What are the requirements for the installation environment of the electromagnetic flow meter?

What are the requirements for the installation environment of the electromagnetic flow meter?

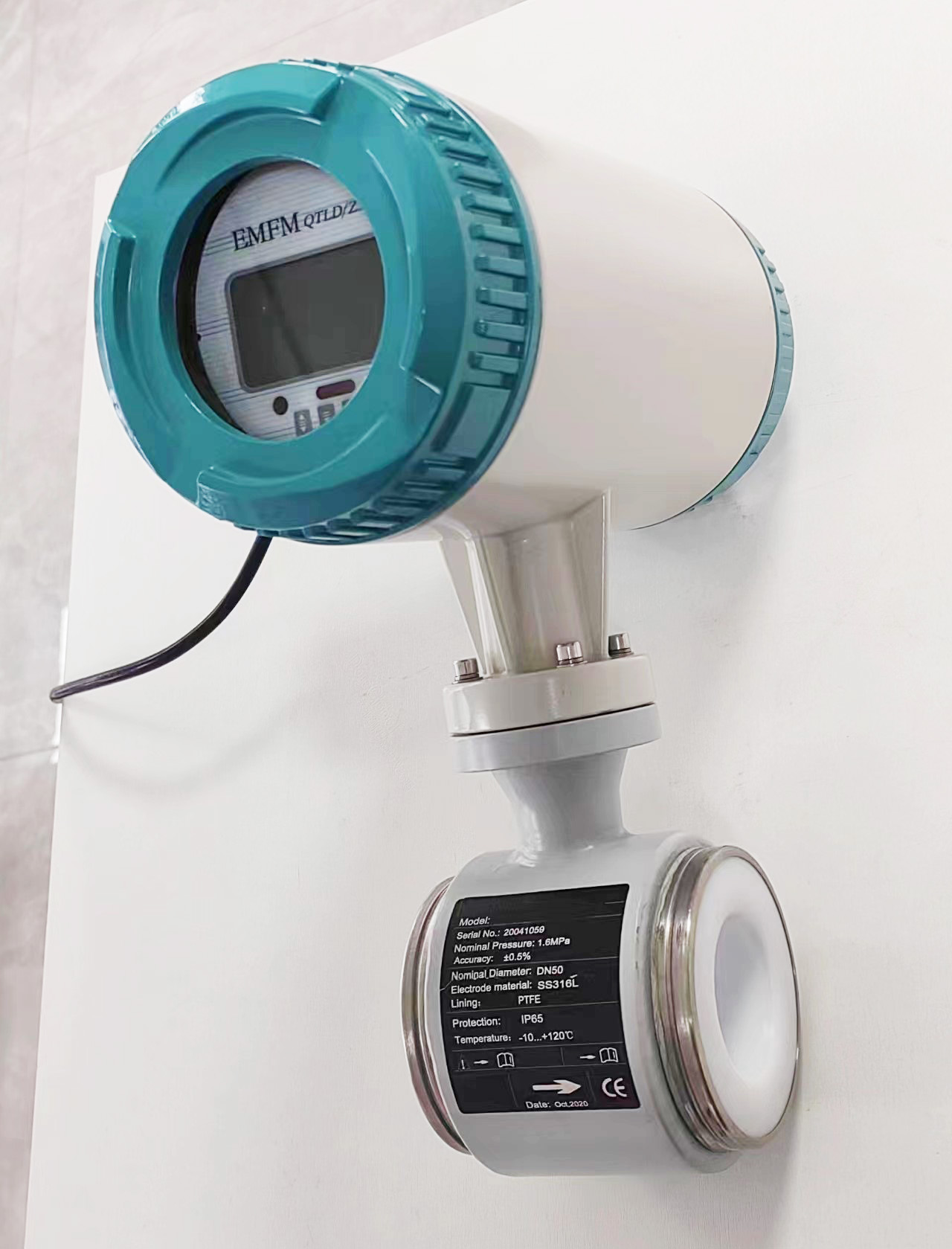

1. The installation environment of the converter The environmental requirements for the use of electromagnetic flowmeters

a. The ambient temperature is between -10 and 45℃;

b. The installation location is away from the strong vibration area;

c. The surrounding air does not contain corrosive gases;

d. Install it indoors if possible. When installed outdoors, there should still be measures to prevent sun and rain.

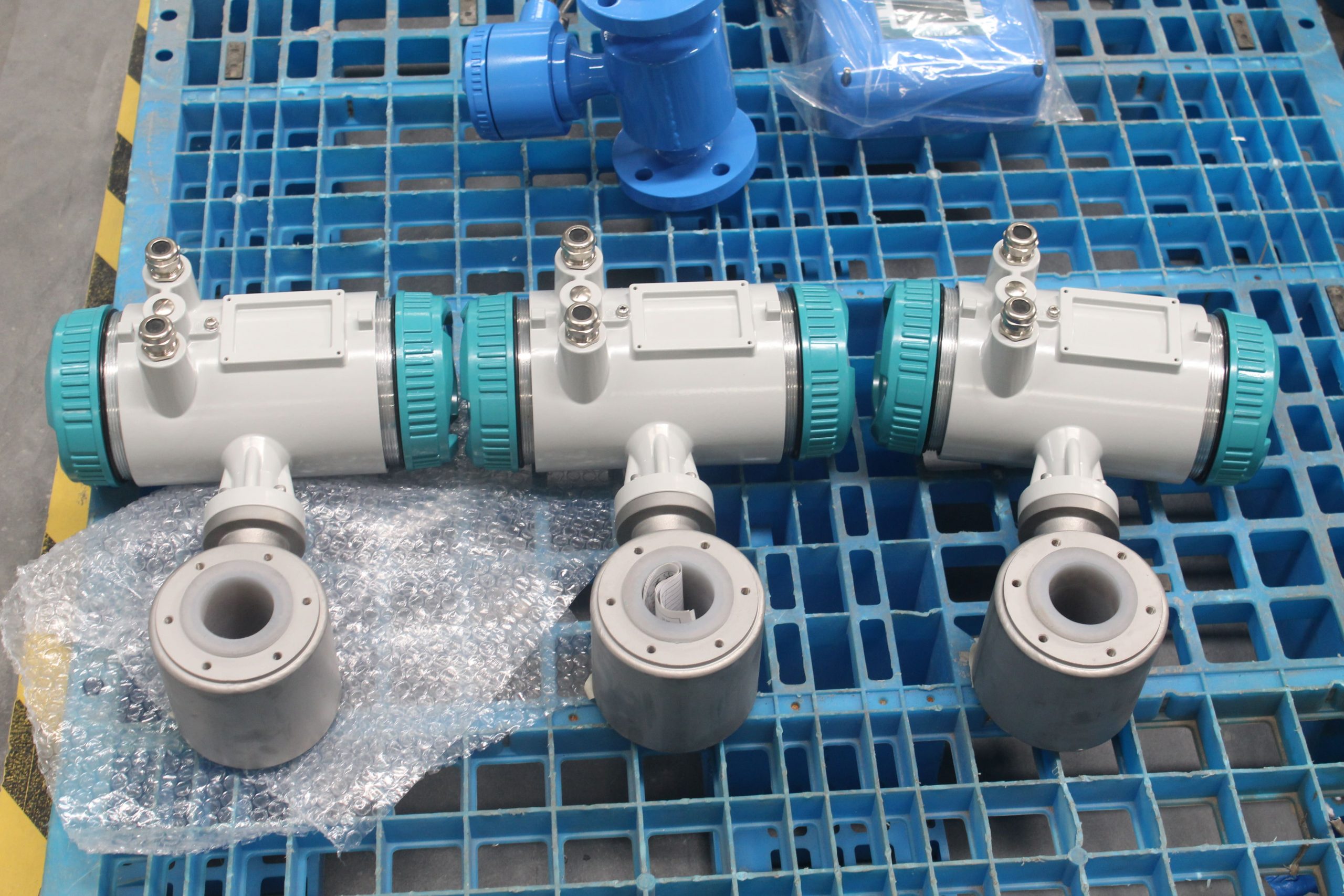

2. Installation site and environment of the sensor

The protection grade of the sensor of the electromagnetic flowmeter is generally IP65, IP67 and IP68, and the company’s protection grade is generally IP67 (one type) and IP68 (part type). Installation site requirements are as follows:

a. Try to avoid direct sunlight and exposure;

b. The ambient temperature is in the range of -25/-10℃ -50/60 ℃, and the temperature of the one-body structure is narrower due to the limitation of its internal electronic devices;

c. Avoid high-concentration corrosive gases in the surrounding environment as much as possible;

d. Avoid nearby large transformers, large motors and other equipment that is easy to cause strong magnetic field, so as not to cause electromagnetic field interference;

e. Try to avoid negative pressure in the measuring tube (especially for the tetrafluorofluoride lining);

f. Choose a place with small vibration, especially for a type of flowmeter

g. When measuring mixed phase flow fluids, select a location that will not cause phase separation; When measuring two component liquids (such as adding liquids with different electrical conductivity from the main liquid), avoid loading downstream where the mixture has not been uniform; When measuring chemical reaction pipes, install them downstream of the fully completed section of the reaction

-.jpg)

-.jpg)