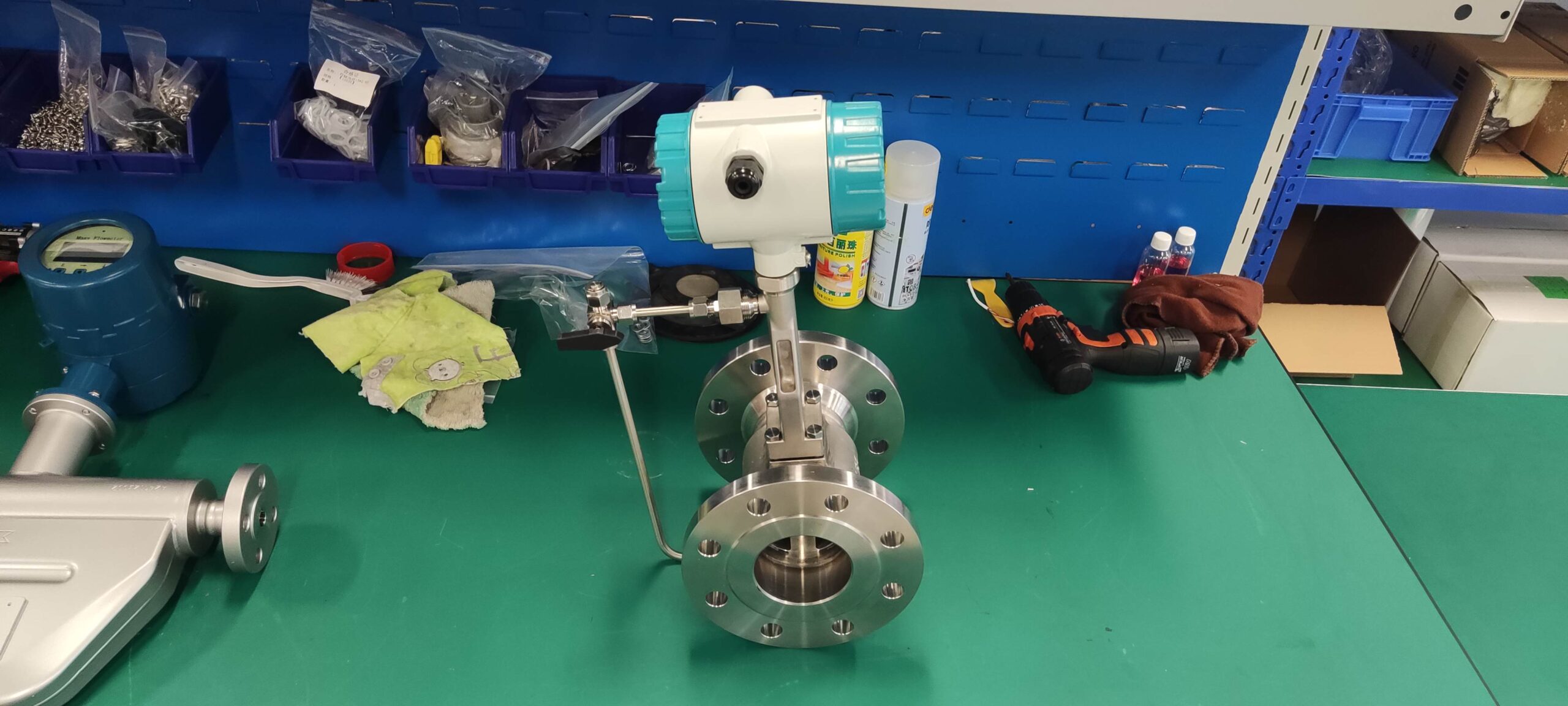

What are the points to pay attention to when installing vortex flow meters?

With the continuous production progress of the reform and opening up industry, it has been applied in more and more industries, and the vortex flowmeter is widely used in large, medium and small pipeline water supply and drainage, industrial circulation, and sewage treatment.

Oil and chemical reagents as well as compressed air, saturated vapor and superheated vapor, natural gas flow measurement of various media and can be used as a flow transmitter in automated control systems.

Today, Aister instrument explains the main points to pay attention to when installing vortex flowmeters:

1, reasonable choice of installation site and environment

Avoid strong power equipment, high frequency equipment, strong power switchgear; Avoid the influence of high temperature heat sources and radiation sources, avoid strong vibration places and strong corrosion environments, etc., and consider convenient installation and maintenance.

2, upstream and downstream must have enough straight pipe section

If there are two 90-degree elbows on the same plane upstream of the sensor installation point, the upstream straight pipe section is ≥25D, and the downstream straight pipe section is ≥5D.

If the upstream of the sensor installation point has two 90-degree elbows on different planes, the upstream straight pipe section is ≥40D, and the downstream straight pipe section is ≥5D.

The regulating valve should be installed in the downstream 5D of the sensor, if it must be installed in the upstream of the sensor, the upstream straight pipe section of the sensor should not be less than 50D, and the downstream should not be less than 5D.

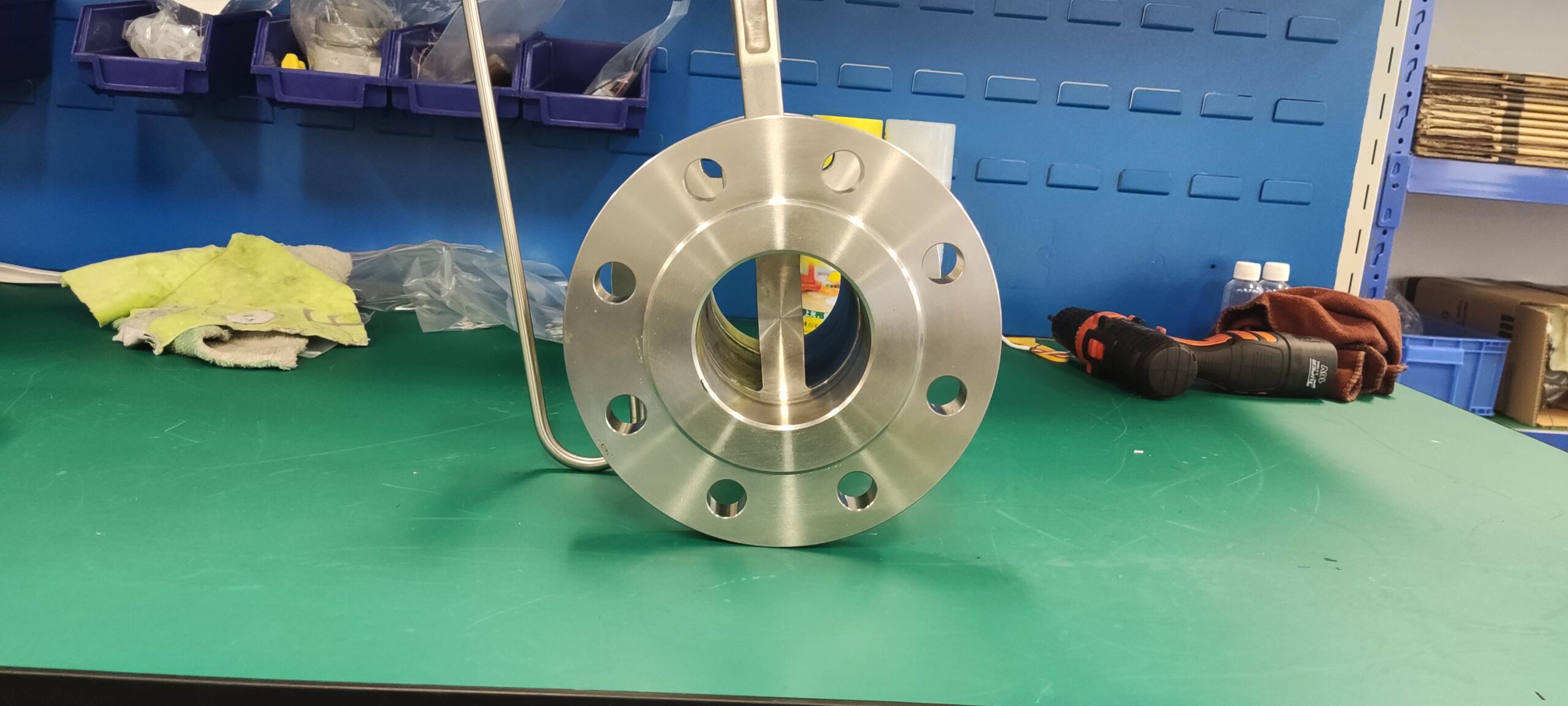

3, the sensor is installed on the pipeline with insulation layer

When measuring high temperature vapor, the insulation layer should not exceed one third of the height of the support.

4, when measuring gas flow, the sensor can be installed on the vertical pipe, the flow direction is unlimited.