What should be paid attention to in the daily inspection of the electromagnetic flow meter?

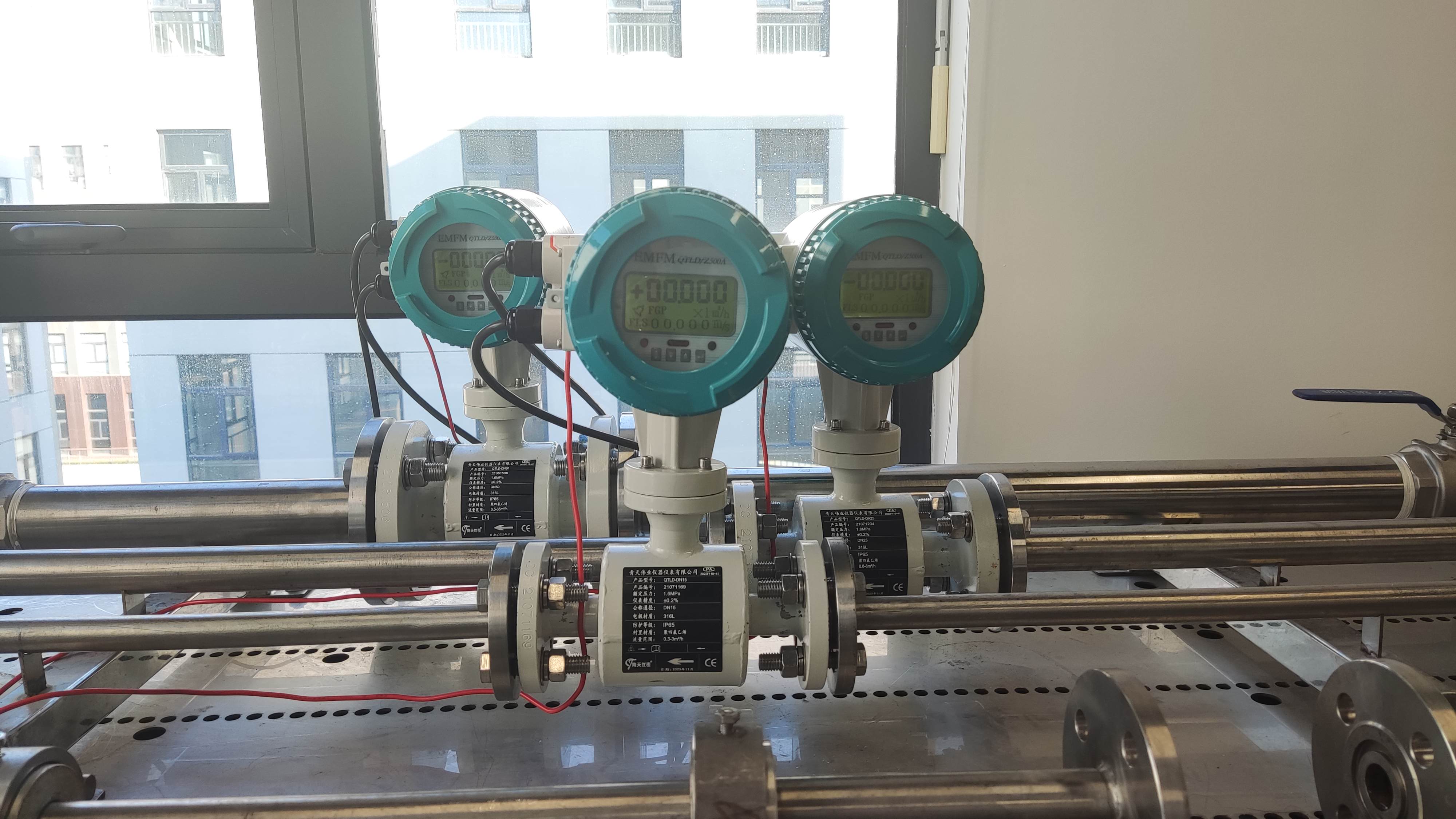

For the daily inspection of the electromagnetic flow meter, in addition to the inspection of the sensor we talked about last time, it is also necessary to check the sensor of the electromagnetic flow meter, connecting cables, etc., below we will understand how to operate.

Complete zero check

The technical requirements of the zero point inspection of the whole machine are: the measuring tube of the flow sensor is filled with liquid and does not flow, and it is not easy for many enterprises in production to meet this condition and give up the zero point inspection and adjustment of the whole machine, but the flow converter can be made a separate zero point inspection and adjustment. Technically speaking, it is only practical when the sensor is checked and the insulation resistance of the sensor excitation circuit and signal circuit is normal, otherwise the whole machine can not operate normally. Usually the single zero of the converter is negative and the value is small; If its absolute value is greater than 5% of the full scale, it needs to be checked first, and then adjusted after the cause is confirmed. Under normal circumstances, the zero point difference between the electromagnetic flowmeter and the converter is less than 1%. There are many cases in which the zero difference value of greater than 5% is caused by incorrect zeroing operation of the user in the case of poor closure of the pipeline valve.

Connection cable inspection

To connect cables, check the conduction and insulation resistance of each core of the signal and excitation cables, and check whether the grounding of each shield layer is intact.

Converter check

The converter is checked by using a common instrument and an analog signaler matching the flow meter model to provide the flow signal instead of the sensor for zeroing and calibration. Calibration includes zero point check and adjustment, set point check, excitation current measurement, current/frequency output check, etc. It should be noted that the check value (or factory value) of the check item should be compared with the last time to analyze whether it has changed or whether the change meets the original measurement requirements.

-.jpg)