What are the advantages and precautions of the thermal gas mass flowmeter

What are the advantages and precautions of the thermal gas mass flowmeter

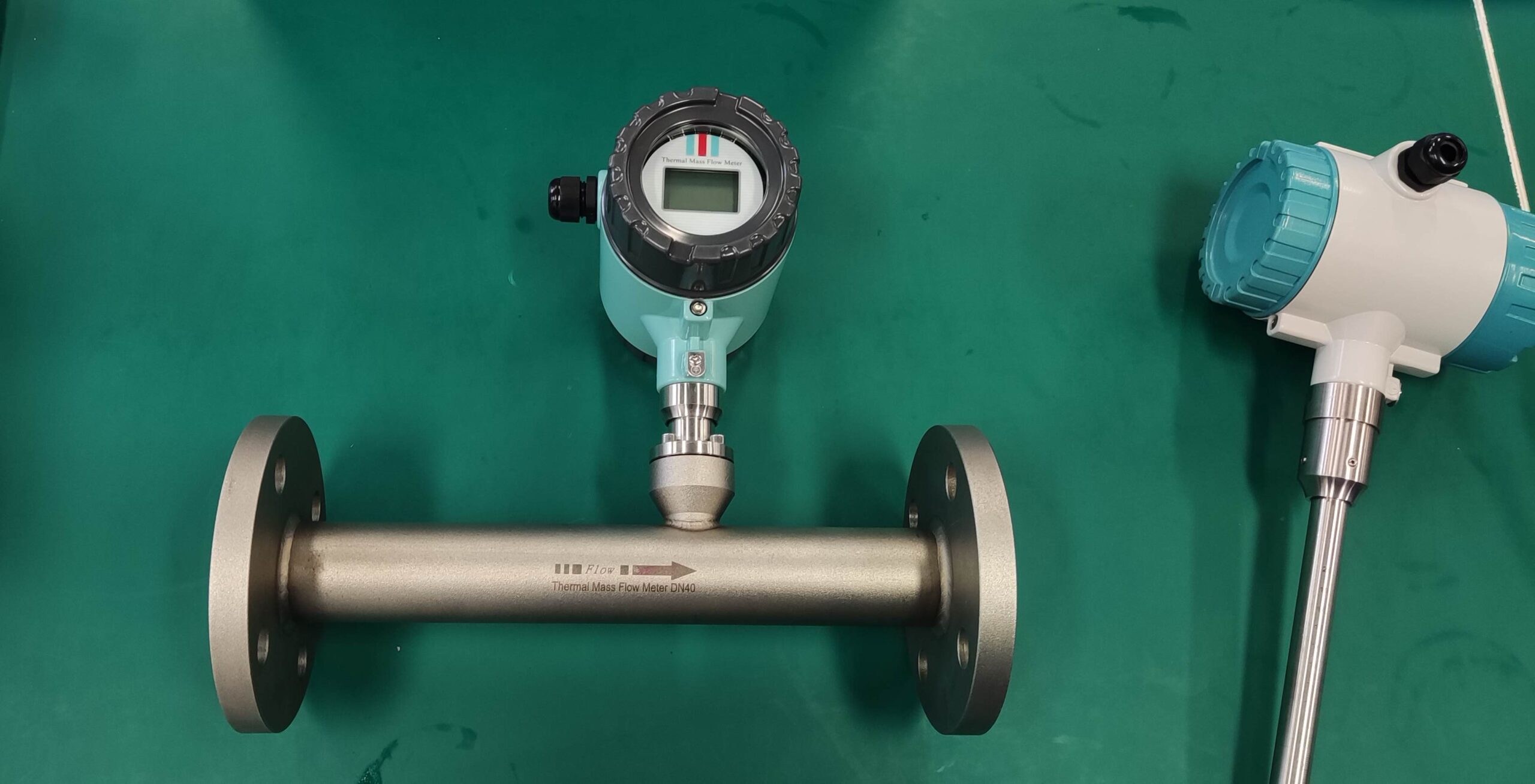

1. Advantages of thermal gas mass flowmeter

a. The thermal gas mass flowmeter is a true mass flowmeter, which is convenient and accurate for gas flow measurement without temperature and pressure compensation. The mass flow rate or standard volume flow rate of the gas can be obtained;

b. Wide range ratio, can measure the flow rate of up to 100Nm/s to 0.5Nm/s gas, can be used for gas leak detection;

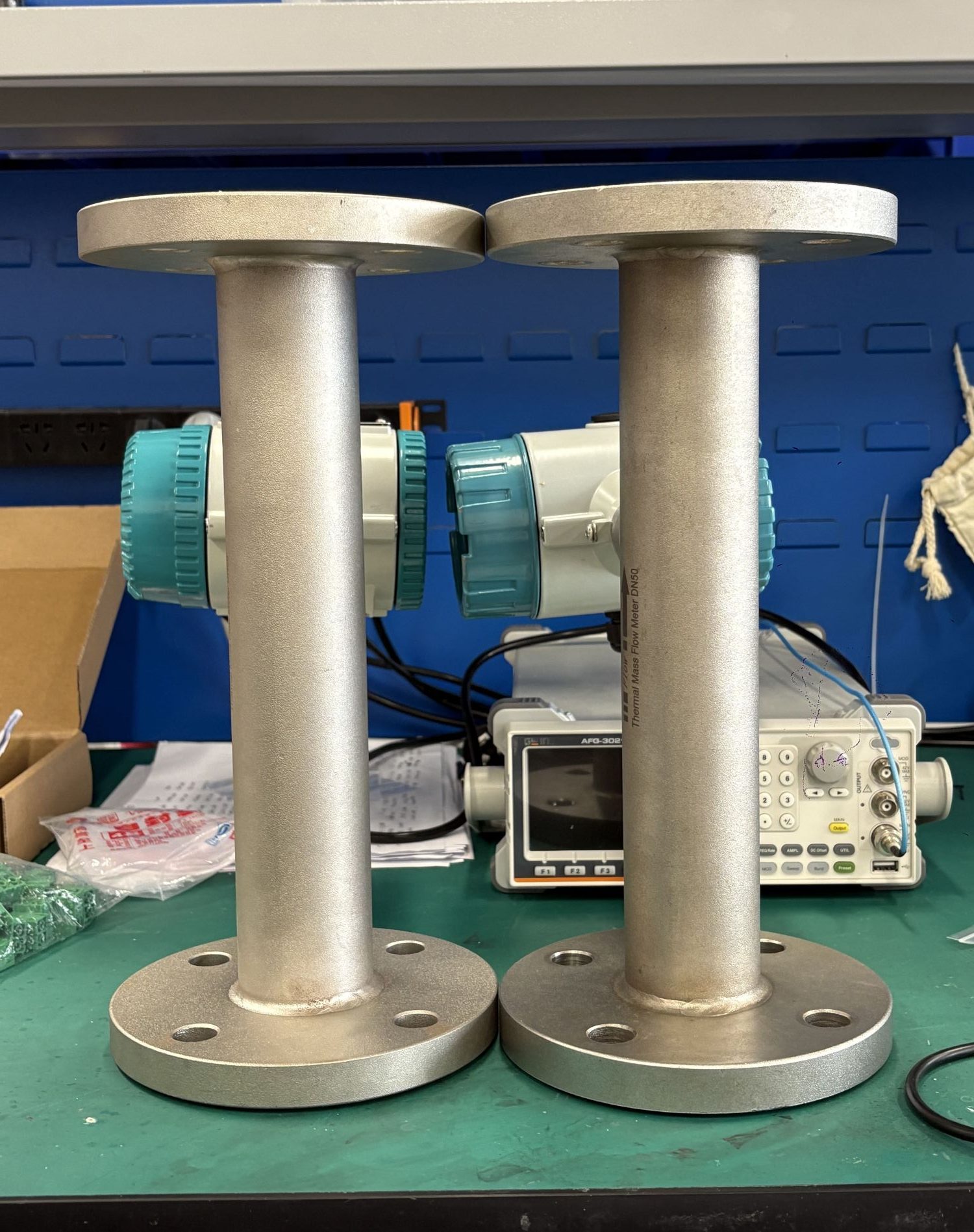

c. Good seismic performance, long service life. The sensor has no moving parts and pressure sensing parts, and is not affected by vibration on the measurement accuracy;

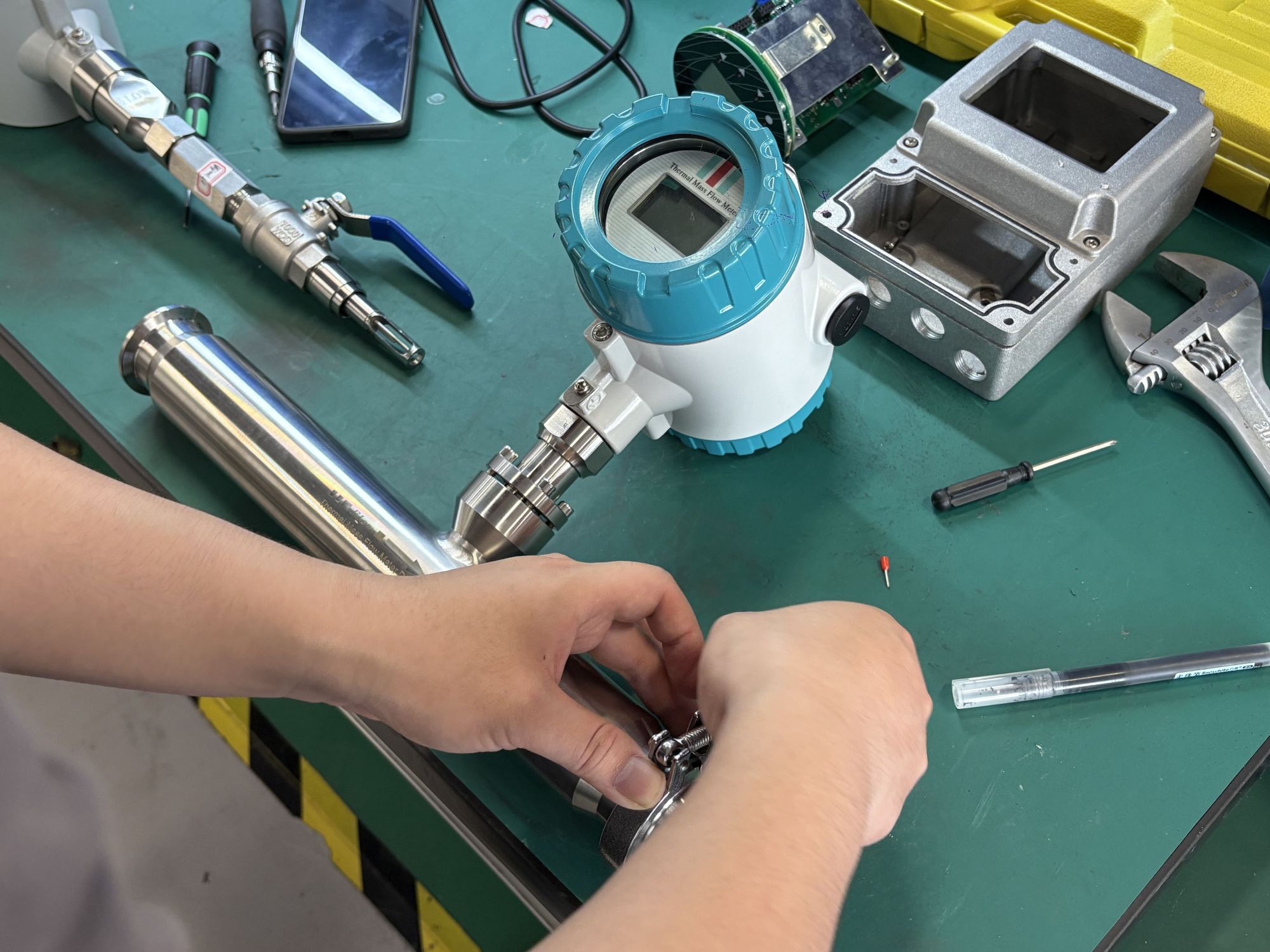

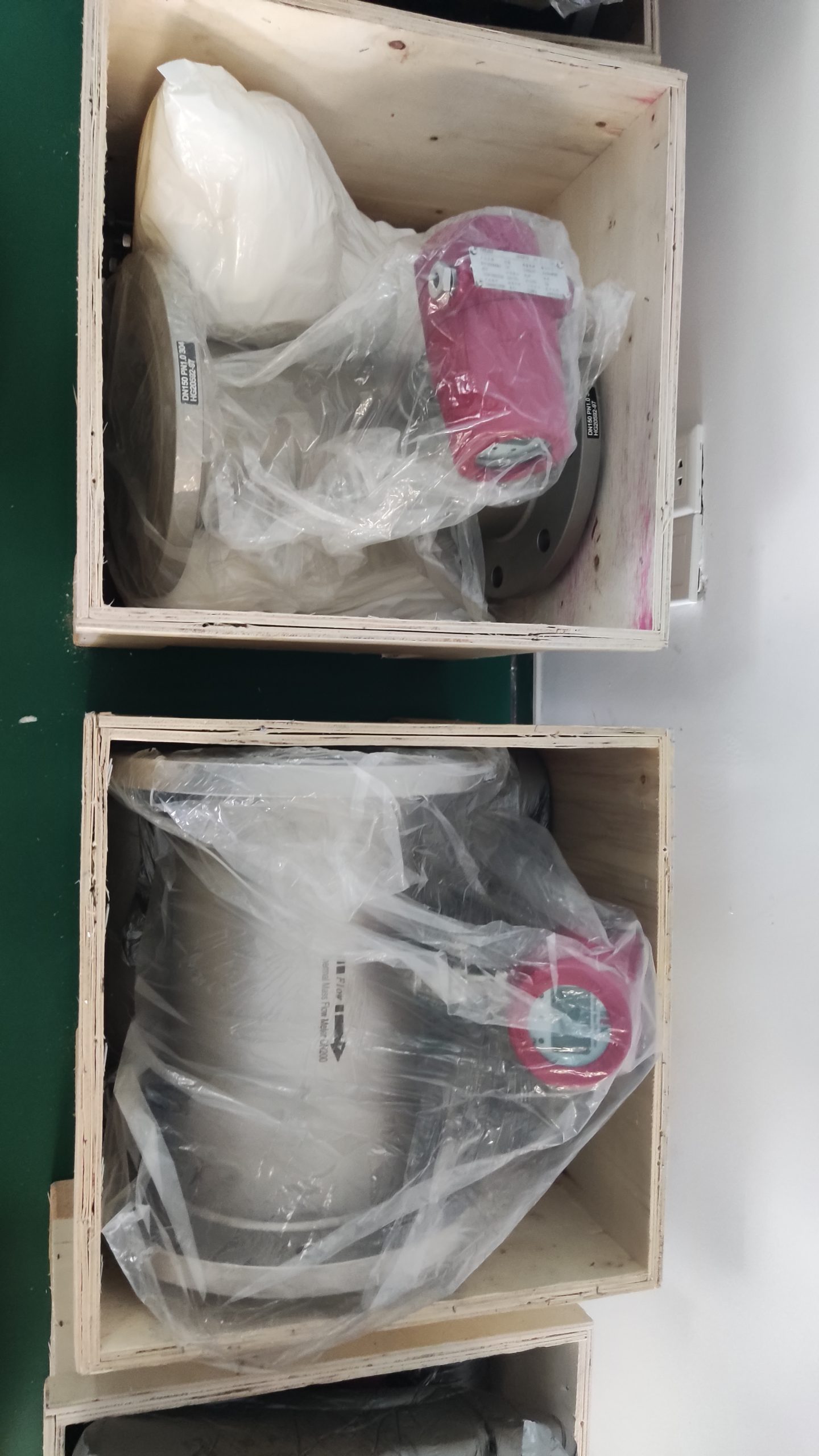

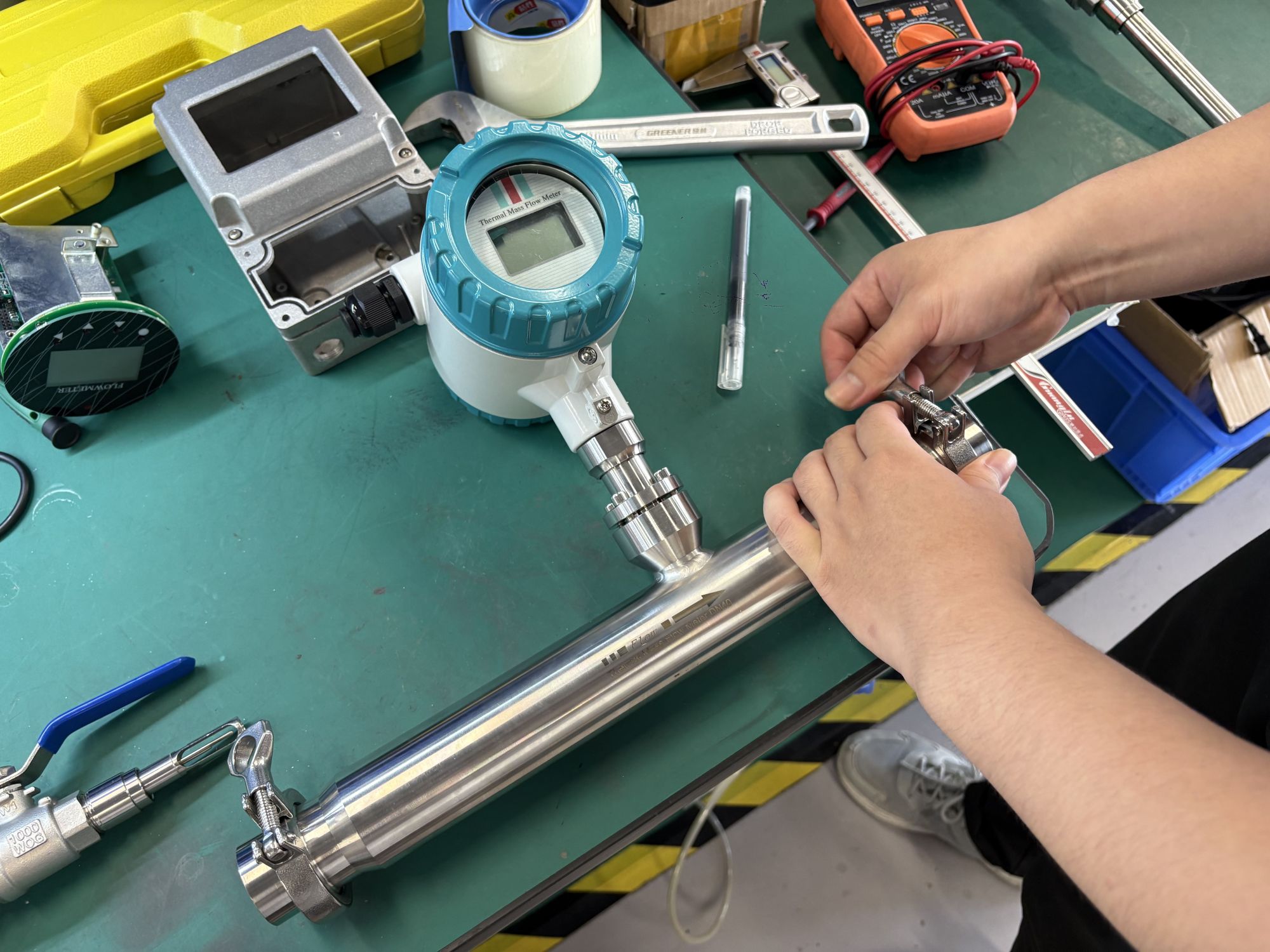

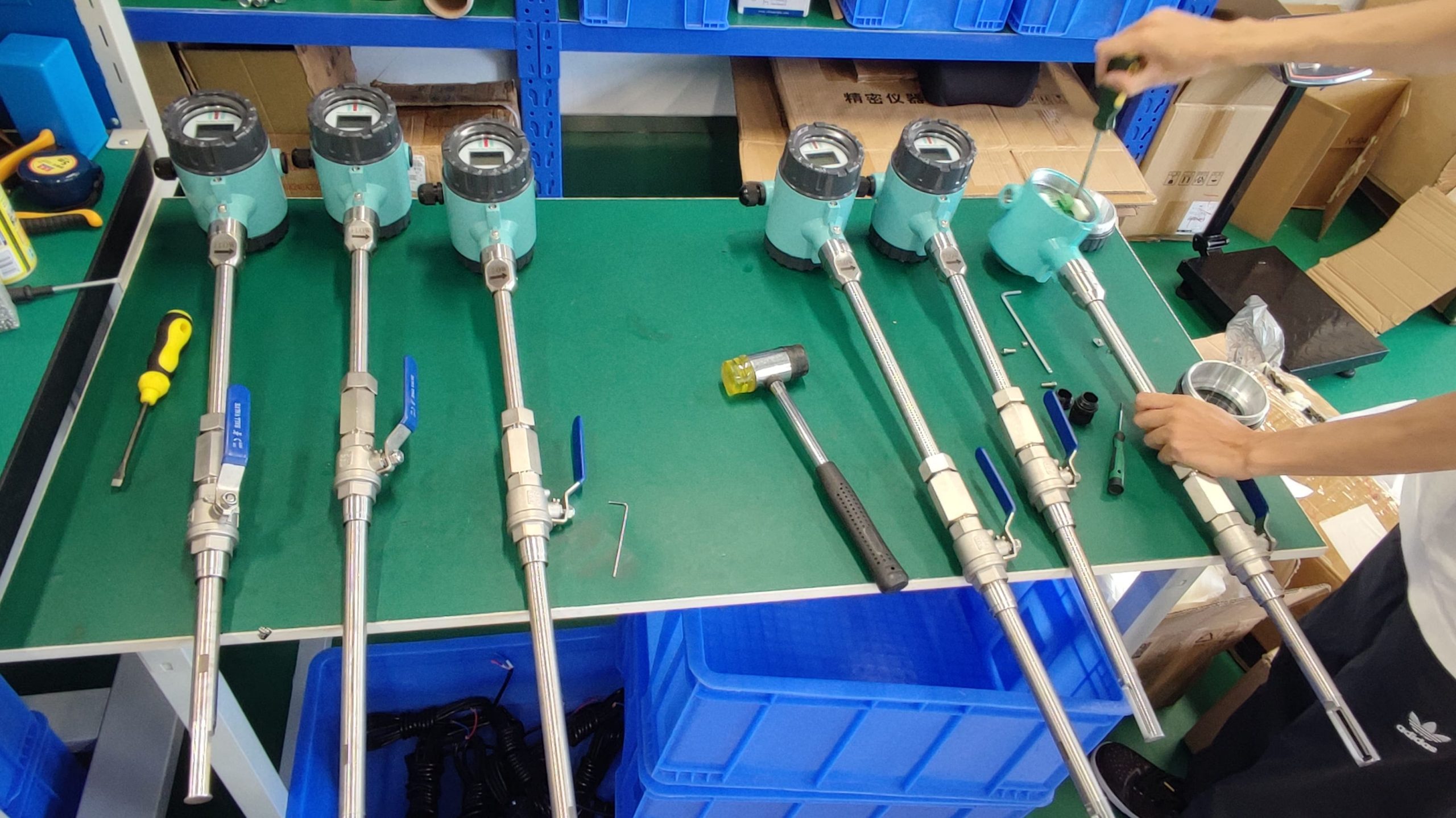

d. Easy installation and maintenance. If site conditions permit, it can be installed and maintained without stopping production. (See Safety Precautions);

e. Digital design. Overall digital circuit measurement, accurate measurement, easy maintenance;

f. Using RS-485 communication, or HART communication, can achieve factory automation and integration.

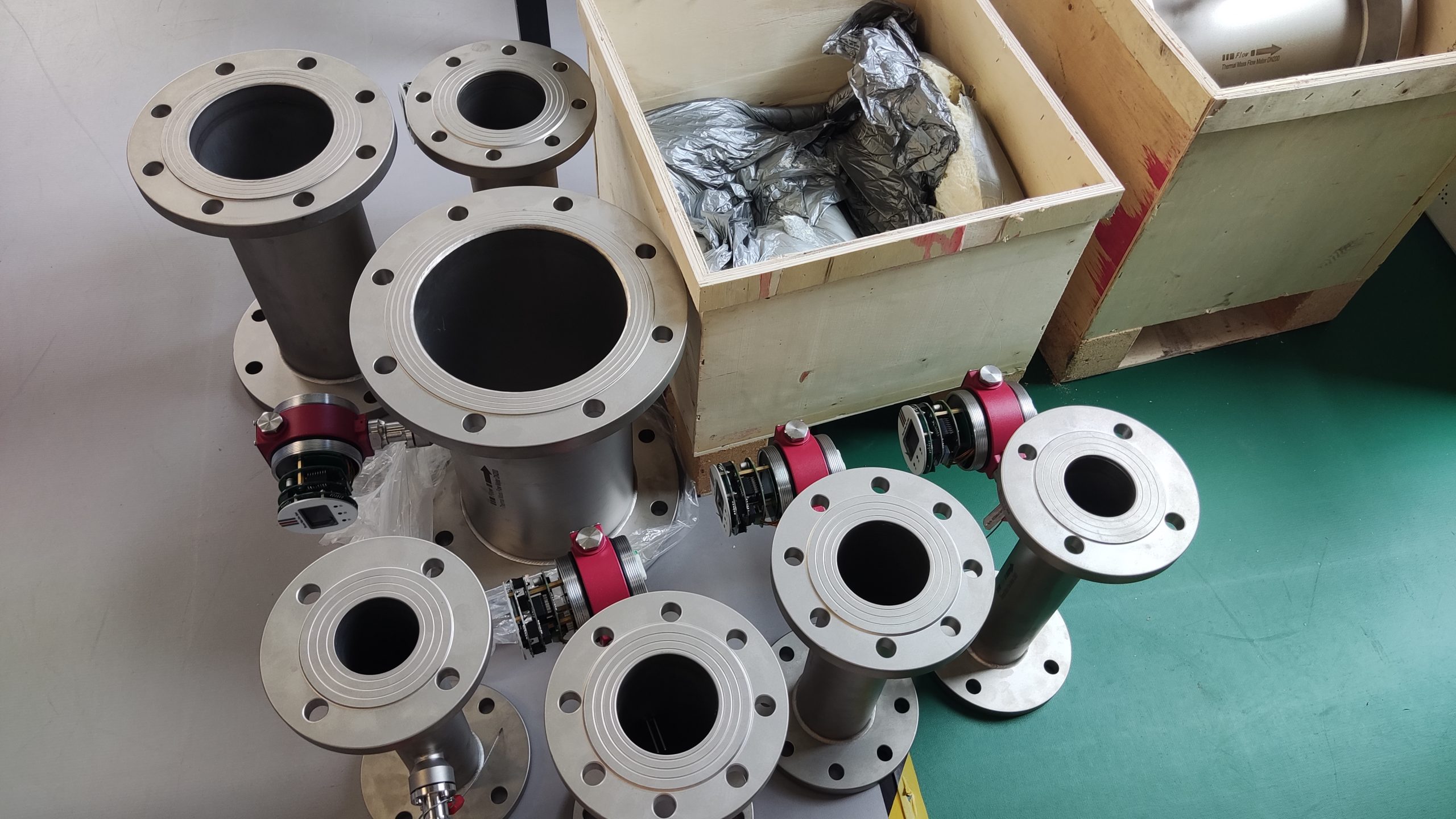

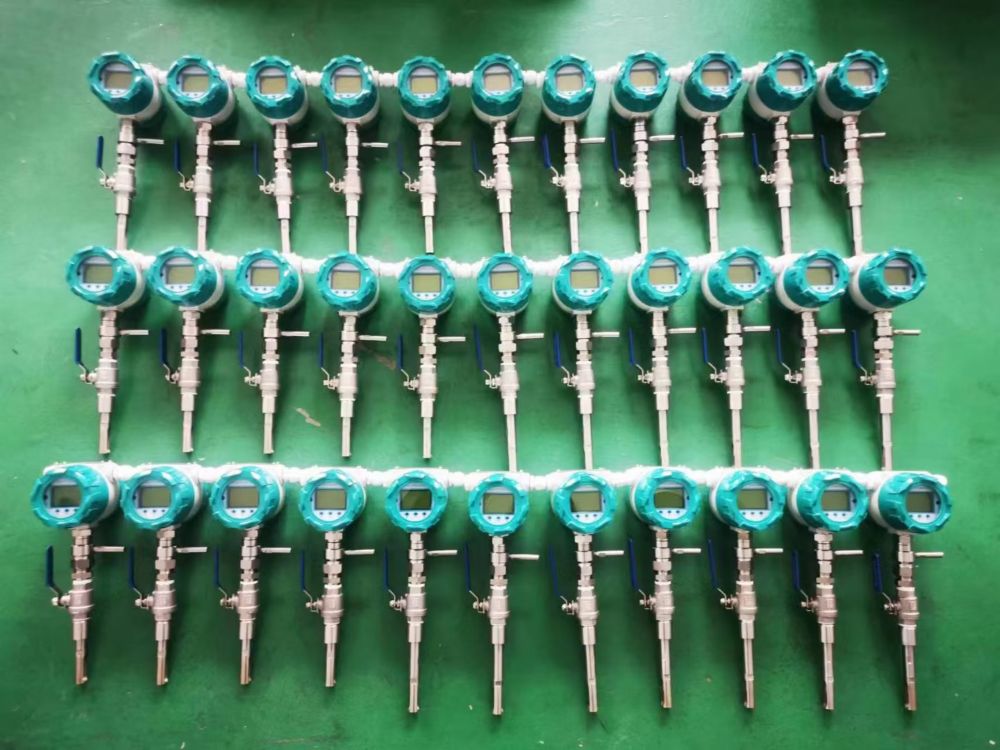

2. Application scope

Thermal gas mass flowmeter is widely used in petroleum, chemical industry, metallurgy, power plant and other industries, suitable for all kinds of dry pipeline gas (except acetylene) flow measurement.

3. Precautions

Thermal gas mass flowmeter has certain operating procedures and precautions in use, and must pay attention to these points when in use:

a. Explosion-proof instruments are used in explosive environment applications. Verify that there is an explosion-proof certification mark and a temperature group mark on the nameplate of the instrument, without which the instrument cannot be used in an explosive environment;

b. The explosion-proof temperature group of the instrument must meet the environmental requirements of on-site explosion-proof and temperature. When it is used in occasions with explosion-proof requirements, it is necessary to confirm the explosion-proof temperature group of the instrument to meet the requirements of on-site explosion-proof and temperature;

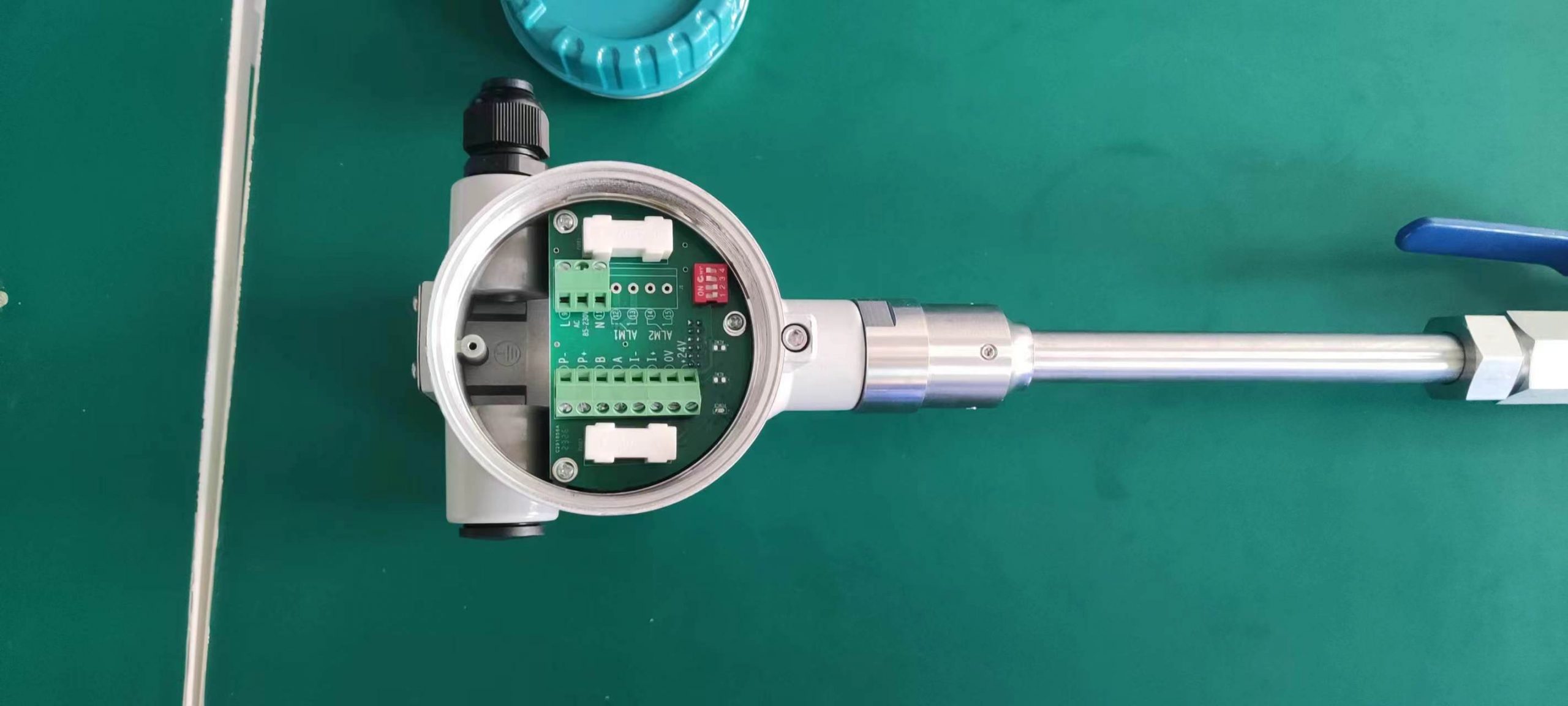

c. Live lid operation is prohibited in explosive environment. Before connecting cables, disconnect the power supply. When the parameter Settings need to be corrected. You can choose to modify it remotely, modify it with an external manual copy, or return to the site environment after the safe environment is successfully modified to avoid explosion;

d. The protection level of the instrument should meet the requirements of the current working conditions. The protection grade of the thermal gas mass flowmeter is tested and divided according to the relevant requirements in GB4208-93 (equivalent to IEC529). The protection level required by the site should be lower than or equal to the protection level of the instrument to ensure a good working environment of the instrument;

e. Check the power supply type. The user can choose two power supply methods to power the instrument, AC 220V and DC +24V (the order should indicate) must confirm whether the power supply type matches the instrument before installation;

f. Confirm the instrument working environment and medium temperature. The design temperature of the site environment and the medium should be lower than the nominal value of the instrument (the nominal value is detailed in the “Technical Parameters and Functions” in this manual;

g. When the media temperature is too high, do not perform online installation and maintenance operations. When the temperature of the measured medium is higher than the temperature borne by the human body or higher than the temperature that can cause danger, it should be stopped or cooled down. When the safe temperature is reached, the operation should be stopped without conditions for online operation to avoid danger.

h. Confirm the instrument working environment pressure and medium pressure. The site environmental pressure and the design pressure of the medium should be lower than the nominal value of the instrument (the nominal value is detailed in the “Technical Parameters and Functions” in this manual) the nominal value of the environmental pressure of the instrument is a standard atmospheric pressure ±10%;