Vortex flowmeter pipe with flow meter without output solution

The vortex flowmeter has a flow meter in the pipeline without output. The reasons for this failure and the corresponding solutions are as follows:

1. The possible cause is that the power supply is faulty or disconnected. Therefore, it is necessary to detect whether the power supply voltage meets the requirements and whether the power supply polarity is correct. Such as the current output vortex flowmeter, if the power supply polarity is reversed, the output current is 0mA instead of 4mA.

2. The possible cause is that the cable is disconnected or connected incorrectly. Check whether the cable is normal. If the cable is faulty, reconnect the cable and check.

3. The possible cause of the fault is that the ripple coefficient of the power supply is too large. The test can be performed with a filtered electrolytic capacitor, which generally requires a capacitance of ³100μF and 50V.

4. The possible cause of the failure is that a certain level of the vortex flowmeter amplifier plate is faulty. You can observe the changes at the output end by observing the waveform at the input and output end of the amplifier, or injecting the human sensor signal from the input end. If there is no change in the output, the amplifier is not working properly. In the actual maintenance, you can also use other types of flowmeter motherboards on site to replace for inspection. Confirm that the amplifier plate is faulty and should be replaced.

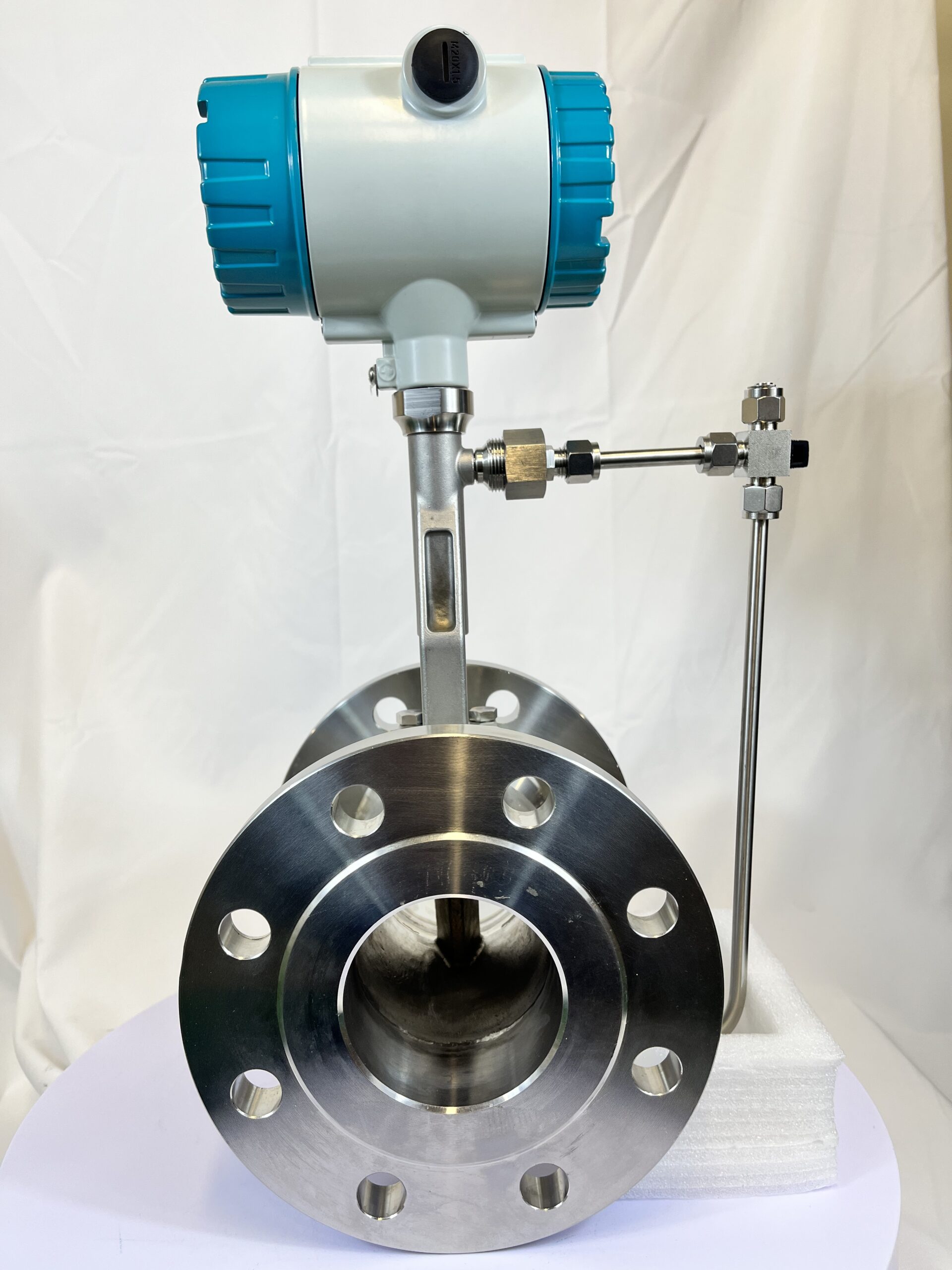

5. The possible cause of failure is the damage of the vortex flowmeter sensor. The detection method first increases the flow rate, and the vortex main board is replaced with the same type of vortex flowmeter, such as eliminating the fault of the main board and checking the occurrence body.

Vortex flow meter body damage occurs in the steam measurement system, because the process personnel open the valve too fast, so that high temperature and high pressure water vapor entrainment condensate severe impact on the vortex body, resulting in its damage, that is, the often said “water hammer” phenomenon. Therefore, it is necessary to open the guide shower to drain the condensate and then slowly open the steam valve to avoid damaging the whirlpool.

6. The possible cause of failure is that the pipeline flow is too low and does not enter the measurement range. The flow rate can be increased to see the response of the flowmeter. In the pipeline near the vortex flowmeter is regularly continuously tapped, no matter what type of vortex flowmeter will appear flow display. If the measured medium is liquid, empty tube test, because the liquid itself is a vibration absorber. The method of troubleshooting is to replace the flow meter with a smaller diameter or increase the flow rate if the process conditions allow.

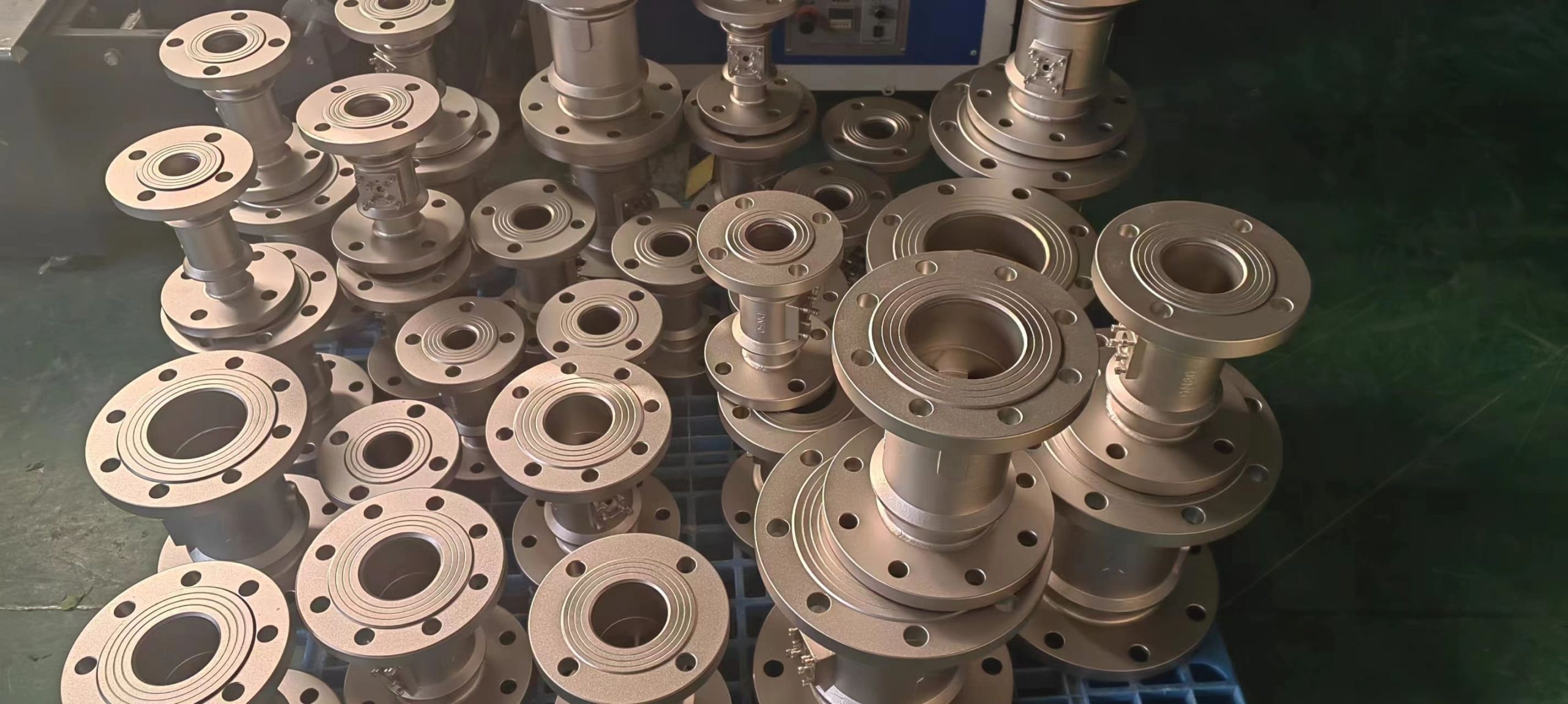

7. The possible cause of failure is whether the gap between the generating body and the housing is stuck by fine particles. This phenomenon generally occurs after normal work, stop and start. If so, if it is confirmed that the conversion amplifier and the generator are intact, especially if the measuring medium is liquid, it is generally considered to be such a fault. The method of treatment is to open the flow rate as much as possible if the production process conditions allow, and use a wooden or rubber hammer to hit the welding table at the lower part of the flow meter vertically, so that the negative pressure generated by the high-speed fluid will take away the fine solid particles. If the site allows disassembly and cleaning, the generator can be removed, but it is required to know the structure of the flow meter, especially the sealing gasket and pressure plate screws, etc., and must be installed strictly according to the requirements of the instruction manual. At the same time, it is necessary to pay attention to the generation body that is reinstalled after disassembly, which may bring some changes to the flow coefficient, although it does not change much, it needs to be corrected.

8. Check whether there is any error in parameter setting against the vortex flowmeter instruction manual. If so, correct it.