Use and maintenance of gas turbine flow meter

In order to ensure the long-term normal operation of the gas turbine flowmeter, it is necessary to check the running status of the flowmeter frequently, do maintenance work, and eliminate problems in time.

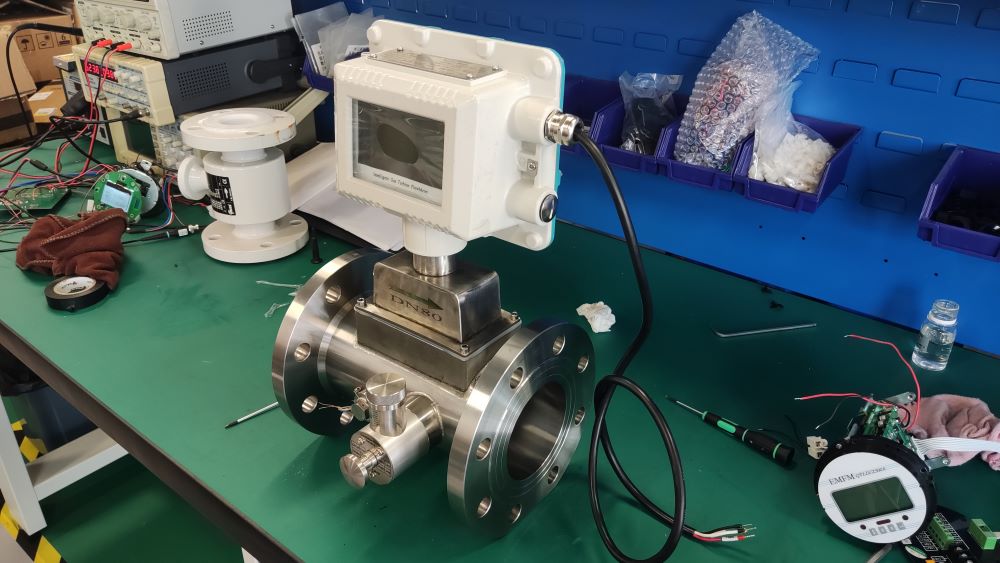

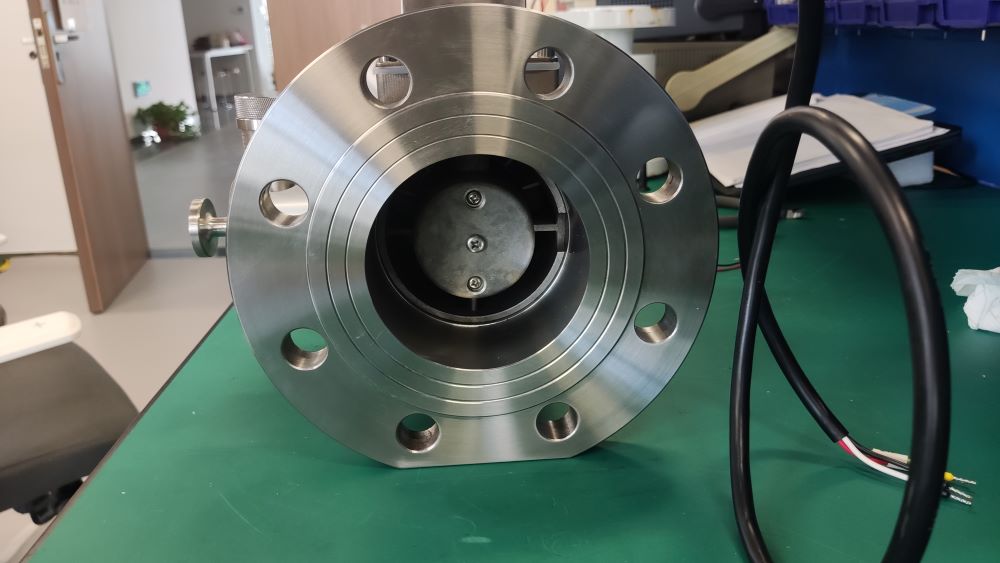

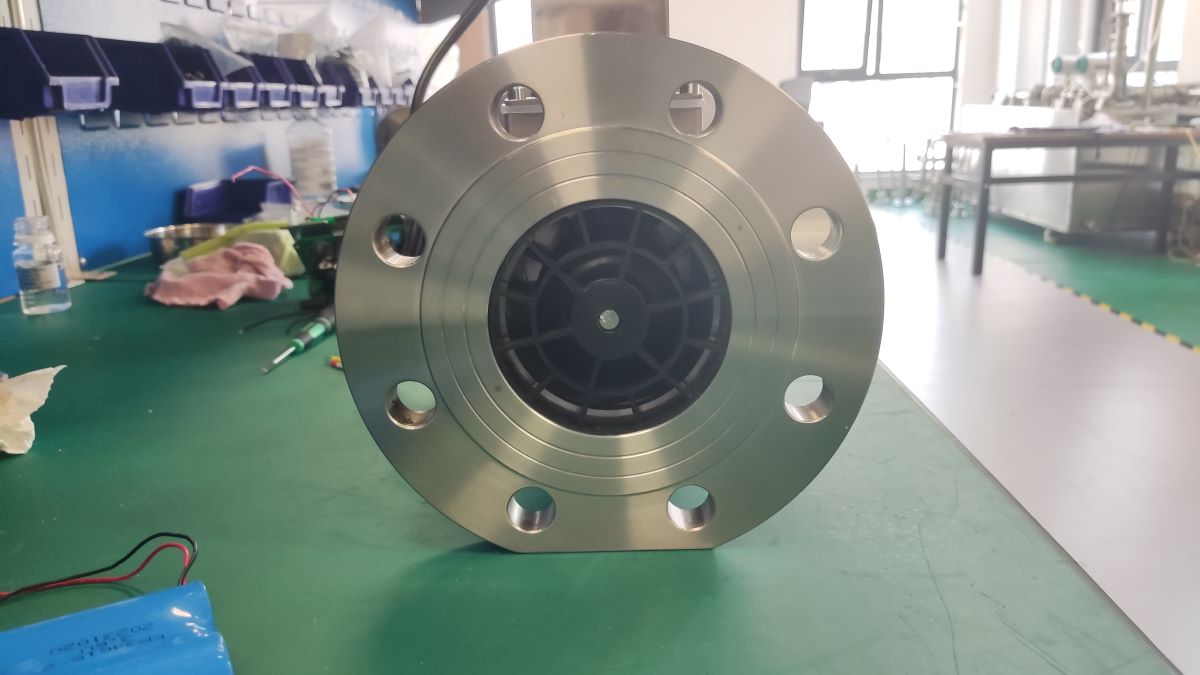

1. Before the turbine flowmeter is put into operation, the instrument coefficient should be set first, and the meter should be carefully checked to ensure that the flowmeter is properly connected and well grounded before it can be powered.

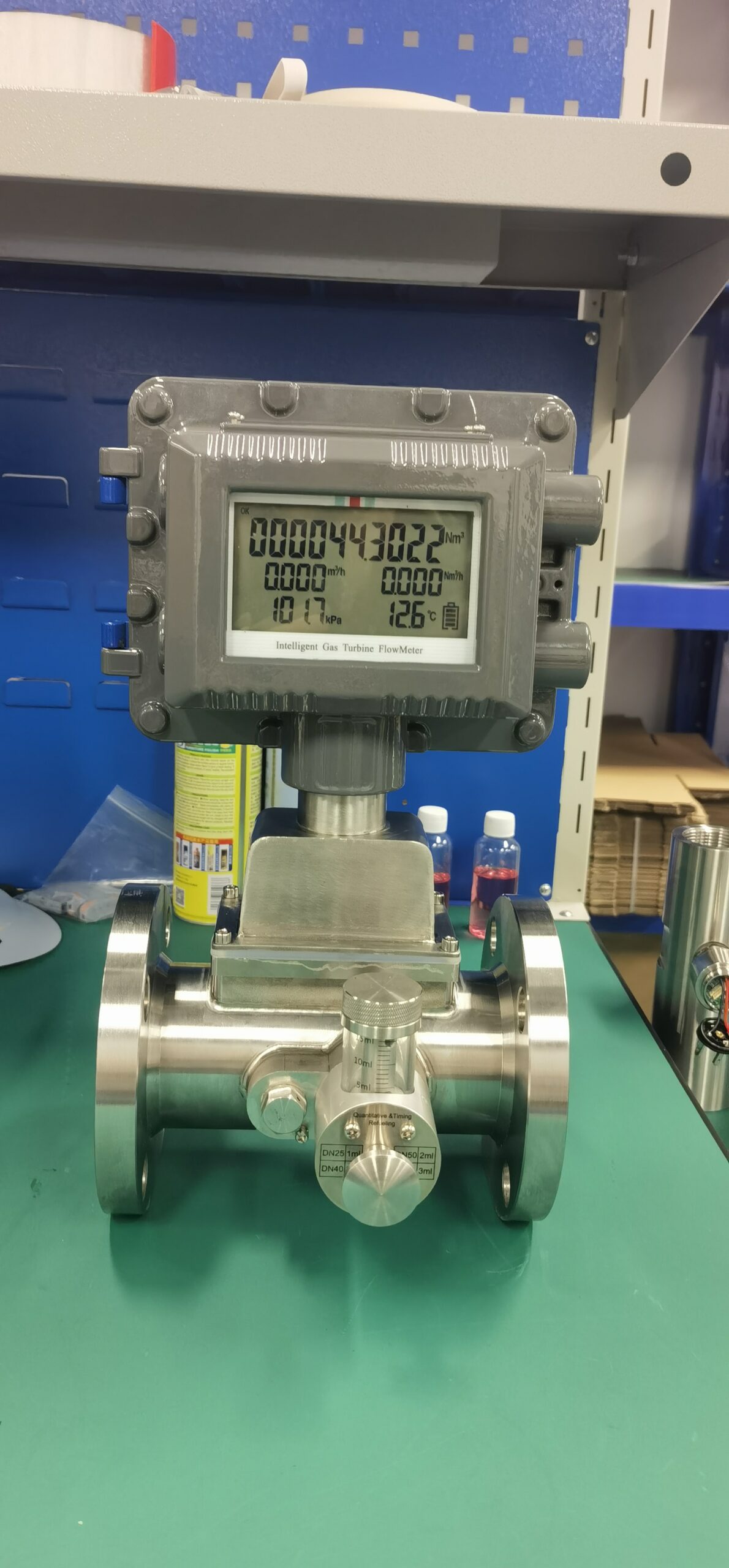

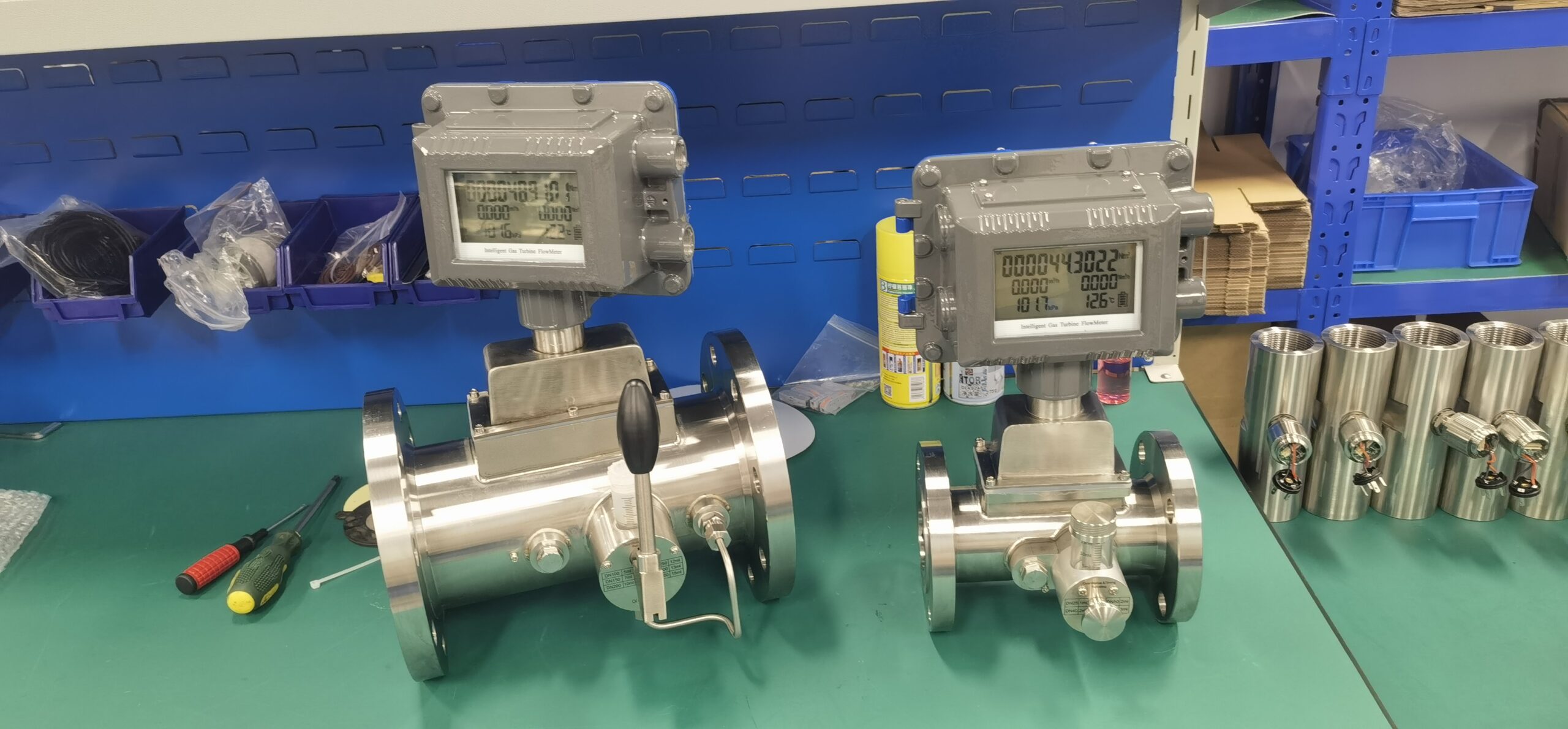

2, regularly clean, check and re-calibrate the flow meter. Flow meters with lubricating oil or cleaning fluid injection ports should be regularly injected with lubricating oil or cleaning fluid according to the requirements of the instructions to maintain the good operation of the impeller.

3, monitor the condition of the display instrument, evaluate the reading of the display instrument, and check in time if there is an anomaly.

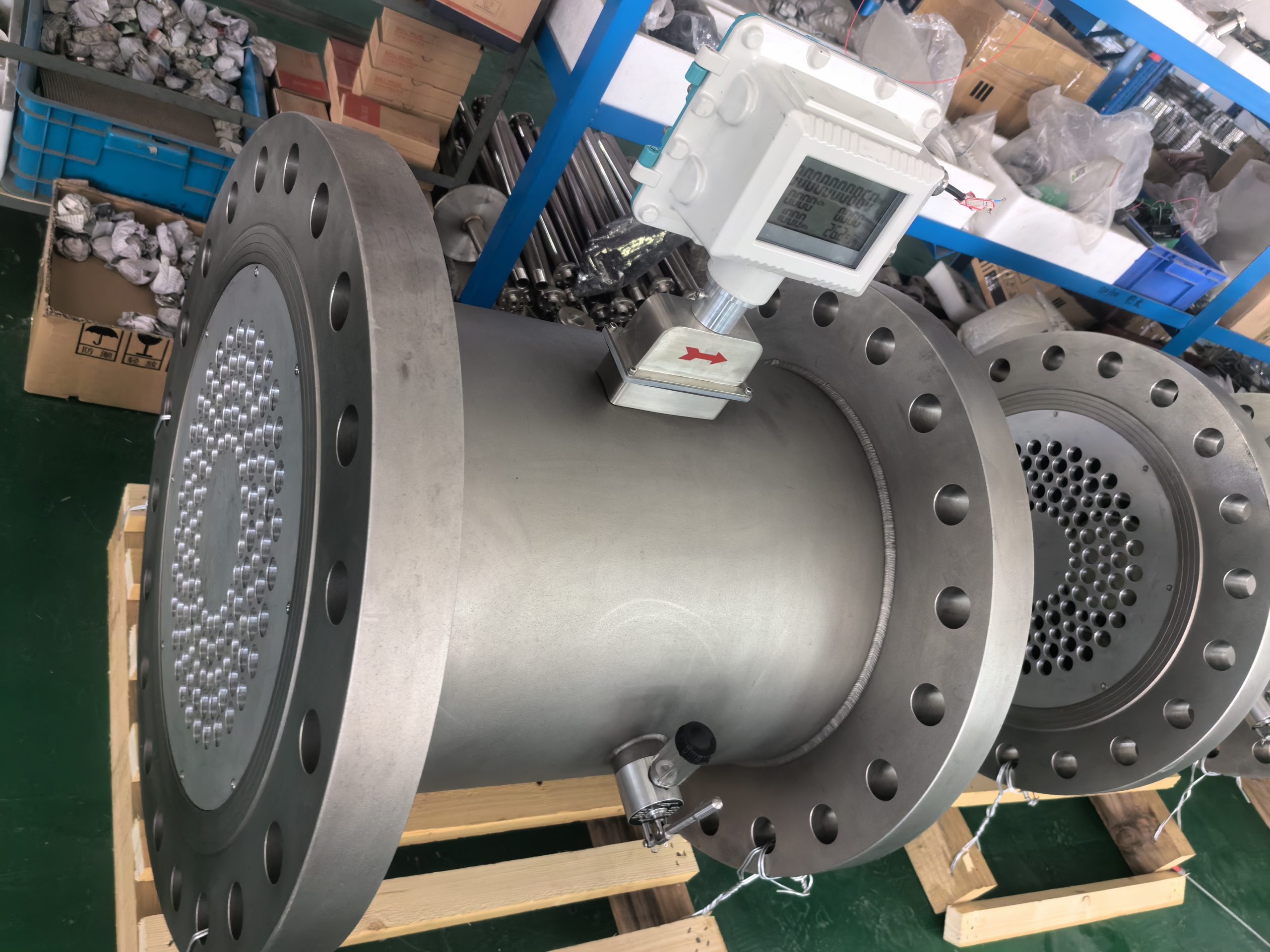

4. Keep the filter unblocked. The filter is blocked by impurities, which can be judged from the increase of the difference in the reading of the pressure gauge at the entrance and exit, and the blockage is eliminated in time, otherwise, the flow rate will be seriously reduced.

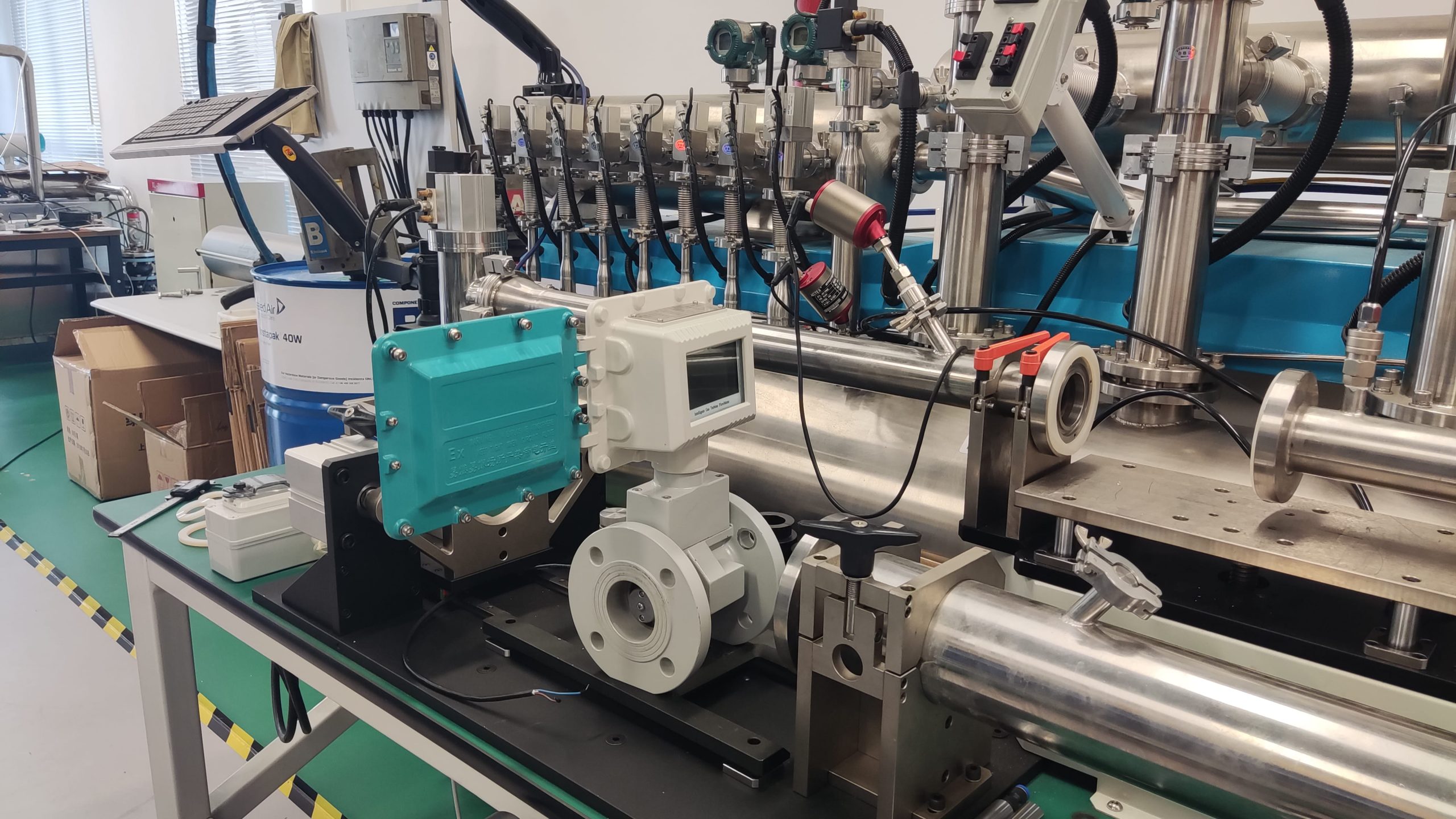

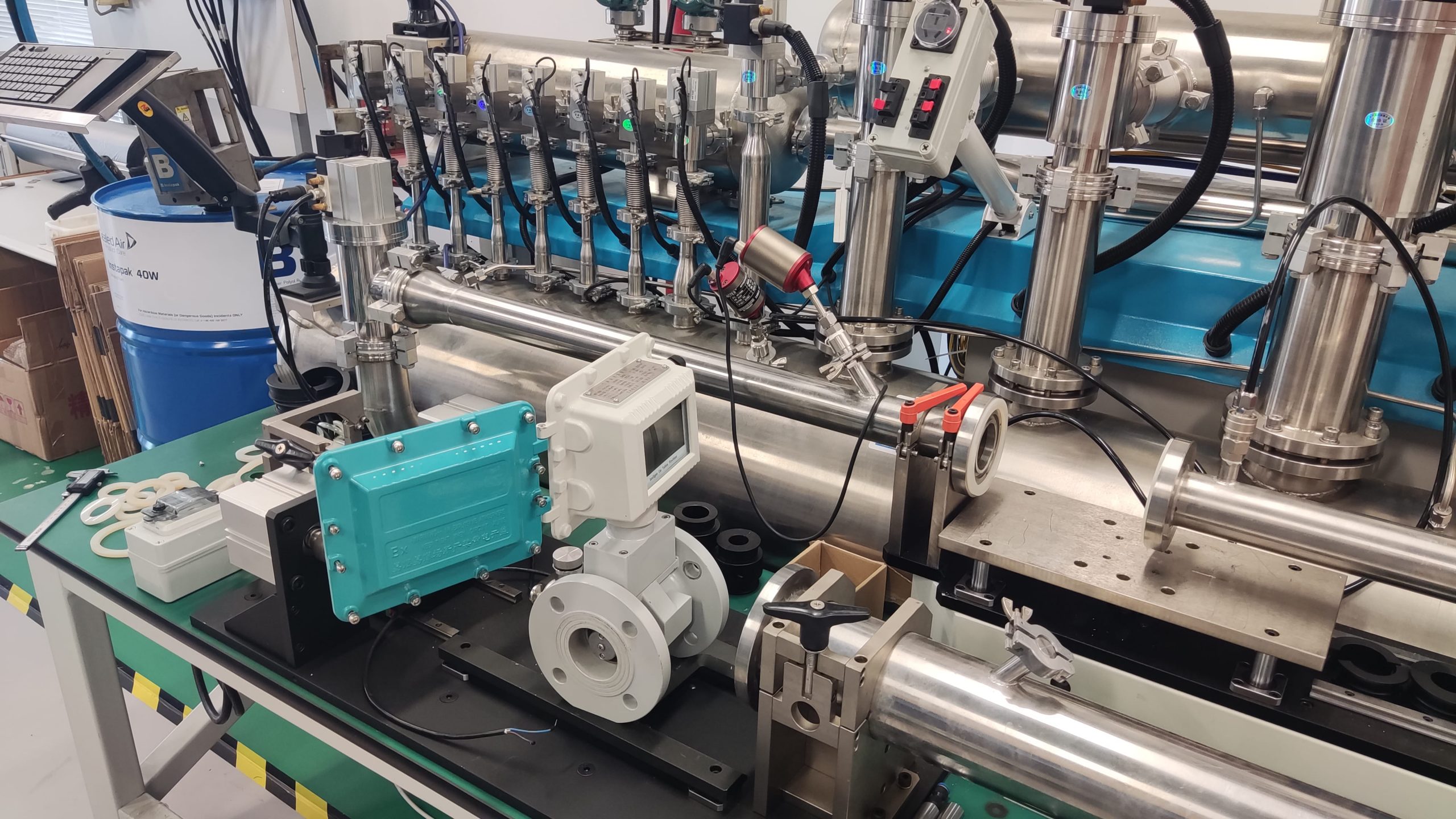

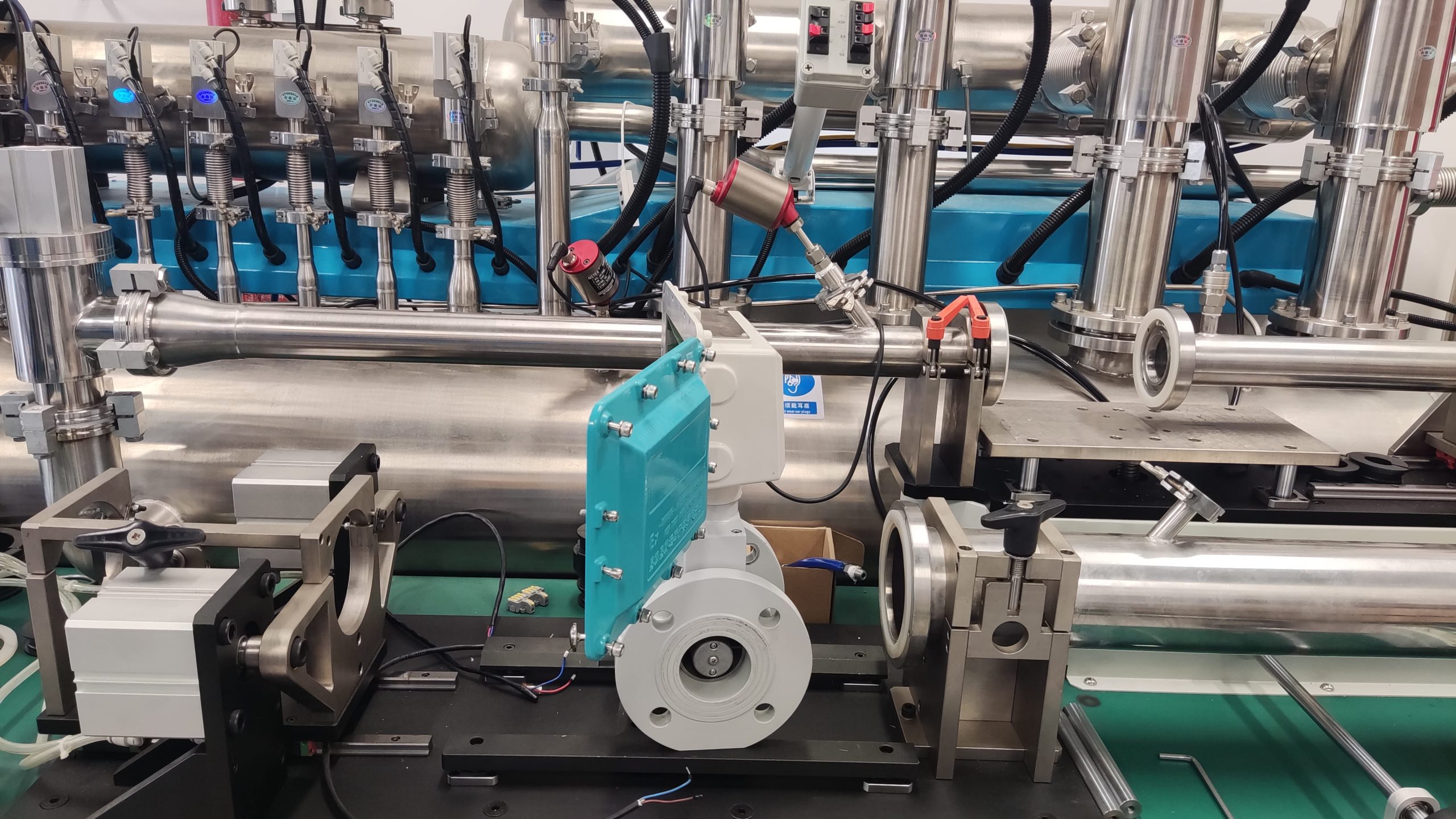

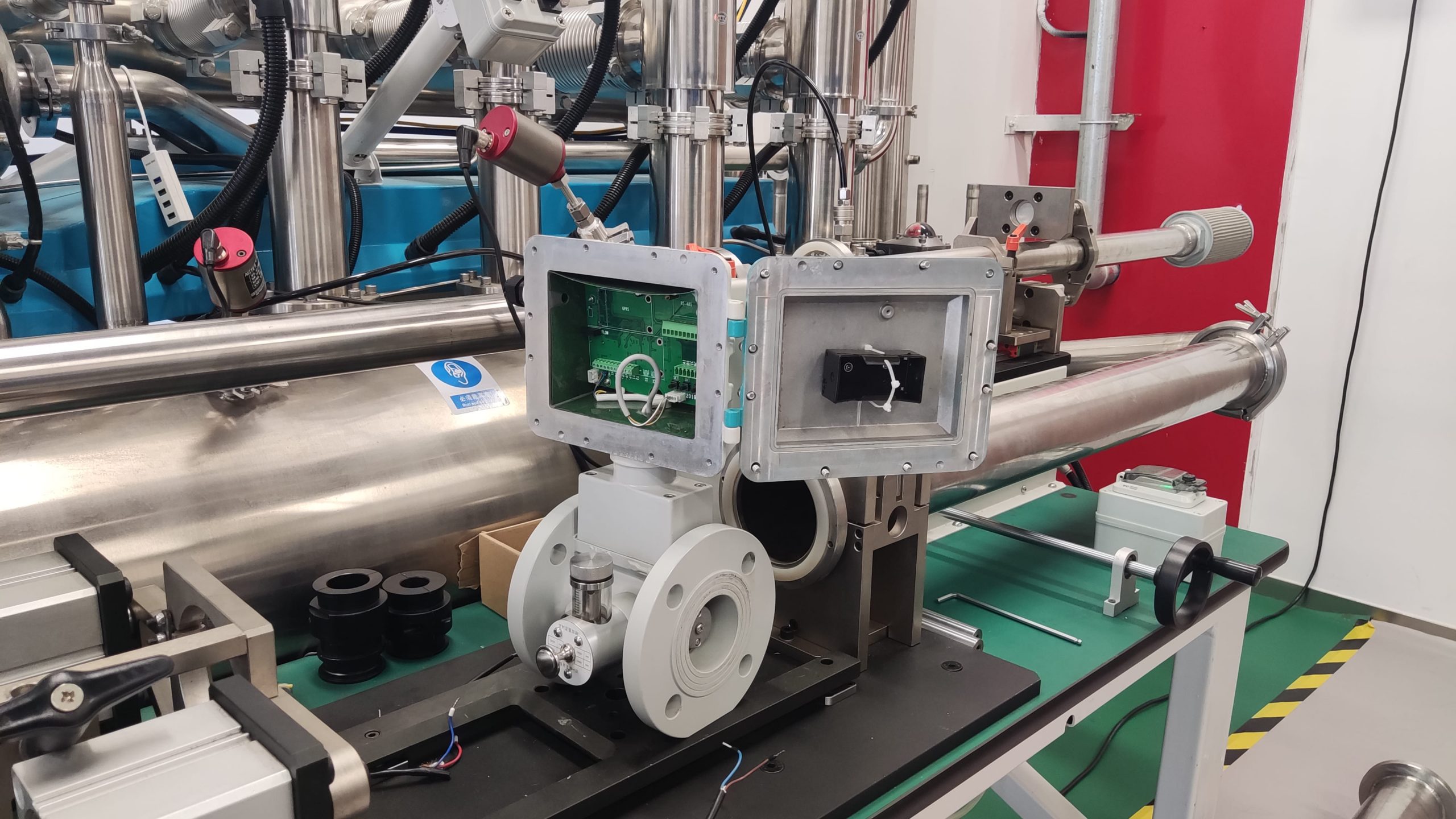

5, for large flow trade settlement measurement, in order to ensure the accuracy of the flow meter, the flow meter must be regularly checked. The site should be equipped with online calibration equipment, or equipped with mobile calibration equipment, although the one-time investment is large, but it is worth considering the long-term economic interests.

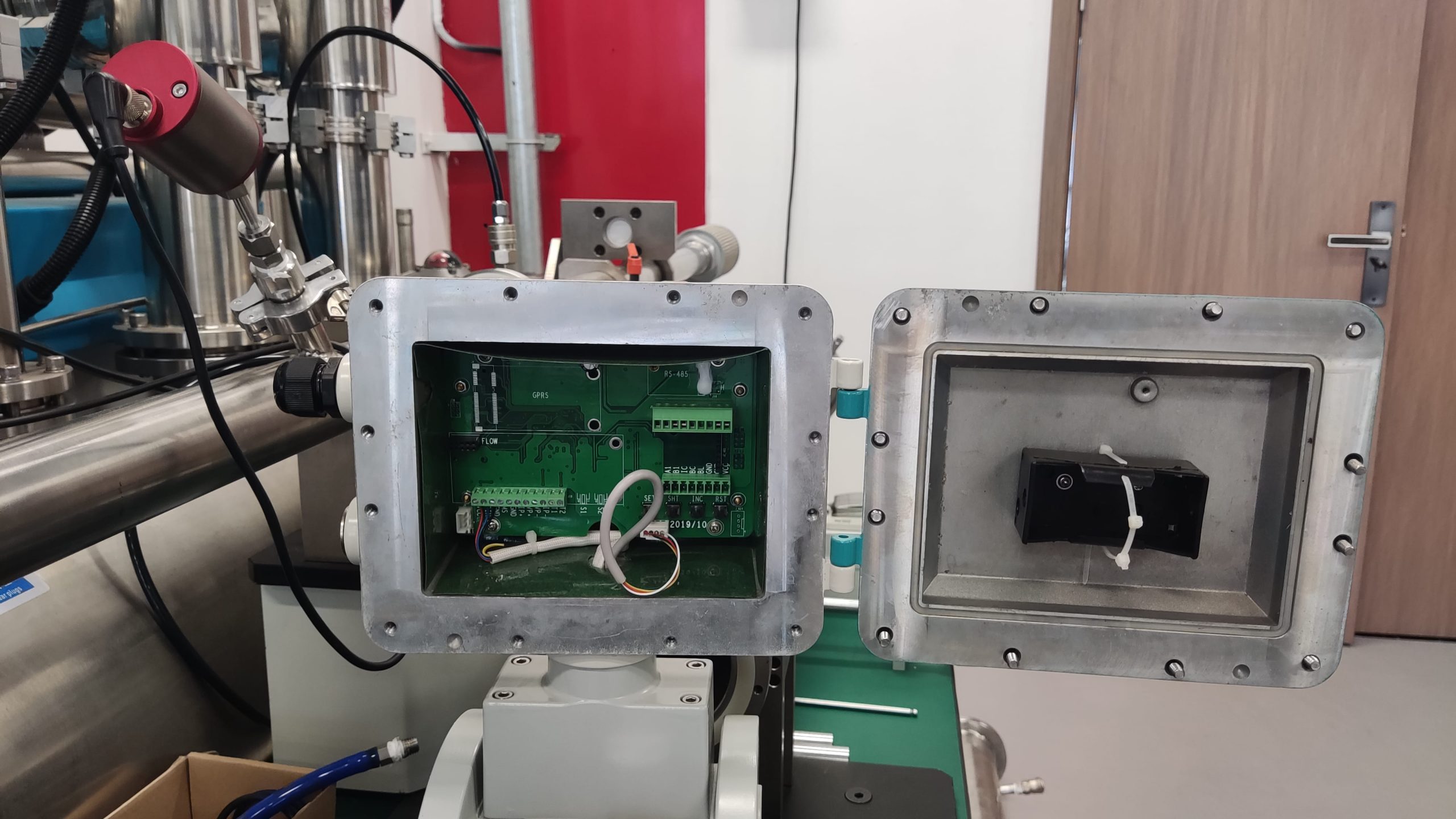

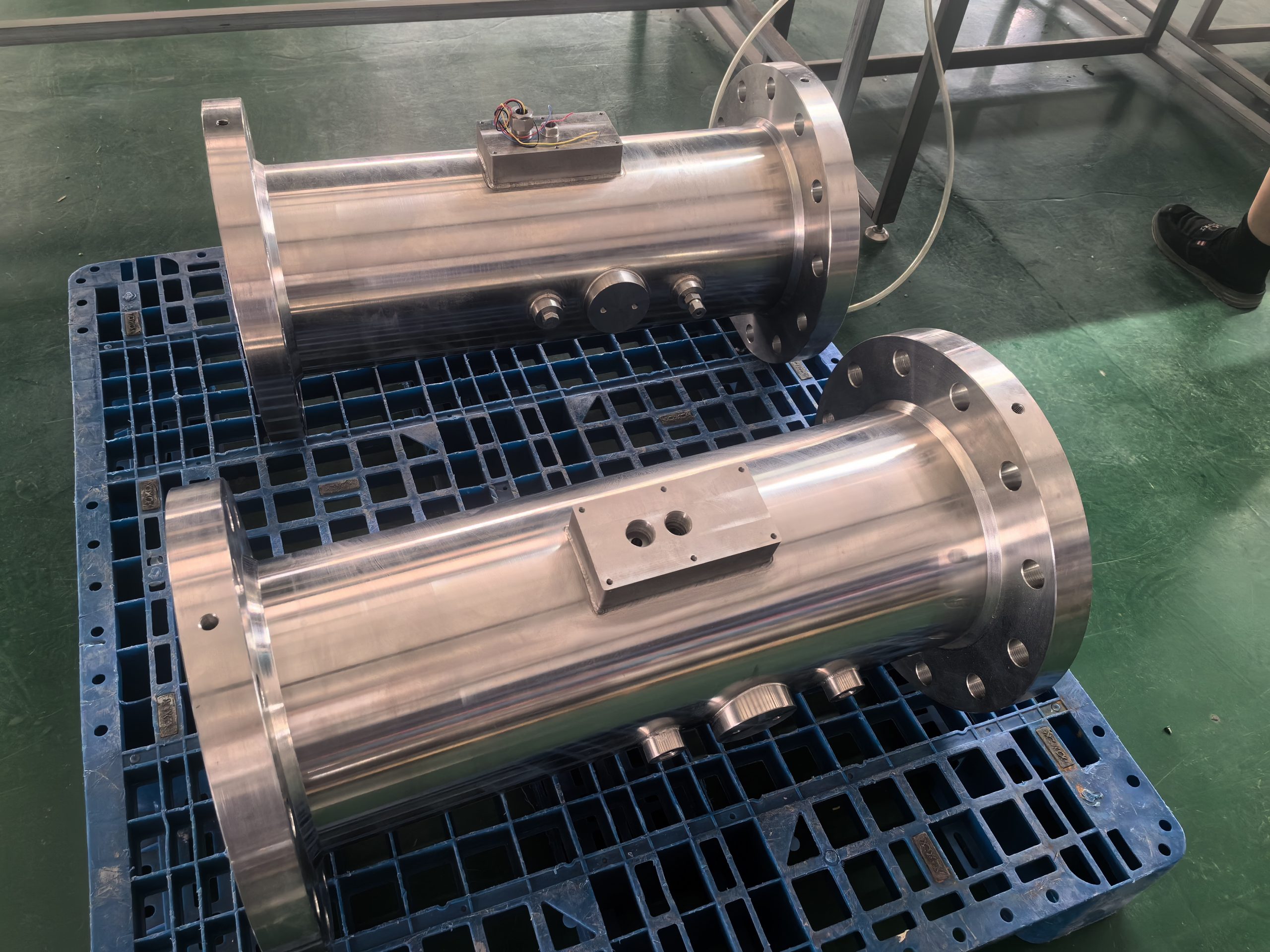

Aister Instrument develops and produces gas turbine flowmeters, and has sonic nozzle verification device real flow calibration to ensure the accuracy of each flowmeter, if there are other questions about turbine flowmeters, you can contact us at any time.