What are the points that need to be paid attention to in the application of the thermal gas mass flow meter

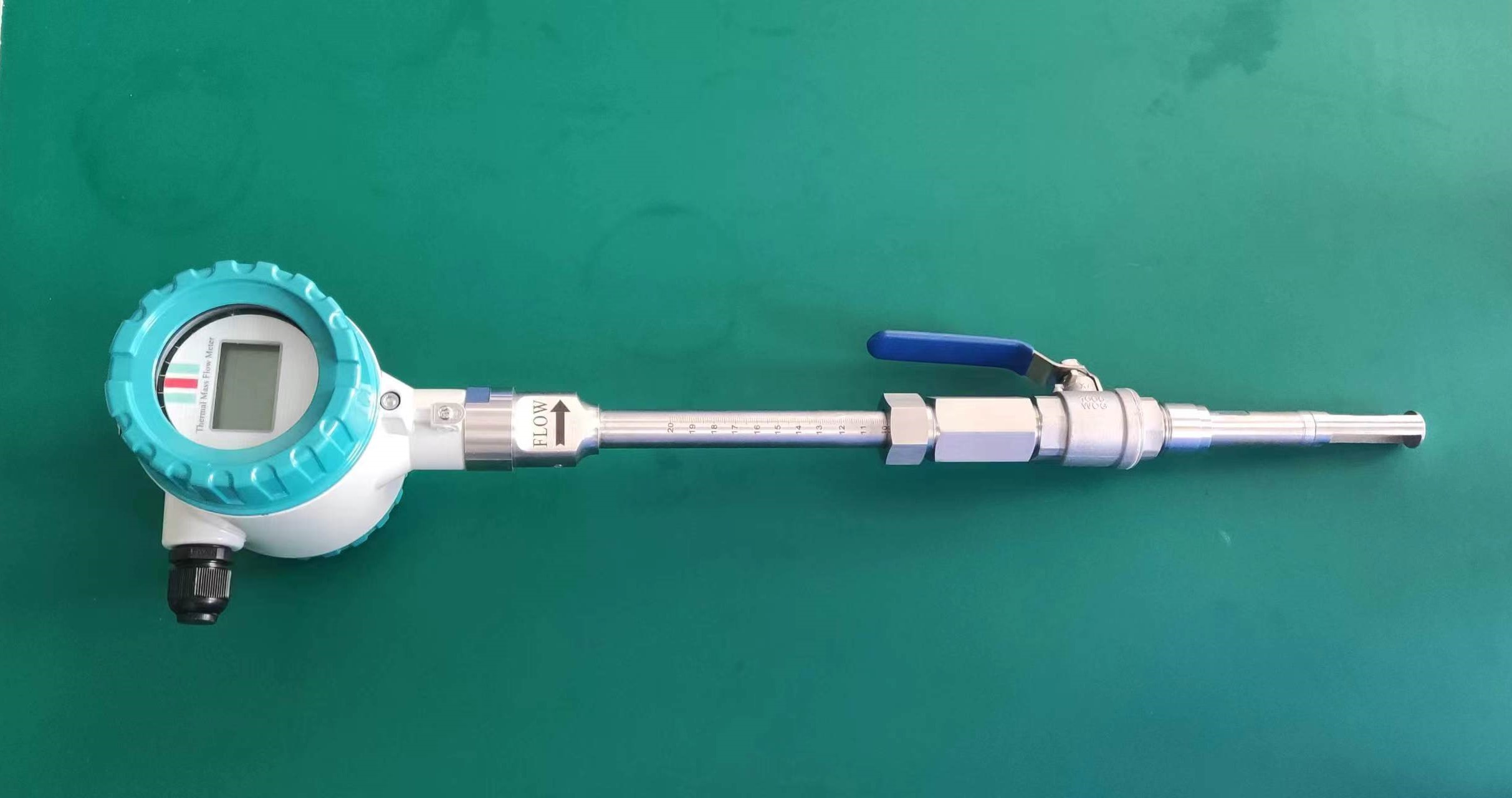

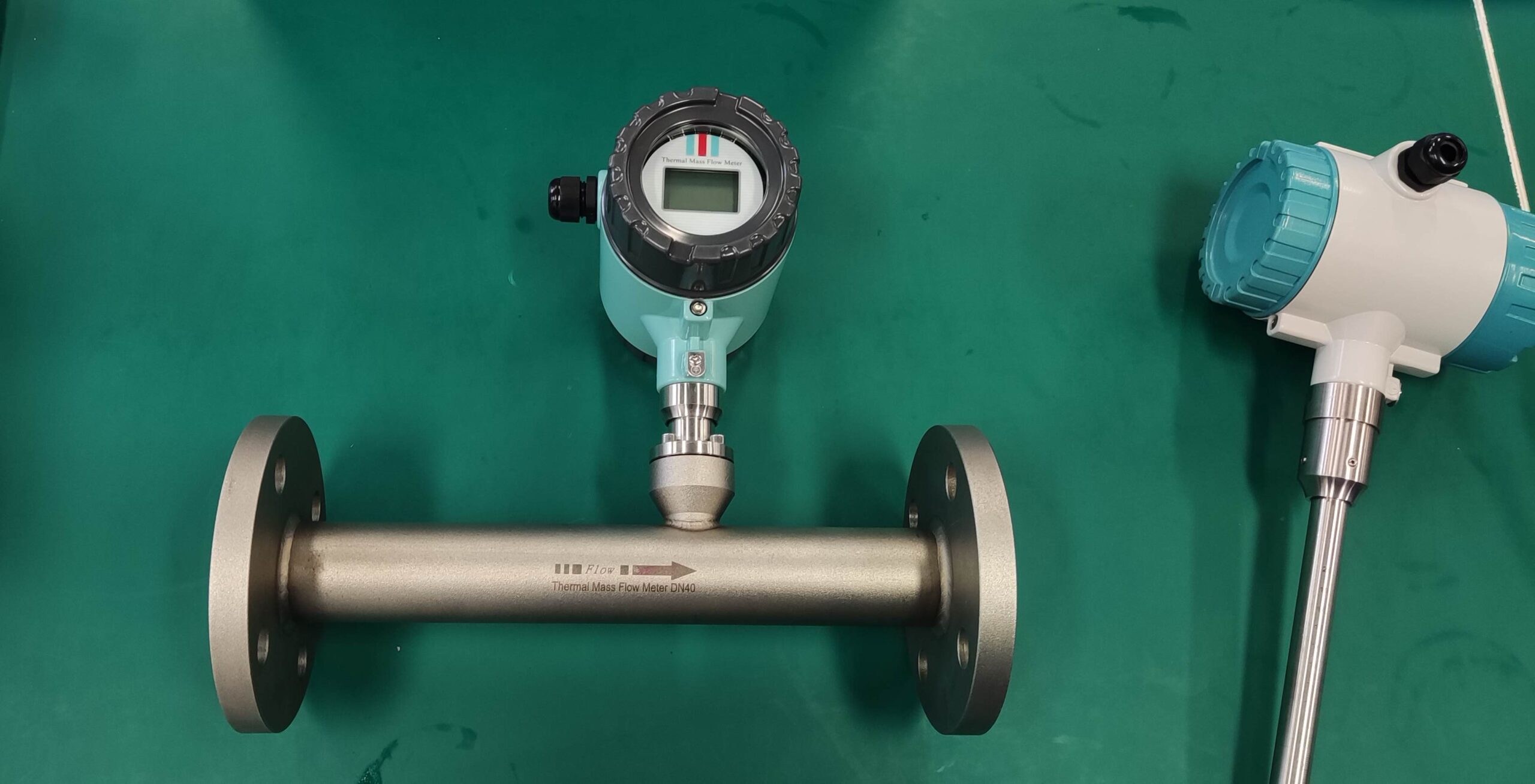

The thermal gas mass flowmeter is an instrument for measuring fluid flow by using the principle of heat conduction. The instrument uses constant temperature difference method to accurately measure the gas mass flow.

The thermal gas mass flowmeter has the following characteristics

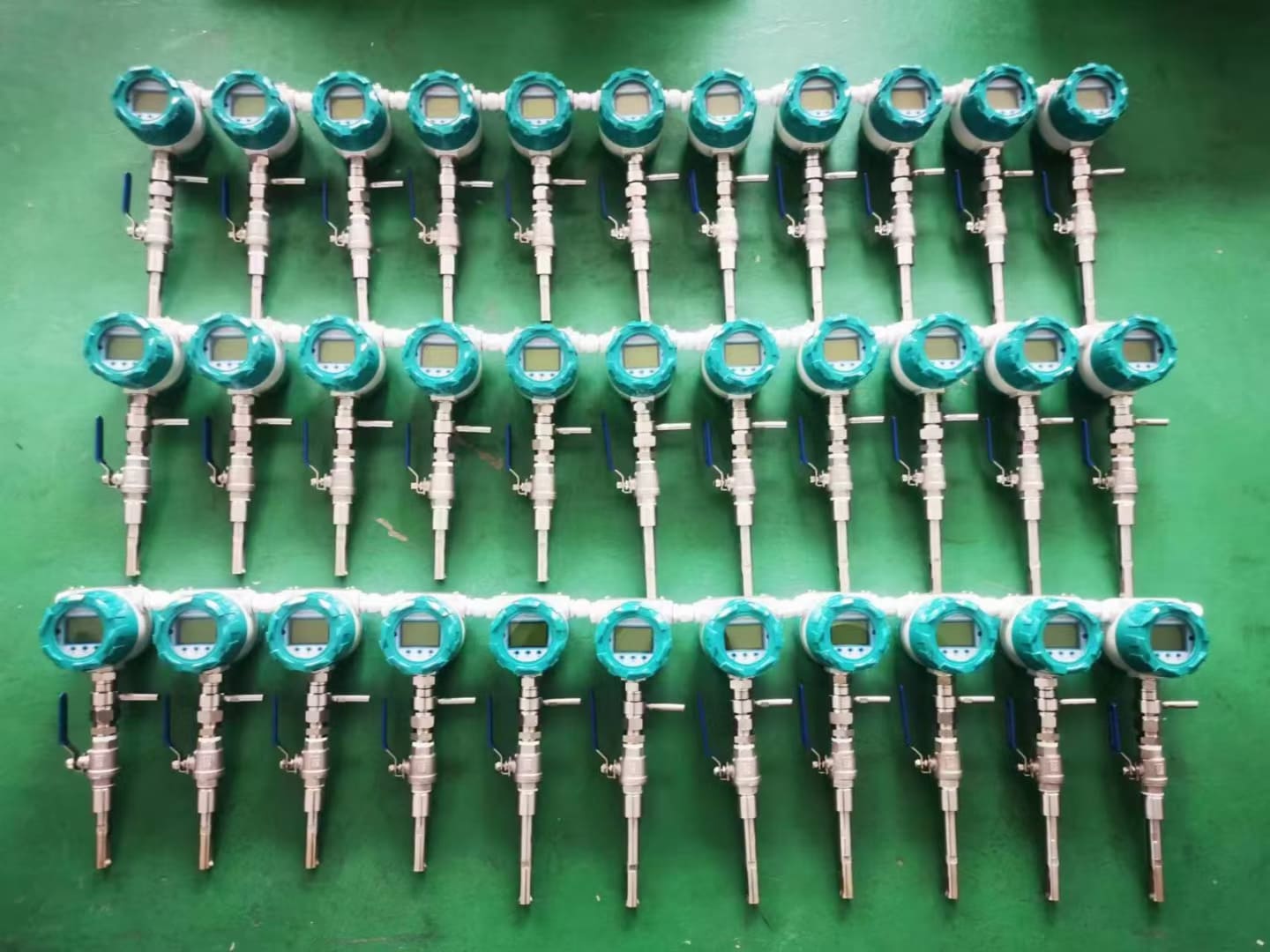

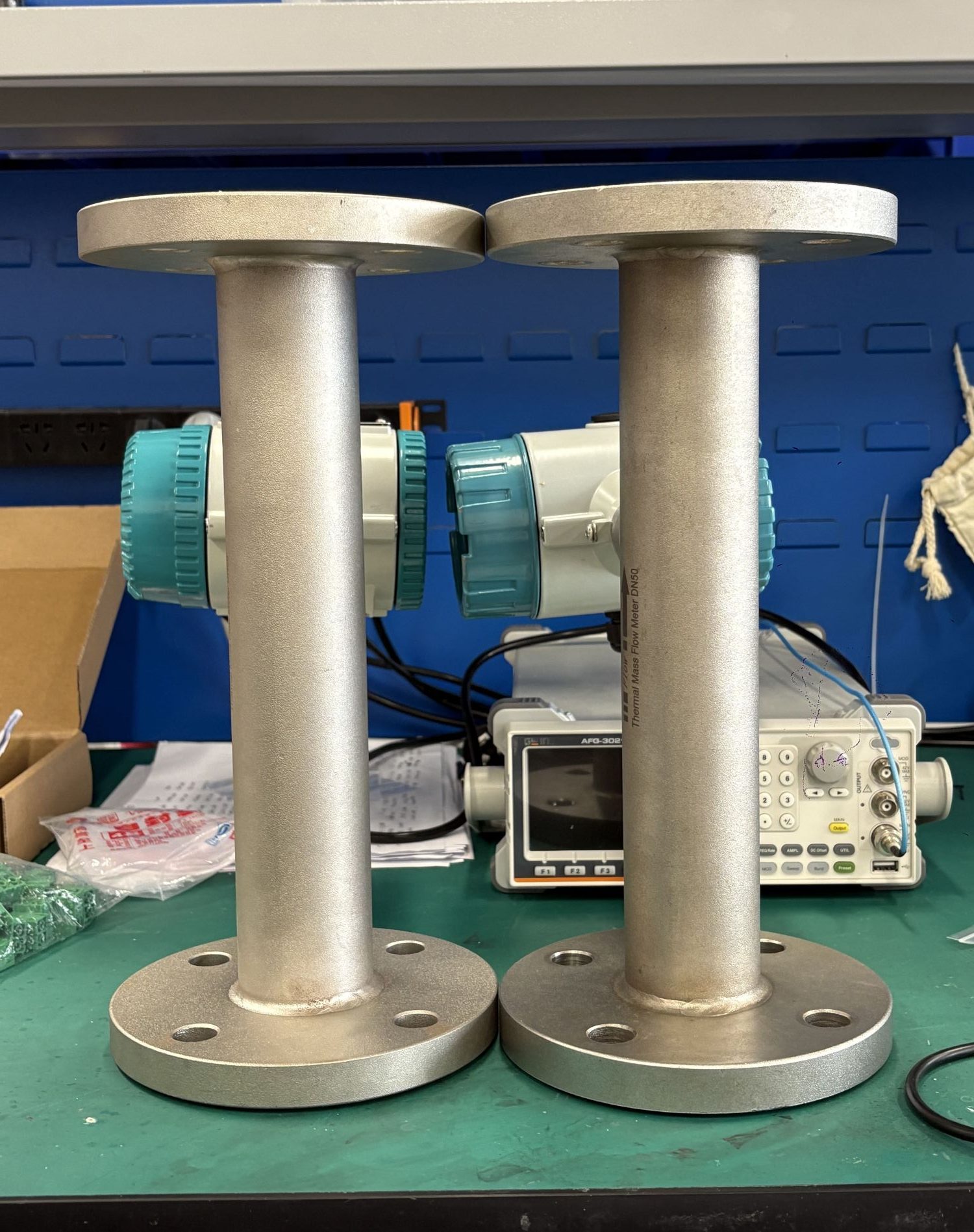

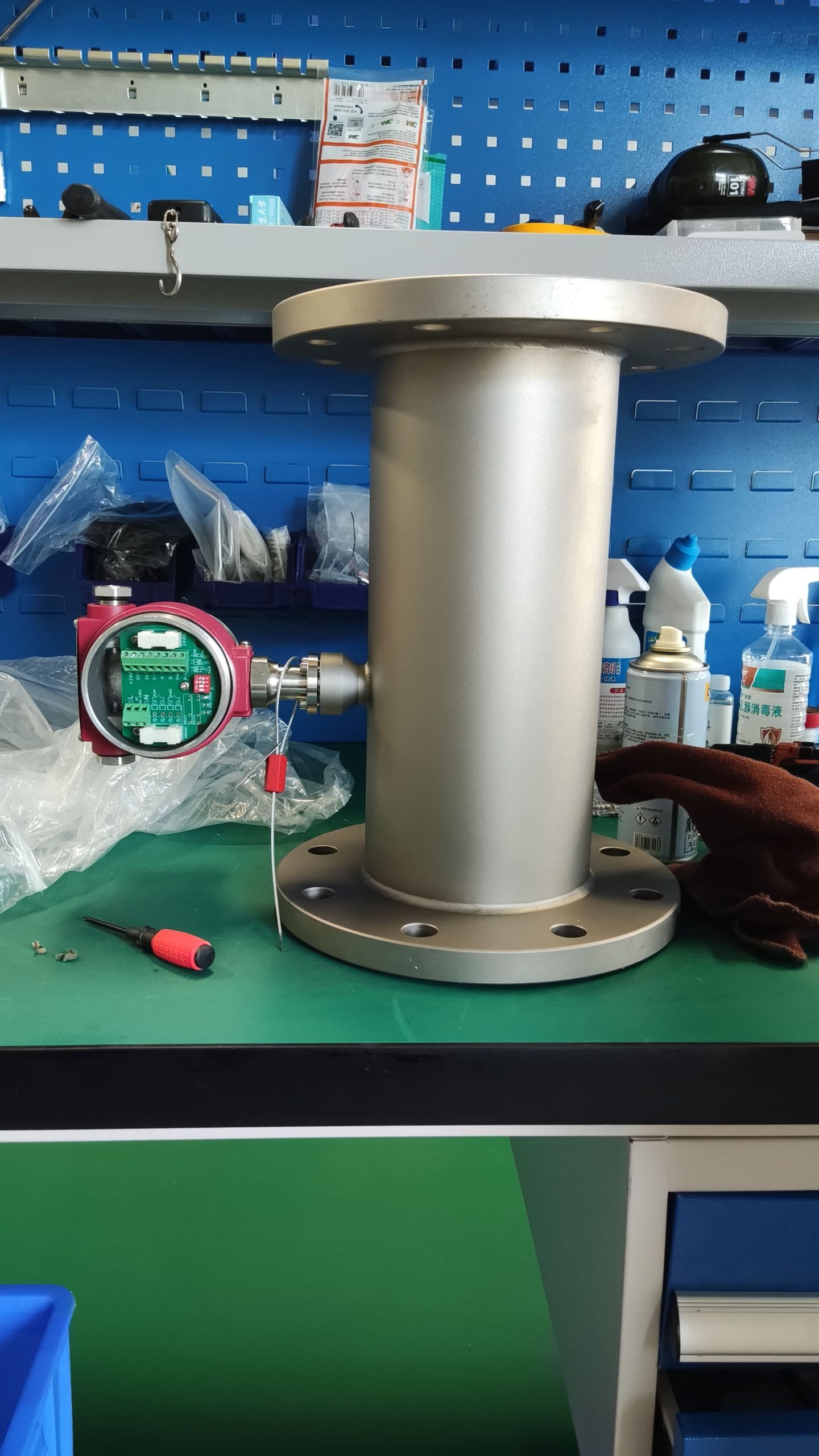

1, the flow meter has small size, high degree of digitalization, easy installation, accurate measurement;

2, flowmeter proprietary flow data model algorithm;

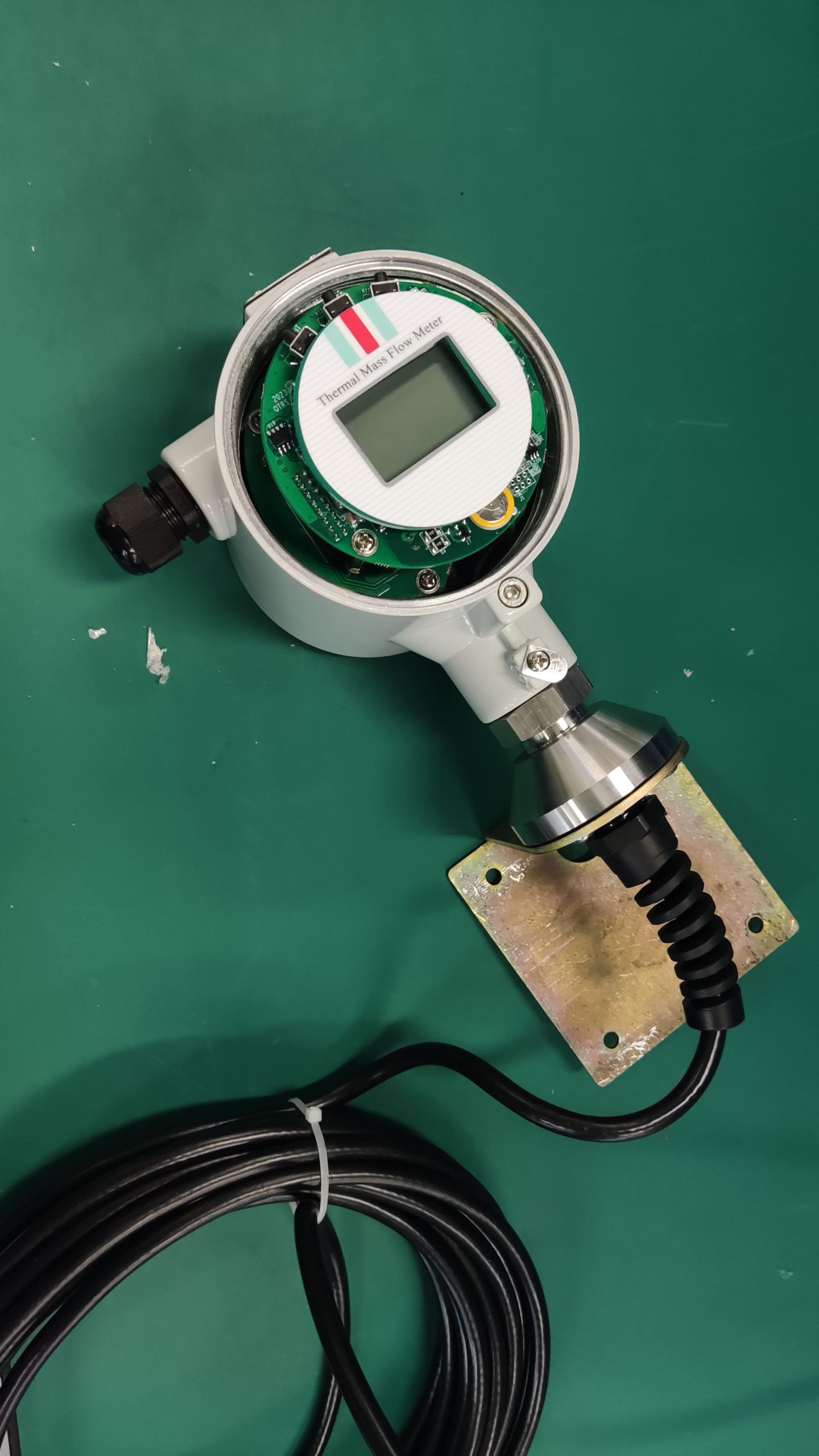

3, fuzzy theory control temperature, humidity algorithm;

4, high-performance intelligent microprocessor and analog-to-digital, digital-to-analog conversion chip;

5, wide range ratio 1000:1;

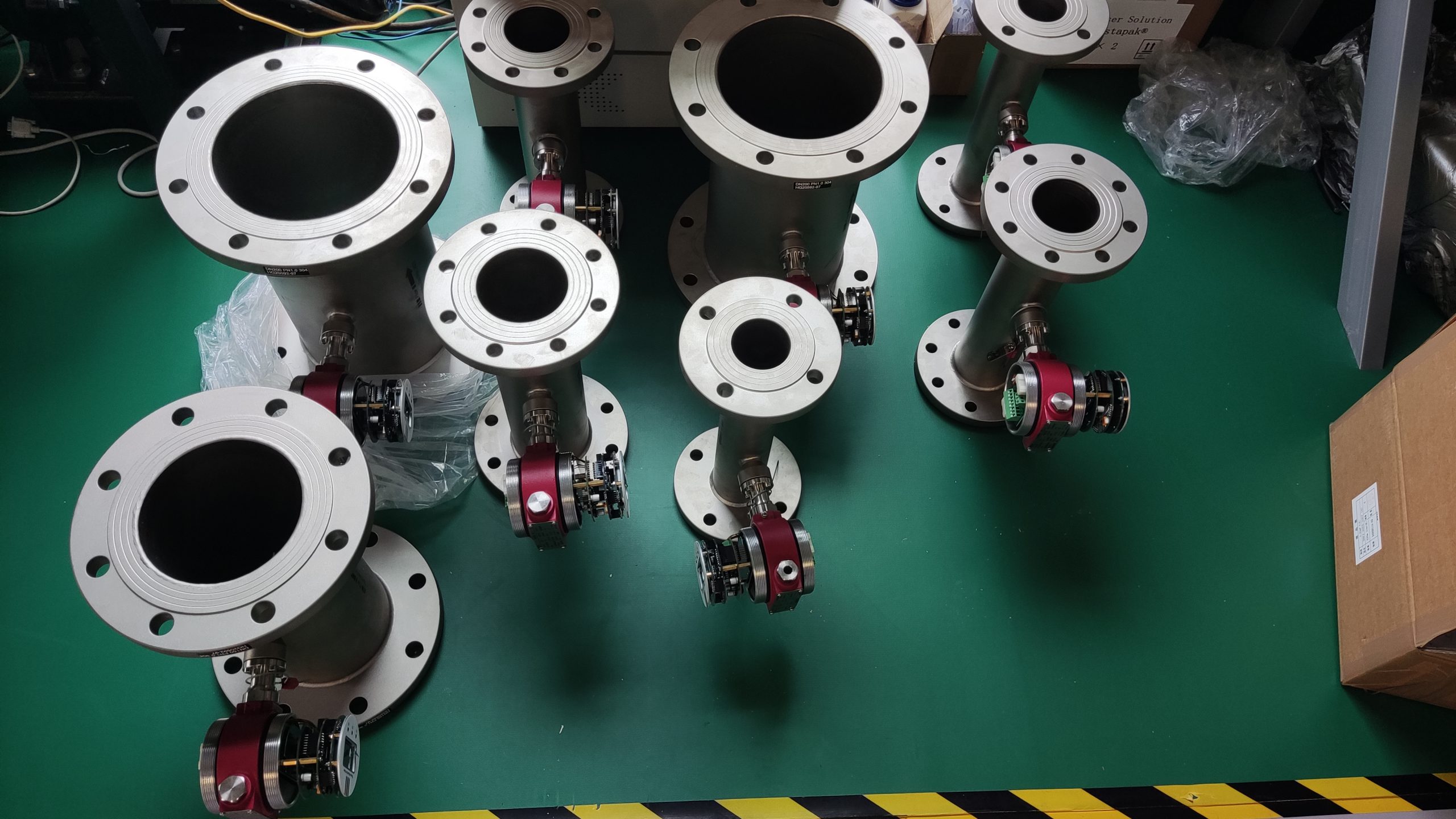

6, large caliber, low flow rate, pressure loss can be ignored;

7, direct measurement of mass flow, without temperature and pressure compensation; Low velocity measurements are very sensitive;

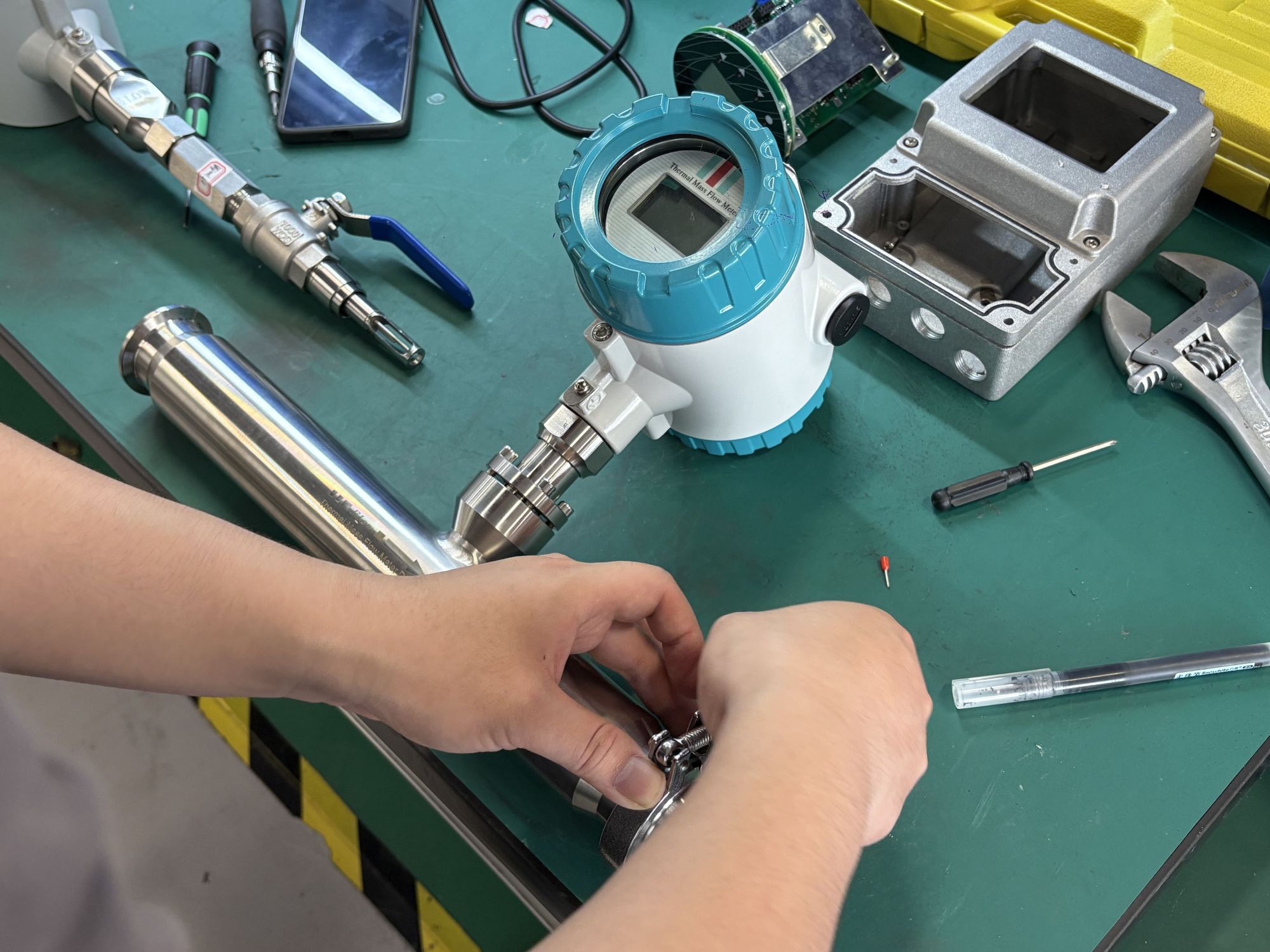

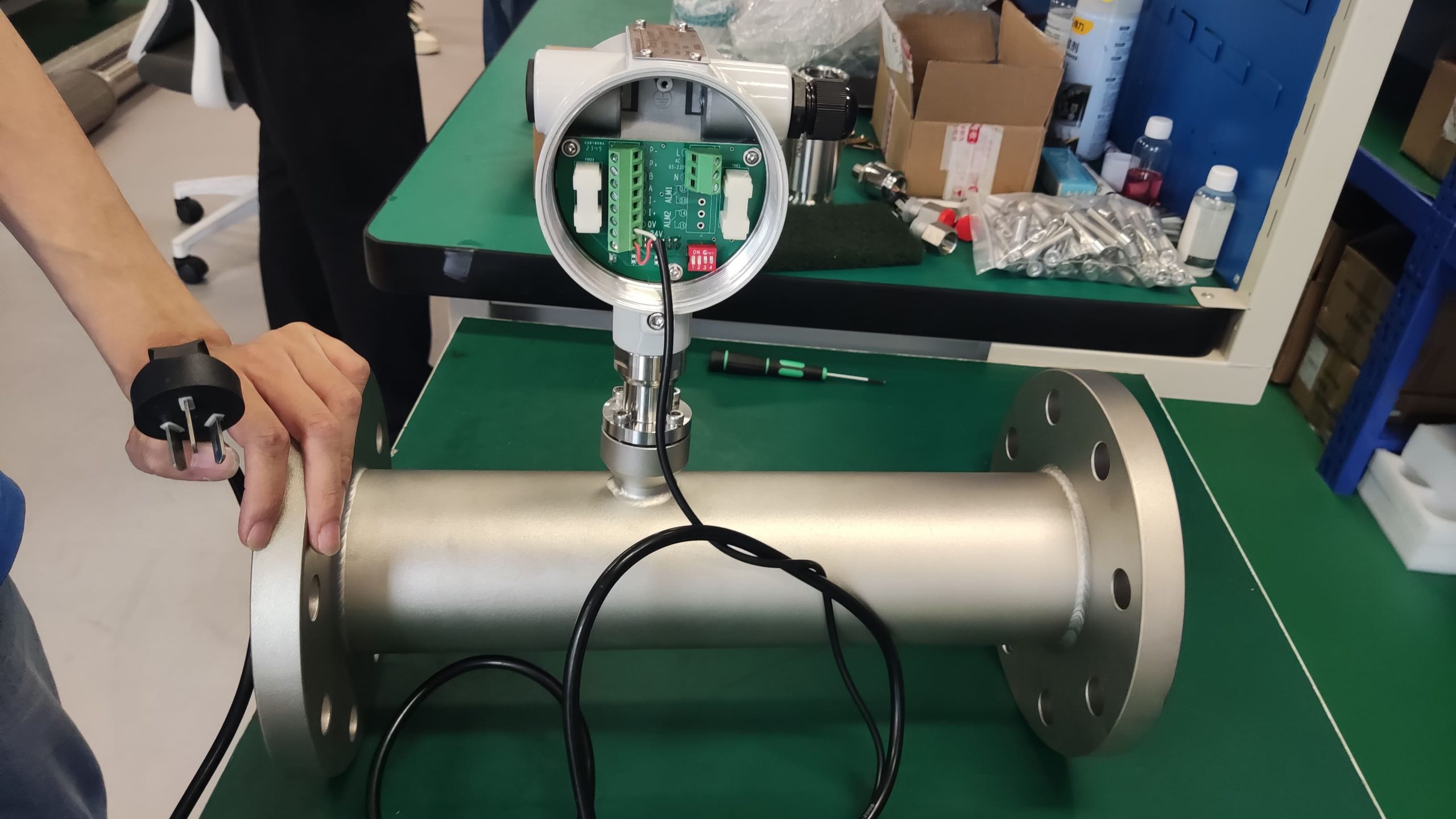

8. Convenient design, selection, installation and use.

Points that need attention in the application of thermal gas mass flowmeter:

1, usually in the use of mass flow meters, should prevent artificial power and disconnection. The method of power failure and signal line removal makes the mass flowmeter not measure for a short time, resulting in metering disputes, and such problems should be paid attention to. The solution is to have a lock on the instrument box, and a special person is responsible for management.

2, thermal gas mass flow meter in the use of the process under the conditions of use, it is necessary to carry out accurate zero calibration, mass flow meter belongs to the online use of height measurement instrument, zero drift has an impact on the measurement results, long-term use must be regularly calibrated.

3, be sure to avoid exceeding the use of mass flow meter range, which will cause a decline in the measurement of the instrument, serious damage to the instrument. For example, due to steam sweeping operations beyond the instrument’s operating temperature range, the detection coil will be damaged and the mass flowmeter can no longer be used.

4, it is required to carefully maintain, such as to equip it with high-quality voltage regulation power supply, frequent inspection of the vibration and use conditions of the site, etc., to ensure the safety of the degree and instrument.

5, the success of the application of thermal gas mass flowmeter is directly related to the installation. In addition to the normal installation requirements, special attention should be paid to reducing the impact of vibration, because the mass flow meter is based on the principle of vibration, and vibration will introduce interference. However, the smallest possible external interference is undoubtedly beneficial to the measurement, so the vibration from the pipeline and the field environment should be avoided as far as possible.