What role does the thermal gas mass flowmeter play

Thermal gas mass flowmeter is the use of fluid flowing through the pipe heated by an external heat source when the temperature field changes, is a high-sensitivity, high-precision gas measurement instrument, in the gas flow measurement conditions, good stability, used for gas process control and gas flow measurement one of the most used instruments.

Design principles of thermal gas mass flowmeter manufacturers

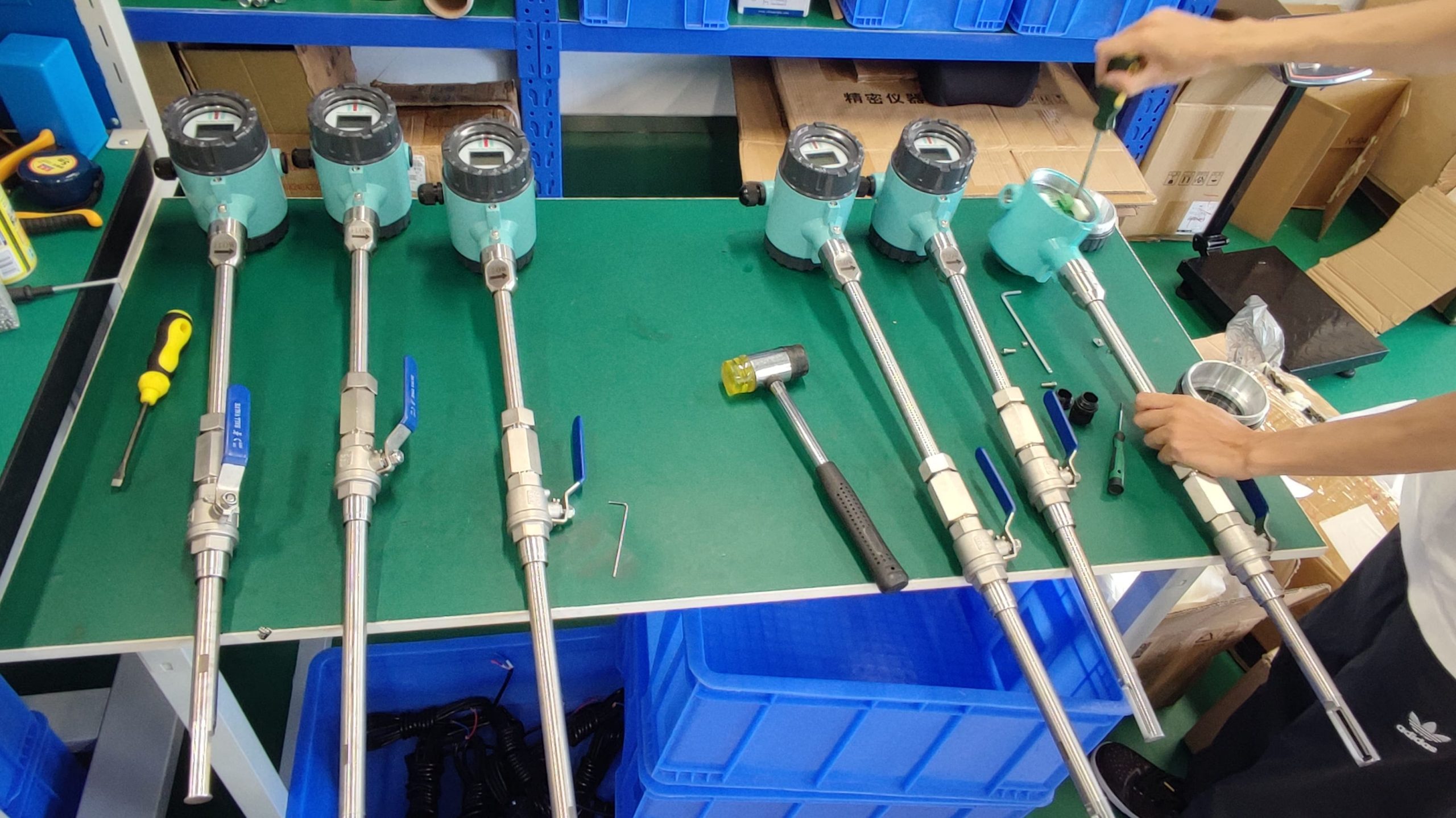

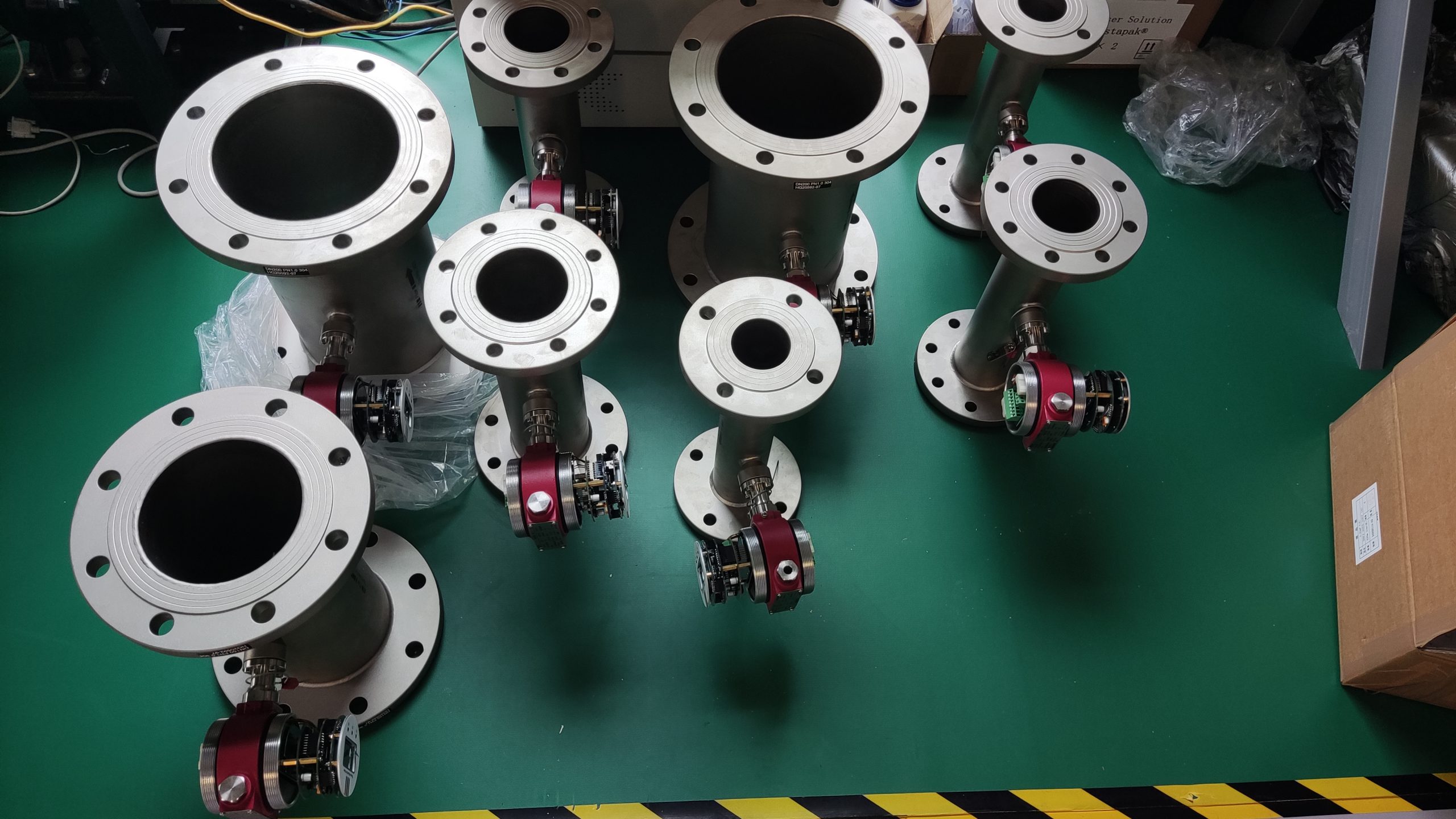

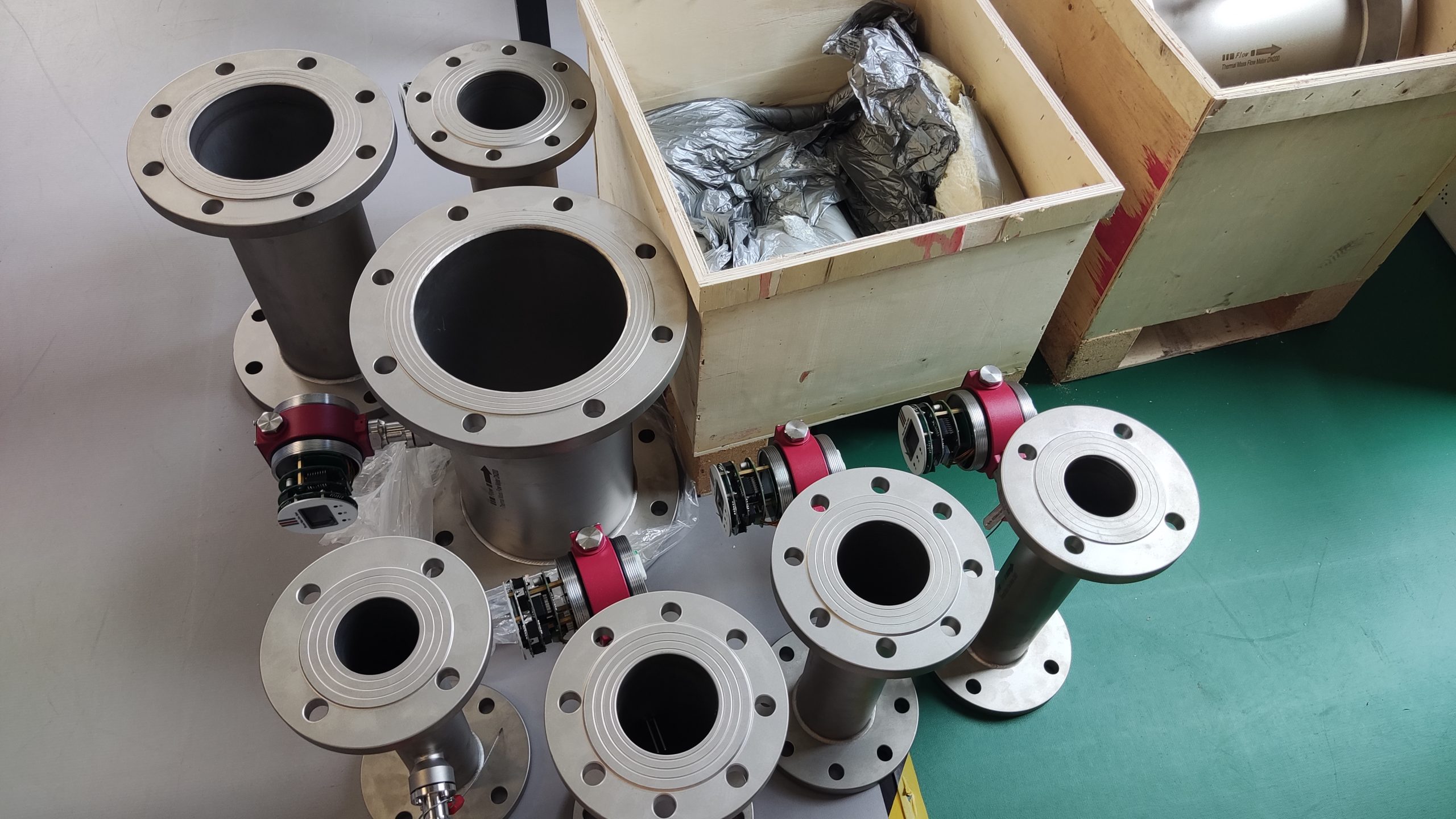

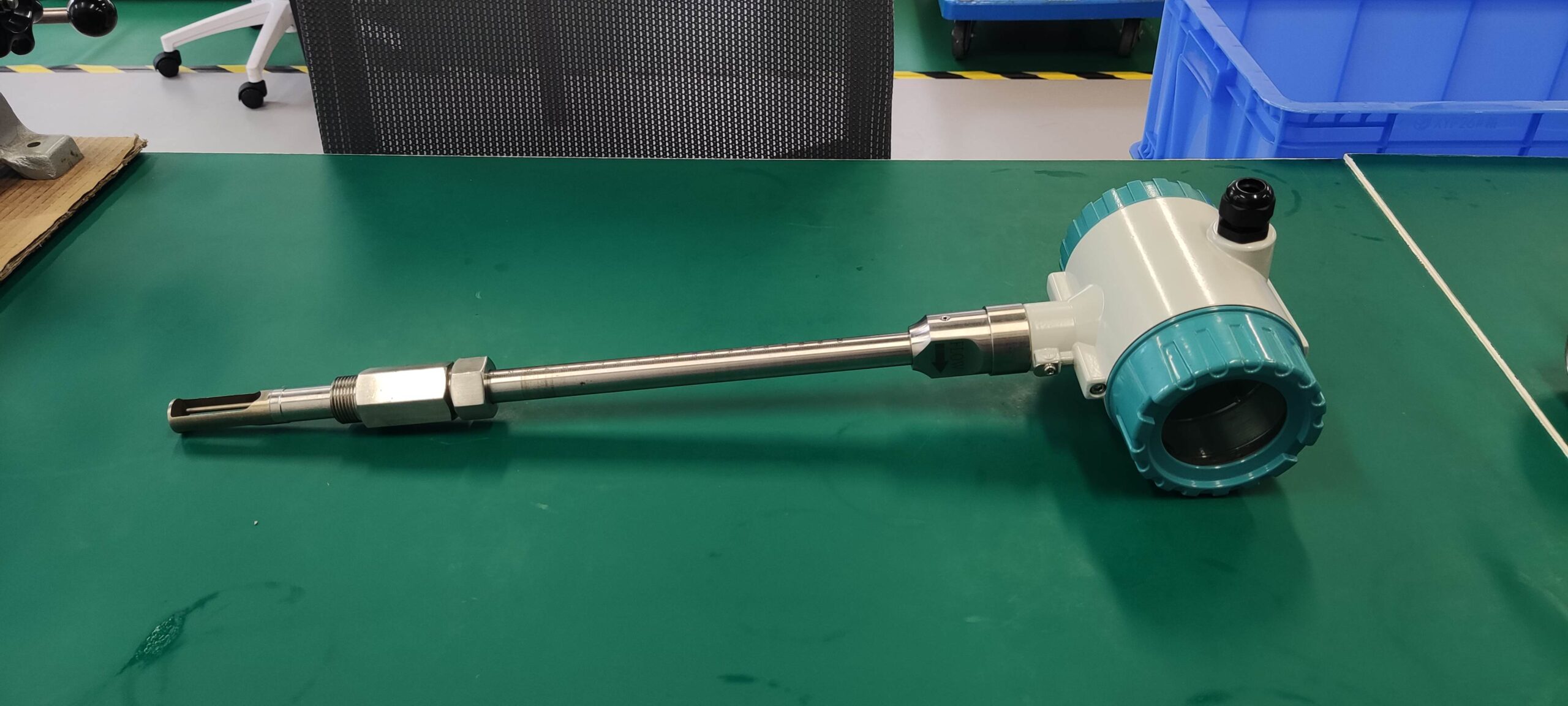

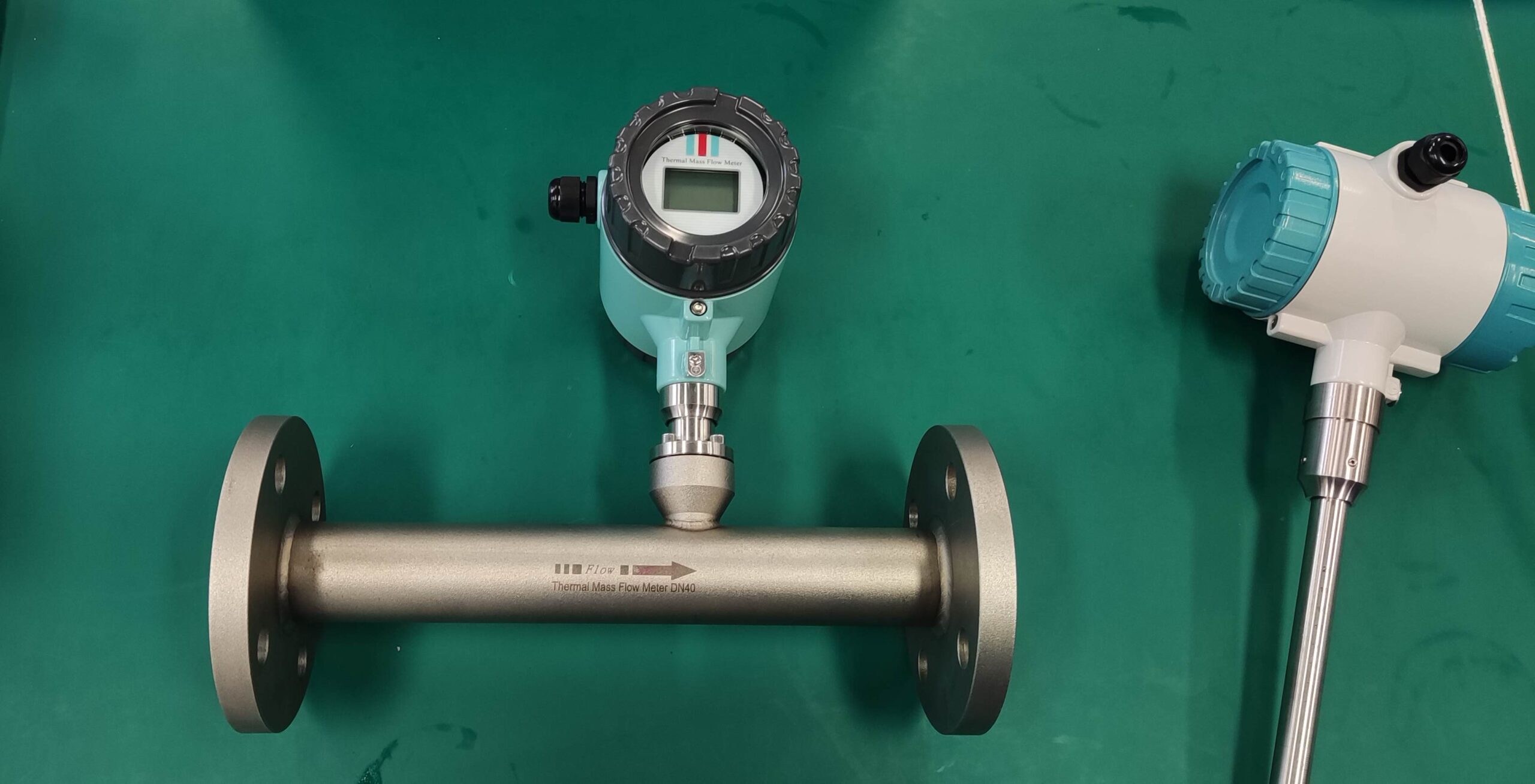

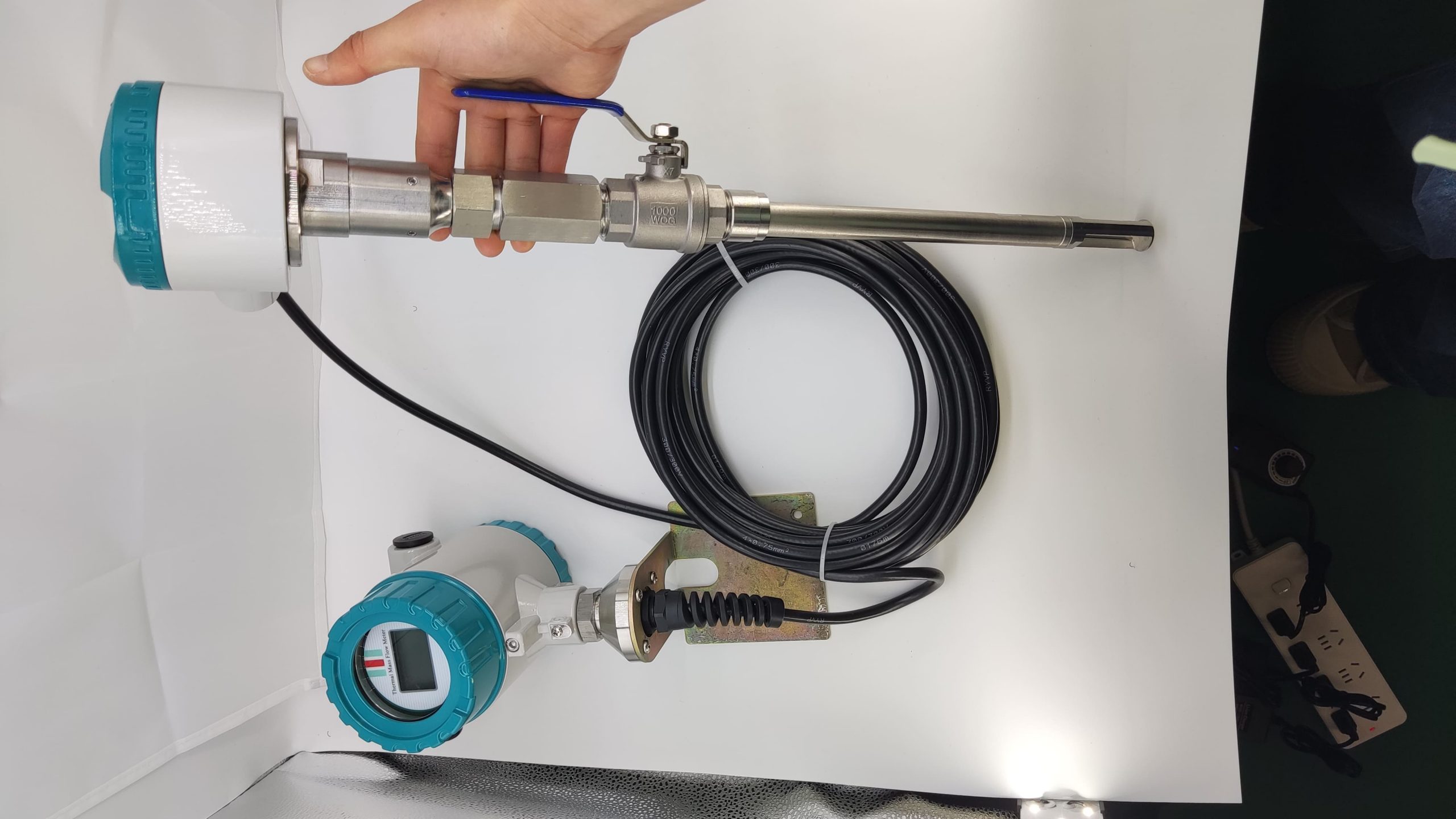

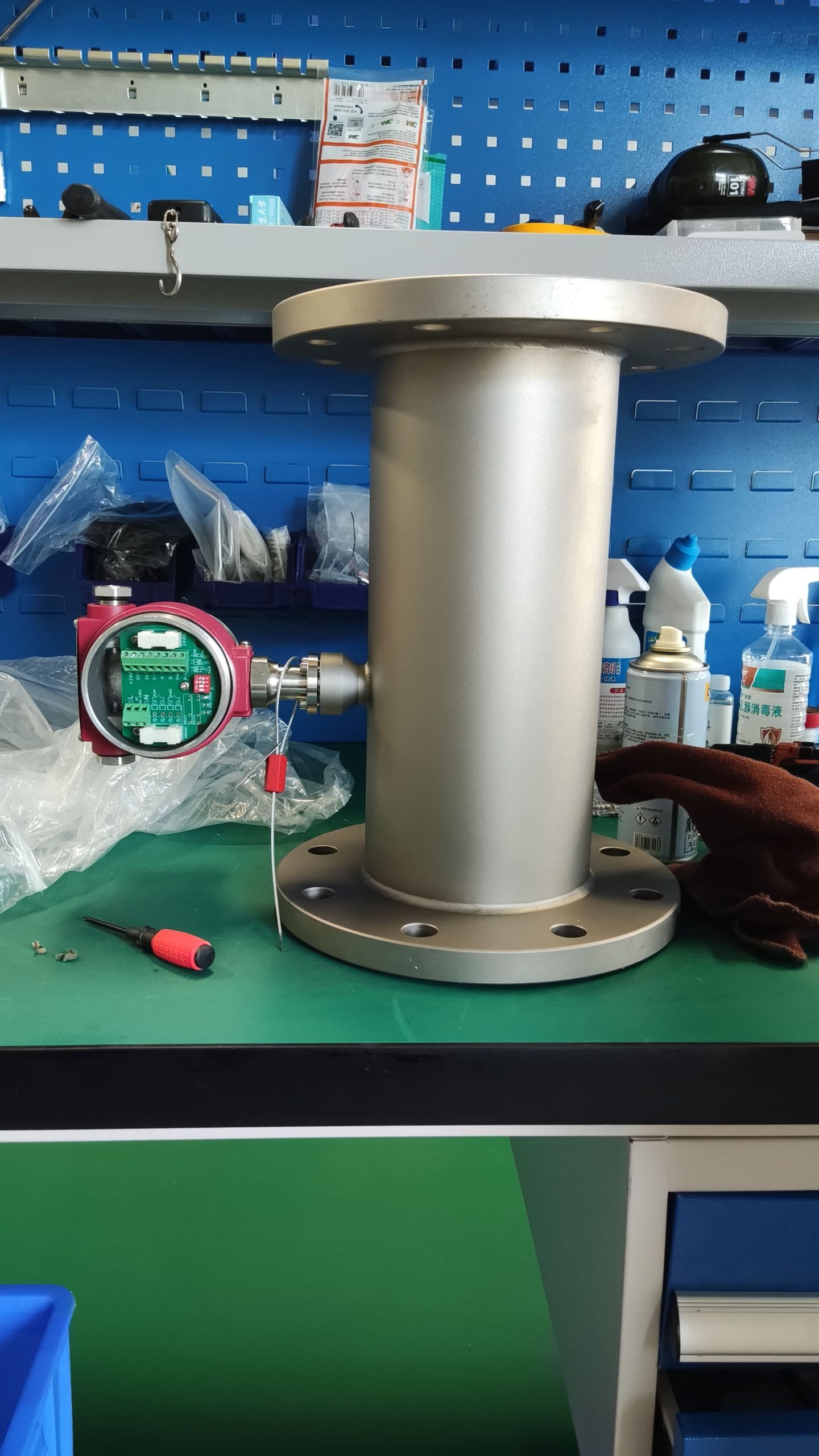

Thermal gas mass flowmeter is used to weigh heat flowmeter in China, composed of sensors and transmitters, sensors have two ways, namely straight-through and plug-in. When measuring large pipe diameter, generally choose insert type; When the diameter of the process pipe is small, the straight-through type is generally selected. Either way, the temperature constant heat source and detection element are not directly in contact with the fluid medium, sealed inside the sensor, so the heat and temperature measurement element will not be damaged, the flow meter can be used for a long time, but also make the user’s maintenance and low.

The relationship between temperature difference and flow rate is as follows: Pv=K(Q/△T), where v is the fluid velocity m/h), p is the fluid density (kg/m3), Q is the heat flow rate (J/h), K is the calibration constant, and △T is the temperature difference (℃). It can be seen from the above formula that the function of gas flow rate and heat dissipation capacity is directly related to the mass flow rate, which is the basic principle formula of the thermal gas mass flowmeter. We can carefully verify the relevant data through these formulas, and thus obtain the mass flow rate. The early TMF directly put the heating coil and temperature measuring element into the fluid and the fluid is in direct contact with the contact flowmeter. Because it can not solve the problems of corrosion, wear and explosion protection, its industrial application is greatly limited.

With the development of science and technology, through the redesign of the flow meter structure, on the basis of the contact flow meter, people put forward the immersion TMF, which has also been rapidly developed and can be used to measure the gas flow of larger diameters.

Thermal gas mass flowmeter: an instrument that uses the principle of heat transfer to measure flow, that is, an instrument that uses the heat exchange relationship between the flowing fluid and the heat source (the heated object or measuring tube in the fluid plus a hot body) to measure flow. In the past, China used to call the thermal flowmeter.

According to the manufacturer, the basic principle is to measure the gas flow rate by measuring the cooling effect of the gas flowing through the heating element in the flow meter. The measuring section through which the gas passes has two thermal resistance elements, one of which acts as a temperature detector and the other as a heater. The temperature sensor is used to detect the temperature of the gas, and the heater maintains a constant temperature difference between its temperature and the temperature of the measured gas by changing the current. As the gas flow rate increases, the cooling effect increases and the current required to keep the temperature between the thermal resistors constant increases. This heat transfer is proportional to the gas mass flow, that is, there is a corresponding functional relationship between the power supply current and the gas mass flow to reflect the gas flow.