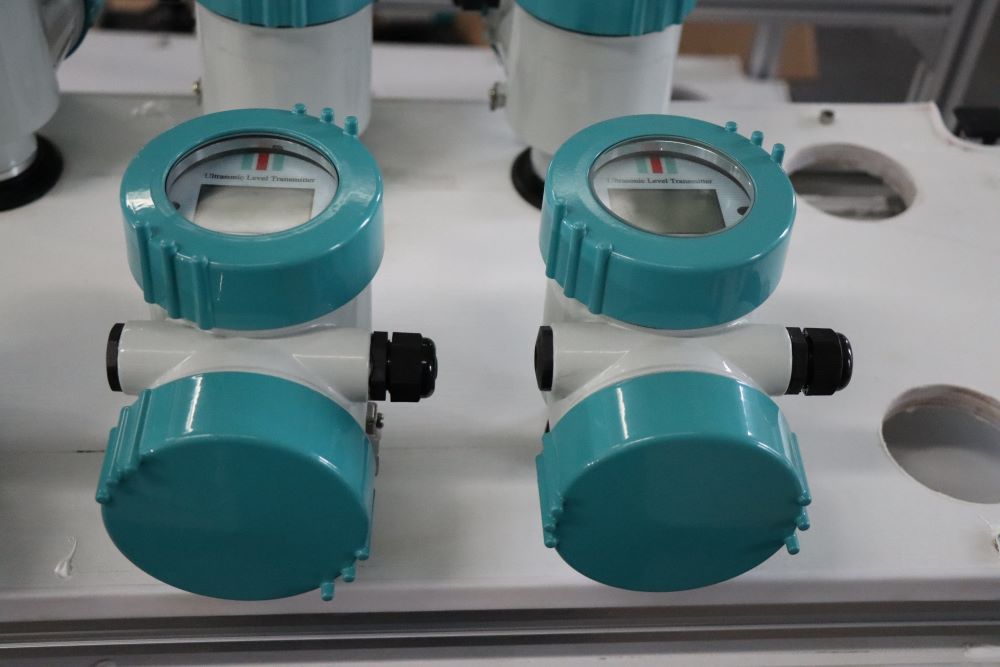

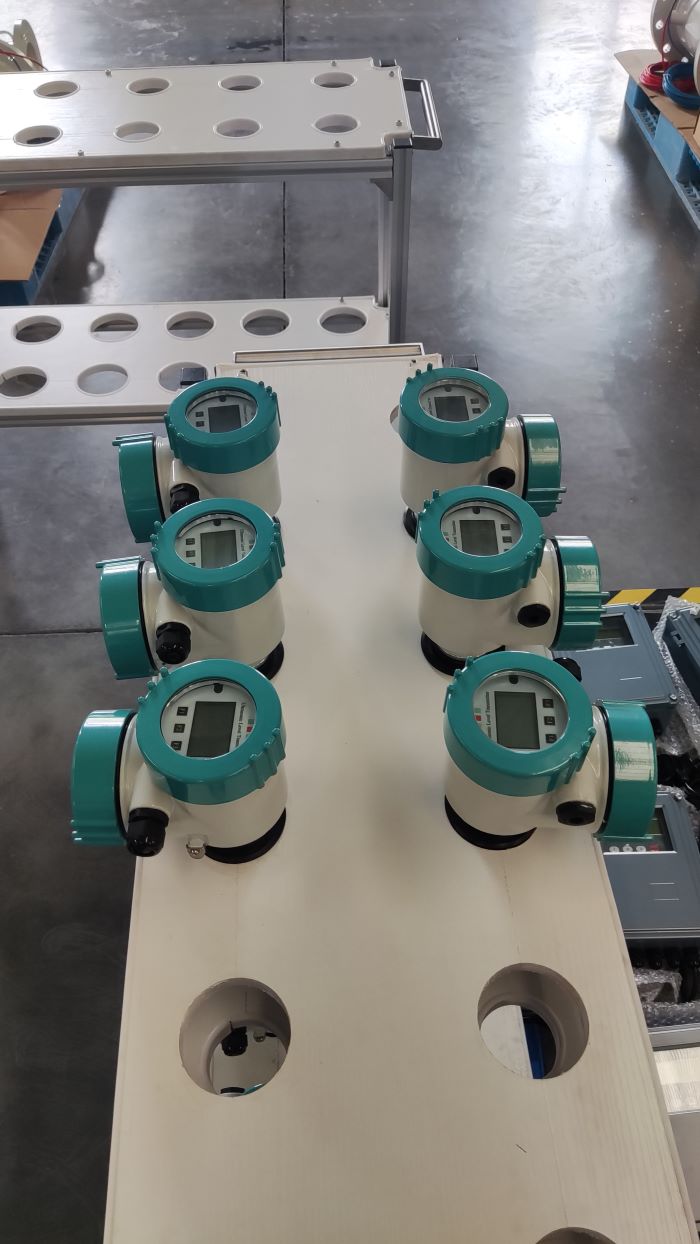

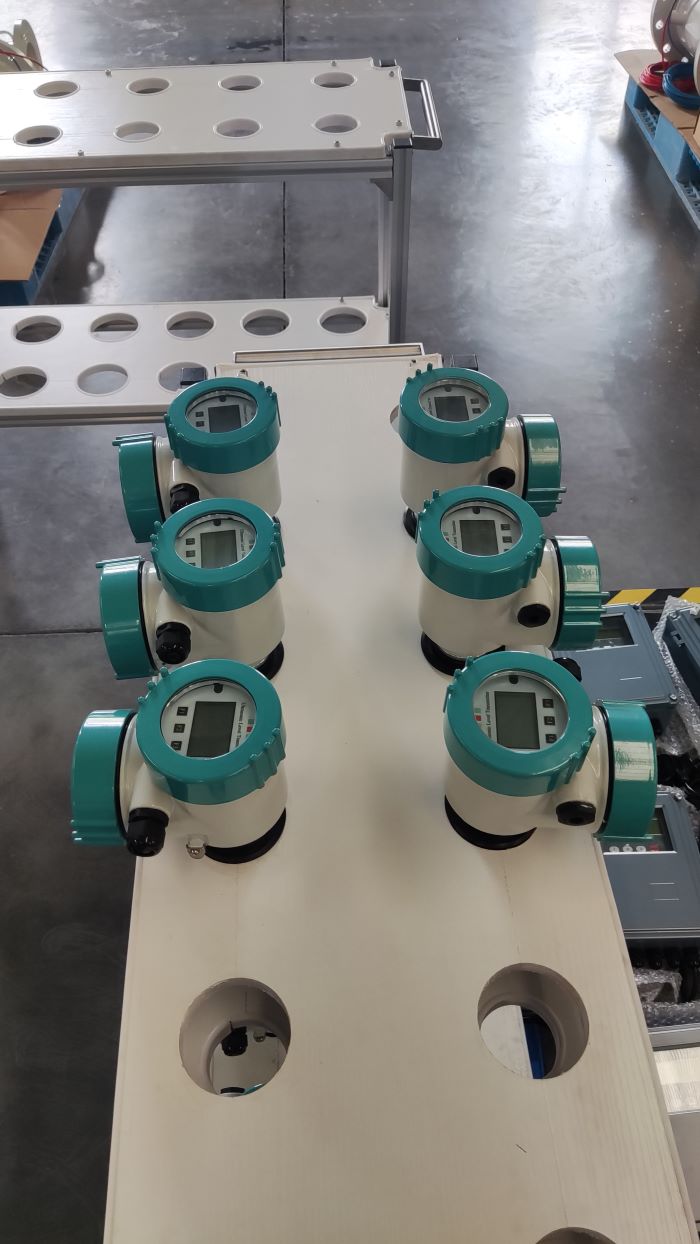

Ultrasonic Fuel Diesel Tank Ultrasonic Liquid Level Controller Gauge Sensor Ultrasonic Sensor Water Level Meter

Ultrasonic liquid level meters, while reliable, may encounter common faults that can impact their performance. Understanding these issues and implementing appropriate treatment methods is crucial for maintaining the accuracy and functionality of these devices. Here are some common faults and their treatment methods:

Signal Loss or Weak Signal:

Cause: Signal loss can occur due to factors such as air bubbles, foam, or contaminants in the liquid.

Treatment: Regular maintenance and cleaning of the transducer and sensor surface can help eliminate contaminants. Installing filters or ensuring proper liquid conditions can prevent signal weakening.

False Echoes:

Cause: False echoes may result from obstructions, reflective surfaces, or changes in liquid composition.

Treatment: Identify and remove obstructions, install baffles or shields to minimize interference, and adjust the device settings to account for changes in liquid properties.

Temperature Effects:

Cause: Ultrasonic waves travel at different speeds in liquids of varying temperatures, leading to measurement inaccuracies.

Treatment: Calibrate the device regularly to account for temperature variations. Some advanced ultrasonic level meters have compensation features to address temperature effects.

Mounting and Alignment Issues:

Cause: Incorrect mounting or misalignment of the transducer can affect measurement accuracy.

Treatment: Ensure proper installation and alignment of the transducer according to the manufacturer’s guidelines. Periodically check and adjust if necessary.

Interference from External Sources:

Cause: Radio frequency interference or other electronic signals can disrupt ultrasonic measurements.

Treatment: Shielding the device or using signal filtering techniques can help mitigate external interference. Installing the level meter away from electronic equipment can also reduce the impact.

Power Supply Problems:

Cause: Inadequate power supply or electrical issues can lead to erratic readings.

Treatment: Check the power supply and wiring for any faults. Ensure the device is receiving stable and sufficient power according to the manufacturer’s specifications.

Transducer Failure:

Cause: Over time, transducers may degrade or fail due to wear and tear.

Treatment: Regularly inspect and replace transducers as needed.