What are the selection factors of gas turbine flow meter?

Customers choose flow timing selection for the site is a very important step, need to consider the actual conditions of the site to choose the more appropriate metering instrument, the following small series and share with you about the selection of gas flow meter need to consider factors:

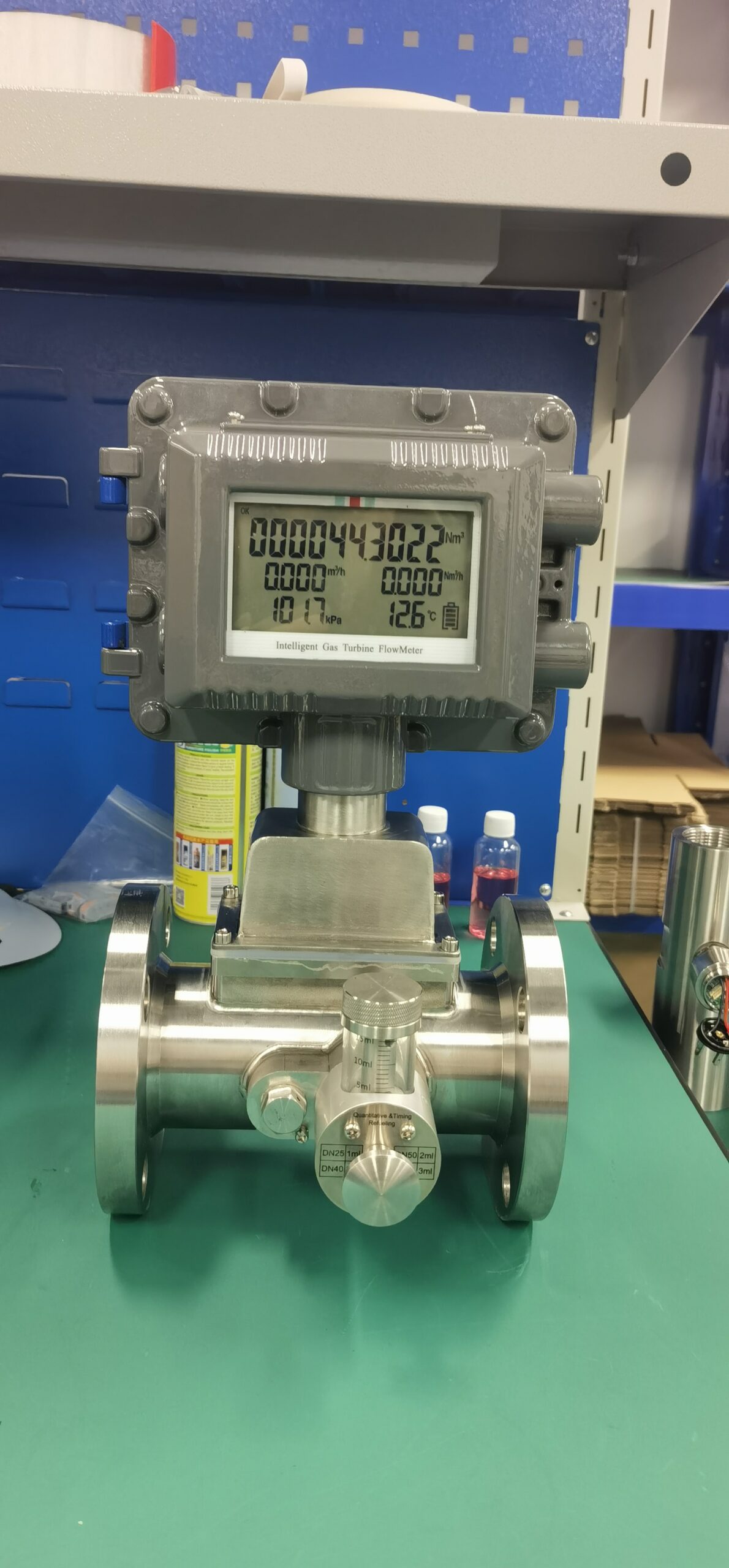

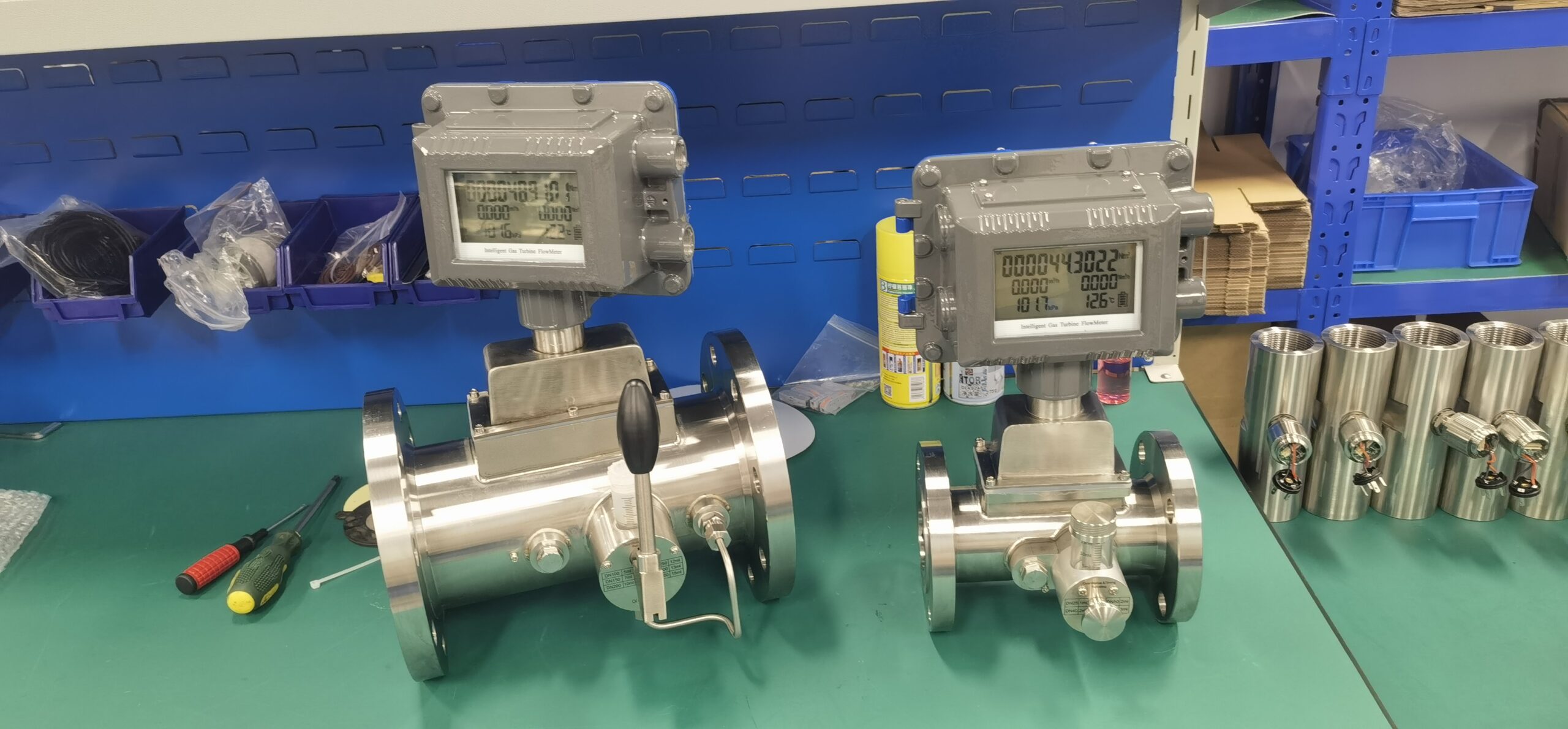

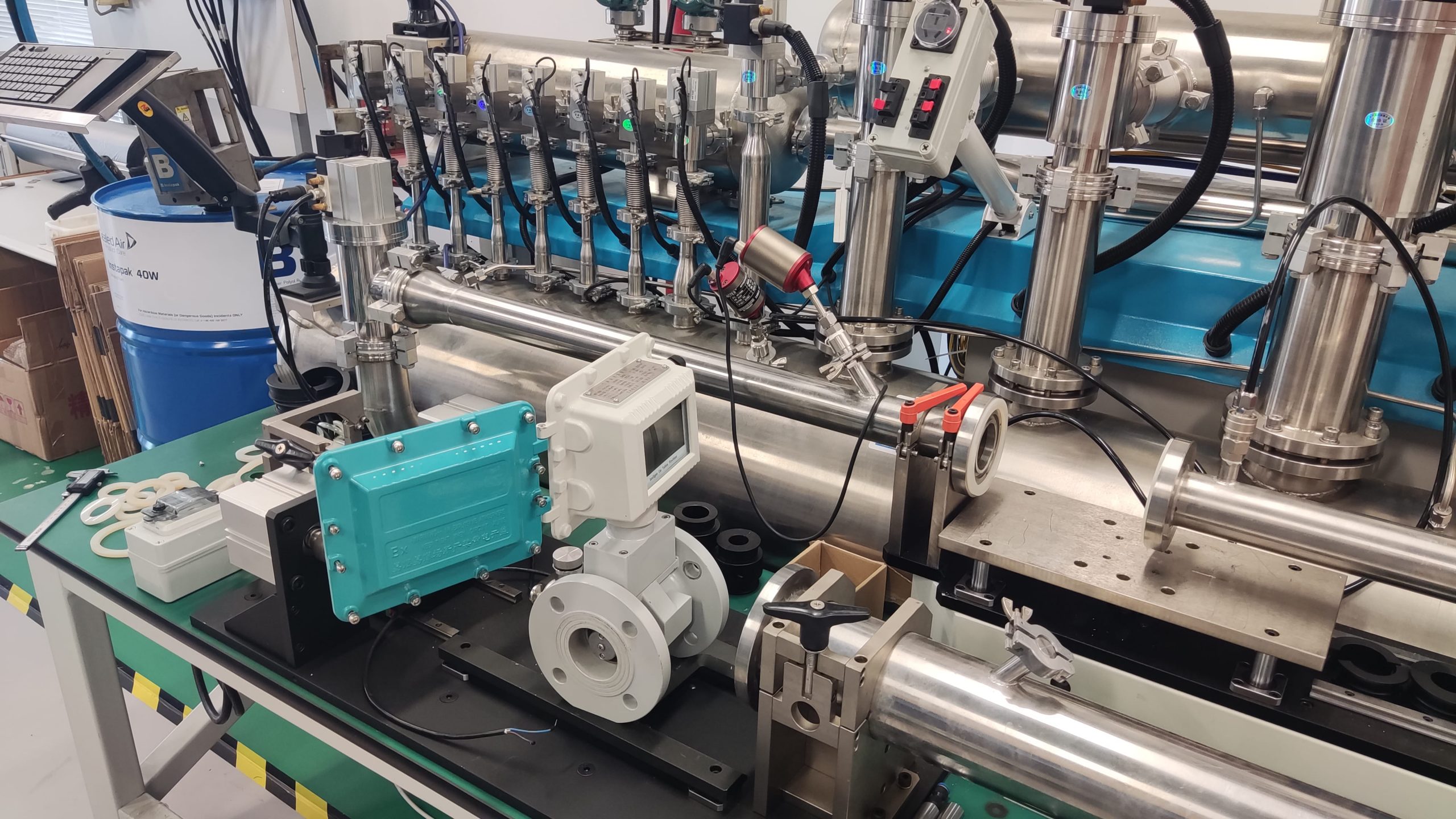

1, accuracy level: Generally speaking, the selection of gas turbine flowmeter is mainly due to its high accuracy, but the higher the accuracy of the flowmeter, the more inspired the change in the field conditions of use, so the choice of instrument accuracy should be careful, from the economic point of view. For the trade settlement instrument of the large-caliber gas transmission pipeline, it is cost-effective to invest more in the instrument, and for the occasion of small throughput, the medium precision level can be selected.

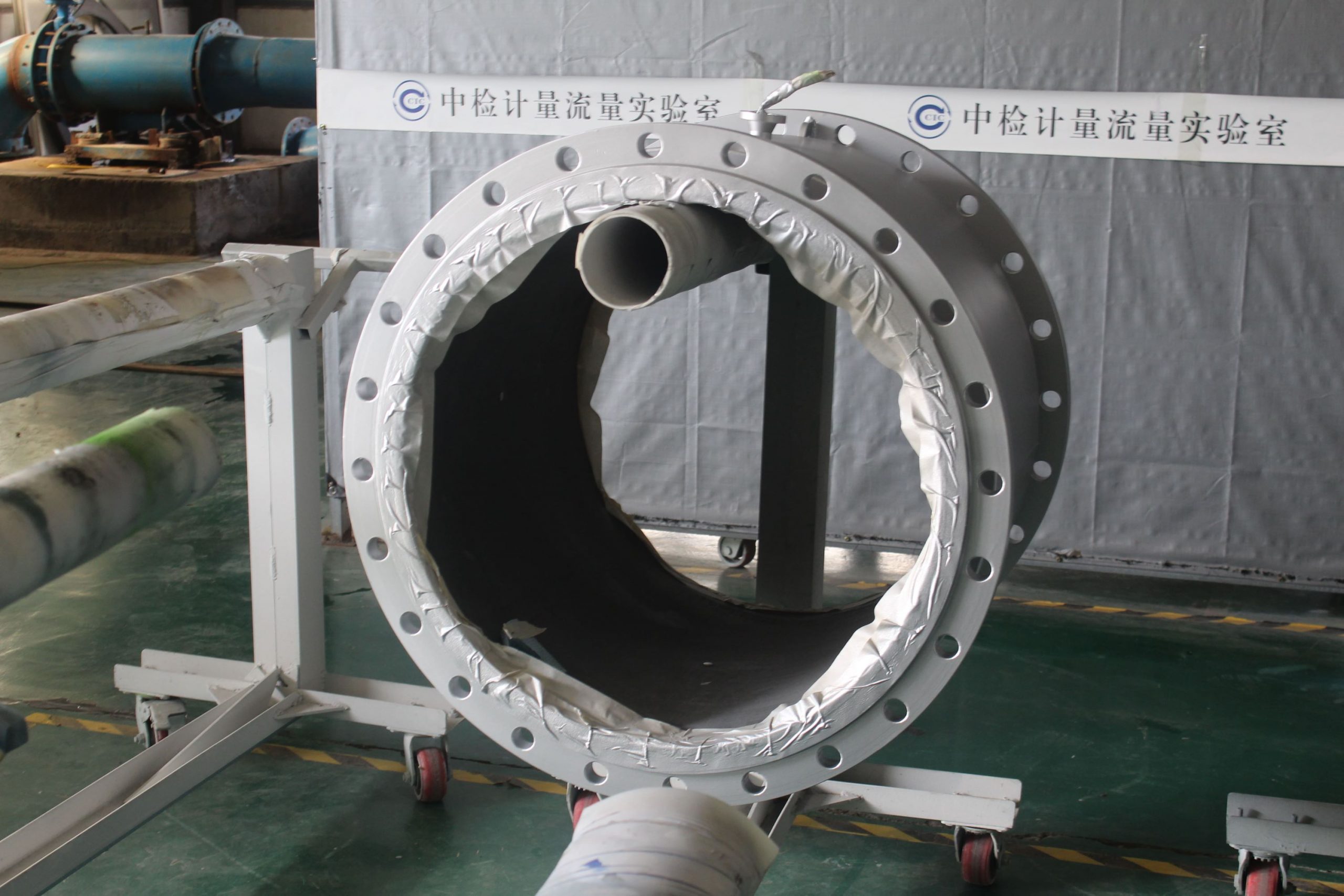

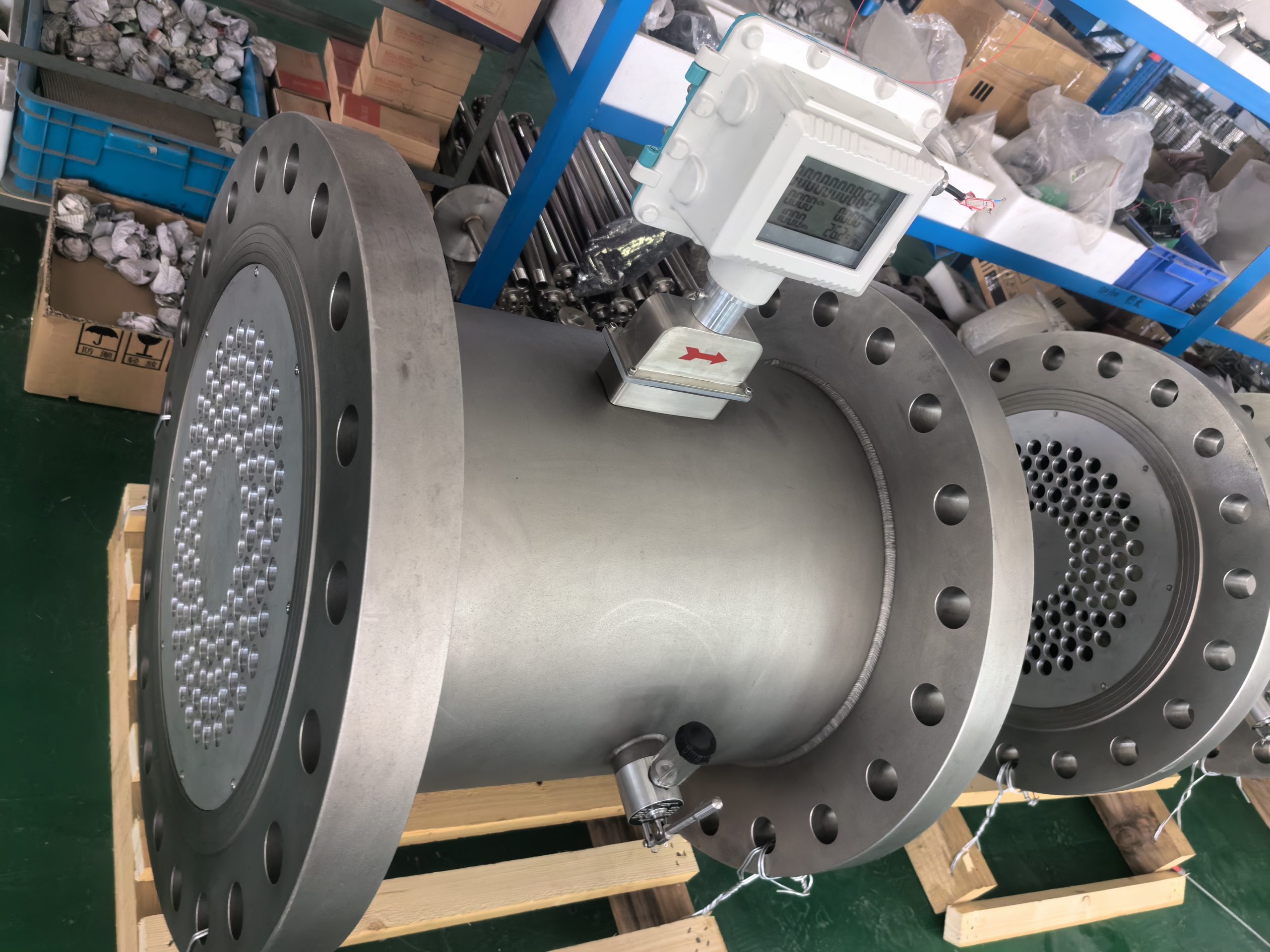

2, flow range: the choice of flow range of gas turbine flowmeter has a greater impact on its accuracy and service life, and each caliber of flowmeter has a certain measurement range, the choice of flowmeter caliber is also determined by the flow range. The principle of selecting the flow range is: the smaller flow when used shall not be lower than the smaller flow allowed by the instrument, and the larger flow when used shall not be higher than the larger flow allowed by the instrument. For intermittent working occasions where the actual running time of the instrument is not less than 8 hours per day, 1.3 times the maximum flow rate in actual use is selected as the upper limit of the flow range; For continuous working situations where the actual running time of the instrument is not less than 8 hours per day, 1.4 times the maximum flow rate in actual use is selected as the upper limit of the flow range. The lower limit flow rate of the instrument should be 0.8 times of the actual use of the smaller flow rate.

3, the density of gas: the gas flow meter, the impact of fluid physical properties is mainly the gas density, it has a greater impact on the instrument coefficient, and mainly in the low flow area. If the gas density changes frequently, the flow coefficient of the flowmeter should be corrected.

4, pressure loss: try to choose a small pressure loss turbine flowmeter. Because the pressure loss of the fluid through the turbine flowmeter is smaller, the energy consumed by the fluid from the input to the output pipeline is less, that is, the total power required will be reduced, which can greatly save energy, reduce transportation costs, and improve utilization.

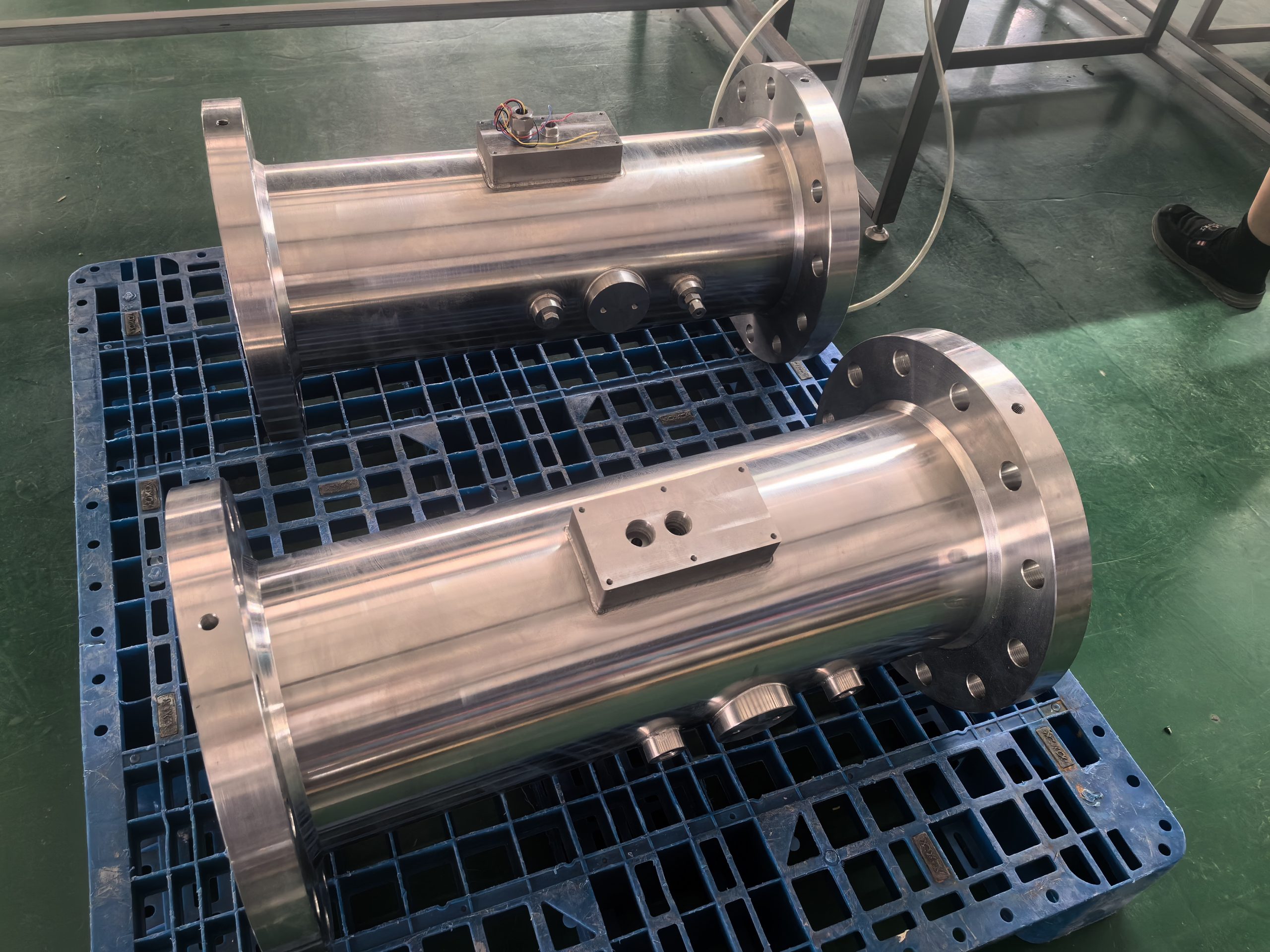

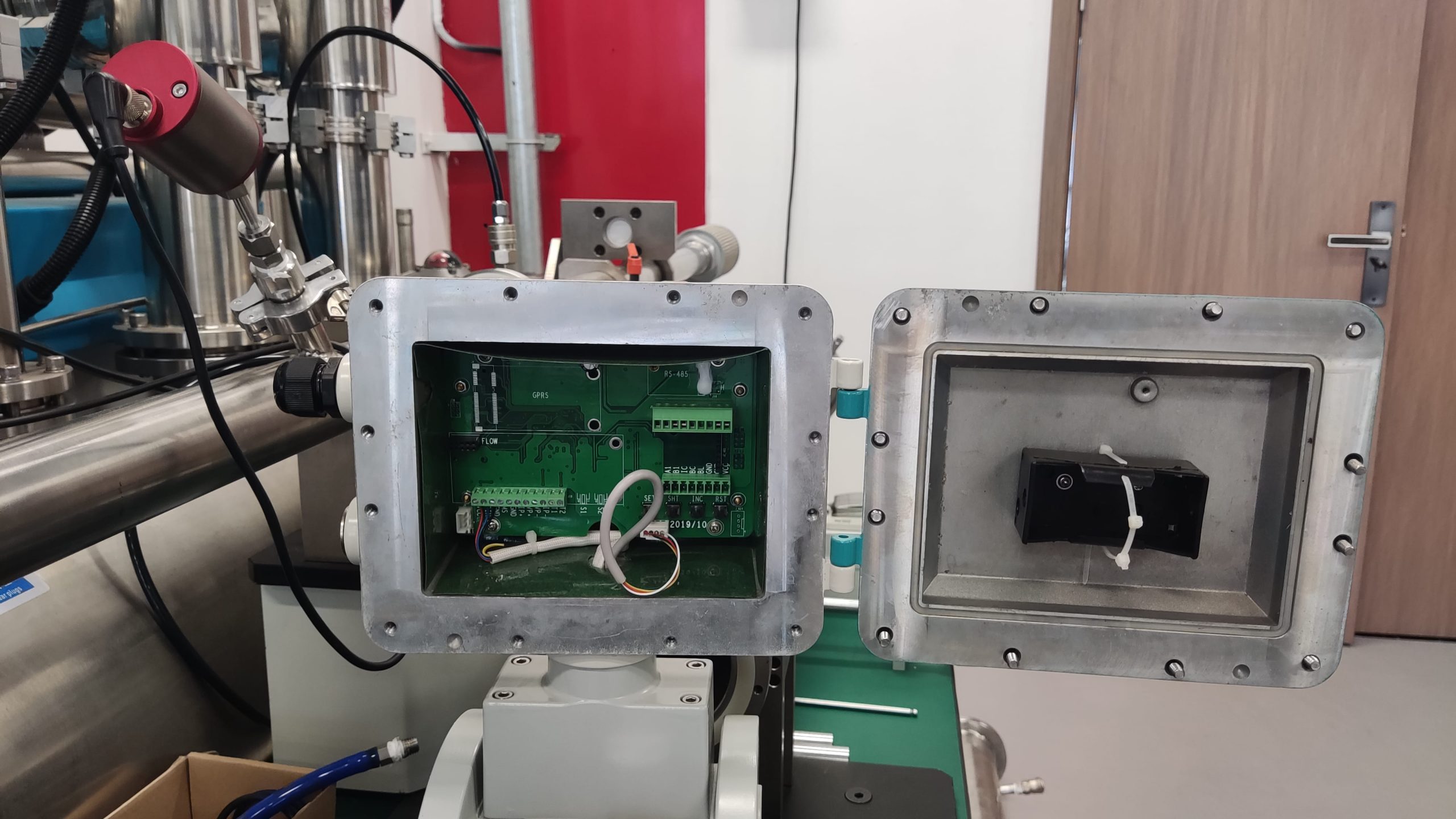

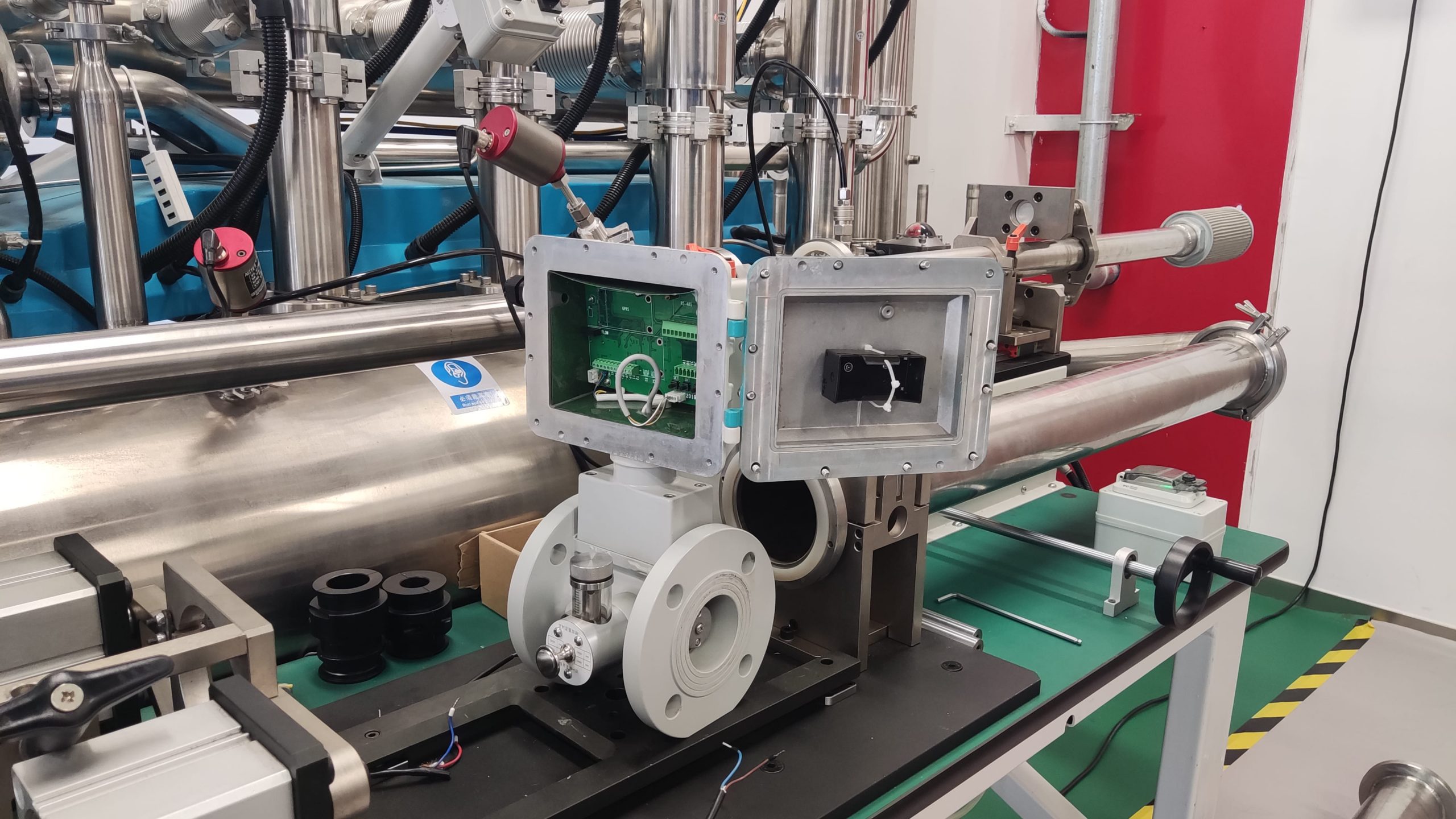

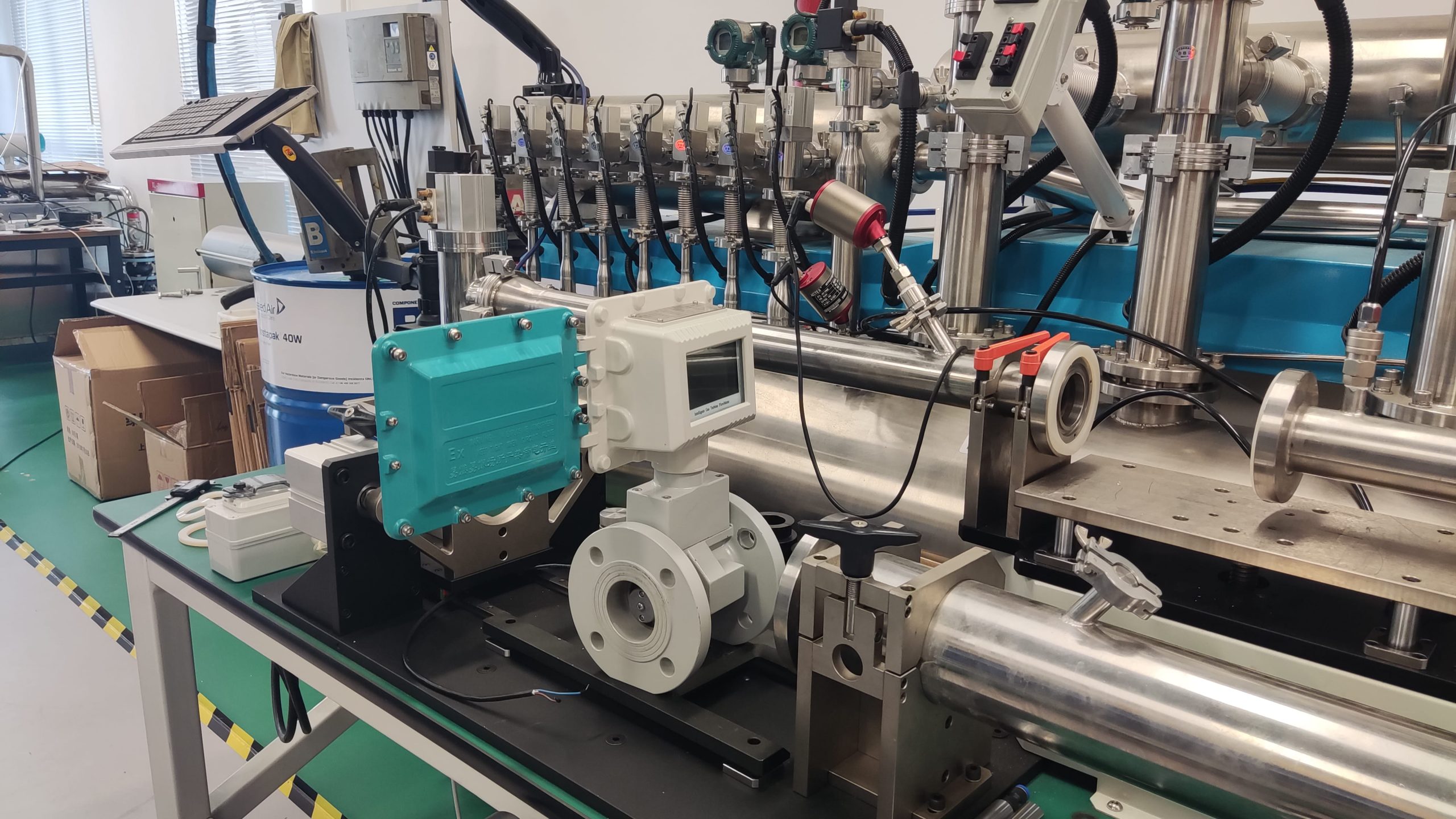

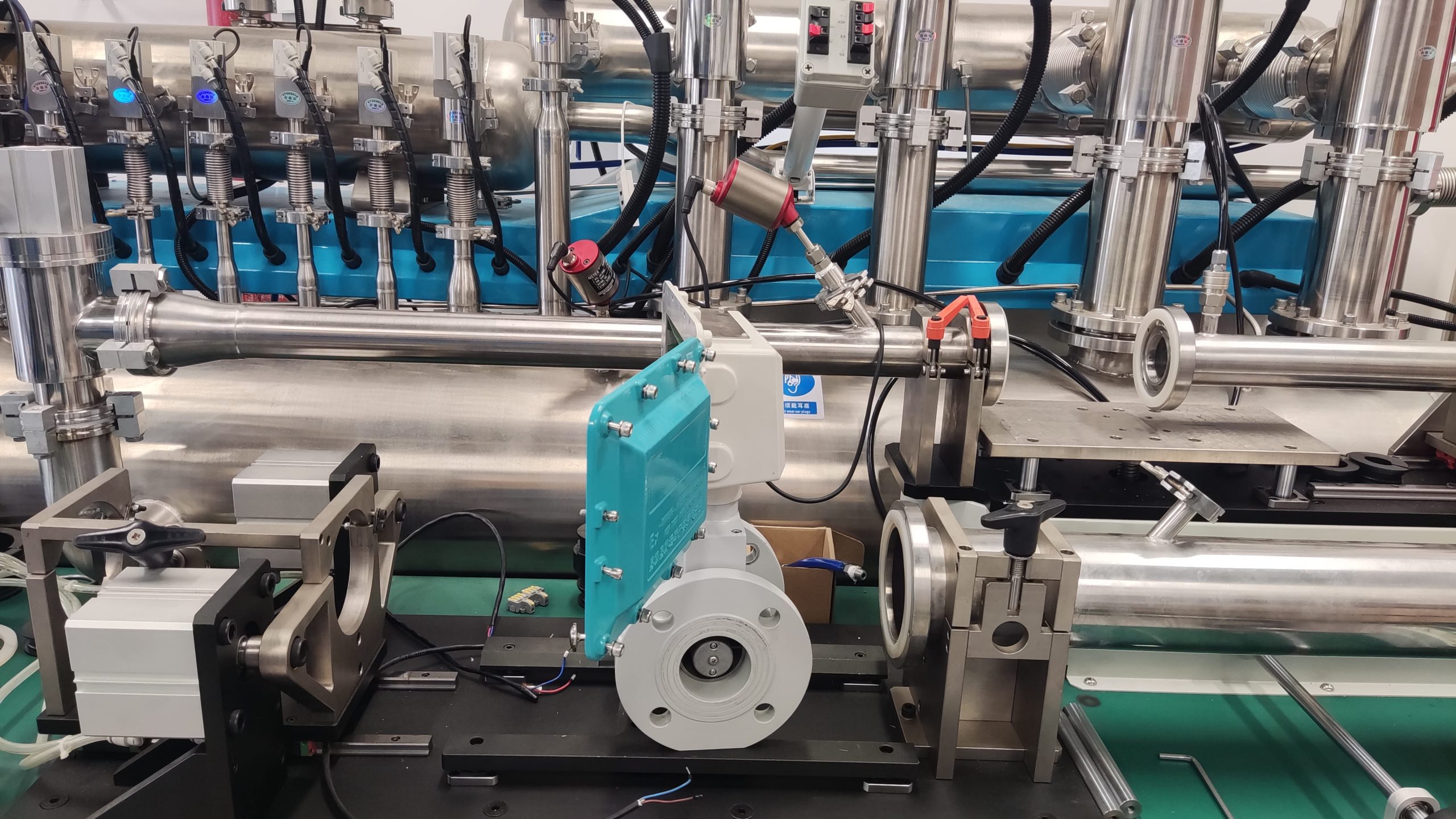

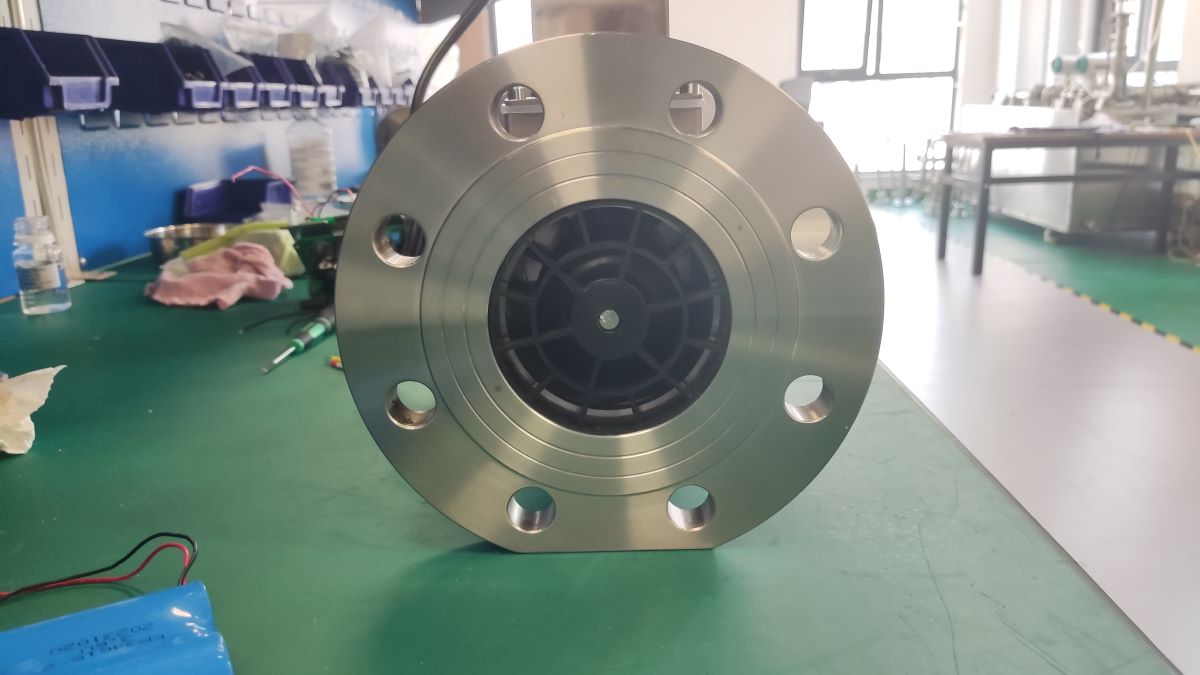

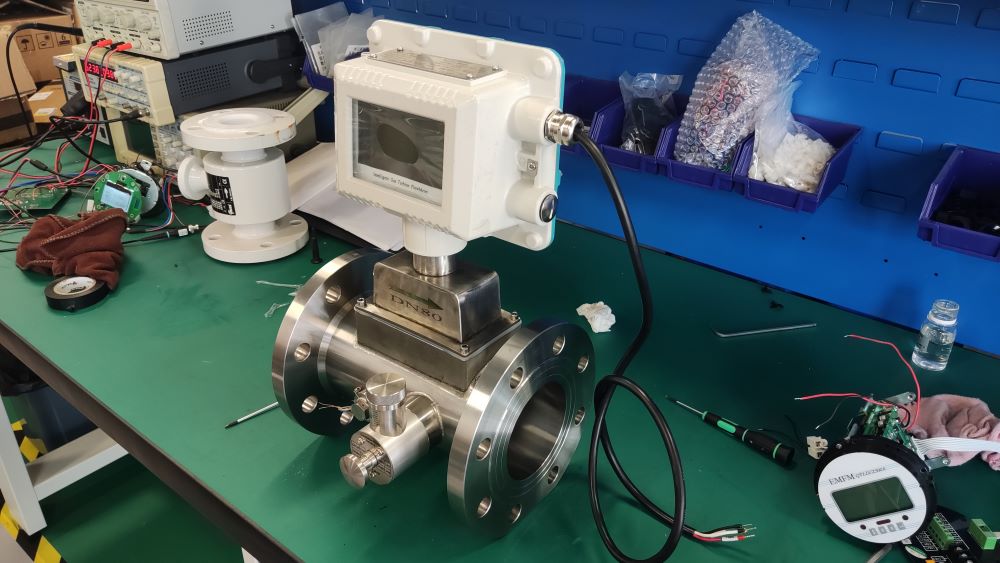

5, structure type: 1) The internal structure should choose the reverse thrust turbine flowmeter. Because the reverse thrust structure can make the impeller in a floating state within a certain flow range, there is no contact point in the axial direction, and there is no end friction and wear, which can extend the service life of the bearing. 2) According to the type selection of pipeline connection, the flow meter has two ways of horizontal and vertical installation, and the horizontal installation and pipeline connection have flange connection, thread connection and clamp connection. Medium diameter flange connection; Small diameter and high pressure pipes are threaded; Clamp connection is only suitable for low pressure pipe diameter; Vertical mounting only threaded connections. 3) Selection according to environmental conditions, considering the influence of temperature and humidity. Natural gas metering should choose intrinsic safety explosion-proof turbine flowmeter.

6, bearings: gas turbine flow meter bearings generally have tungsten carbide, polytetrafluoroethylene, carbon graphite three types of materials. Gas metering instrument bearings should be made of tungsten carbide.