What are the installation requirements for mass flowmeters

Coriolis mass flowmeter can directly measure the mass and density of the fluid when installed correctly, and only reasonable installation can maintain the accuracy and stability of the mass flowmeter.

1, Coriolis mass flow meter installation routine points

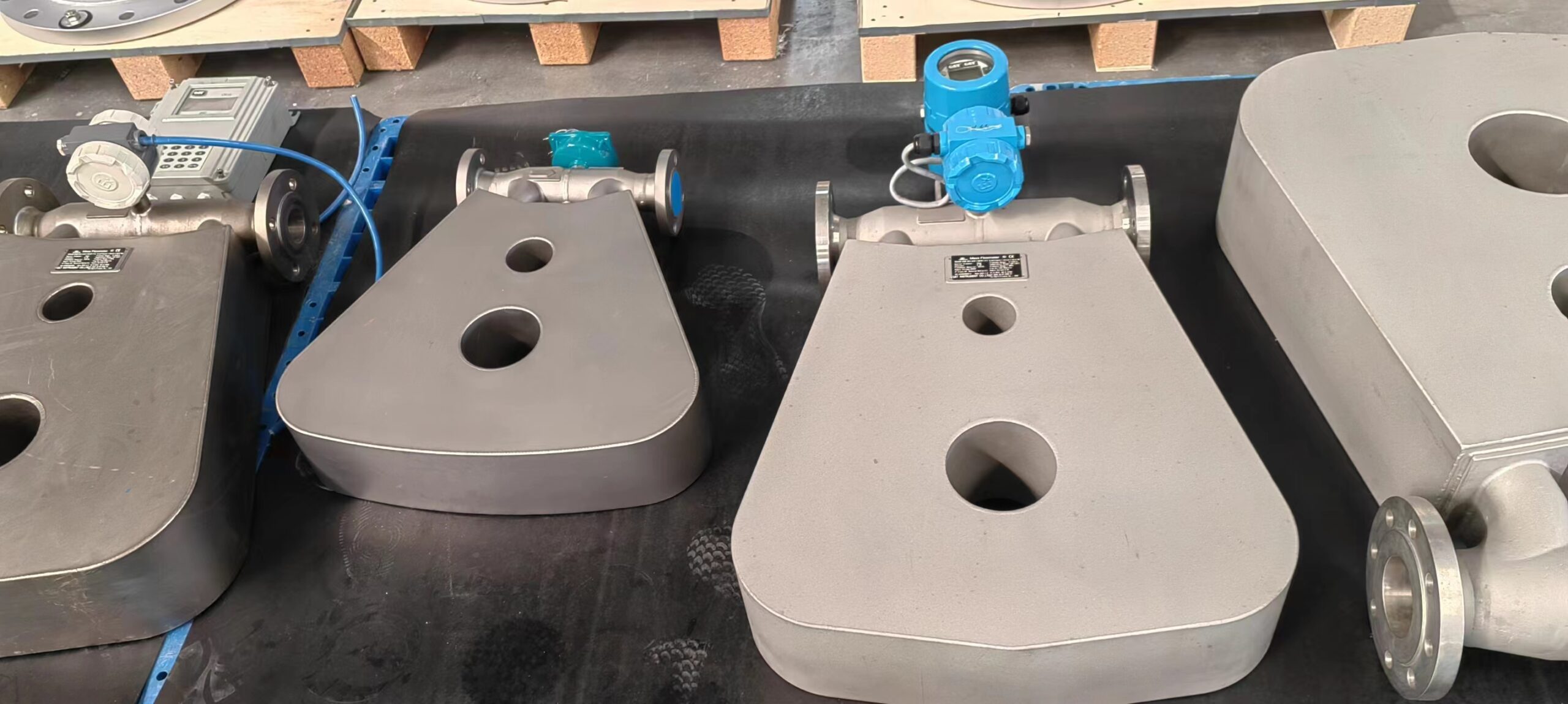

There should be at least 0.6m between the sensor and the large transmitter or motor. Because the sensor work depends on electromagnetic fields, it is necessary to avoid installing the sensor near a large interfering electromagnetic field. In addition, the installation location should be carefully selected to avoid vibration.

2. Installation direction

The requirements of the process and the position of the arranged process pipes determine the orientation of most sensors. Although the installation Angle of the sensor does not affect the flow meter operation, the following recommendations should be considered as far as possible:

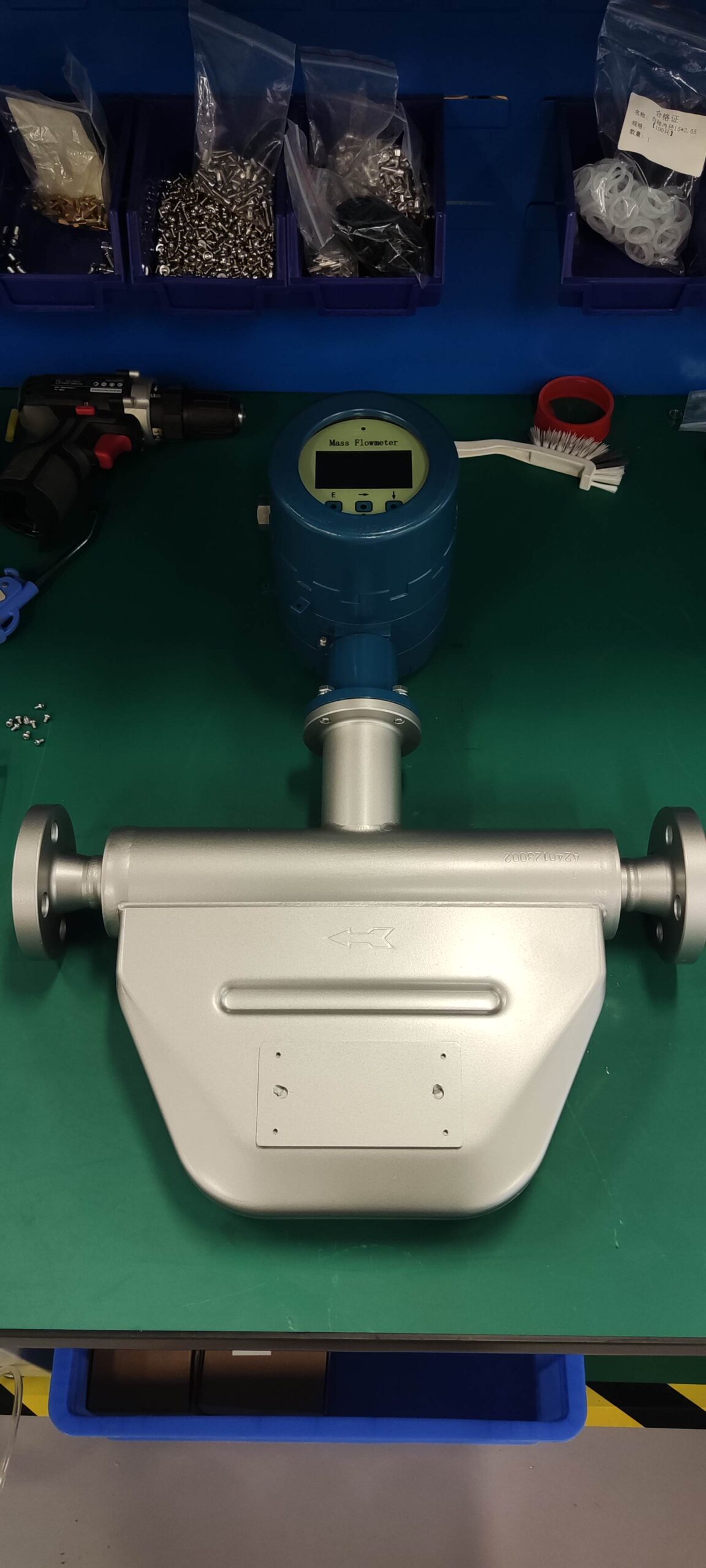

1) When measuring liquid, the sensor housing should be mounted downward to avoid air concentration in the flow tube;

2) When measuring gas, the sensor housing should be mounted upward to avoid condensation water gathering in the flow tube;

3) When measuring liquid slurry, the sensor should be installed vertically, like a flag, to avoid particles accumulating in the flow tube. The process medium should flow from the bottom up to avoid the jet pipe.

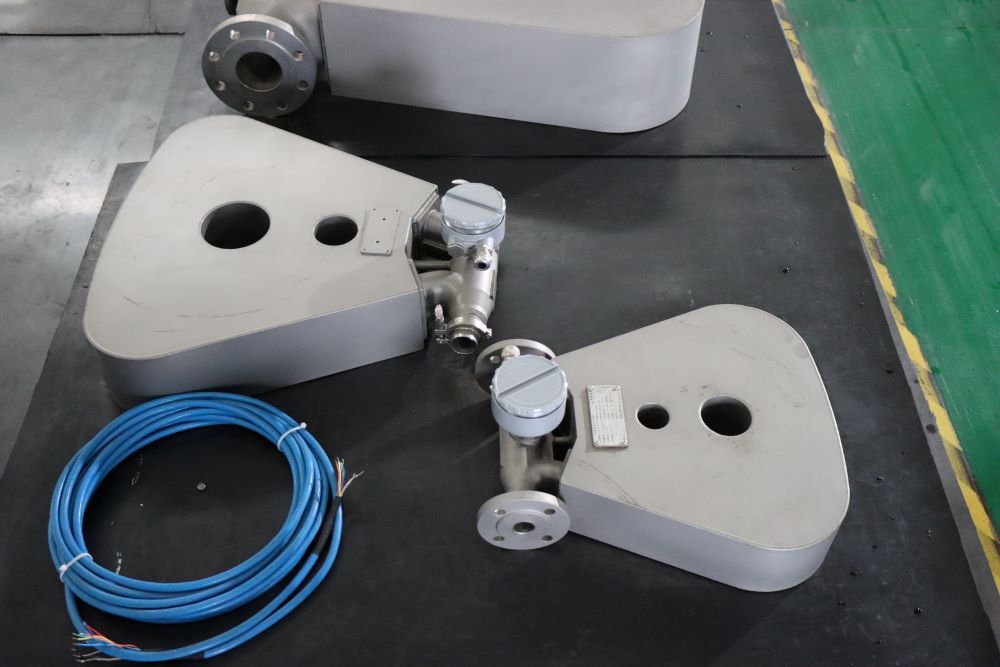

3. Valve

In order to facilitate the zero adjustment of the flow meter, a stop valve should be installed downstream of the sensor. In order to facilitate batch operation, the sensor and stop valve should be as close as possible to the receiving container. No hose should be installed between the sensor and the stop valve to avoid batch errors caused by expansion or compression. In addition, a regulator can be installed downstream to prevent vaporization or evacuation of the medium.

4. Flow direction of mass flowmeter installation

Regardless of the direction of flow, the flow sensor accurately measures the flow. Generally, arrows are used on the sensor to indicate the normal flow direction of the fluid.

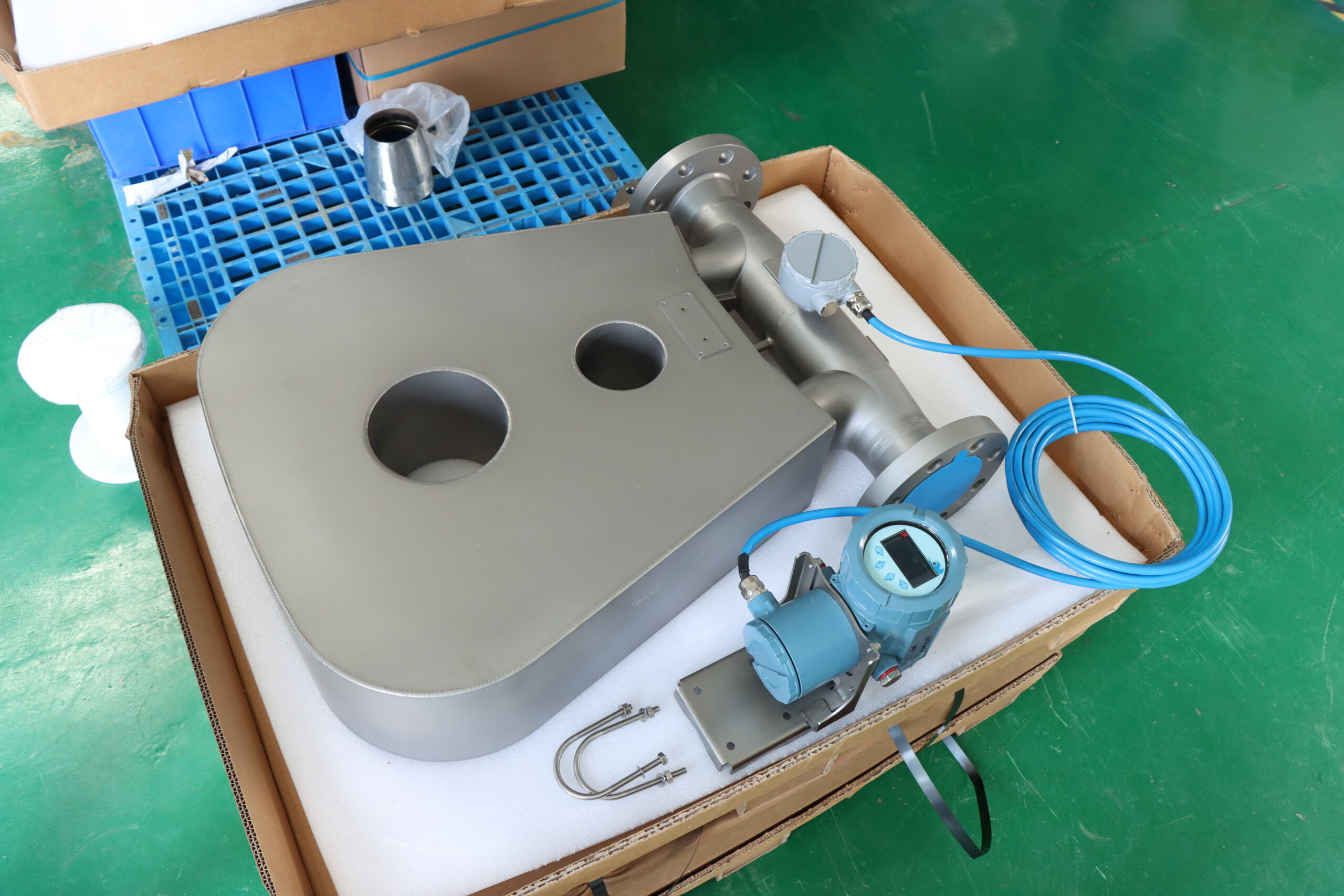

5. Gas-liquid two-phase flow

If the process medium produces a gas-liquid two-phase flow, the sensor housing should be mounted downward or mounted on a vertical pipe. This installation method can avoid the accumulation of gas in the medium in the flow pipe.

When installing the Coriolis mass flow meter, the direction of installation is very important, the direction of installation is determined according to the position of the process pipeline arranged on the site, and reasonable installation can ensure the long-term stable work of the Coriolis mass flow meter.