What are the precautions for the use of ultrasonic liquid level meter on site

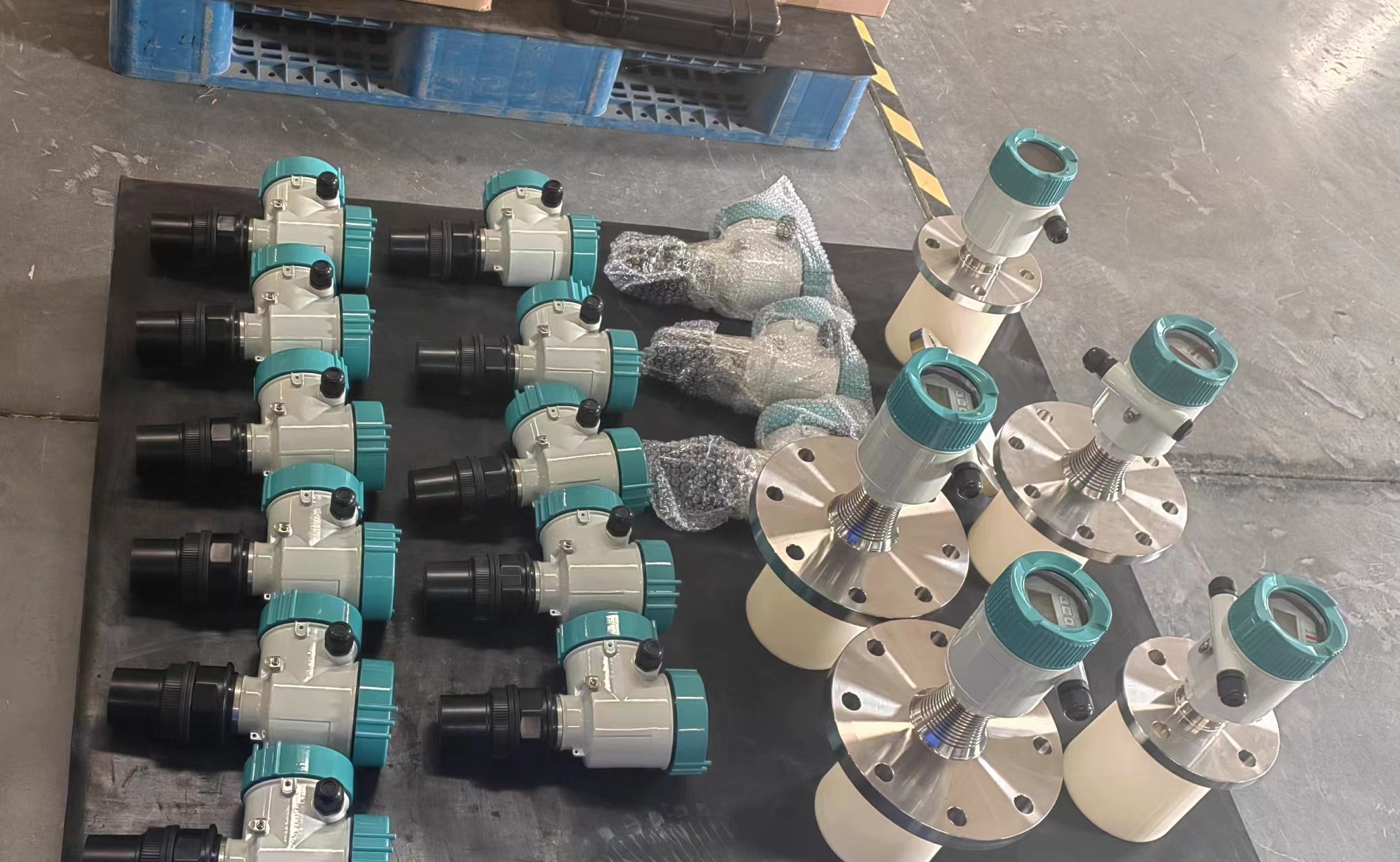

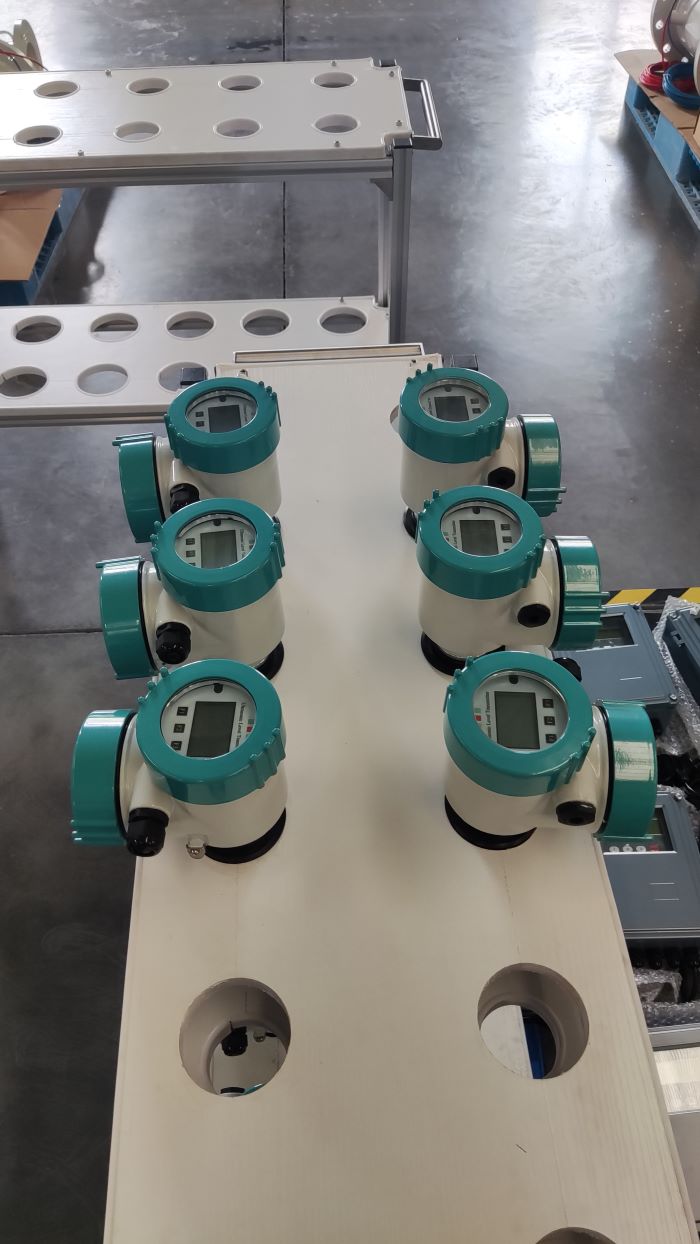

Ultrasonic level meter can be widely used in chemical industry, water treatment, water conservancy, food, grain and other industries level measurement. The product has the characteristics of safety, cleanliness, high precision, long life, stability and reliability, easy installation and maintenance, simple reading and so on. Ultrasonic level meter is a digital level meter controlled by microprocessor.

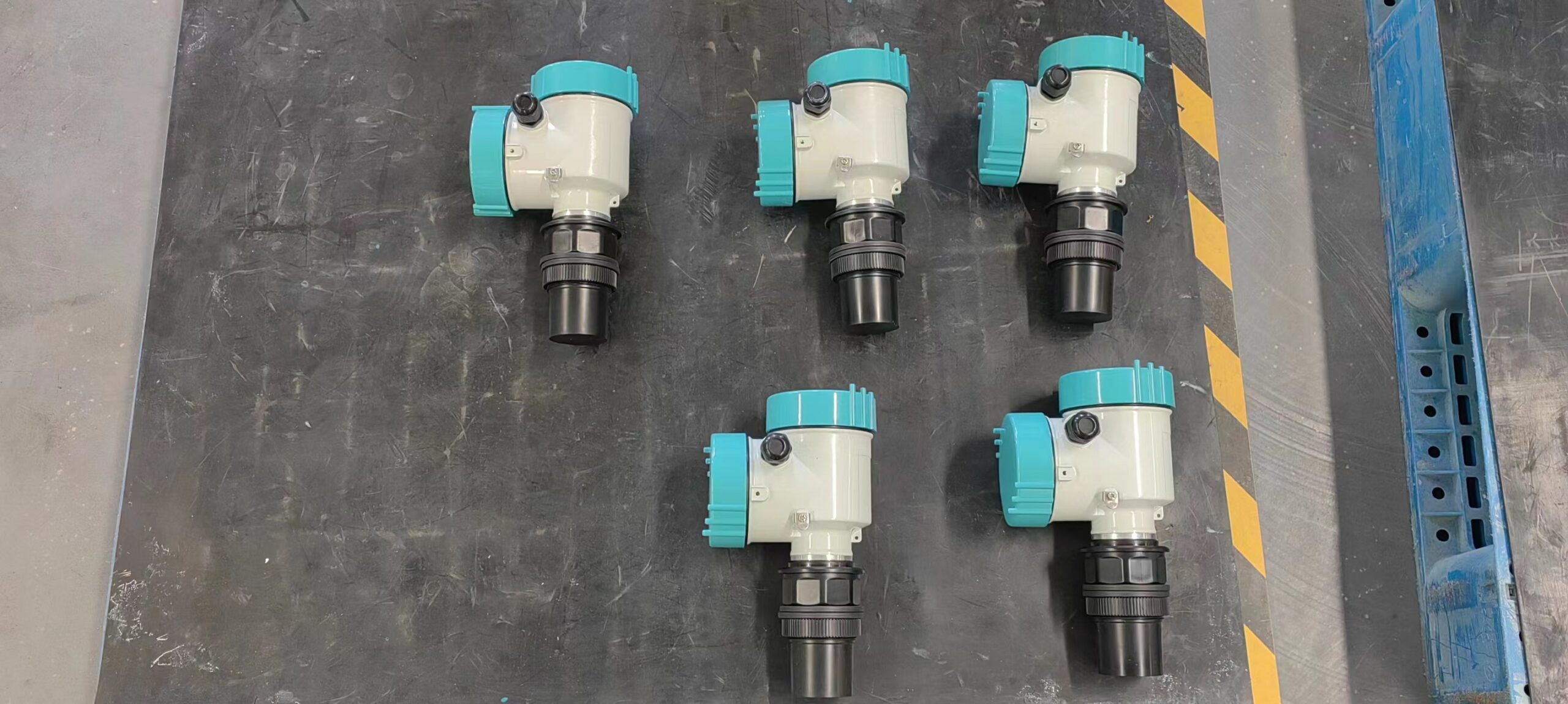

In the measurement, the pulse ultrasonic wave is emitted by the sensor (transducer), and the sound wave is received by the same sensor after being reflected by the surface of the object and converted into an electrical signal. The distance between the sensor and the measured object is calculated by the time between the transmission and reception of the sound wave. Due to the non-contact measurement, the measured medium is almost unrestricted, and can be widely used in the height measurement of various liquid and solid materials.

Ultrasonic liquid level meter field conditions:

1, the instrument in the outdoor installation is recommended to install a sun visor to extend the service life of the instrument.

2, wire, cable protection tube, pay attention to seal to prevent water.

3. Although the instrument itself has a lightning protection device, when the instrument is used in the mine area, it is recommended to install a special lightning protection device at the inlet and outlet end of the instrument.

4, ultrasonic liquid level meter is used in particularly hot and cold places, that is, when the ambient temperature may exceed the working requirements of the instrument, it is recommended to add high and low temperature devices around the liquid level meter.

5, the same container installed multiple ultrasonic level meter, ultrasonic easily interfere with each other resulting in measurement error, so try not to install the ultrasonic level meter in the same container.

6, the ultrasonic level meter should be installed away from the feed port, and ensure that there are no obstacles to block, so as not to be interfered with by materials or obstacles.

7, vibration or shaking is easy to cause the ultrasonic level meter loose, in order to avoid affecting the normal measurement, the ultrasonic level meter should avoid being installed in the strong vibration area, such as installed in the light vibration area, rubber shock absorber should be installed, and should ensure that the ultrasonic level meter installation is firm enough.