What are the applications of flowmeters in food processing

The application of flowmeter in food processing is very extensive, mainly reflected in the following aspects:

1. Accurately measure and control flow

Raw material metering: In the food processing process, the flow meter can accurately measure the flow of various raw materials, such as the input of liquid, gas or steam. This is essential for controlling product formulation and ensuring consistency in product quality and taste.

Mixing ratio control: In food processing where a variety of raw materials need to be mixed, the flow meter can precisely control the mixing ratio of various raw materials, such as the mixing ratio of milk and water, to ensure the final quality of the product.

2. Improve production efficiency and cost control

Optimize production processes: By monitoring and controlling flow in real time, flow meters can help enterprises optimize production processes, reduce waste and loss, and thus reduce production costs.

Energy management: In the use of energy such as steam, flow meters can accurately measure the flow of steam, helping enterprises to achieve energy management optimization and cost control.

3. Ensure product safety and quality

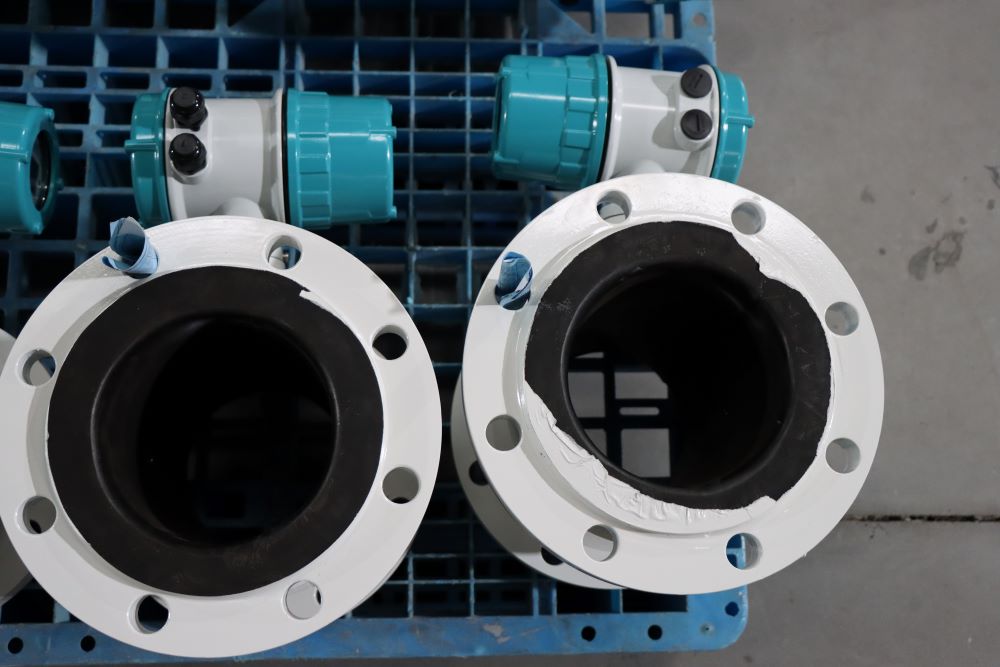

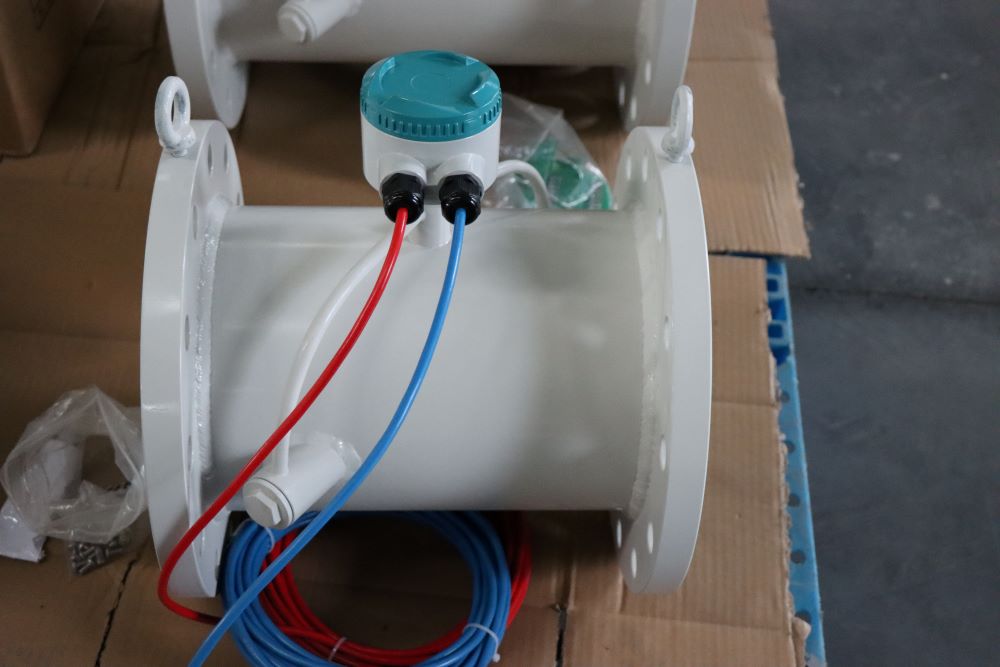

Health standards: The food processing industry has strict requirements for health standards, and the design and manufacturing of flowmeters need to meet relevant health standards to ensure the safety and health quality of products.

Quality control: The flow meter can ensure the accuracy of flow control during food processing and avoid product quality problems caused by inaccurate flow. For example, in juice processing, the flow meter can precisely control the flow of the juice to ensure that the concentration and acidity of the juice are consistent, thus guaranteeing taste and quality.

4. Specific application examples

Juice processing: Electromagnetic flowmeters can accurately measure the flow of juice, control its concentration and acidity, and ensure the taste and quality of each batch of juice is consistent.

Dairy processing: In dairy processing, the flow meter can measure the mixing ratio of milk and water, and control the fat content and taste of the milk. At the same time, the flow rate of steam can also be measured to optimize the heating and cooling process.

Packaging and filling: During the filling and packaging process, the flow meter ensures that the amount of liquid in each bottle or package is consistent, increasing the standardization of the product.

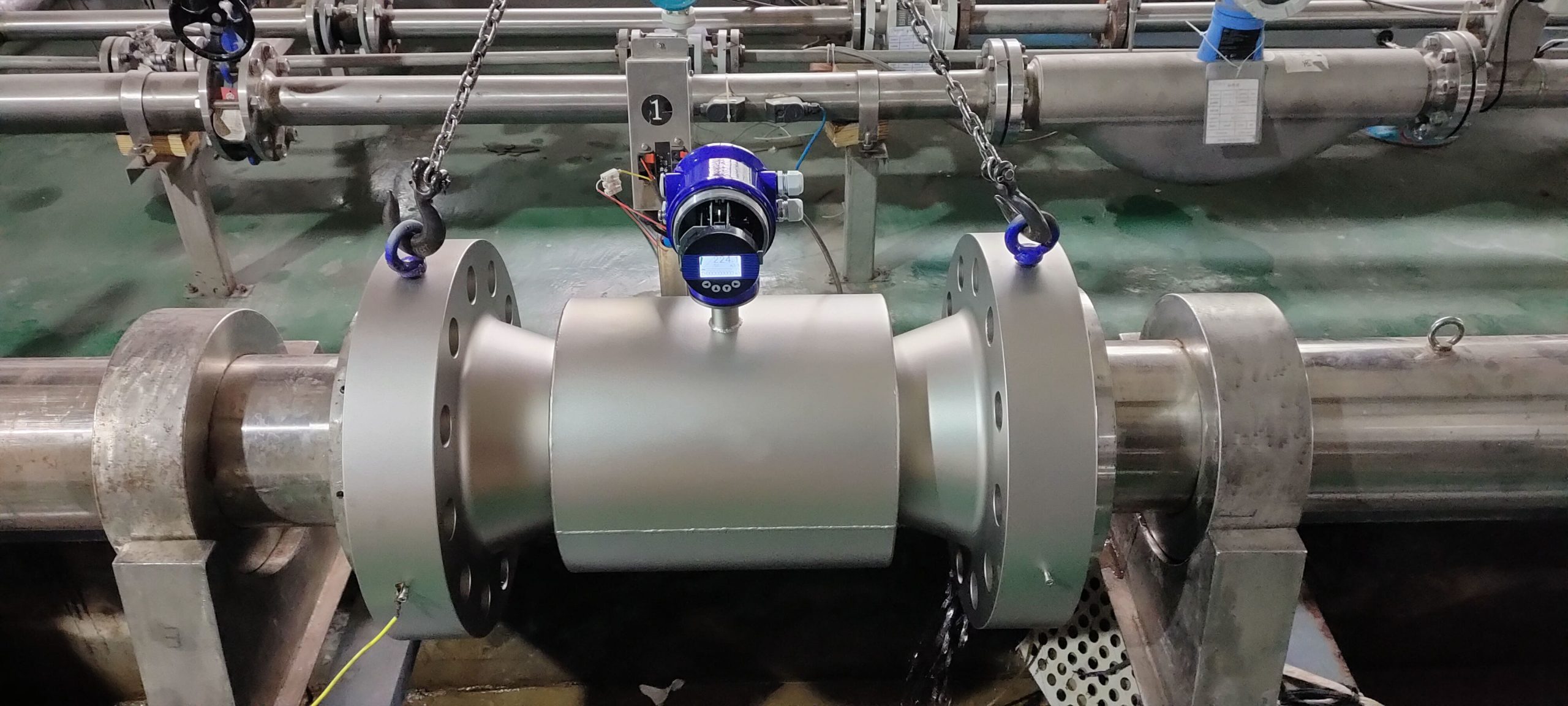

5. Type and technical characteristics of flowmeter

Flowmeter types commonly used in food processing include electromagnetic flowmeter, vortex flowmeter and so on. These flowmeters have the advantages of high accuracy, high reliability and low maintenance cost. For example, electromagnetic flowmeters use Faraday’s law of electromagnetic induction to measure flow, with an accuracy of up to ±0.5%, and can measure flow rates as low as 0.1m/s; The vortex flowmeter calculates the flow rate by detecting the vortex frequency generated by the fluid in the pipeline, which has the characteristics of high precision, wide measuring range and high reliability.

-.jpg)