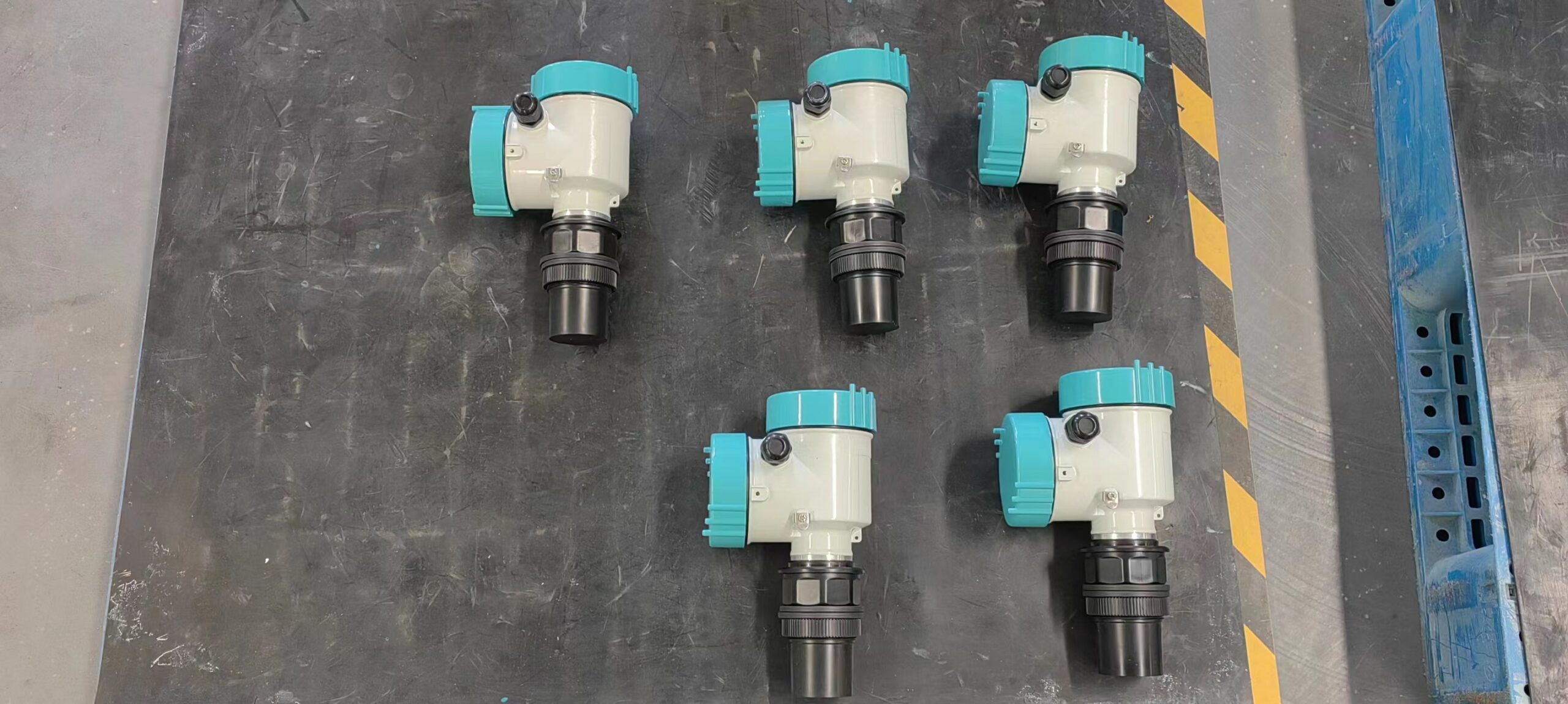

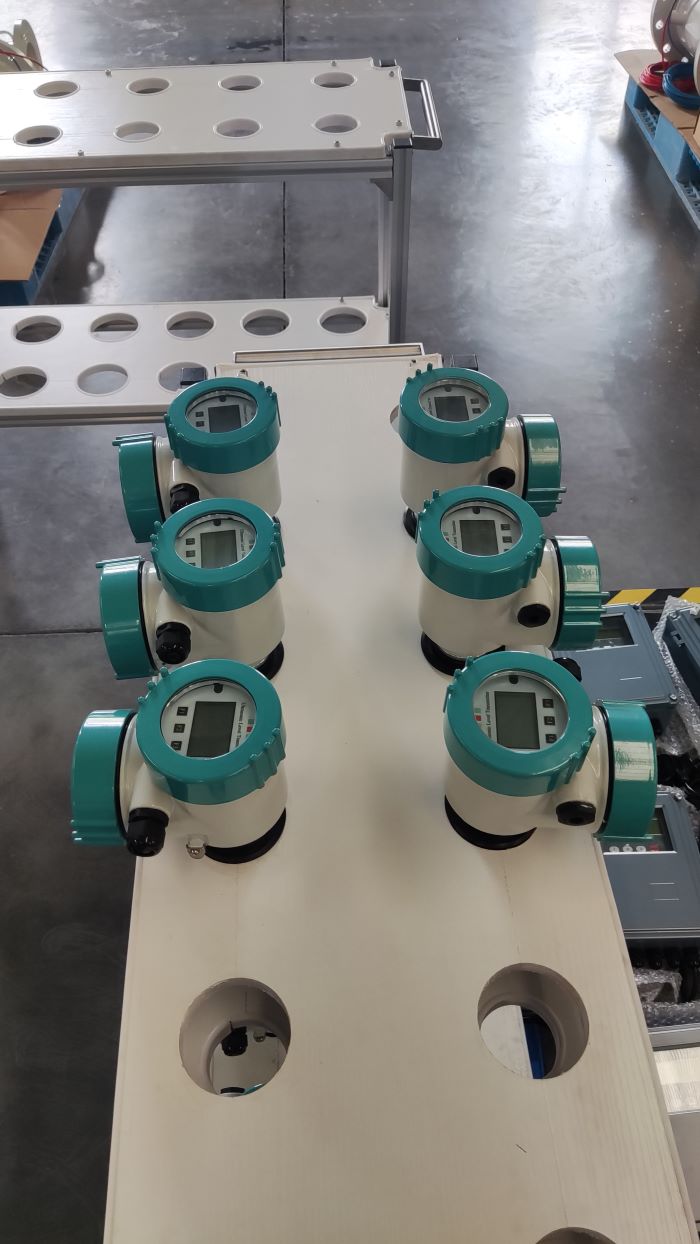

Ultrasonic Level Transmitter with 4-20mA RS485 Modbus for Water Bank River Level Sensor Liquid Ultrasonic Lever Meter

Installing an ultrasonic level meter accurately is crucial for ensuring reliable and precise measurements. Here are key considerations to pay attention to during the installation of an ultrasonic level meter:

Mounting Location:

Choose a mounting location that provides an unobstructed line of sight between the transducer and the liquid surface.

Avoid locations where turbulence, foam, or excessive vapor may affect the ultrasonic signal.

Transducer Alignment:

Align the ultrasonic transducer properly according to the manufacturer’s guidelines. Incorrect alignment can result in inaccurate readings.

Ensure that the transducer is perpendicular to the liquid surface for optimal signal transmission.

Avoid Obstructions:

Install the ultrasonic level meter away from obstructions, such as pipes, walls, or other structures, that could cause signal reflections or echoes.

Use baffles or shields to minimize the impact of obstructions if necessary.

Correct Distance and Height:

Install the transducer at an appropriate height above the highest liquid level to prevent damage during high-level conditions.

Maintain the recommended distance between the transducer and the liquid surface for accurate measurements.

Liquid Properties:

Consider the properties of the liquid being measured (e.g., temperature, density, viscosity) as they can impact the speed of sound and affect measurement accuracy.

Some ultrasonic level meters have compensation features to account for changes in liquid properties.

Vapor and Foam Management:

If the liquid tends to produce vapor or foam, take measures to minimize their impact on the ultrasonic signal. This may include installing baffles or choosing a different measurement technique.

Environmental Conditions:

Ensure that the installation environment meets the specified temperature and humidity conditions outlined by the manufacturer.

Protect the ultrasonic level meter from extreme weather conditions, direct sunlight, and corrosive atmospheres.

Secure Mounting:

Securely mount the ultrasonic level meter to prevent movement or vibration that could affect its accuracy. Use appropriate mounting hardware according to the installation guidelines.

Power Supply:

Provide a stable and reliable power supply within the specified voltage range. Ensure proper grounding to avoid electrical interference.

Calibration:

Calibrate the ultrasonic level meter according to the manufacturer’s recommendations and schedule regular calibration checks.

Perform initial calibration after installation and recalibrate as needed to maintain accuracy over time.

Safety Considerations:

Adhere to safety guidelines during installation to protect personnel and equipment.

Follow any specific safety instructions provided by the manufacturer.