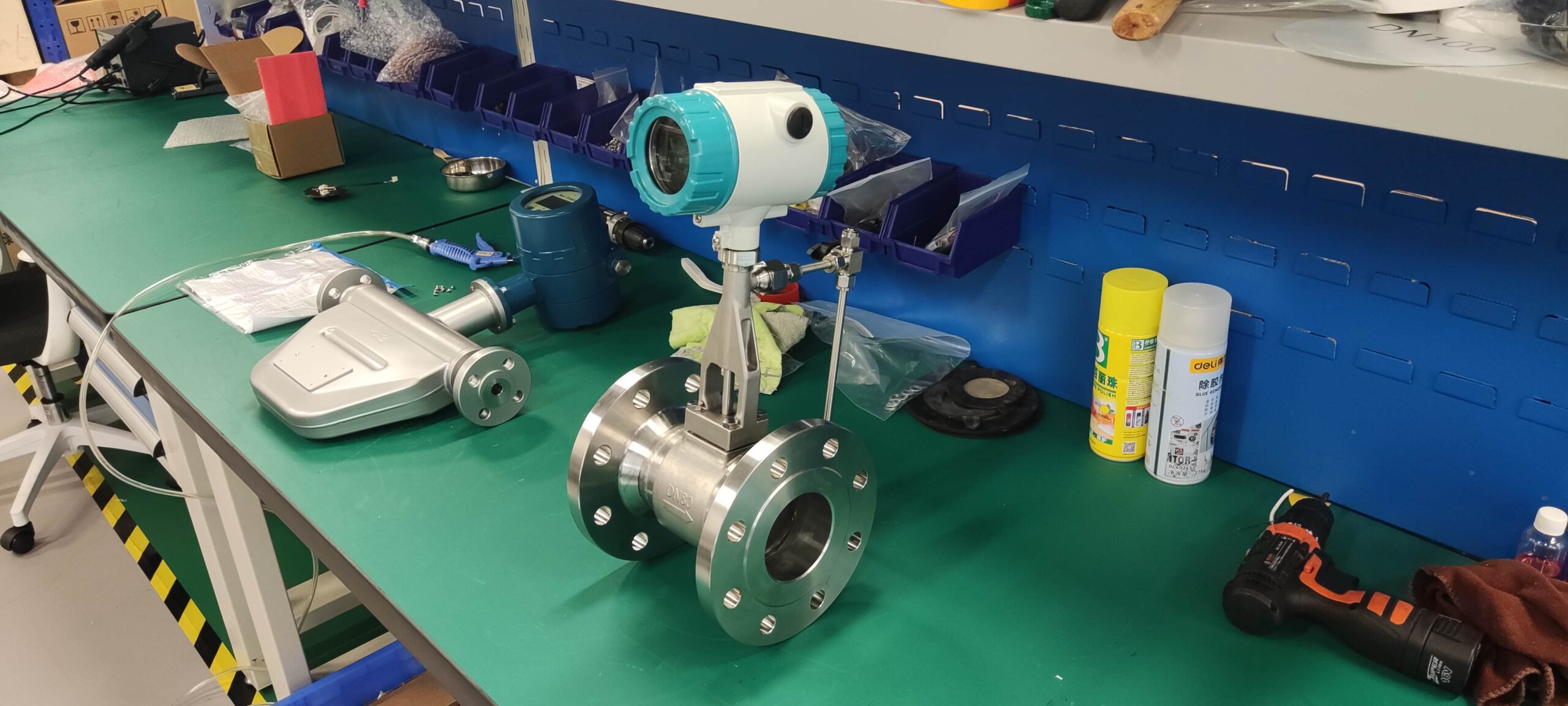

Vortex flow meter common faults and solutions

1. After power-on, there is fluid flow in the pipeline, but the vortex flowmeter has no signal output

1. After power-on, there is fluid flow in the pipeline, but the vortex flowmeter has no signal output

a. Check whether the meter is connected correctly and whether there are short wires

b. Check whether the instrument is installed in the correct direction

c. Check whether the traffic is below the normal range

2. There is no fluid flow in the power-on pipeline, but the vortex flowmeter has signal output

a. Check whether the vortex flowmeter is grounded to introduce interference due to poor grounding

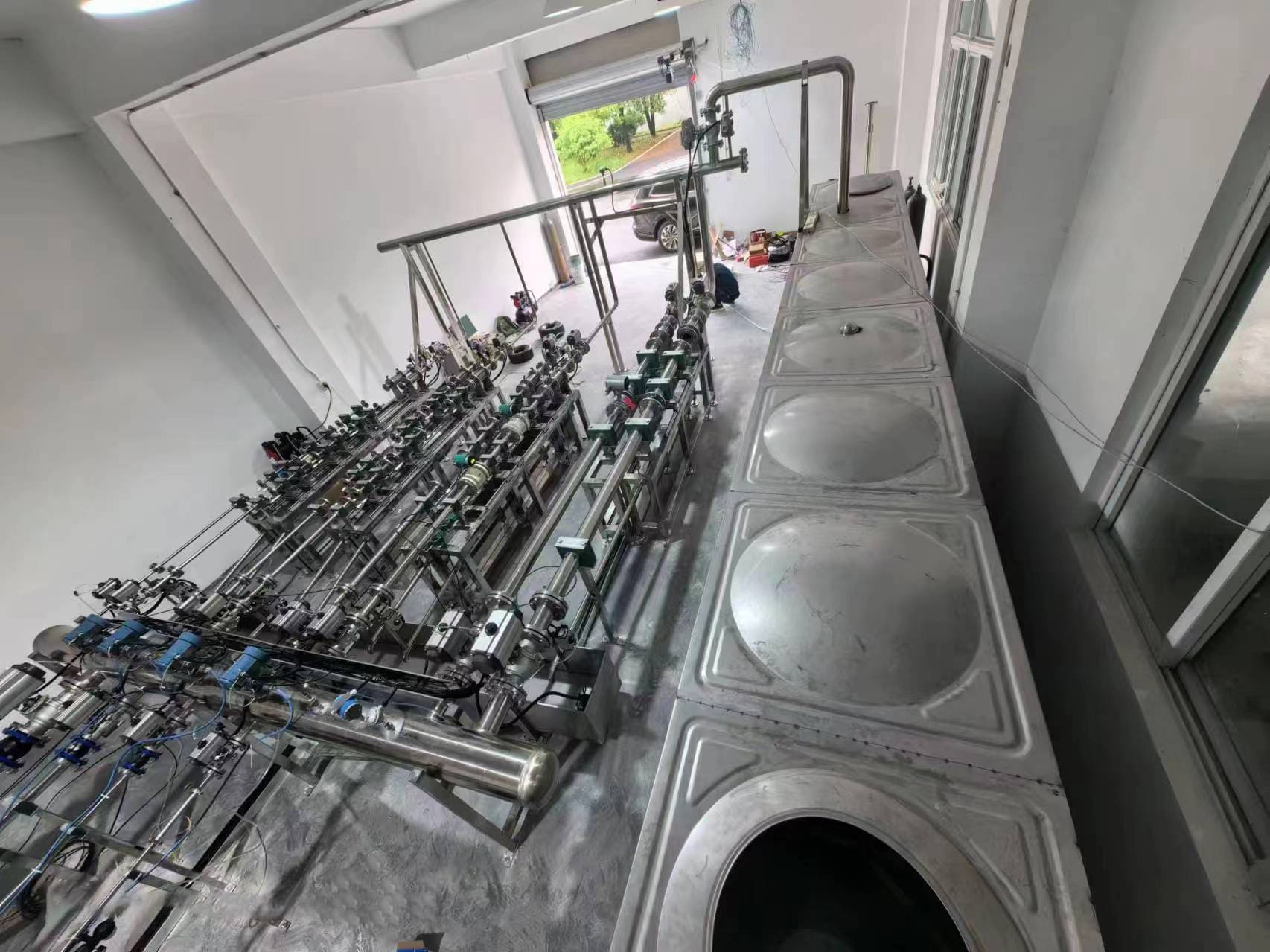

b. Check whether the pipeline has strong mechanical vibration

c. Check whether the environment has strong electromagnetic interference, such as high-power electrical appliances or frequency converters and other strong electrical equipment

d. Check whether the sensitivity is too high and adjust the two potentiometers counterclockwise until there is no output

3. The flow of fluid in the pipeline is stable and meets the flow requirements, but the output changes too much and is unstable

a. Interference may be caused by poor grounding

b. Can be the pipeline vibration is too strong to introduce interference

c. The sensitivity may be too low, there is a leakage trigger phenomenon, improve the sensitivity can be

4. The displayed traffic is inconsistent with the actual traffic

a. The instrument parameters may be set incorrectly

b. May be the temperature and pressure instrument measurement error is too large

c. The traffic may be lower or higher than the normal traffic range

d. It may be that the installation does not meet the requirements, such as the installation of different centers of vortex flowmeters, obstacles in the pipeline, and insufficient straight pipe sections