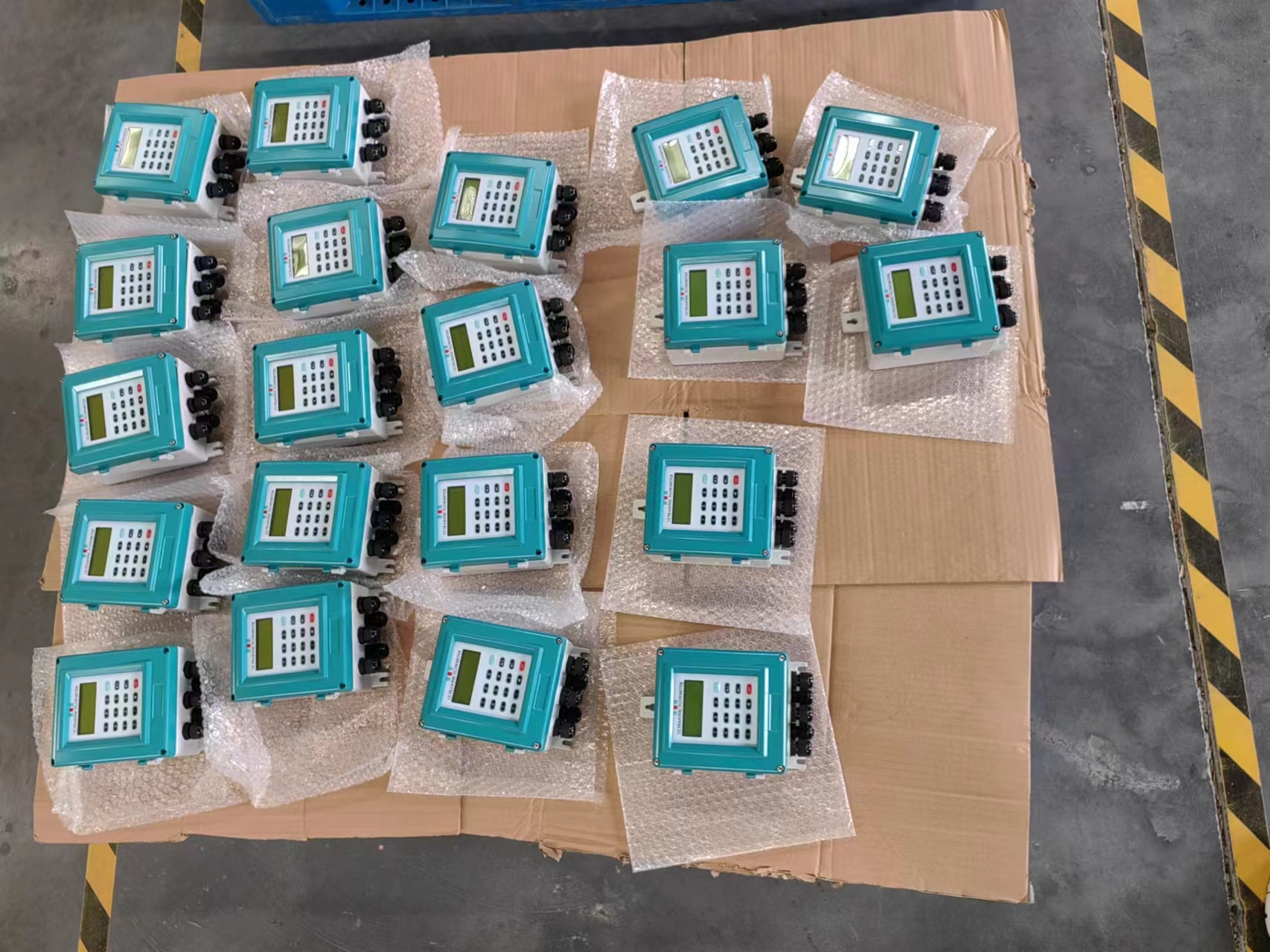

Wall Mounted Clamp on Ultrasonic Water Flow Meter with RS485 Interface and 4-20mA Analog Output

Ultrasonic flowmeters are widely used for measuring the flow of liquids in various industrial applications. Like any other equipment, they may experience common faults in practical applications. Some of the common fault situations with ultrasonic flowmeters include:

Signal Loss or Weak Signal:

Causes: This can be due to air bubbles, impurities, or deposits on the transducer surface, improper installation, or damaged transducers.

Solution: Check and clean transducer surfaces, ensure proper installation, and inspect for any physical damage.

Temperature and Pressure Fluctuations:

Causes: Changes in temperature and pressure can affect the speed of sound in the liquid, leading to inaccuracies.

Solution: Compensate for temperature and pressure variations or use flowmeters with built-in compensation features.

Pipe Vibrations and Noise:

Causes: Vibrations and noise in the pipe can interfere with the ultrasonic signal.

Solution: Ensure proper pipe supports, insulation, and use signal filtering to eliminate external interference.

Obstacles or Blockages in the Pipe:

Causes: Presence of solids, gas bubbles, or other obstructions in the fluid can disrupt the ultrasonic signal.

Solution: Regularly inspect and clean the pipe, use filters or strainers, and ensure a clear fluid path.

Incorrect Installation:

Causes: Poor installation, incorrect alignment, or inadequate coupling between transducers and the pipe can lead to measurement errors.

Solution: Follow manufacturer guidelines for proper installation, alignment, and coupling. Ensure that the pipe is free from obstructions.

Electromagnetic Interference (EMI):

Causes: EMI from nearby electrical equipment can disrupt the ultrasonic signal.

Solution: Shield the flowmeter from EMI sources, use twisted pair cables, and maintain proper grounding.

Calibration Issues:

Causes: Improper calibration or drift over time can result in inaccurate measurements.

Solution: Regularly calibrate the flowmeter according to manufacturer recommendations and industry standards.

Power Supply Problems:

Causes: Fluctuations or interruptions in the power supply can affect the performance of the flowmeter.

Solution: Ensure a stable power supply and use appropriate surge protection devices.

Transducer Aging:

Causes: Over time, transducers may degrade, affecting their performance.

Solution: Periodically inspect and replace transducers as needed, following the manufacturer’s recommendations.