What failure will occur during the debugging of electromagnetic flow meter

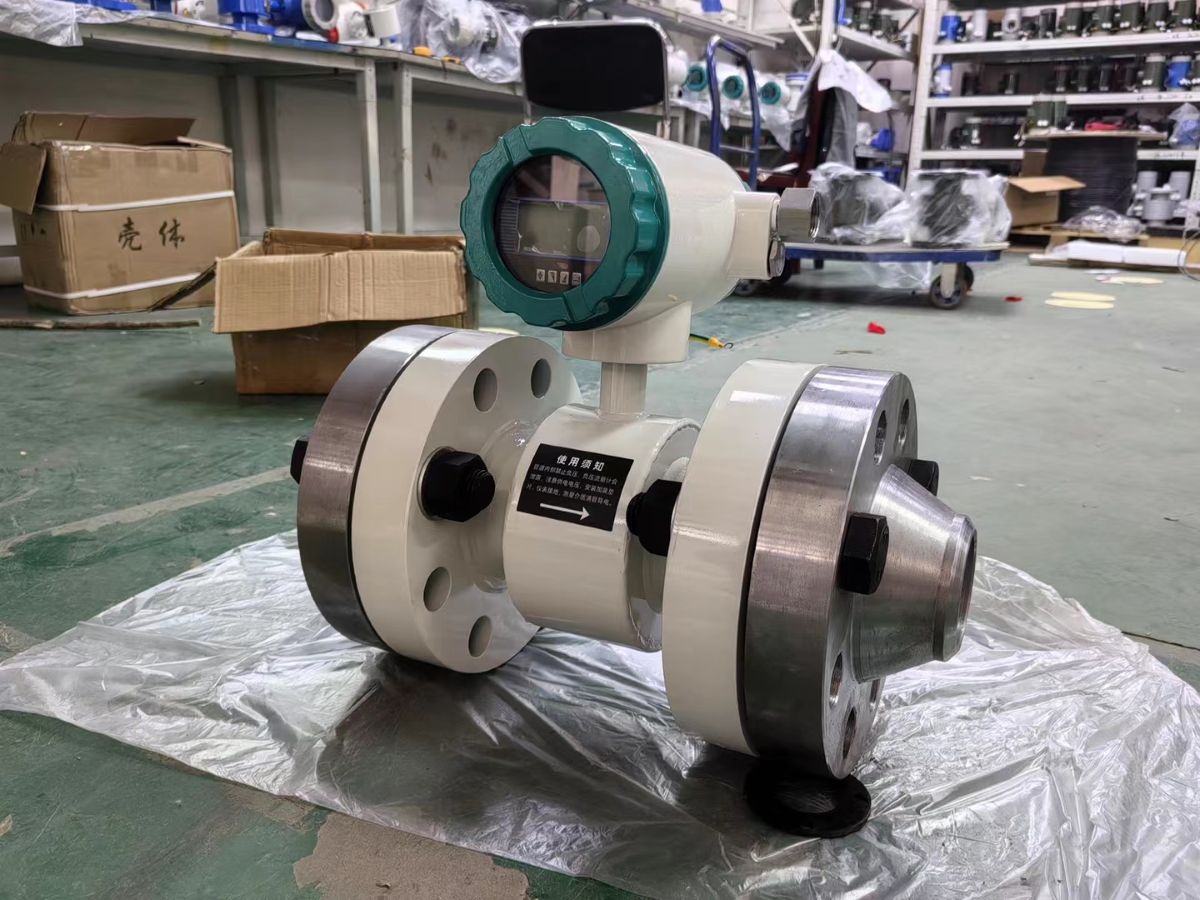

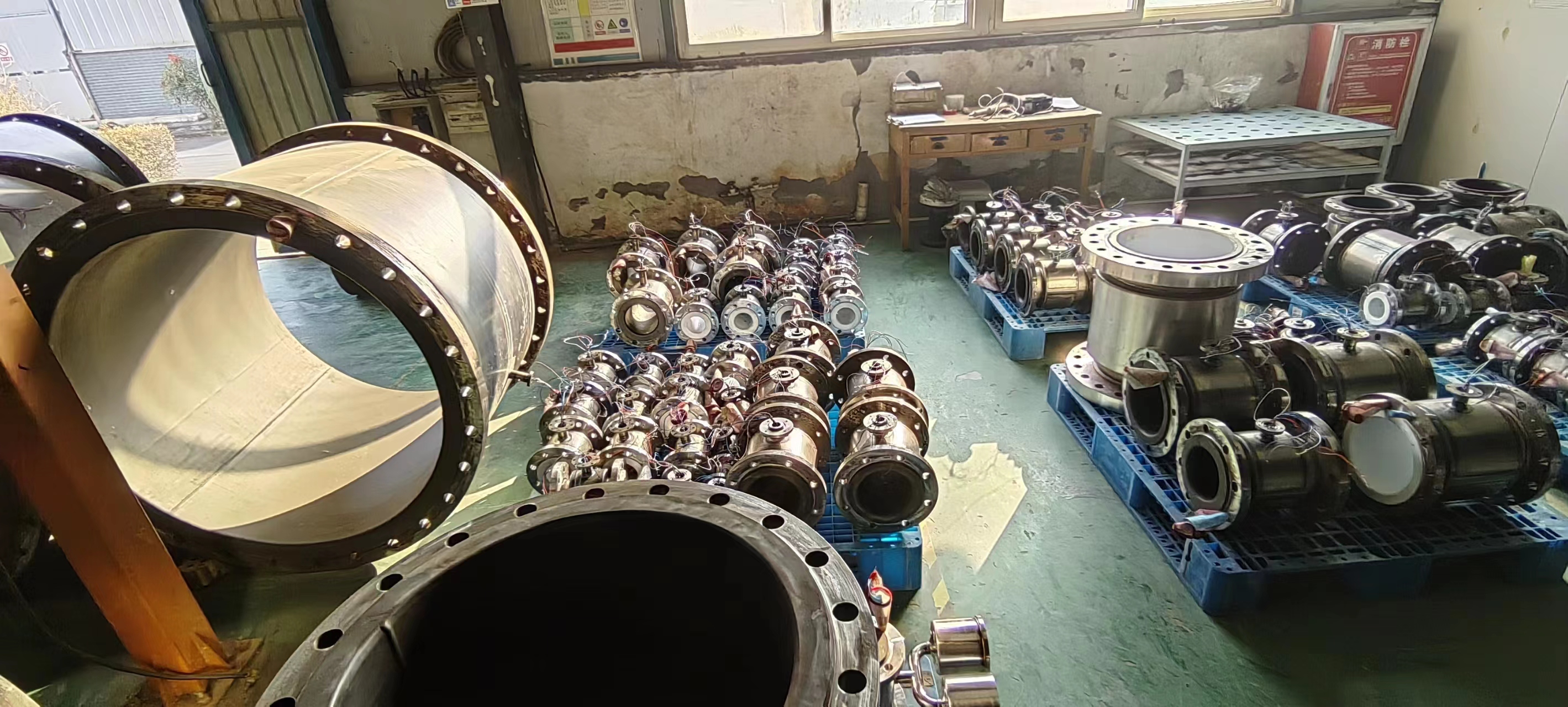

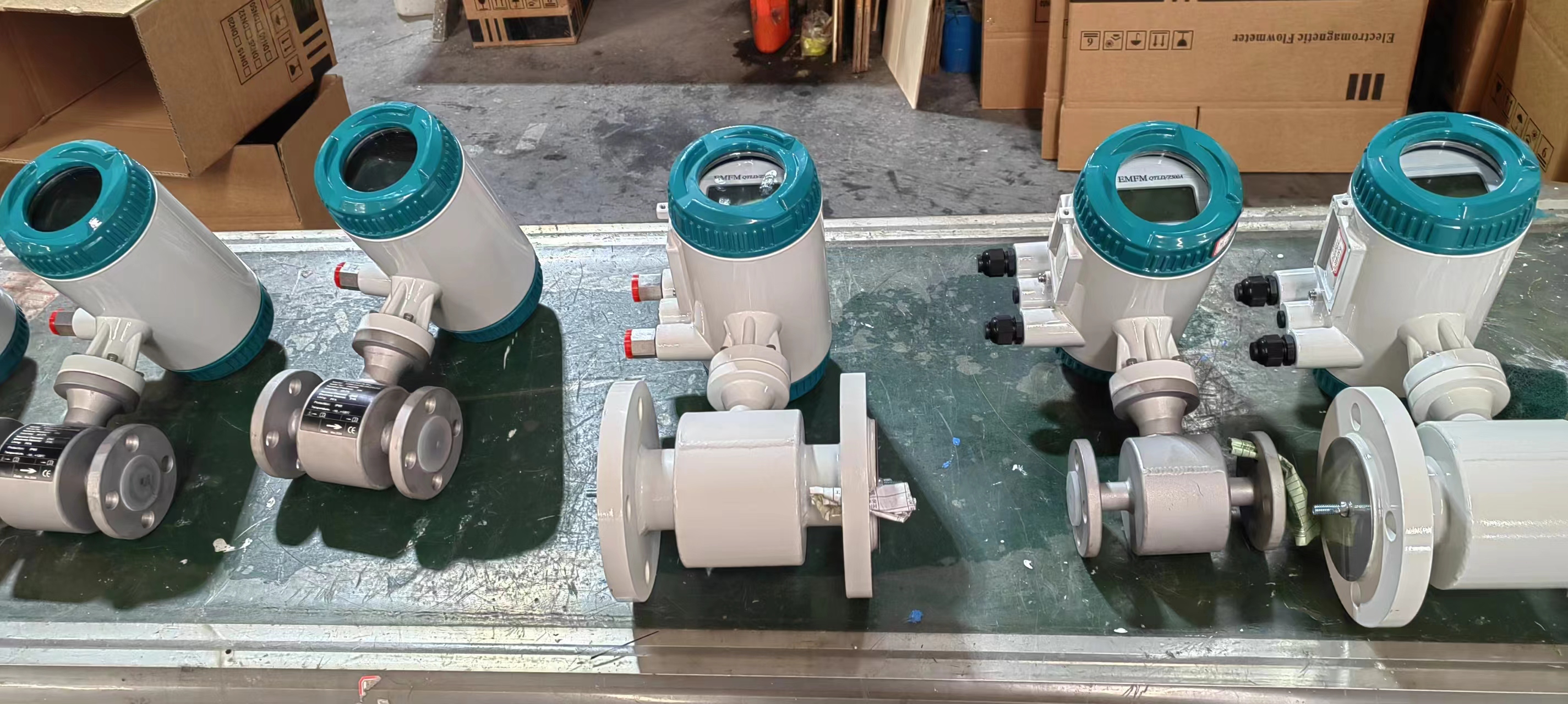

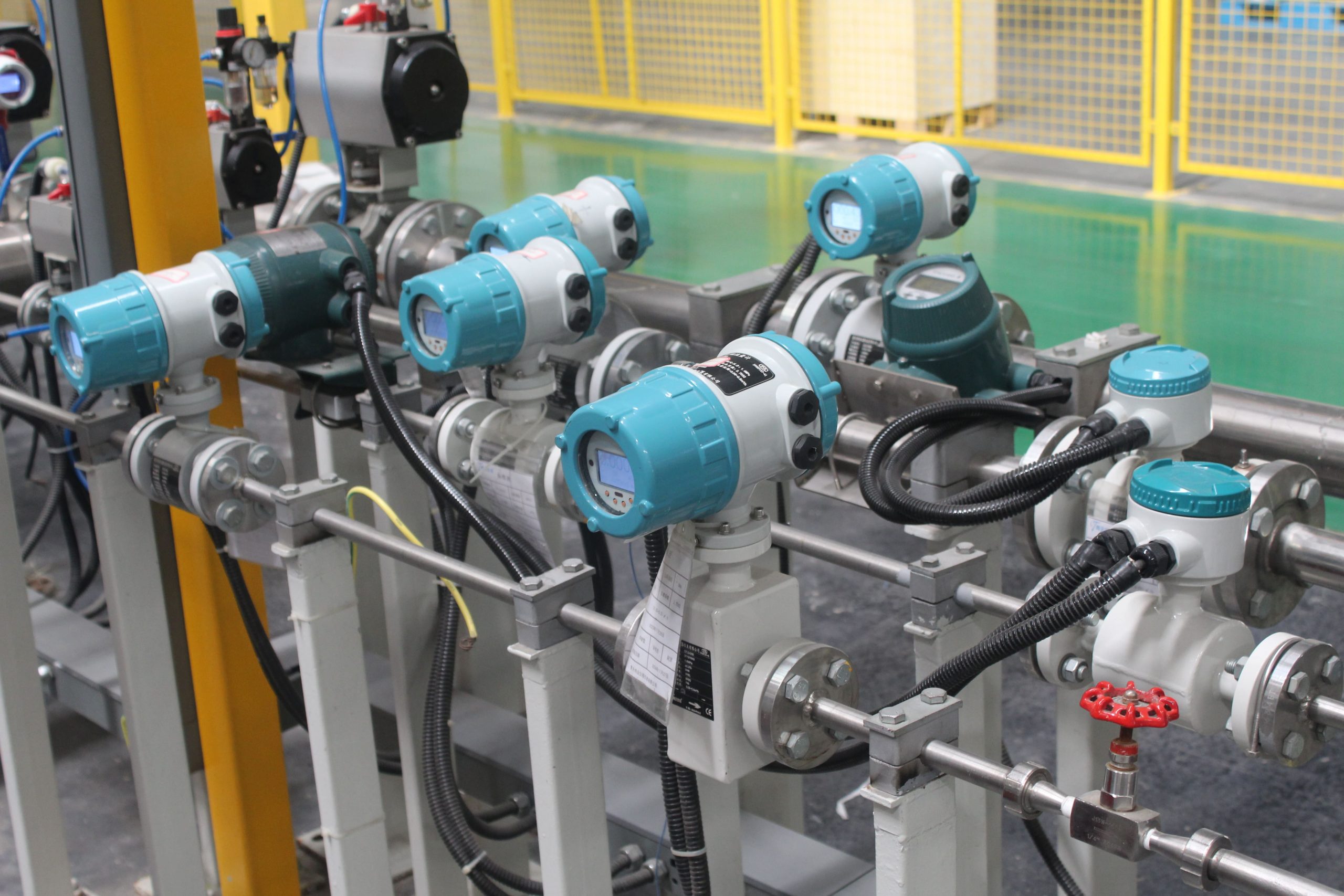

What fault will occur during the debugging period of the plug-in electromagnetic flowmeter, the split electromagnetic flowmeter and the initial debugging fault, but once the fault is improved, it will generally not occur again under the same conditions.

What fault will occur during the debugging period of the plug-in electromagnetic flowmeter, the split electromagnetic flowmeter and the initial debugging fault, but once the fault is improved, it will generally not occur again under the same conditions. Common failures and installation and commissioning period mainly, environmental interference, the influence of fluid characteristics, three reasons.

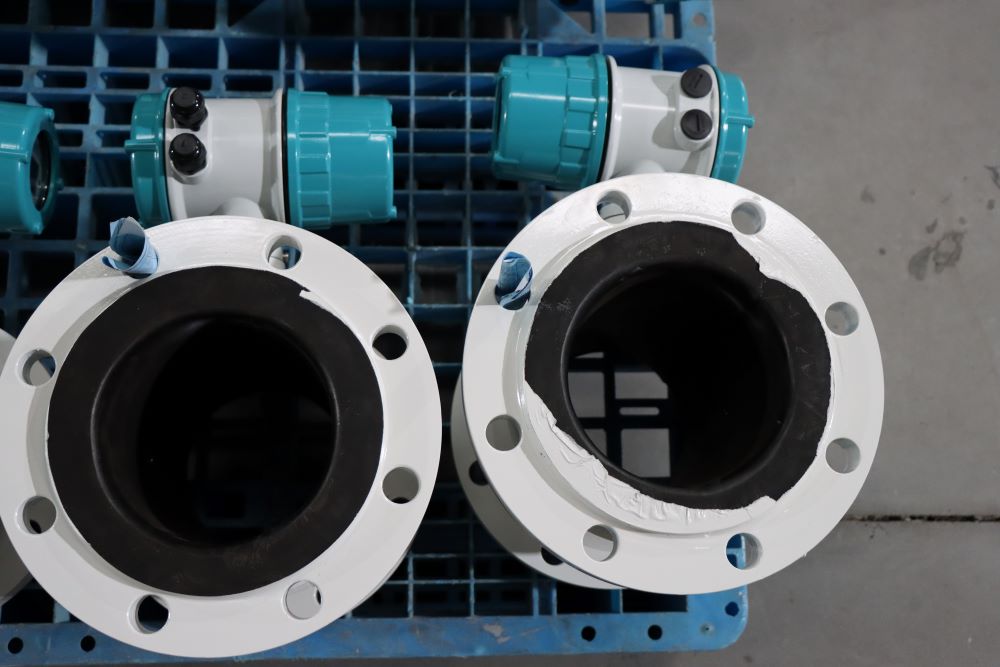

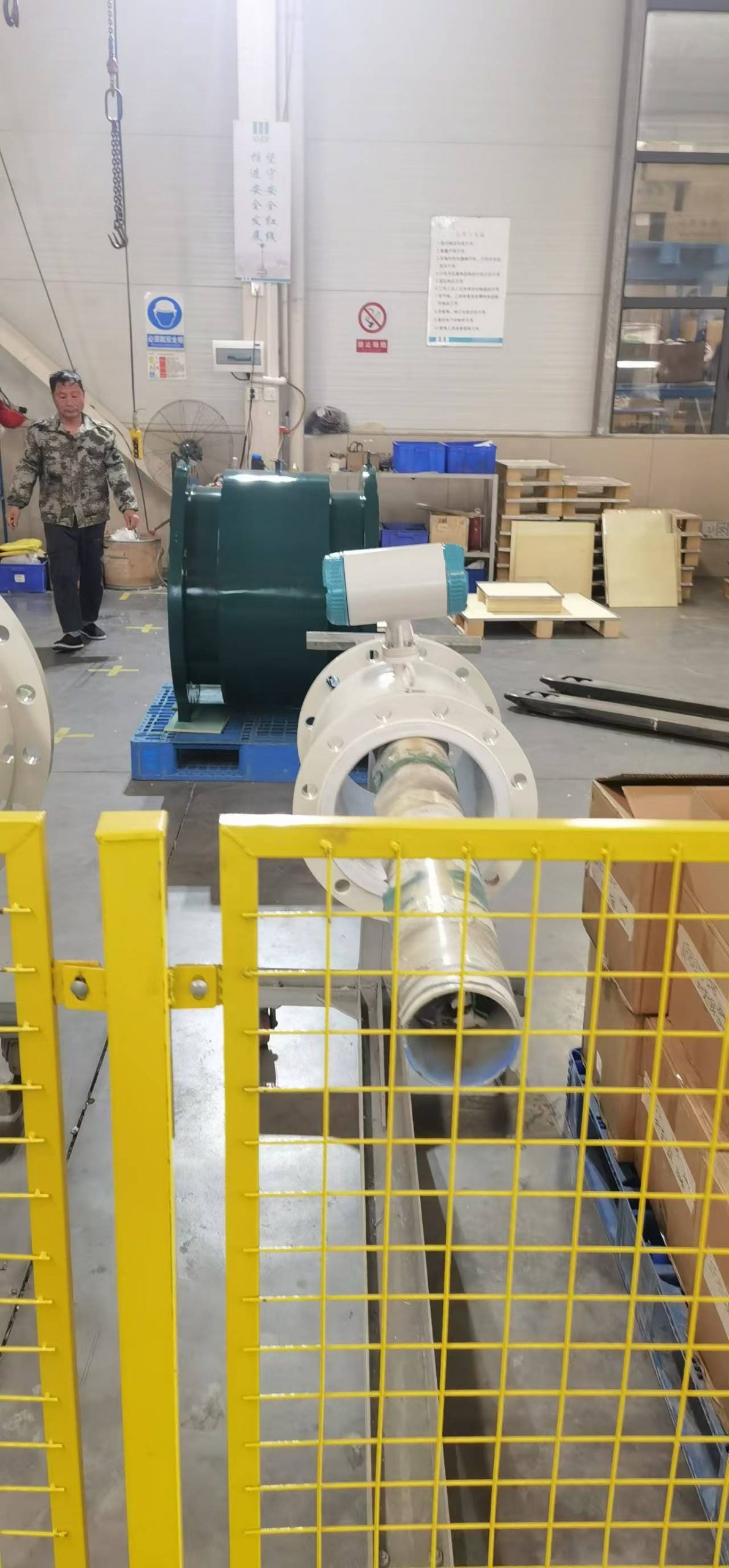

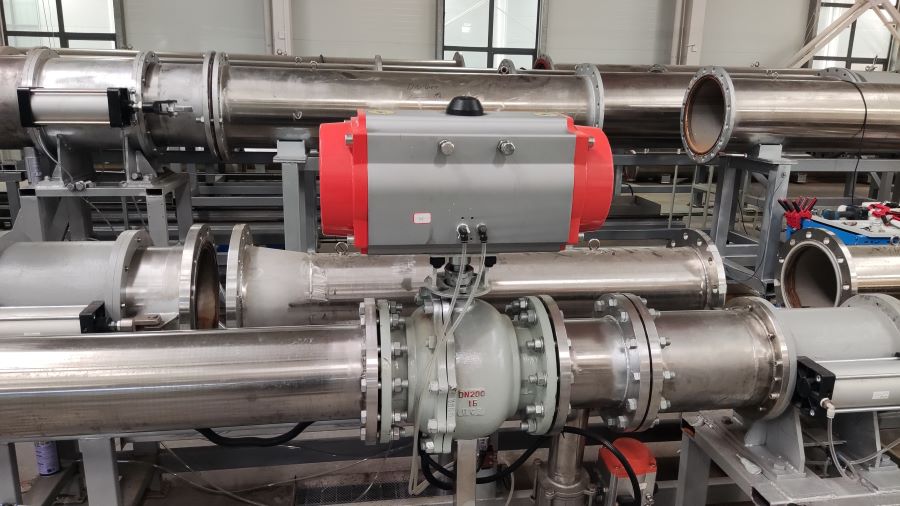

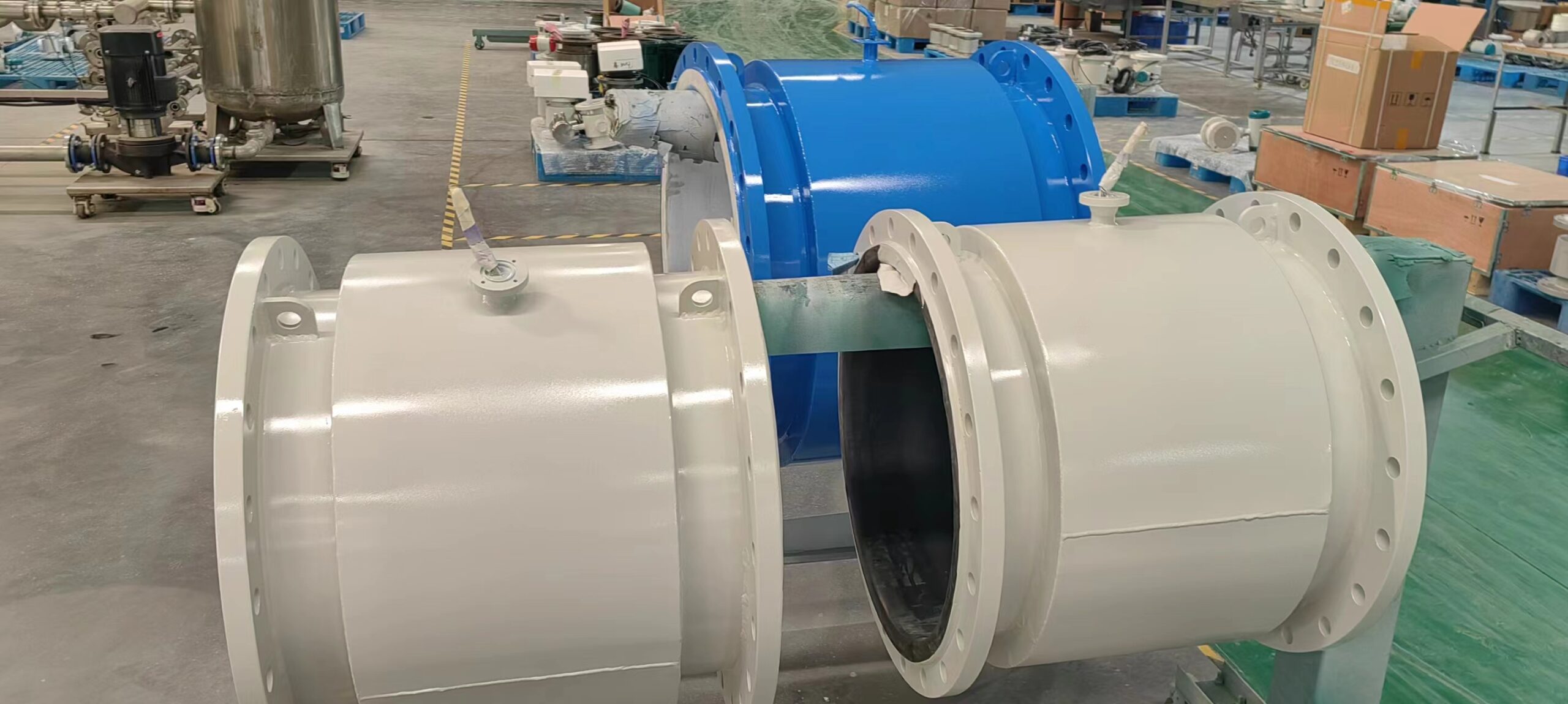

Pipeline system installation, etc., the usual electromagnetic flow sensor installation position is not correct fault, common such as flow sensor installation in the natural gas pipeline network to facilitate the accumulation of high retention; The flow sensor does not have any pressure, and the liquid is directly discharged into the atmosphere to form a complete measuring tube; Installed in the vertical line due to dirty, may appear empty, installation flowmeters are special because of the potential underwater to ensure that there is no floating.

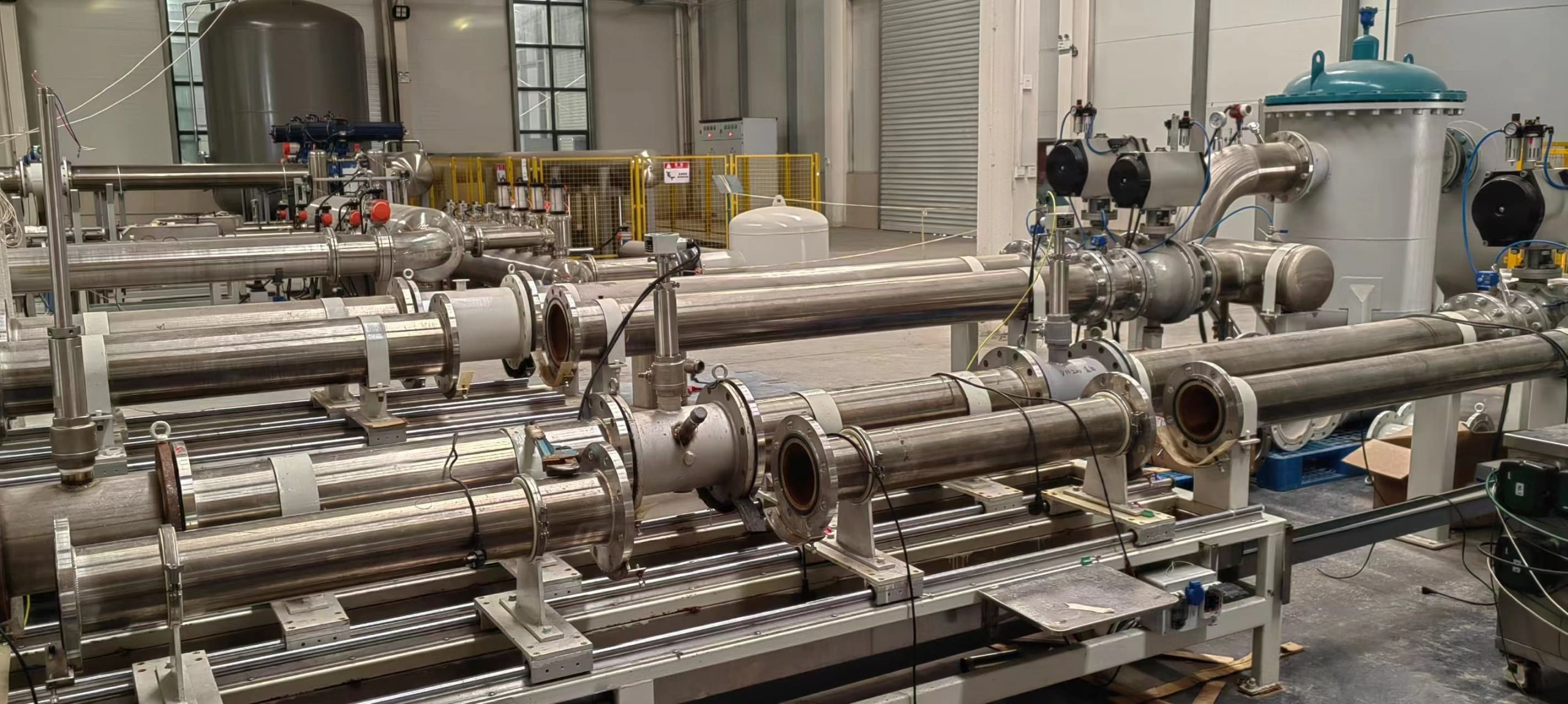

Environment, main pipe stray current interference, space electromagnetic wave interference, large motor magnetic field interference, and other pipe stray current interference usually take good grounding protection can be satisfactorily measured separately, but in the case of pipe with strong stray current (such as electrolytic workshop line) can not be overcome, should take flow sensor and pipe edge unique measures. Electromagnetic wave – space signal cable introduction, usually single or multiple shielding protection, but also encountered shielding protection is insurmountable.

Fluid liquids containing tiny bubbles are usually evenly distributed and do not affect normal measurement, only the volume flow of liquid and gas combined; The bubble will increase the fluctuation of the output signal, if the large bubble covers the entire electrode surface of the flow through the electrode, so that the electrode signal is instantly disconnected from the circuit, the output signal will produce a large fluctuation.

The low frequency (50/16 HZ-50/6 hz) rectangular wave exciting split electromagnetic flowmeter will produce noise when measuring liquid containing solids in more than a certain amount of slurry, and the output signal will also fluctuate to a certain extent.