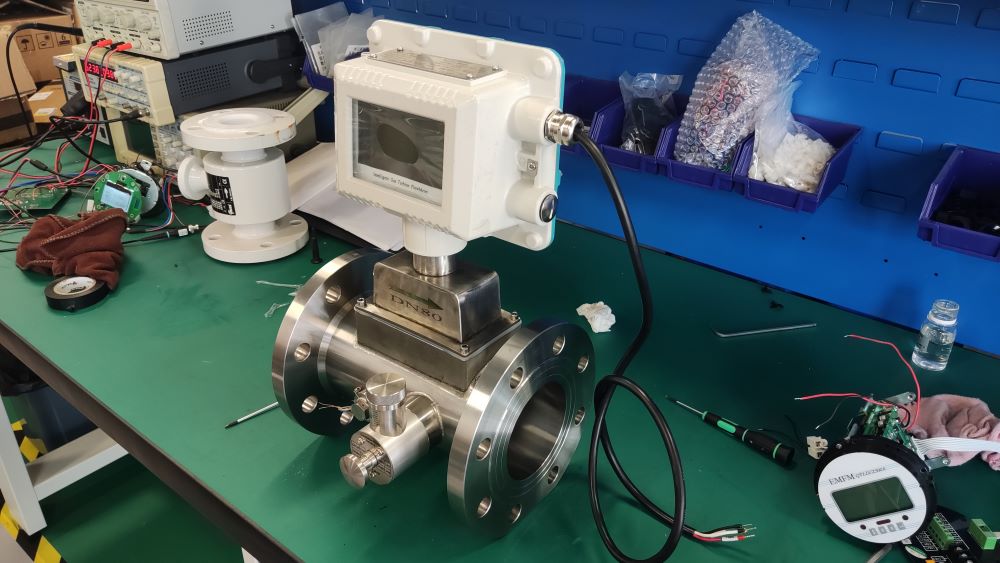

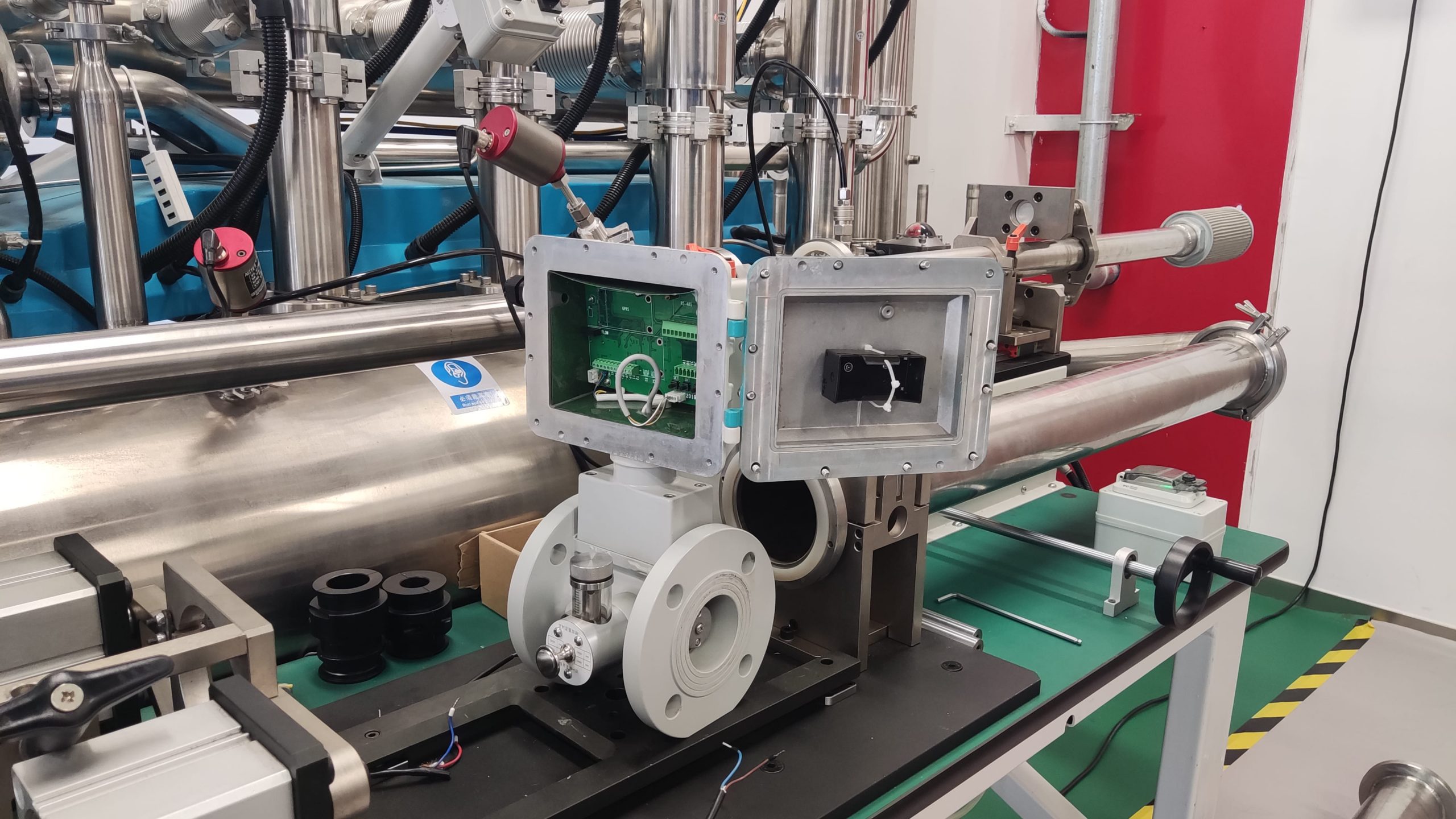

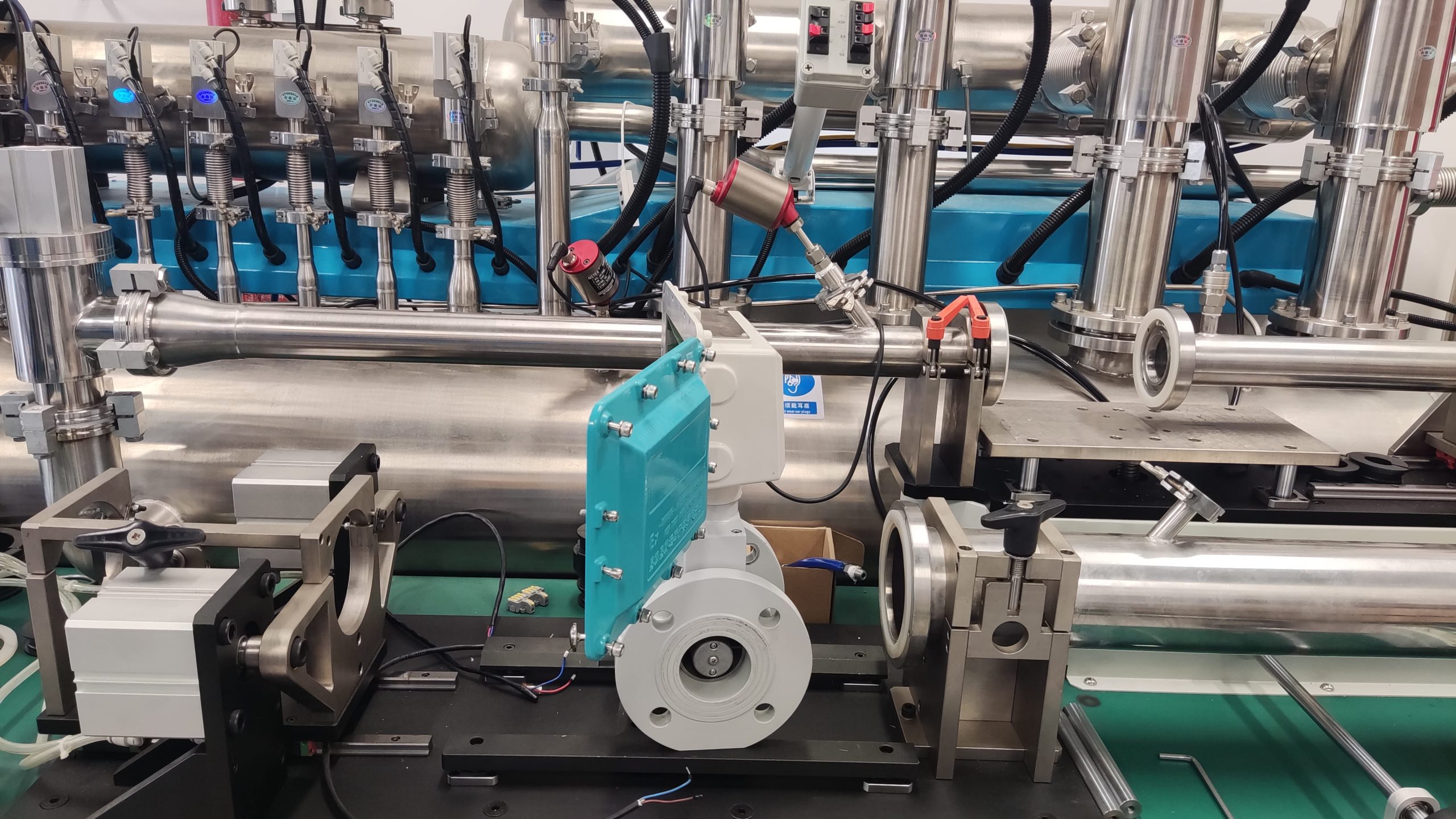

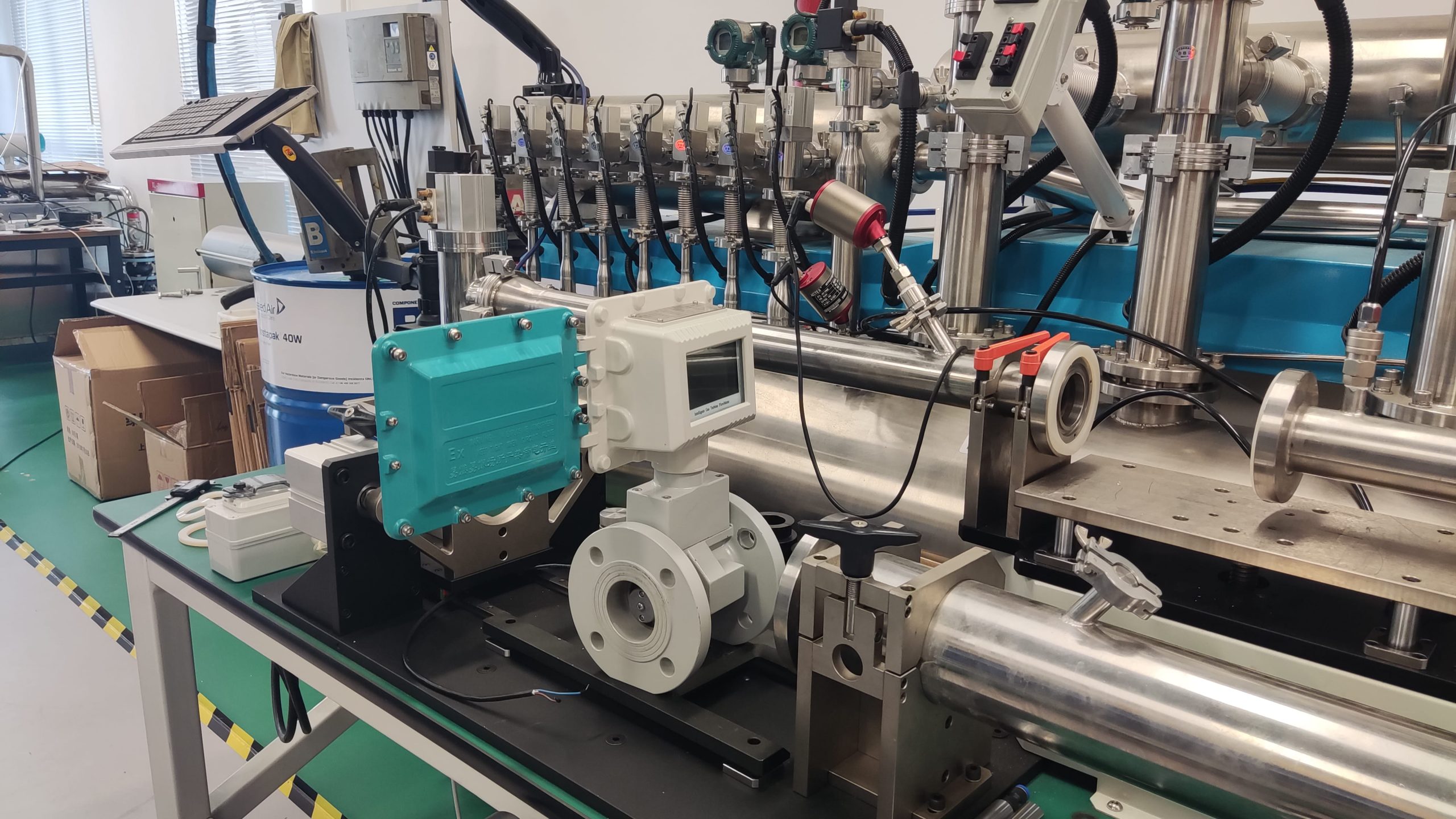

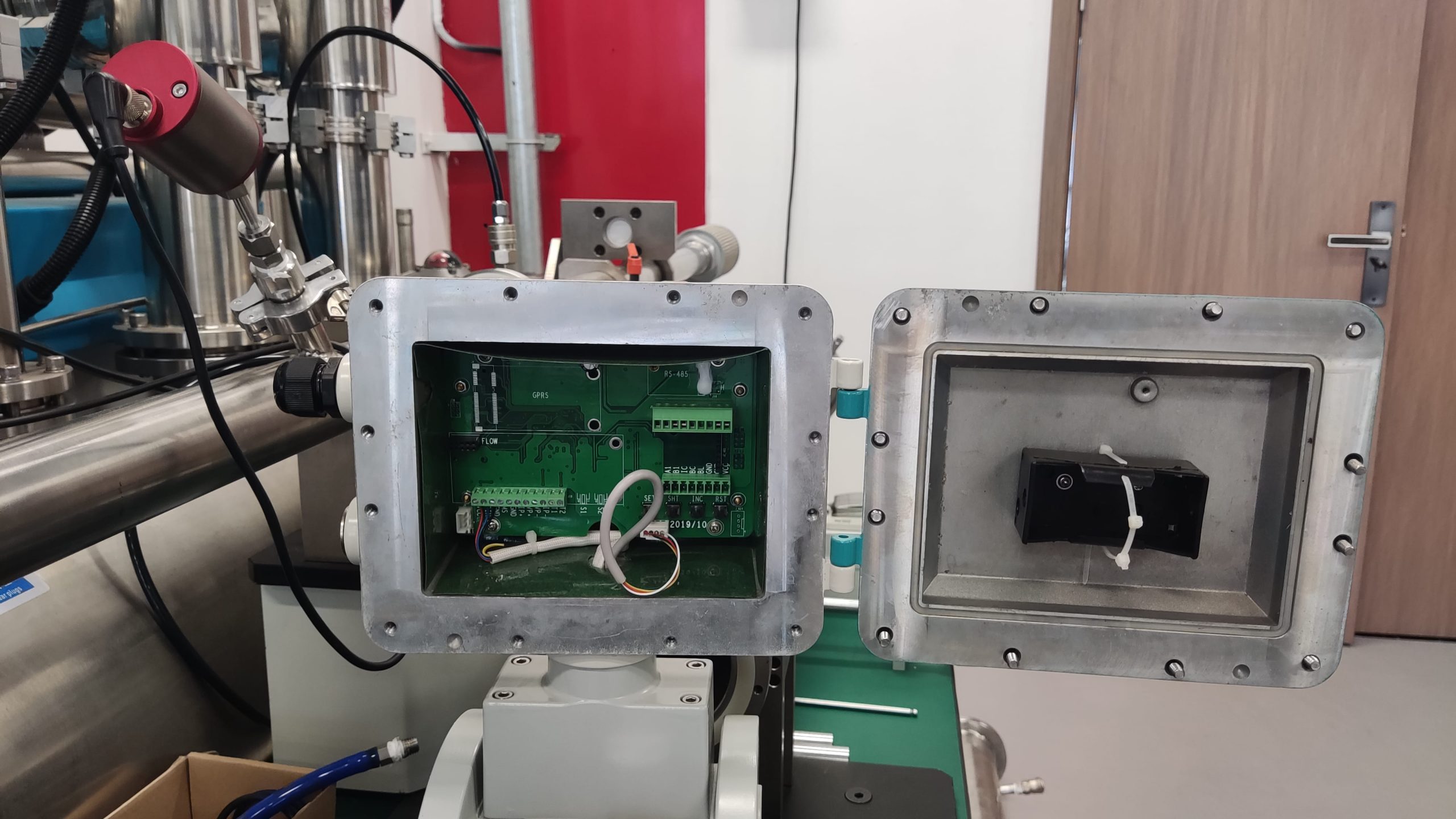

1. In the process of installation and connection of gas turbine flowmeter, each link should be kept accurate, including on-site inspection before installation, wiring of gas turbine flowmeter during installation, system grounding wire, etc., so as to maintain the detection of real data and accurate output.

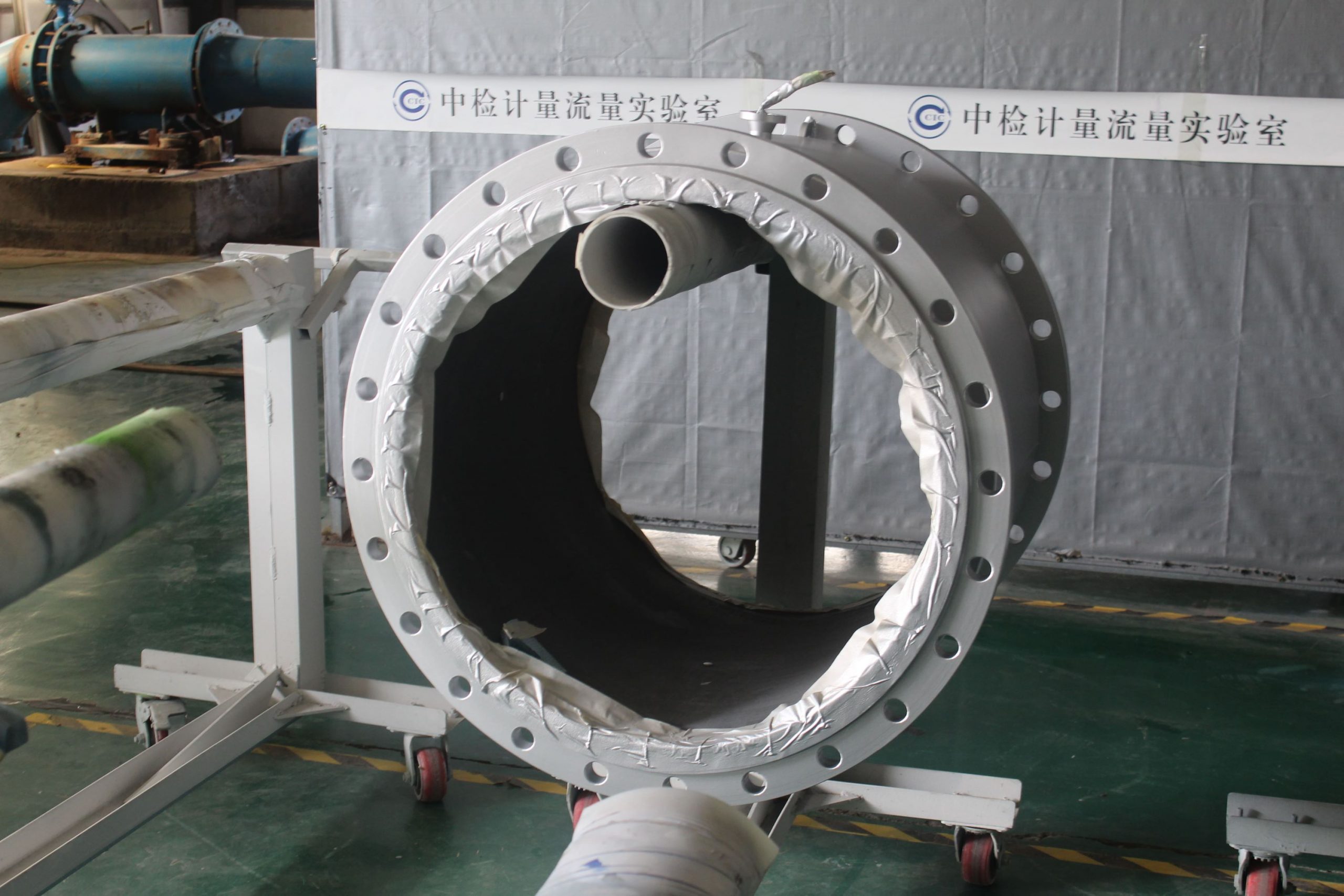

2. For the operating metering system, the “alternative method” can be used to confirm and eliminate the faults of the metering gas turbine flowmeter in operation.

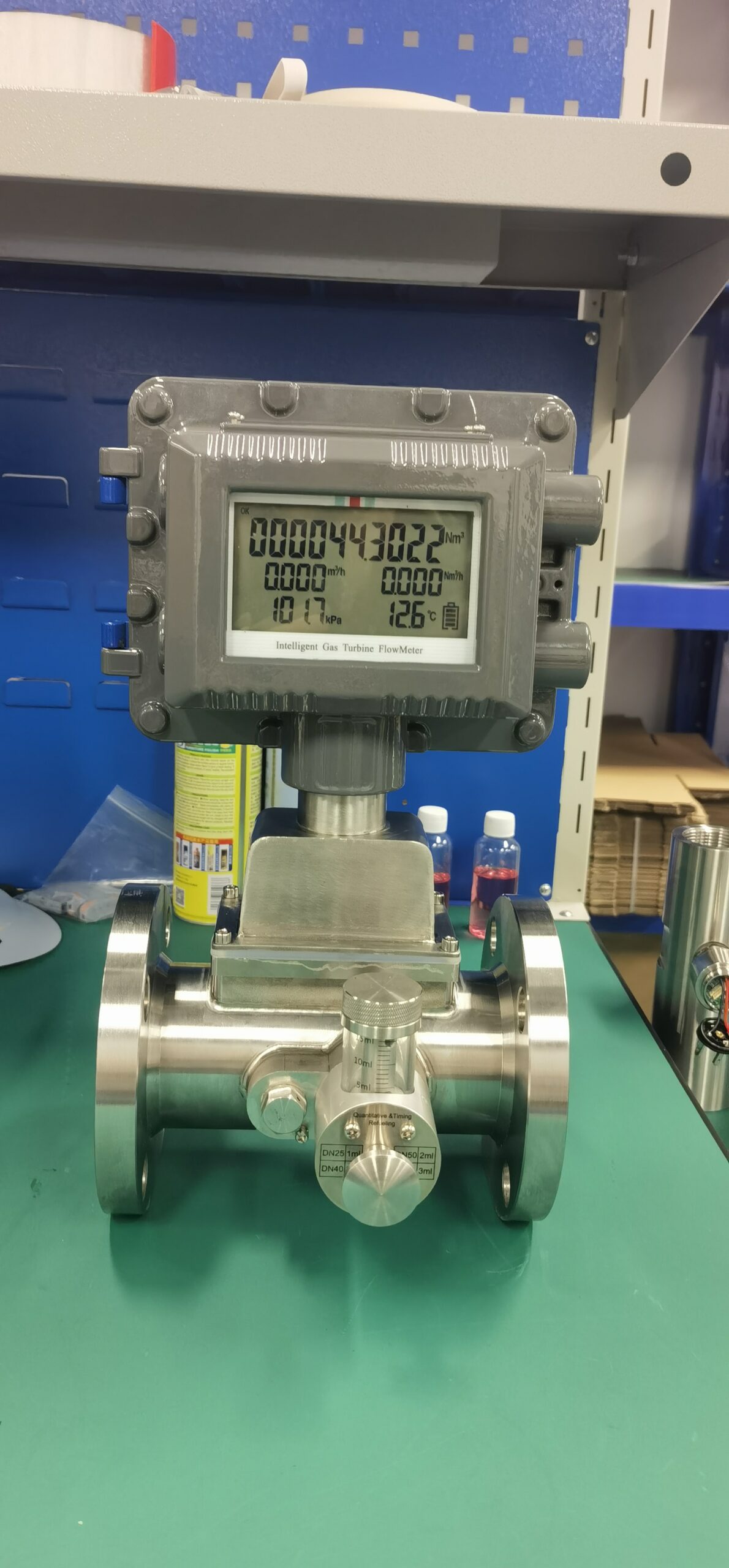

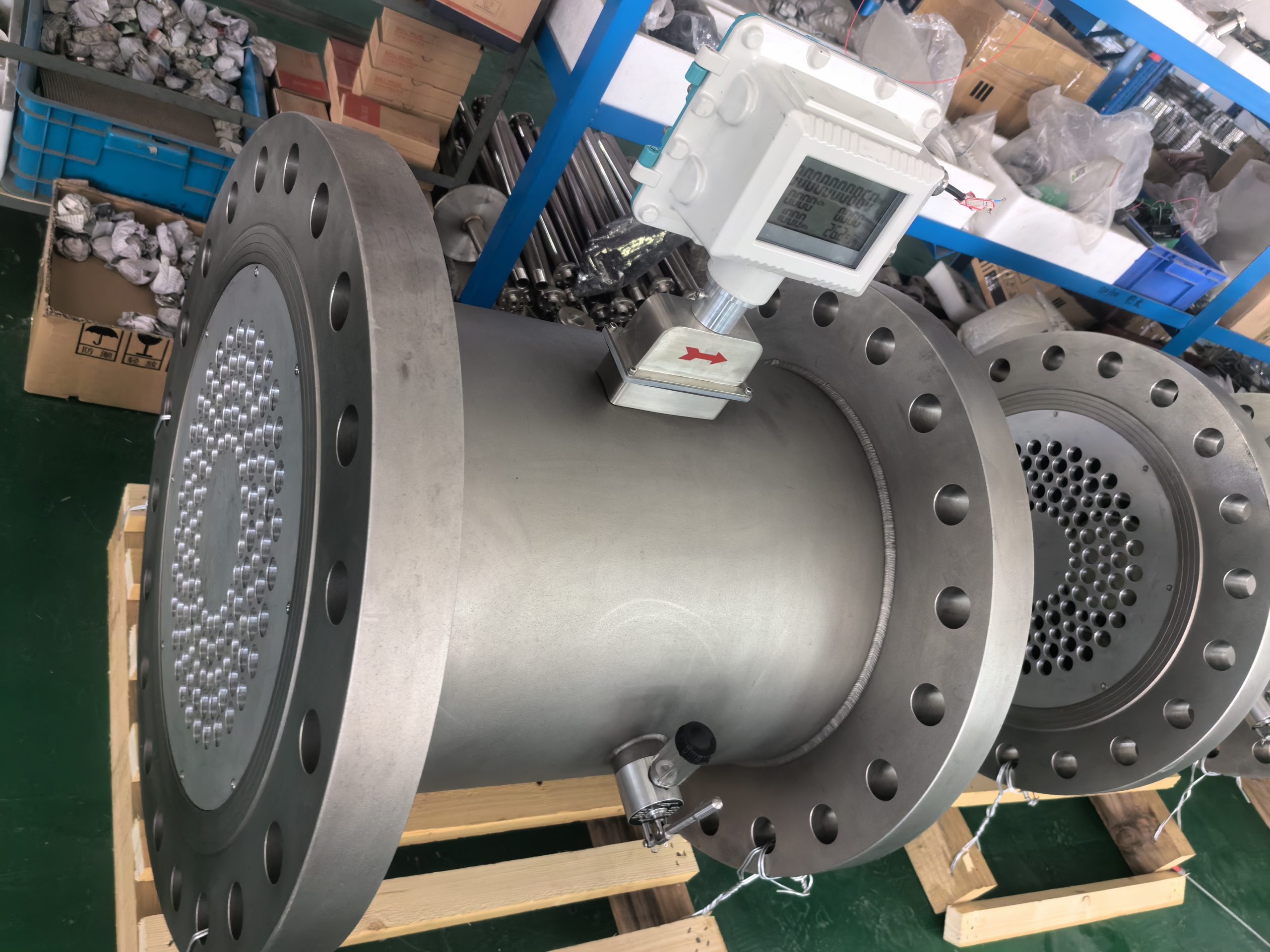

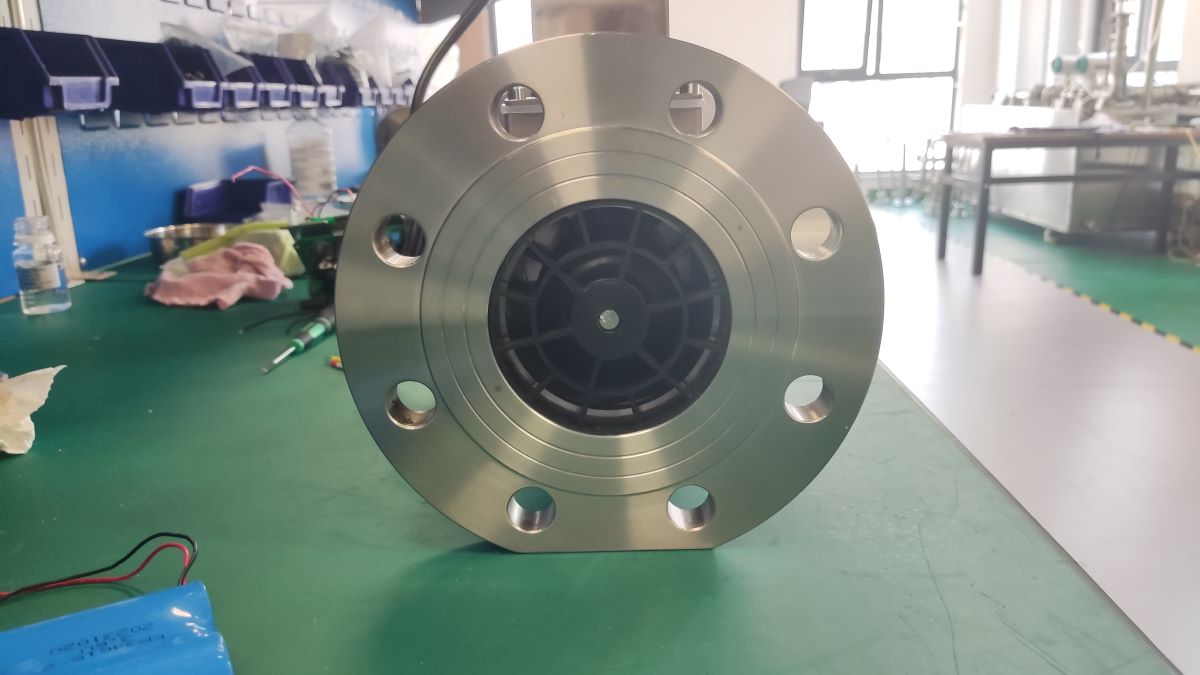

3, the gas turbine flowmeter regularly cleans the gas turbine flowmeter as a whole, and if necessary, the sensing head part of the gas turbine flowmeter can be purged to avoid the condensation of impurities at the sensing head. The addition of heat tracing devices in the metering straight pipe section and the gas turbine flowmeter section in the cold season is also beneficial to remove the condensation of impurities in the metering gas turbine flowmeter.

4, the gas turbine flow meter regularly drains the pipeline, especially the water in front of the straight pipe section, and sets a special person to discharge regularly according to the specific situation, so as to reduce the water in the metering pipe section as much as possible and eliminate the pulsation in the fluid to a greater extent.

5. Strengthen the management of the data of the measurement system and analyze the operation of the gas turbine flowmeter combined with the production situation.